Abstract

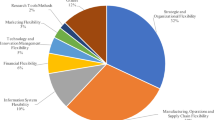

The purpose of this study is twofold: first, to establish the current themes on the topic of manufacturing and supply chain flexibility (MSCF), assess their level of maturity in relation to each other, identify the emerging ones and reflect on how they can inform each other, and second, to develop a conceptual model of MSCF that links different themes connect and highlight future research opportunities. The study builds on a sample of 222 articles published from 1996 to 2018 in international, peer-reviewed journals. The analysis of the sample involves two complementary approaches: the co-word technique to identify the thematic clusters as well as their relative standing and a critical reflection on the papers to explain the intellectual content of these thematic clusters. The results of the co-word analysis show that MSCF is a dynamic topic with a rich and complex structure that comprises five thematic clusters. The value chain, capability and volatility clusters showed research topics that were taking a central role in the discussion on MSCF but were not mature yet. The SC purchasing practices and SC planning clusters involved work that was more focused and could be considered more mature. These clusters were then integrated in a framework that built on the competence–capability perspective and identified the major structural and infrastructural elements of MSCF as well as its antecedents and consequences. This paper proposes an integrative framework helping managers keep track the various decisions they need to make to increase flexibility from the viewpoint of the entire value chain.

Similar content being viewed by others

Notes

Bullwhip effect: “the progressive increasing of upstream production variability caused by demand variability at the retail level in the chain” (Pereira 2010, p. 6358).

This perspective conceptualized SCF as an internal competence, i.e. what the organization excels at the leads to the external capability of agility, which is the organization’s ability to use its resources and processes to effectively respond to its environment dynamic needs.

Measures employed have a wide range of indicators from logistics, flexibility or delivery performance to overall firm performance.

It considers the complexity arising due to the way in which customer interacts with multiple identical suppliers (Simangunsong et al. 2012).

References

Abdelilah, B., El Korchi, A., & Balambo, M. A. (2018). Flexibility and agility: Evolution and relationship. Journal of Manufacturing Technology Management,29(7), 1138–1162.

Ali, M., & Murshid, M. (2016). Performance evaluation of flexible manufacturing system under different material handling strategies. Global Journal of Flexible Systems Management,17(3), 287–305.

Alves Filho, A. G., Nogueira, E., & Bento, P. E. G. (2015). Operations strategies of engine assembly plants in the Brazilian automotive industry. International Journal of Operations & Production Management,35(5), 817–838.

Aprile, D., Garavelli, A., & Giannoccaro, I. (2005). Operations planning and flexibility in a supply chain. Production Planning & Control,16(1), 21–31.

Arnold, V., Benford, T., Canada, J., & Sutton, S. (2015). Leveraging integrated information systems to enhance strategic flexibility and performance: The enabling role of enterprise risk management. International Journal of Accounting Information Systems,19, 1–16.

Asmussen, J., Kristensen, J., & Wæhrens, B. (2018). Outsourcing of production: The valuation of volume flexibiltiy in decision-making. LogForum Scientific Journal of Logistics,14(1), 73–83.

Avittathur, B., & Swamidass, P. (2007). Matching plant flexibility and supplier flexibility: Lessons from small suppliers of US manufacturing plants in India. Journal of Operations Management,25(3), 717–735.

Babazadeh, R., Razmi, J., & Ghodsi, R. (2013). Facility location in responsive and flexible supply chain network design (SCND) considering outsourcing. International Journal of Operational Research,17(3), 295–310.

Bag, S., & Gupta, S. (2017). Antecedents of sustainable innovation in supplier networks: A South African experience. Global Journal of Flexible Systems Management,18(3), 231–250.

Bai, C., & Sarkis, J. (2013). Flexibility in reverse logistics: A framework and evaluation approach. Journal of Cleaner Production,47, 306–318.

Balakrishnan, A., & Geunes, J. (2003). Production planning with flexible product specifications: An application to specialty steel manufacturing. Operations Research,51(1), 94–112.

Bandaly, D., Satir, A., Kahyaoglu, Y., & Shanker, L. (2012). Supply chain risk management—I: Conceptualization, framework and planning process. Risk Management,14(4), 249–271.

Bandaly, D., Shanker, L., Kahyaoglu, Y., & Satir, A. (2013). Supply chain risk management—II: A review of individual and integrated operational and financial approaches. Risk Management,15(1), 1–31.

Banker, R., & Bardhan, A. (2006). Understanding the impact of collaboration software on product design and development. Information Systems Research,17(4), 352–373.

Barad, M., & Sapir, D. (2003). Flexibility in logistic systems—Modeling and performance evaluation. International Journal of Production Economics,85(2), 155–170.

Bardhan, I., Whitaker, J., & Mithas, S. (2006). Information technology, production process outsourcing, and manufacturing plant performance. Journal of Management Information Systems,23(2), 13–40.

Bassamboo, A., Randhawa, R., & Mieghem, J. (2012). A little flexibility is all you need: On the asymptotic value of flexible capacity in parallel queuing systems. Operations Research,60(6), 1423–1435.

Beach, R., Muhlemann, A., Price, D., Paterson, A., & Sharp, J. (2000). A review of manufacturing flexibility. European Journal of Operational Research,122(1), 41–57.

