Abstract

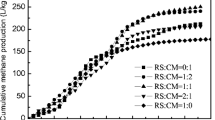

The effects of seven mixing ratios (1:0, 3:1, 2:1, 1:1, 1:2, 1:3, and 0:1, swine manure (SM)/rice straw (RS), based on total solid) on anaerobic co-digestion (co-AD) of SM and RS mixtures were investigated in batch tests. The results showed that the highest methane yield (188.79 mL/g VSadded) was obtained at the ratio of 1:1, which was higher than that of the mono-digestion of RS or SM by 178.77% and 18.94%, respectively. For the remained six ratios, the methane yield increased with the increase of SM proportion. The highest organic matter degradation rates were also observed at the ratio of 1:1. The methane content of biogas and the pH, total alkalinity, and total ammonia nitrogen of the digestate all decreased with the increase of RS proportion and decrease of SM proportion. Additionally, the kinetic results of each anaerobic digestion (AD) step suggested that the co-AD of SM and RS at the ratio of 1:1 significantly improved the reaction rates of the four AD steps. Meanwhile, the methane production time was prolonged and the lag time of methanogenesis was shortened at the ratio of 1:1.

Similar content being viewed by others

References

Pellera F-M, Gidarakos E (2017) Anaerobic digestion of solid agroindustrial waste in semi-continuous mode: evaluation of mono-digestion and co-digestion systems. Waste Manag 68:103–119. https://doi.org/10.1016/j.wasman.2017.06.026

Neshat SA, Mohammadi M, Najafpour GD, Lahijani P (2017) Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew Sust Energ Rev 79:308–322. https://doi.org/10.1016/j.rser.2017.05.137

Patinvoh RJ, Lundin M, Taherzadeh MJ, Sárvári Horváth I (2020) Dry anaerobic co-digestion of Citrus wastes with keratin and Lignocellulosic wastes: batch and continuous processes. Waste Biomass Valorization 11:423–434. https://doi.org/10.1007/s12649-018-0447-y

Pagés-díaz J, Pereda-reyes I, Sanz JL et al (2017) A comparison of process performance during the anaerobic mono- and co-digestion of slaughterhouse waste through different operational modes. J Environ Sci 64:149–156. https://doi.org/10.1016/j.jes.2017.06.004

Makara A, Kowalski Z (2018) Selection of pig manure management strategies: case study of polish farms. J Clean Prod 172:187–195. https://doi.org/10.1016/j.jclepro.2017.10.095

Li D, Liu S, Mi L, Li Z, Yuan Y, Yan Z, Liu X (2015) Effects of feedstock ratio and organic loading rate on the anaerobic mesophilic co-digestion of rice straw and pig manure. Bioresour Technol 187:120–127. https://doi.org/10.1016/j.biortech.2015.03.040

Jurado E, Antonopoulou G, Lyberatos G, Gavala HN, Skiadas IV (2016) Continuous anaerobic digestion of swine manure: ADM1-based modelling and effect of addition of swine manure fibers pretreated with aqueous ammonia soaking. Appl Energy 172:190–198. https://doi.org/10.1016/j.apenergy.2016.03.072

Mao C, Zhang T, Wang X, Feng Y, Ren G, Yang G (2017) Process performance and methane production optimizing of anaerobic co-digestion of swine manure and corn straw. Sci Rep 7:9379. https://doi.org/10.1038/s41598-017-09977-6

Zhang T, Mao C, Zhai N, Wang X, Yang G (2015) Influence of initial pH on thermophilic anaerobic co-digestion of swine manure and maize stalk. Waste Manag 35:119–126. https://doi.org/10.1016/j.wasman.2014.09.004

Wu X, Yao W, Zhu J, Miller C (2010) Biogas and CH4 productivity by co-digesting swine manure with three crop residues as an external carbon source. Bioresour Technol 101:4042–4047. https://doi.org/10.1016/j.biortech.2010.01.052

Gu Y, Chen X, Liu Z, Zhou X, Zhang Y (2014) Effect of inoculum sources on the anaerobic digestion of rice straw. Bioresour Technol 158:149–155. https://doi.org/10.1016/j.biortech.2014.02.011

Mancini G, Papirio S, Riccardelli G, Lens PNL, Esposito G (2018) Trace elements dosing and alkaline pretreatment in the anaerobic digestion of rice straw. Bioresour Technol 247:897–903. https://doi.org/10.1016/j.biortech.2017.10.001

Beniche I, El Bari H, Siles JA et al (2020) Methane production by anaerobic co-digestion of mixed agricultural waste: cabbage and cauliflower. Environ Technol 31:1–25. https://doi.org/10.1080/09593330.2020.1770341

Wang X, Lu X, Li F, Yang G (2014) Effects of temperature and carbon-nitrogen (C/N) ratio on the performance of anaerobic co-digestion of dairy manure, Chicken Manure and Rice Straw: Focusing on Ammonia Inhibition. PLoS One 9:e97265. https://doi.org/10.1371/journal.pone.0097265

