Abstract

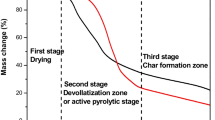

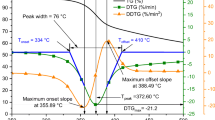

The potential of thermo-chemical performance of three biomass materials namely Syzygium cumini seeds (JP), Cassia fistula L. seed (AT), and Cassia fistula L. fruit peels (AP) has been investigated in detail in the present study. Thermo-gravimetric analysis (TGA) was conducted for pyrolysis kinetic parameters at various temperatures (heating rates). Five temperatures (10, 15, 20, 25, and 30 °C/min) and two model-free techniques (especially Flynn-Wall-Ozawa (FWO) and Kissinger-Akahira-Sunose (KAS)) were applied to evaluate the response. It was found that the respective average activation energies were 222.66, 200.82, and 224.57 kJ/mol for JP, AT, and AP, respectively, in the case of the FWO model, while the average activation energies 223.49, 201.19, and 227.43 kJ/mol were obtained by using the KAS model. The activation energy, enthalpy, and pre-exponential factor for the studied biomass materials are shown in the order of AP > JP > AT in both these models. Moreover, the highest values of pre-exponential factor were found for JP in FWO (1.27 × 1039) and KAS (1.81 × 1040) models. The active pyrolysis zone was also noticed in the temperature range of 175–600 °C, which represents the maximum weight loss range as well in the present study.

Similar content being viewed by others

References

Wright MM, Daugaard DE, Satrio JA, Brown RC (2010) Techno-economic analysis of biomass fast pyrolysis to transportation fuels. Fuel 89:S2–S10

Singh N, Kumar A, Rai S (2014) Potential production of bioenergy from biomass in an Indian perspective. Renew Sust Energ Rev 39:65–78

Dorta E, Gonzalez M, Lobo MG, Sánchez-Moreno C, Ancos B (2014) Screening of phenolic compounds in by-product extracts from mangoes (Mangifera indica L.) by HPLC–ESI–QTOF–MS and multivariate analysis for use as a food ingredient. Food Res Int 57:51–60

Mishra, Kumar R, Mohanty K (2018) Characterization of non-edible lignocellulosic biomass in terms of their candidacy towards alternative renewable fuels. Biomass Convers Biorefin 8(4):799–812

Manurung R, Wever D, Wildschut J, Venderbosch R, Hidayat H, Van Dam J, Leijenhorst E, Broekhuis A, Heeres H (2009) Valorisation of Jatropha curcas L. plant parts: Nut shell conversion to fast pyrolysis oil. Food Bioprod Process 87(3):187–196

Hashemi Z, Sharfiifard H, Lashanizadegan A (2018) Grape stalks biomass as raw material for activated carbon production: synthesis, characterization and adsorption ability. Mater Res Express 5:055603

McKendry P (2002) Energy production from biomass (part 1): overview of biomass. Bioresour Technol 83(1):37–46

Yao JC, Manal H, Alexandria P, Cecile D, Colleen L, Jeannette EM, Eddie KA (2008) One hundred years after “carcinoid”: epidemiology of and prognostic factors for neuroendocrine tumors in 35,825 cases in the United States. Journal of clinical oncology 26(18):3063–3072

Alwani M, Siti HAK, Sulaiman O, Islam MN, Dungani R (2014) An approach to using agricultural waste fibres in biocomposites application: Thermogravimetric analysis and activation energy study. Bio Resour 9:218–230

Liew RK, Azwar E, YuhYek PN, Lim XY, Cheng CH, Ng JH, Jusoh A, Lam WH, Ibrahim MD, Ma NL, Lam SS (2018) Microwave pyrolysis with KOH/NaOH mixture activation: A new approach to produce micro-mesoporous activated carbon for textile dye adsorption. Bioresour Technol 266:1–10