Benaroch, M., Dai, Q., & Kauffman, R. (2010). Should we go our own way? Backsourcing flexibility in IT services contracts. Journal of Management Information Systems,26(4), 317–358.

Benavides-Velasco, C., Quintana-García, C., & Guzmán-Parra, V. (2013). Trends in family business research. Small Business Economics,40(1), 41–57.

Bernardes, E., & Hanna, M. (2009). A theoretical review of flexibility, agility and responsiveness in the operations management literature: Toward a conceptual definition of customer responsiveness. International Journal of Operations & Production Management,29(1), 30–53.

Bish, E., Muriel, A., & Biller, S. (2005). Managing flexible capacity in a make-to-order environment. Management Science,51(2), 167–180.

Bish, E., & Wang, Q. (2004). Optimal investment strategies for flexible resources, considering pricing and correlated demands. Operations Research,52(6), 954–964.

Blomé, C., Schoenherr, T., & Rexhausen, D. (2013). Antecedents and enablers of supply chain agility and its effect on performance: a dynamic capabilities perspective. International Journal of Production Research, 51(4), 1295–1318.

Blomé, C., Schoenherr, T., & Eckstein, D. (2014). The impact of knowledge transfer and complexity on supply chain flexibility: A knowledge-based view. International Journal of Production Economics,147, 307–316.

Bloss, D., & Pillai, D. (2001). E-manufacturing opportunities in semiconductor processing. Semiconductor International,24(8), 88–96.

Boonlua, S., & Photong, L. (2012). Comparative study of supply chain development in Thai and Malaysian firms. Journal of International Business Strategy,12(1), 30–38.

Boulaksil, Y., Grunow, M., & Fransoo, J. (2011). Capacity flexibility allocation in an outsourced supply chain with reservation. International Journal of Production Economics,129(1), 111–118.

Braunscheidel, M., & Suresh, N. (2009). The organizational antecedents of a firm’s supply chain agility for risk mitigation and response. Journal of Operations Management,27(2), 119–140.

Brozovic, D. (2018). Strategic flexibility: A review of the literature. International Journal of Management Reviews,20(1), 3–31.

Cachon, G., & Olivares, M. (2010). Drivers of finished-goods inventory in the US automobile industry. Management Science,56(1), 202–216.

Callon, M., Penan, H., & Courtial, J. (1995). Cienciometría: la medición de la actividad científica: de la bibliometría a la vigilancia tecnológica. Trea editions.

Calma, A., Martí-Parreño, J., & Davies, M. (2019). Journal of the Academy of Marketing Science 1973–2018: An analytical retrospective. Scientometrics,119(2), 879–908.

Calvo, R., Domingo, R., & Rubio, E. (2006). A heuristic approach for decision-making on assembly systems for mass customization. Materials Science Forum,526, 1–6.

Calvo, R., Domingo, R., & Sebastián, M. (2007). Operational flexibility quantification in a make-to-order assembly system. International Journal of Flexible Manufacturing Systems,19(3), 247–263.

Candace, Y., Ngai, E., & Moon, K. (2011). Supply chain flexibility in an uncertain environment: Exploratory findings from five case studies. Supply Chain Management: An International Journal,16(4), 271–283.

Chambost, V., & Stuart, P. (2007). Selecting the most appropriate products for the forest biorefinery. Industrial Biotechnology,3(2), 112–119.

Chan, F., Bhagwat, R., & Wadhwa, S. (2009). Study on suppliers’ flexibility in supply chains: Is real-time control necessary? International Journal of Production Research,47(4), 965–987.

Chan, A., Ngai, E., & Moon, K. (2017). The effects of strategic and manufacturing flexibilities and supply chain agility on firm performance in the fashion industry. European Journal of Operational Research,259(2), 486–499.

Chandra, A., Deshmukh, S., & Kanda, A. (2010). Flexibility and sustainability of supply chains: Are they together? Global Journal of Flexible Systems Management,11(1–2), 25–38.

Chang, S., Chen, R., Lin, R., Tien, S., & Sheu, C. (2006). Supplier involvement and manufacturing flexibility. Technovation,26(10), 1136–1146.

Chang, K., & Huang, H. (2012). Using influence strategies to advance supplier delivery flexibility: The moderating roles of trust and shared vision. Industrial Marketing Management,41(5), 849–860.

Chatzikontidou, A., Longinidis, P., Tsiakis, P., & Georgiadis, M. (2017). Flexible supply chain network design under uncertainty. Chemical Engineering Research and Design,128, 290–305.

Chaudhuri, A., Boer, H., & Taran, Y. (2018). Supply chain integration, risk management and manufacturing flexibility. International Journal of Operations & Production Management,38(3), 690–712.

Chen, M., Wang, S., & Chiou, C. (2009). The e-business policy of global logistics management for manufacturing. International Journal of Electronic Business Management,7(2), 86–97.

Chiang, C., Kocabasoglu-Hillmer, C., & Suresh, N. (2012). An empirical investigation of the impact of strategic sourcing and flexibility on firm’s supply chain agility. International Journal of Operations & Production Management,32(1), 49–78.