Negi S, Dhar H, Hussain A, Kumar S (2018) Biomethanation potential for co-digestion of municipal solid waste and rice straw: a batch study. Bioresour Technol 254:139–144. https://doi.org/10.1016/j.biortech.2018.01.070

Chen X, Yuan H, Zou D, Liu Y, Zhu B, Chufo A, Jaffar M, Li X (2015) Improving biomethane yield by controlling fermentation type of acidogenic phase in two-phase anaerobic co-digestion of food waste and rice straw. Chem Eng J 273:254–260. https://doi.org/10.1016/j.cej.2015.03.067

Chen H, Wu J, Wang H, Zhou Y, Xiao B, Zhou L, Yu G, Yang M, Xiong Y, Wu S (2020) Dark co-fermentation of rice straw and pig manure for biohydrogen production: effects of different inoculum pretreatments and substrate mixing ratio. Environ Technol 0:1–11. https://doi.org/10.1080/09593330.2020.1770340

Valenti F, Zhong Y, Sun M, Porto SMC, Toscano A, Dale BE, Sibilla F, Liao W (2018) Anaerobic co-digestion of multiple agricultural residues to enhance biogas production in southern Italy. Waste Manag 78:151–157. https://doi.org/10.1016/j.wasman.2018.05.037

Mao C, Wang X, Xi J, Feng Y, Ren G (2017) Linkage of kinetic parameters with process parameters and operational conditions during anaerobic digestion. Energy 135:352–360. https://doi.org/10.1016/j.energy.2017.06.050

Nguyen DD, Chang SW, Jeong SY, Jeung J, Kim S, Guo W, Ngo HH (2016) Dry thermophilic semi-continuous anaerobic digestion of food waste: performance evaluation, modified Gompertz model analysis, and energy balance. Energy Convers Manag 128:203–210. https://doi.org/10.1016/j.enconman.2016.09.066

Angelidaki I, Alves M, Bolzonella D et al (2009) Defining the biomethane potential ( BMP ) of solid organic wastes and energy crops : a proposed protocol for batch assays. Water Sci Technol 59:927–934. https://doi.org/10.2166/wst.2009.040

Zhang W, Wu S, Guo J, Zhou J, Dong R (2015) Performance and kinetic evaluation of semi-continuously fed anaerobic digesters treating food waste: role of trace elements. Bioresour Technol 178:297–305. https://doi.org/10.1016/j.biortech.2014.08.046

Bayr S, Pakarinen O, Korppoo A, Liuksia S, Väisänen A, Kaparaju P, Rintala J (2012) Effect of additives on process stability of mesophilic anaerobic monodigestion of pig slaughterhouse waste. Bioresour Technol 120:106–113. https://doi.org/10.1016/j.biortech.2012.06.009

Nordell E, Nilsson B, Nilsson Påledal S, Karisalmi K, Moestedt J (2016) Co-digestion of manure and industrial waste - the effects of trace element addition. Waste Manag 47:21–27. https://doi.org/10.1016/j.wasman.2015.02.032

Xiao B, Zhang W, Yi H, Qin Y, Wu J, Liu J, Li YY (2019) Biogas production by two-stage thermophilic anaerobic co-digestion of food waste and paper waste: effect of paper waste ratio. Renew Energy 132:1301–1309. https://doi.org/10.1016/j.renene.2018.09.030

Xiao B, Qin Y, Zhang W, Wu J, Qiang H, Liu J, Li YY (2018) Temperature-phased anaerobic digestion of food waste: a comparison with single-stage digestions based on performance and energy balance. Bioresour Technol 249:826–834. https://doi.org/10.1016/j.biortech.2017.10.084

APHA (2017) Standard methods for the examination of water and wastewater, 23rd edn. American Public Health Association, American Water Works Association, Water Environment Federation, Washington

Niu Q, Qiao W, Qiang H, Hojo T, Li YY (2013) Mesophilic methane fermentation of chicken manure at a wide range of ammonia concentration: stability, inhibition and recovery. Bioresour Technol 137:358–367. https://doi.org/10.1016/J.BIORTECH.2013.03.080

Mancini G, Papirio S, Lens PNL, Esposito G (2018) Increased biogas production from wheat straw by chemical pretreatments. Renew Energy 119:608–614. https://doi.org/10.1016/j.renene.2017.12.045

Prajapati KB, Singh R (2018) Kinetic modelling of methane production during bio-electrolysis from anaerobic co-digestion of sewage sludge and food waste. Bioresour Technol 263:491–498. https://doi.org/10.1016/j.biortech.2018.05.036

Li Q, Qiao W, Wang X, Takayanagi K, Shofie M, Li YY (2015) Kinetic characterization of thermophilic and mesophilic anaerobic digestion for coffee grounds and waste activated sludge. Waste Manag 36:77–85. https://doi.org/10.1016/j.wasman.2014.11.016