Norouzi S, Heidari M, Alipour V, Rahmanian O, Fazlzadeh F, Nourmoradi H, Goudarzi B, Dindarloo K (2018) Preparation, characterization and Cr (VI) adsorption evaluation of NaOH-activated carbon produced from Date Press Cake; an agro-industrial waste. Biores.Techn. 258:48–56

Adebisi GA, Chowdhury ZZ, Alaba PA (2017) Equilibrium, kinetic, and thermodynamic studies of lead ion and zinc ion adsorption from aqueous solution onto activated carbon prepared from palm oil mill effluent. J Clean Prod 148:958–968

Slopiecka K, Bartocci P, Fantozzi F (2012) Thermo-gravimetric analysis and kinetic study of poplar wood pyrolysis. Appl Energy 97:491–497

Prasad N, Thakur P, Pal DB (2020) Cadmium removal from aqueous solution by jackfruit seed bio-adsorbent. Springer Nat Appl Sci 2:1018

Poletto M, Zattera AJ, Forte MMC, Santana RM (2012) Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour Technol 109:148–153

Yang H, Yan R, Chen H, Zheng C, Lee DH, Liang DT (2006) In-depth investigation of biomass pyrolysis based on three major components: hemicellulose, cellulose and lignin. Energy & Fuels 20(1):388–393

Mansora AM, Lima JS, Anib FN, Hashima H, Hoa WS (2019) Characteristics of cellulose, hemicellulose and lignin of MD2 pineapple biomass. Chem Eng 72:79–84

Raj AAS, Ranganathan TV (2018) Characterization of cellulose from jackfruit (Artocarpus integer) peel. J Pharm Res 12(3):311–315

Kouadri I, Hamid S (2018) Extraction and characterization of cellulose and cellulose nanofibers from Citrullus colocynthis seeds. Ind Crop Prod 124:787–796

Flynn JH, Wall LA (1966) General treatment of the thermogravimetry of polymers. Journal of research of the National Bureau of Standards. J Res Natl Bur Stand A 70:487

Gogoi M, Konwar K, Bhuyan N, Borah RC, Kalita AC, Nath HP, Saikia N (2018) Assessments of pyrolysis kinetics and mechanisms of biomass residues using thermogravimetry. Biores Tech Rep 4:40–49

Demirbas A (2008) Heavy metal adsorption onto agro-based waste materials: A review. J Hazard Mater 157:220

Raj T, Kapoor M, Gaur R, Christopher J, Lamba B, Tuli DK, Kumar R (2015) Physical and chemical characterization of various Indian agriculture residues for biofuels production. Energy Fuel 29(5):3111–3118

Pradhan D, Singh RK, Bendu H, Mund R (2016) Pyrolysis of Mahua seed (Madhuca indica)–Production of biofuel and its characterization. Energy Convers Manag 108:529–538

Ahmad MS, Mehmood MA, Al Ayed OS, Ye G, Luo H, Ibrahim M, Rashid U, Nehdi IA, Qadir G (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol 224:708–713

Oza S, Ning H, Ferguson I, Lu N (2014) Effect of surface treatment on thermal stability of the hemp-PLA composites: correlation of activation energy with thermal degradation. Comp Part B: Eng 67:227–232

Arbelaiz A, Fernandez B, Ramos JA, Mondragon I (2006) Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: Effect of treatments. Thermochim Acta 440(2):111–121

Monteiro SN, Calado V, Rodriguez RJS, Margem FM (2012) Thermogravimetric behavior of natural fibers reinforced polymer composites-An overview. J Mat Res Technol 557:17–28

Benitez GM, Lopez Beceiro J, Sanchez Jimenez PE, Pascual Cosp J (2014) Comparison of thermal behavior of natural and hot-washed sisal fibers based on their main components: Cellulose, xylan and lignin. TG-FTIR analysis of volatile products. Thermochim Acta 581:70–86

Prasad N, Agarwal VK, Sinha S (2018) Banana fiber reinforced low-density polyethylene composites: effect of chemical treatment and compatibilizer addition. Iranian Polymer Journal 25(3):229–241