Chirra, S., & Kumar, D. (2018). Evaluation of supply chain flexibility in automobile industry with fuzzy DEMATEL approach. Global Journal of Flexible Systems Management,19(4), 305–319.

Chod, J., Rudi, N., & Van-Mieghem, J. (2010). Operational flexibility and financial hedging: Complements or substitutes? Management Science,56(6), 1030–1045.

Chou, C., Chua, G., Teo, C., & Zheng, H. (2010). Design for process flexibility: Efficiency of the long chain and sparse structure. Operations Research,58(1), 43–58.

Chou, C., Geoffrey, A., Chung-Piaw, T., & Zheng, H. (2011). Process flexibility revisited: The graph expander and its applications. Operations Research,59(5), 1090–1105.

Chu, Y., Chang, K., & Huang, F. (2011). The role of social mechanisms in promoting supplier flexibility. Journal of Business-to-Business Marketing,18(2), 155–187.

Chu, Y., Chang, K., & Huang, F. (2012). How to increase supplier flexibility through social mechanisms and influence strategies? Journal of Business & Industrial Marketing,27(2), 115–131.

Clyde, E. (1999). Palletizing unit loads: Many options. Material Handling Engineering,54(1), 99–106.

Cobo, M., López-Herrera, A., Herrera-Viedma, E., & Herrera, F. (2011). An approach for detecting, quantifying, and visualizing the evolution of a research field: A practical application to the fuzzy sets theory field. Journal of Informetrics,5(1), 146–166.

Coronado, M., & Lyons, A. (2007). Evaluating operations flexibility in industrial supply chains to support build-to-order initiatives. Business Process Management Journal,13(4), 572–587.

Correll, D., Suzuki, Y., & Martens, B. (2014). Biorenewable fuels at the intersection of product and process flexibility: A novel modeling approach and application. International Journal of Production Economics,150, 1–8.

Coulter, N., Monarch, I., & Konda, S. (1998). Software engineering as seen through its research literature: A study in co-word analysis. Journal of the American Society of Information Sciences,49(13), 1206–1223.

Cucchiella, F., Gastaldi, M., & Koh, S. (2010). Performance improvement: An active life cycle product management. International Journal of Systems Science,41(3), 301–313.

Cvsa, V., & Gilbert, S. (2002). Strategic commitment versus postponement in a two-tier supply chain. European Journal of Operational Research,141(3), 526–543.

Dabhilkar, M., & Bengtsson, L. (2008). Invest or divest? On the relative improvement potential in outsourcing manufacturing. Production Planning and Control,19(3), 212–228.

Dabhilkar, M., Bengtsson, L., Von Haartman, R., & Åhlström, P. (2009). Supplier selection or collaboration? Determining factors of performance improvement when outsourcing manufacturing. Journal of Purchasing and Supply Management,15(3), 143–153.

Dansereau, L., El-Halwagi, M., Mansoornejad, B., & Stuart, P. (2014). Framework for margins-based planning: Forest biorefinery case study. Computers & Chemical Engineering,63, 34–50.

Dansereau, L., El-Halwagi, M., & Stuart, P. (2012). Value-chain planning in the forest biorefinery: Case study analyzing manufacturing flexibility. J-for-Journal of Science & Technology for Forest Products and Processes,2(4), 60–69.

Das, K. (2011). Integrating effective flexibility measures into a strategic supply chain planning model. European Journal of Operational Research,211(1), 170–183.

Dauzère-Pérès, S., Nordli, A., Olstad, A., Haugen, K., Koester, U., Per Olav, M., et al. (2007). Omya Hustadmarmor optimizes its supply chain for delivering calcium carbonate slurry to European paper manufacturers. Interfaces,37(1), 39–51.

De Giovanni, D., & Massabò, I. (2018). Capacity investment under uncertainty: The effect of volume flexibility. International Journal of Production Economics,198, 165–176.

Devaraj, S., Vaidyanathan, G., & Mishra, A. (2012). Effect of purchase volume flexibility and purchase mix flexibility on e-procurement performance: An analysis of two perspectives. Journal of Operations Management,30(7), 509–520.

Dey, S., Sharma, R. R. K., & Pandey, B. K. (2019). Relationship of manufacturing flexibility with organizational strategy. Global Journal of Flexible Systems Management, 20(3), 237–256.

Di Stefano, G., Peteraf, M., & Verona, G. (2010). Dynamic capabilities deconstructed: A bibliographic investigation into the origins, development, and future directions of the research domain. Industrial and Corporate Change,19(4), 1187–1204.

Duclos, L., Vokurka, R., & Lummus, R. (2003). A conceptual model of supply chain flexibility. Industrial Management & Data Systems,103(6), 446–456.

Dulluri, S., & Srinivasa, N. (2009). Stochastic operational planning model for production and distribution in a hi-tech manufacturing network. International Journal of Operational Research,5(2), 163–189.

Durach, C., Kembro, J., & Wieland, A. (2017). A new paradigm for systematic literature reviews in supply chain management. Journal of Supply Chain Management,53(4), 67–85.

Dwaikat, N., Money, H., Behashti, H., & Salehi-Sangari, E. (2018). How does information sharing affect first-tier suppliers’ flexibility? Evidence from the automotive industry in Sweden. Production Planning & Control,29(4), 289–300.