Martín MA, Fernández R, Gutiérrez MC, Siles JA (2018) Thermophilic anaerobic digestion of pre-treated orange peel: modelling of methane production. Process Saf Environ Prot 117:245–253. https://doi.org/10.1016/j.psep.2018.05.008

Hagos K, Zong J, Li D, Liu C, Lu X (2017) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sust Energ Rev 76:1485–1496. https://doi.org/10.1016/j.rser.2016.11.184

Xie S, Lawlor PG, Frost JP, Hu Z, Zhan X (2011) Effect of pig manure to grass silage ratio on methane production in batch anaerobic co-digestion of concentrated pig manure and grass silage. Bioresour Technol 102:5728–5733. https://doi.org/10.1016/j.biortech.2011.03.009

Kafle GK, Kim SH (2013) Anaerobic treatment of apple waste with swine manure for biogas production: batch and continuous operation. Appl Energy 103:61–72. https://doi.org/10.1016/j.apenergy.2012.10.018

Xiao B, Qin Y, Wu J, Chen H, Yu P, Liu J, Li YY (2018) Comparison of single-stage and two-stage thermophilic anaerobic digestion of food waste: performance, energy balance and reaction process. Energy Convers Manag 156:215–223. https://doi.org/10.1016/j.enconman.2017.10.092

Nielfa A, Cano R, Vinot M, Fernández E, Fdz-Polanco M (2015) Anaerobic digestion modeling of the main components of organic fraction of municipal solid waste. Process Saf Environ Prot 94:180–187. https://doi.org/10.1016/j.psep.2015.02.002

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sust Energ Rev 45:540–555. https://doi.org/10.1016/j.rser.2015.02.032

Dai X, Hua Y, Dai L, Cai C (2019) Particle size reduction of rice straw enhances methane production under anaerobic digestion. Bioresour Technol 293:122043. https://doi.org/10.1016/j.biortech.2019.122043

Sun Y, Wang D, Qiao W, Wang W, Zhu T (2013) Anaerobic co-digestion of municipal biomass wastes and waste activated sludge: dynamic model and material balances. J Environ Sci 25:2112–2122. https://doi.org/10.1016/S1001-0742(12)60236-8

Lin J, Zuo J, Gan L, Li P, Liu F, Wang K, Chen L, Gan H (2011) Effects of mixture ratio on anaerobic co-digestion with fruit and vegetable waste and food waste of China. J Environ Sci 23:1403–1408. https://doi.org/10.1016/S1001-0742(10)60572-4

Shi X, Lin J, Zuo J, Li P, Li X, Guo X (2017) Effects of free ammonia on volatile fatty acid accumulation and process performance in the anaerobic digestion of two typical bio-wastes. J Environ Sci 55:49–57. https://doi.org/10.1016/J.JES.2016.07.006

Massé DI, Droste RL (2000) Comprehensive model of anaerobic digestion of swine manure slurry in a sequencing batch reactor. Water Res 34:3087–3106. https://doi.org/10.1016/S0043-1354(00)00064-6

Arias DE, Veluchamy C, Dunfield KE, Habash MB, Gilroyed BH (2020) Hygienization and microbial metabolic adaptation during anaerobic co- digestion of swine manure and corn Stover. Bioresour Technol 306:123168. https://doi.org/10.1016/j.biortech.2020.123168

Anthonisen AC, Loehr RC, Prakasam TBS, Srinath EG (1976) Inhibition of nitrification by Ammonia and nitrous acid. J (Water Pollut Control Fed) 48:835–852

Ye J, Li D, Sun Y, Wang G, Yuan Z, Zhen F, Wang Y (2013) Improved biogas production from rice straw by co-digestion with kitchen waste and pig manure. Waste Manag 33:2653–2658. https://doi.org/10.1016/j.wasman.2013.05.014

Li Y, Jin Y, Li J, Li H, Yu Z (2016) Effects of pungency degree on mesophilic anaerobic digestion of kitchen waste. Appl Energy 181:171–178. https://doi.org/10.1016/j.apenergy.2016.08.057

Wei W, Zhou X, Wang D, Sun J, Wang Q (2017) Free ammonia pre-treatment of secondary sludge significantly increases anaerobic methane production. Water Res 118:12–19. https://doi.org/10.1016/j.watres.2017.04.015

Funding

This work was supported by the Major Science and Technology Program for Water Pollution Control and Treatment of China (No. 2017ZX07106003), the China Hunan Provincial Science and Technology Department (No. 2017SK2361), and the State Key Joint Laboratory of Environment Simulation and Pollution Control (Research Center for Eco-Environmental Sciences, Chinese Academy of Sciences) (No. 19Z02ESPCR).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, W., Xiao, B., Zhang, K. et al. Effects of mixing ratios on anaerobic co-digestion of swine manure and rice straw: methane production and kinetics. Biomass Conv. Bioref. 13, 1553–1563 (2023). https://doi.org/10.1007/s13399-020-01211-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01211-0