Ghani NT, Hegazy AK, El Chaghaby GA (2009) Int J Environ Sci Technol 6(2):243

Rajnish KS, Pandey D, Patil T, Sawarkar AN (2020) Pyrolysis of banana leaves biomass: physico-chemical characterization, thermal decomposition behaviour, kinetic and thermodynamic analyses. Bioresour Technol 310:123464

Liao X, Singh S, Yang H, Wu C, Zhang S (2021) A thermogravimetric assessment of the tri-combustion process for coal, biomass and polyethylene. Fuel 287:119355

Yao X, Zhou H, Xu K, Chen S, Ge J, Xu Q (2020) Systematic study on ash transformation behaviour and thermal kinetic characteristics during co-firing of biomass with high ratios of bituminous coal. Renew Energy 147:1453–1468

Bohli T, Santaló NF, Gil IV, Ouederni A (2013) Adsorption on activated carbon from olive stones: kinetics and equilibrium of phenol removal from aqueous solution. J Chem Eng Process Technol 165:2013

Theivasanthi T, Alagar M (2011) X-ray diffraction studies of copper nanopowder. Nano Biomed Eng 3(4):215

Gupta GK, Mondal MK (2019) Kinetics and thermodynamic analysis of maize cob pyrolysis for its bioenergy potential using thermogravimetric analyzer. Journal of Thermal Analysis and Calorimetry 137(4):1431–1441

Damartzis T, Vamvuka D, Sfakiotakis S, Zabaniotou A (2011) Thermal degradation studies and kinetic modeling of cardoon (Cynara cardunculus) pyrolysis using thermo-gravimetric analysis (TGA). Bioresour Technol 102(10):6230–6238

Heydari M, Rahman M, Gupta R (2015) Kinetic study and thermal decomposition behaviour of lignite coal. Int J Chem Eng 9

Farooq S, Sania ZI, Hao L, Muhammad I, Colin ES (2020) Thermal and kinetic analysis of diverse biomass fuels under different reaction environment: a way forward to renewable energy sources. Energy Convers Manag 203:112266

Santos VO, Leandro SQ, Rayanne OA, Flaviana CPR, Mariana NG, Carlos EFC, Jamal SC, Luiz KCS Pyrolysis of acai seed biomass: kinetics and thermodynamic parameters using thermogravimetric analysis. Biores Tech Rep 12(2020):100553

Sahoo A, Kumar S, Mohanty K (2021) Kinetic and thermodynamic analysis of Putranjiva roxburghii (putranjiva) and Cassia fistula (amaltash) non-edible oilseeds using Thermogravimetric analyzer. Renew Energy 165:261–277

Acknowledgements

The authors acknowledge the Birla Institute of Technology, Mesra, Ranchi, JH, and the Indian Institute of Technology (BHU), Varanasi, for providing raw materials, facilities, and characterization facilities, respectively. Authors express their heartiest thanks to both institutions for valuable support. The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University.

Funding

The authors are recipients of grant and financial support from the AICTE/NPIU (TEQIP-III), all co-PIs of the project, and UGC Start-up Grant (BSR, No. F 30-461/2019), New Delhi, GOI. The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for funding this research group NO (RGP-271).

Author information

Authors and Affiliations

Contributions

All the co-authors have sufficiently contributed in this work and in the writing of final manuscript, and they all agreed with the submission of this manuscript into the journal.

Corresponding author

Ethics declarations

Ethics approval

No animal or human cells have been used in this work.

Competing interests

The authors declare no competing interests.

Additional information

This manuscript has not been published somewhere else, or it is not in consideration under any other journal in full or in partial.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pal, D.B., Tiwari, A.K., Srivastava, N. et al. Thermal studies of biomass obtained from the seeds of Syzygium cumini and Cassia fistula L. and peel of Cassia fistula L. fruit. Biomass Conv. Bioref. 13, 7601–7612 (2023). https://doi.org/10.1007/s13399-021-01492-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01492-z