Engelhardt-Nowitzki, C. (2012). Improving value chain flexibility and adaptability in build-to-order environments. International Journal of Physical Distribution & Logistics Management,42(4), 318–337.

Esmaeilikia, M., Fahimnia, B., Sarkis, J., Govindan, K., Kumar, A., & Mo, J. (2016). Tactical supply chain planning models with inherent flexibility: Definition and review. Annals of Operations Research,244(2), 407–427.

Fahimnia, B., Sarkis, J., & Davarzani, H. (2015). Green supply chain management: A review and bibliometric analysis. International Journal of Production Economics,162, 101–114.

Fantazy, K., Kumar, V., & Kumar, U. (2009). An empirical study of the relationships among strategy, flexibility, and performance in the supply chain context. Supply Chain Management: An International Journal,14(3), 177–188.

Fantazy, K., & Salem, M. (2016). The value of strategy and flexibility in new product development. Journal of Enterprise Information Management,29(4), 525–548.

Fayezi, S., & Zomorrodi, M. (2015). The role of relationship integration in supply chain agility and flexibility development: An Australian perspective. Journal of Manufacturing Technology Management,26(8), 1126–1157.

Fayezi, S., Zutshi, A., & O’Loughlin, A. (2014). Developing an analytical framework to assess the uncertainty and flexibility mismatches across the supply chain. Business Process Management Journal,20(3), 362–391.

Fayezi, S., Zutshi, A., & O’Loughlin, A. (2015). How Australian manufacturing firms perceive and understand the concepts of agility and flexibility in the supply chain. International Journal of Operations & Production Management,35(2), 246–281.

Fayezi, S., Zutshi, A., & O’Loughlin, A. (2017). Understanding and development of supply chain agility and flexibility: A structured literature review. International Journal of Management Reviews,19(4), 379–407.

Feng, Y., Zhu, Q., & Lai, K. (2017). Corporate social responsibility for supply chain management: A literature review and bibliometric analysis. Journal of Cleaner Production,158, 296–307.

Ferdows, K., & Carabetta, C. (2006). The effect of inter-factory linkage flexibility on inventories and backlogs in integrated process industries. International Journal of Production Research,44(2), 237–255.

Foo, D., Tan, R., Lam, H., Aziz, M., & Klemeš, J. (2013). Robust models for the synthesis of flexible palm oil-based regional bioenergy supply chain. Energy,55, 68–73.

Francas, D., & Minner, S. (2009). Manufacturing network configuration in supply chains with product recovery. Omega,37(4), 757–769.

Fredriksson, A. (2014). Manufacturing and supply chain flexibility—Towards a tool to analyse production network coordination at operational level. Strategic Outsourcing: An International Journal,7(2), 173–194.

Garavelli, A. (2003). Flexibility configurations for the supply chain management. International Journal of Production Economics,85(2), 141–153.

Giachetti, R., Martinez, L., Sáenz, O., & Chen, C. (2003). Analysis of the structural measures of flexibility and agility using a measurement theoretical framework. International Journal of Production Economics,86(1), 47–62.

Gligor, D. (2014). A cross-disciplinary examination of firm orientations’ performance outcomes: The role of supply chain flexibility. Journal of Business Logistics,35(4), 281–298.

Gligor, D., & Holcomb, M. (2012). Understanding the role of logistics capabilities in achieving supply chain agility: A systematic literature review. Supply Chain Management: An International Journal,17(4), 438–453.

Goldsby, T., & García-Dastugue, S. (2003). The manufacturing flow management process. The International Journal of Logistics Management,14(2), 33–52.

Gosling, J., Naim, M., & Towill, D. (2013). A supply chain flexibility framework for engineer-to-order systems. Production Planning & Control,24(7), 552–566.

Gosling, J., Purvis, L., & Naim, M. (2010). Supply chain flexibility as a determinant of supplier selection. International Journal of Production Economics,128(1), 11–21.

Govindan, K., Fattahi, M., & Keyvanshokooh, E. (2017). Supply chain network design under uncertainty: A comprehensive review and future research directions. European Journal of Operational Research,263(1), 108–141.

Govindarajulu, N., & Daily, B. (2009). Exploring the antecedents of externally-driven flexibilities. Journal of Management Research,9(2), 83.

Grawe, S., Daugherty, P., & Roath, A. (2011). Knowledge synthesis and innovative logistics processes: Enhancing operational flexibility and performance. Journal of Business Logistics,32(1), 69–80.

Grover, P., & Kar, A. K. (2017). Big data analytics: A review on theoretical contributions and tools used in literature. Global Journal of Flexible Systems Management,18(3), 203–229.

Gunasekaran, A., Dubey, R., & Singh, S. P. (2016). Flexible sustainable supply chain network design: Current trends, opportunities and future. Global Journal of Flexible Systems Management,17(2), 109–112.

Gunasekaran, A., & McGaughey, R. (2003). TQM is supply chain management. The TQM Magazine,15(6), 361–363.

Hall, D., Skipper, J., & Hanna, J. (2010). The mediating effect of comprehensive contingency planning on supply chain organisational flexibility. International Journal of Logistics: Research and Applications,13(4), 291–312.

Han, J., Wang, Y., & Naim, M. (2017). Reconceptualization of information technology flexibility for supply chain management: An empirical study. International Journal of Production Economics,187, 196–215.

Harkonen, J., Haapasalo, H., & Hanninen, K. (2015). Productisation: A review and research agenda. International Journal of Production Economics,164, 65–82.

Hasuike, T., & Ishii, H. (2009). On flexible product-mix decision problems under randomness and fuzziness. Omega,37(4), 770–787.

Hayes, R., & Wheelwright, S. (1984). Restoring our competitive edge: Competing through manufacturing. New York, NY: Wiley.

He, Y., Kin, K., Hongyi, S., & Chen, Y. (2014). The impact of supplier integration on customer integration and new product performance: The mediating role of manufacturing flexibility under trust theory. International Journal of Production Economics,147, 260–270.

Holweg, M. (2005). The three dimensions of responsiveness. International Journal of Operations & Production Management,25(7), 603–622.

Huchzermeier, A., & Cohen, M. (1996). Valuing operational flexibility under exchange rate risk. Operations Research,44(1), 100–113.

Indranil, B., Demirkan, H., Kannan, P., Kauffman, R., & Sougstad, R. (2010). An interdisciplinary perspective on IT services management and service science. Journal of Management Information Systems,26(4), 13–64.

Ishfaq, R. (2013). Intermodal shipments as recourse in logistics disruptions. Journal of the Operational Research Society,64(2), 229–240.

Jain, A. (2018). Responding to shipment delays: The roles of operational flexibility & lead-time visibility. Decision Sciences,49(2), 306–334.

Jain, A., Jain, P., Chan, F., & Singh, S. (2013). A review on manufacturing flexibility. International Journal of Production Research,51(19), 5946–5970.

Jin, Y., Vonderembse, M., Ragu-Nathan, T., & Smith, J. (2014). Exploring relationships among IT-enabled sharing capability, supply chain flexibility, and competitive performance. International Journal of Production Economics,153, 24–34.

Jitpaiboon, T., & Sharma, S. (2013). Comparative study of supply chain relationships, mass customization, and organizational performance between SME(s) and LE(s). Journal of Business Administration Research,1(2), 139–157.

Kara, S., Kayis, B., & O’Kane, S. (2002). The role of human factors in flexibility management: A survey. Human Factors and Ergonomics in Manufacturing & Service Industries,12(1), 75–119.

Karrenbauer, J. (2012). Transforming the supply chain: Steps for understanding and reworking your entire network. Materials Management and Distribution,57(3), 22–23.

Kaur, S. P., Kumar, J., & Kumar, R. (2017). The relationship between flexibility of manufacturing system components, competitiveness of SMEs and business performance: A study of manufacturing SMEs in Northern India. Global Journal of Flexible Systems Management,18(2), 123–137.

Kavitha, C., & Vijayalakshmi, C. (2013a). Implementation of fuzzy multi objective linear programming for decision making and planning under uncertainty. Indian Journal of Computer Science and Engineering,4(2), 103–121.

Kavitha, C., & Vijayalakshmi, C. (2013b). Implementation of supplier evaluation and ranking by improved TOPSIS. Applied Mathematical Sciences,7(46), 2265–2270.

Kavitha, C., & Vijayalakshmi, C. (2015). Fuzzy multi objective mixed integer linear programming technique for supply chain management. International Journal of Pure and Applied Mathematics,101(5), 781–790.

Kayis, B., & Kara, S. (2005). The supplier and customer contribution to manufacturing flexibility: Australian manufacturing industry’s perspective. Journal of Manufacturing Technology Management,16(7), 733–752.

Kazaz, B., Dada, M., & Moskowitz, H. (2005). Global production planning under exchange-rate uncertainty. Management Science,51(7), 1101–1119.

Kazemian, I., & Aref, S. (2016). Multi-echelon supply chain flexibility enhancement through detecting bottlenecks. Global Journal of Flexible Systems Management,17(4), 357–372.

Kemmoe, S., Pernot, P., & Tchernev, N. (2014). Model for flexibility evaluation in manufacturing network strategic planning. International Journal of Production Research,52(15), 4396–4411.

Keong, O., Ahmad, M., Ismail, S., Sulaiman, N., & Yusuf, M. (2005). Proposing a non-traditional ordering methodology in achieving optimal flexibility with minimal inventory risk. Asia Pacific Journal of Marketing and Logistics,17(2), 31–43.

Kesen, S. (2014). Capacity-constrained supplier selection model with lost sales under stochastic demand behaviour. Neural Computing and Applications,24(2), 347–356.

Kim, W. (2011). Order quantity flexibility as a form of customer service in a supply chain contract model. Flexible Services and Manufacturing Journal,23(3), 290–315.

Kim, M., & Chai, S. (2016). Assessing the impact of business uncertainty on supply chain integration. The International Journal of Logistics Management,27(2), 463–485.

Kim, M., Suresh, N., & Kocabasoglu-Hillmer, C. (2013). An impact of manufacturing flexibility and technological dimensions of manufacturing strategy on improving supply chain responsiveness: Business environment perspective. International Journal of Production Research,51(18), 5597–5611.

Klueber, R., & O’Keefe, R. (2013). Defining and assessing requisite supply chain visibility in regulated industries. Journal of Enterprise Information Management,26(3), 295–315.

Koste, L., Malhotra, M., & Sharma, S. (2004). Measuring dimensions of manufacturing flexibility. Journal of Operations Management,22(2), 171–196.

Krajewski, L., Wei, J., & Tang, L. (2005). Responding to schedule changes in build-to-order supply chains. Journal of Operations Management,23(5), 452–469.

Kristal, M., Huang, X., & Roth, A. (2010). The effect of an ambidextrous supply chain strategy on combinative competitive capabilities and business performance. Journal of Operations Management,28(5), 415–429.

Kulkarni, S., & Francas, D. (2018). Capacity investment and the value of operational flexibility in manufacturing systems with product blending. International Journal of Production Research,56(10), 3563–3589.

Kumar, R. (2019). Research methodology: A step-by-step guide for beginners. London: Sage Publications Limited.

Kumar, P., & Deshmukh, S. G. (2006). A model for flexible supply chain through flexible manufacturing. Global Journal of Flexible Systems Management,7(3/4), 17–24.

Kumar, V., Fantazy, K. A., Kumar, U., & Boyle, T. (2006). Implementation and management framework for supply chain flexibility. Journal of Enterprise Information Management,19(3), 303–319.

Kumar, R., & Mishra, M. (2017). Manufacturing and supply chain flexibility: An integrated viewpoint. International Journal of Services and Operations Management,27(3), 384–407.

Kumar, A., Pal, A., Vohra, A., Gupta, S., Manchanda, S., & Dash, M. (2018). Construction of capital procurement decision making models to optimize supplier selection using Fuzzy Delphi and AHP-DEMATEL. Benchmarking: An International Journal,25(5), 1528–1547.

Kumar, R., Singh, R. K., & Shankar, R. (2013). Study on coordination issues for flexibility in supply chain of SMEs: A case study. Global Journal of Flexible Systems Management,14(2), 81–92.

Kume, K., & Fujiwara, T. (2016). Production flexibility of real options in daily supply chain. Global Journal of Flexible Systems Management,17(3), 249–264.

Lagoudis, I., Naim, M., & Potter, A. (2010). Strategic flexibility choices in the ocean transportation industry. International Journal of Shipping and Transport Logistics,2(2), 187–205.

Lee, Y., & Kincade, D. H. (2003). US apparel manufacturers’ company characteristic differences based on SCM activities. Journal of Fashion Marketing and Management: An International Journal,7(1), 31–48.

Li, Y., Guo, H., & Zhang, Y. (2018). An integrated location-inventory problem in a closed-loop supply chain with third-party logistics. International Journal of Production Research,56(10), 3462–3481.

Liao, Y., & Marsillac, E. (2015). External knowledge acquisition and innovation: The role of supply chain network-oriented flexibility and organisational awareness. International Journal of Production Research,53(18), 5437–5455.

Lim, B., Ling, F., Ibbs, C., Raphael, B., & Ofori, G. (2010). Empirical analysis of the determinants of organizational flexibility in the construction business. Journal of Construction Engineering and Management,137(3), 225–237.

Lim, B., Ling, F., Ibbs, C., Raphael, B., & Ofori, G. (2012). Mathematical models for predicting organizational flexibility of construction firms in Singapore. Journal of Construction Engineering and Management,138(3), 361–375.

Lin, B. (2003). Cooperating for supply chain effectiveness: Manufacturing strategy for Chinese OEMs. International Journal of Manufacturing Technology and Management,5(3), 232–245.

Ling-yee, L., & Ogunmokun, G. (2008). An empirical study of manufacturing flexibility of exporting firms in China: How do strategic and organizational contexts matter? Industrial Marketing Management,37(6), 738–751.

Lo, S. (2016). The influence of variability and strategy of service supply chains on performance. Service Business,10(2), 393–421.

López-Fernández, M. C., Serrano-Bedia, A. M., & Pérez-Pérez, M. (2016). Entrepreneurship and family firm research: A bibliometric analysis of an emerging field. Journal of Small Business Management,54(2), 622–639.

Lummus, R., Duclos, L., & Vokurka, R. (2003). Supply chain flexibility: Building a new model. Global Journal of Flexible Systems Management,4(4), 1–14.

Lummus, R., Vokurka, R., & Duclos, L. (2005). Delphi study on supply chain flexibility. International Journal of Production Research,43(13), 2687–2708.

Lummus, R., Vokurka, R., & Duclos, L. (2006). The produce-process matrix revisited: Integrating supply chain trade-offs. SAM Advanced Management Journal,71(2), 4–12.

Luo, B. N., & Yu, K. (2016). Fits and misfits of supply chain flexibility to environmental uncertainty: Two types of asymmetric effects on performance. The International Journal of Logistics Management,27(3), 862–885.

Maestrini, V., Luzzini, D., Maccarrone, P., & Caniato, F. (2017). Supply chain performance measurement systems: A systematic review and research agenda. International Journal of Production Economics,183, 299–315.

Malhotra, K., & Mackelprang, A. (2012). Are internal manufacturing and external supply chain flexibilities complementary capabilities? Journal of Operations Management,30(3), 180–200.

Manders, J., Caniëls, M., & Paul, W. (2016). Exploring supply chain flexibility in a FMCG food supply chain. Journal of Purchasing and Supply Management,22(3), 181–195.

Mansoornejad, B., Chambost, V., & Stuart, P. (2010). Integrating product portfolio design and supply chain design for the forest biorefinery. Computers & Chemical Engineering,34(9), 1497–1506.

Manuj, I., & Sahin, F. (2011). A model of supply chain and supply chain decision-making complexity. International Journal of Physical Distribution & Logistics Management,41(5), 511–549.

Mason, R., & Nair, R. (2013a). Strategic flexibility capabilities in the container liner shipping sector. Production Planning & Control,24(7), 640–651.

Mason, R., & Nair, R. (2013b). Supply-side strategic flexibility capabilities in container liner shipping. The International Journal of Logistics Management,24(1), 22–48.

McLaren, T., Head, M., & Yuan, Y. (2004). Supply chain management information systems capabilities. An exploratory study of electronics manufacturers. Information Systems and E-business Management,2(2), 207–222.

Merigó, J. M., Muller, C., Modak, N. M., & Laengle, S. (2019). Research in production and operations management: A university-based bibliometric analysis. Global Journal of Flexible Systems Management,20(1), 1–29.

Merschmann, U., & Thonemann, U. (2011). Supply chain flexibility, uncertainty and firm performance: An empirical analysis of German manufacturing firms. International Journal of Production Economics,130(1), 43–53.

Minner, S. (2003). Multiple-supplier inventory models in supply chain management: A review. International Journal of Production Economics,81, 265–279.

Mishra, R., Pundir, A., & Ganapathy, L. (2014). Manufacturing flexibility research: A review of literature and agenda for future research. Global Journal of Flexible Systems Management,15(2), 101–112.

Mishra, R., Pundir, A., & Ganapathy, L. (2018). Empirical assessment of factors influencing potential of manufacturing flexibility in organization. Business Process Management Journal,24(1), 158–182.

Moon, K., Candace, Y., & Ngai, E. (2012). An instrument for measuring supply chain flexibility for the textile and clothing companies. European Journal of Operational Research,222(2), 191–203.

Moreira, M., & Tjahjono, B. (2016). Applying performance measures to support decision-making in supply chain operations: A case of beverage industry. International Journal of Production Research,54(8), 2345–2365.

Moussaoui, I., Williams, B., Hofer, C., Aloysius, J., & Waller, M. (2016). Drivers of retail on-shelf availability: Systematic review, critical assessment, and reflections on the road ahead. International Journal of Physical Distribution & Logistics Management,46(5), 516–535.

Muñoz-Leiva, F., Viedma-del-Jesús, M., Sánchez-Fernández, J., & López-Herrera, A. (2012). An application of co-word analysis and bibliometric maps for detecting the most highlighting themes in the consumer behaviour research from a longitudinal perspective. Quality & Quantity,46(4), 1077–1095.

Musa, A., & Dabo, A. A. A. (2016). A review of RFID in supply chain management: 2000–2015. Global Journal of Flexible Systems Management,17(2), 189–228.

Nagarajan, V., Savitskie, K., Ranganathan, S., Sen, S., & Alexandrov, A. (2013). The effect of environmental uncertainty, information quality, and collaborative logistics on supply chain flexibility of small manufacturing firms in India. Asia Pacific Journal of Marketing and Logistics,25(5), 784–802.

Naim, M., Ariee, G., & Potter, A. (2010). Determining a logistics provider’s flexibility capability. International Journal of Production Economics,127, 39–45.

Narasimhan, R., Swink, M., & Kim, S. (2006). Disentangling leanness and agility: An empirical investigation. Journal of Operations Management,24(5), 440–457.

Narasimhan, R., Talluri, S., & Das, A. (2004). Exploring flexibility and execution competencies of manufacturing firms. Journal of Operations Management,22(1), 91–106.

Ndubisi, N., Jantan, M., Cha Hing, L., & Salleh-Ayub, M. (2005). Supplier selection and management strategies and manufacturing flexibility. Journal of Enterprise Information Management,18(3), 330–349.

Negahban, A., Yilmaz, L., & Nall, T. (2014). Managing production level in new product diffusion: An agent-based simulation approach. International Journal of Production Research,52(17), 4950–4966.

Nehzat, F. (2015). The impact of supply chain relationship quality on brand promise. Uncertain Supply Chain Management,3(2), 141–146.

Nembhard, H., Shi, L., & Aktan. M. (2002). Valuing operational flexibility in manufacturing systems using real options. In IIE Annual Conference. Proceedings (p. 1). Institute of Industrial and Systems Engineers (IISE), 2

Niranjan, S., Spulick, S., & Savitskie, K. (2018). Mediating and moderating influencers of firm performance: Supply chain managers’ perspective. Journal of Enterprise Information Management,31(1), 38–63.

Oberoi, J. S., Khamba, J. S., & Kiran, R. (2007). Impact of new technology and sourcing practices in managing tactical and strategic manufacturing flexibilities—An empirical study. Global Journal of Flexible Systems Management,8(3), 1–14.

Ojha, D., White, R., Rogers, P., & Kuo, C. (2015). Information processing-related infrastructural antecedents of manufacturing flexibility—A real options perspective. International Journal of Production Research,53(17), 5174–5192.

Omar, A., Sramek, B., Myers, M., & Mentzer, J. (2012). A global analysis of orientation, coordination, and flexibility in supply chains. Journal of Business Logistics,33(2), 128–144.

Pereira, J. (2010). Flexibility dimensions to control the bullwhip effect in a supply chain. International Journal of Production Research,47(22), 6357–6374.

Pereira, G., Sellitto, M., & Borchardt, M. (2018). Flexibility and orientation for two supply chains fashion industry markets: Analysis and model for future research. Gestão & Produção,25(2), 319–330.

Pérez-Pérez, M., Serrano-Bedia, A. M., & López-Fernández, M. C. (2016). A review of manufacturing flexibility: Systematising the concept. International Journal of Production Research,54(10), 3133–3148.

Pérez-Pérez, M., Serrano-Bedia, A. M., López-Fernández, M. C., & García-Piqueres, G. (2018). Research opportunities on manufacturing flexibility domain: A review and theory-based research agenda. Journal of Manufacturing Systems,48, 9–20.

Pierre, H., & Luc, C. (2007). The role of joint collaboration planning actions in a demand-driven supply chain. Industrial Management & Data Systems,107(7), 954–978.

Purvis, L., Gosling, J., & Naim, M. (2014). The development of a lean, agile and leagile supply network taxonomy based on differing types of flexibility. International Journal of Production Economics,151, 100–111.

Qu, W., Ding, Y., Shou, Y., Zhou, H., & Du, H. (2014). The impact of enterprise systems on process flexibility and organisational flexibility. Enterprise Information Systems,8(5), 563–581.

Rao, K. S., & Wadhwa, S. (2002). Understanding flexibility in supply chains: A conceptual framework and models. Global Journal of Flexible Systems Management,3(4), 1–12.

Reichhart, A., & Holweg, M. (2007). Creating the customer-responsive supply chain: A reconciliation of concepts. International Journal of Operations & Production Management,27(11), 1144–1172.

Reimann, M., & Schiltknecht, P. (2009a). The role of risk preferences and flexibility for risk management: Lessons from a custom manufacturing environment. Review of Managerial Science,3(2), 117–140.

Reimann, M., & Schiltknecht, P. (2009b). Studying the interdependence of contractual and operational flexibilities in the market of specialty chemicals. European Journal of Operational Research,198(3), 760–772.

Richardson, J. (1996). Vertical integration and rapid response in fashion apparel. Organization Science,7(4), 400–412.

Richardson, L., & Snaddon, D. (2011). An exploratory study of long supply chain competition: Selected cases in the South African aerospace sector. South African Journal of Industrial Engineering,22(1), 155–165.

Rogers, P., Ojha, D., & White, R. (2011). Conceptualising complementarities in manufacturing flexibility: A comprehensive view. International Journal of Production Research,49(12), 3767–3793.

Rojo, A., Llorens-Montes, J., & Perez-Arostegui, M. (2016). The impact of ambidexterity on supply chain flexibility fit. Supply Chain Management: An International Journal,21(4), 433–452.

Rojo, A., Stevenson, M., Lloréns-Montes, F., & Perez-Arostegui, M. (2018). Supply chain flexibility in dynamic environments: The enabling role of operational absorptive capacity and organisational learning. International Journal of Operations & Production Management,38(3), 636–666.

Saenz, M. J. (2017). Building manufacturing flexibility with strategic suppliers and contingent effect of product dynamism on customer satisfaction. Journal of Purchasing and Supply Management,24(3), 238–246.

Saghiri, S. (2011). A structural approach to assessing postponement strategies: Construct development and validation. International Journal of Production Research,49(21), 6427–6450.

Saghiri, S., & Barnes, S. (2016). Supplier flexibility and postponement implementation: An empirical analysis. International Journal of Production Economics,173, 170–183.

Salvador, F., Rungtusanatham, M., & Forza, C. (2007). Mix flexibility and volume flexibility in a build-to-order environment. International Journal of Operations & Production Management,27(11), 1173–1191.

Sanchez, A., & Perez, M. (2005). Supply chain flexibility and firm performance. A conceptual model and empirical study in the automotive industry. International Journal of Operations & Production Management,25(7–8), 681–700.

Sasikumar, P., & Haq, A. (2010). A multi-criteria decision making methodology for the selection of reverse logistics operating modes. International Journal Enterprise Network Management,4(1), 68–79.

Savaşaneril, S., & Nesim, E. (2010). An analysis of manufacturer benefits under vendor-managed systems. IIE Transactions,42(7), 455–477.

Sawhney, R. (2006). Interplay between uncertainty and flexibility across the value-chain: Towards a transformation model of manufacturing flexibility. Journal of Operations Management,24(5), 476–493.

Scavarda, L., Ceryno, P., Pires, S., & Klingebiel, K. (2015). Supply chain resilience analysis: A Brazilian automotive case. Revista de Administração de Empresas,55(3), 304–313.

Scherrer-Rathje, M., Deflorin, P., & Anand, G. (2014). Manufacturing flexibility through outsourcing: Effects of contingencies. International Journal of Operations & Production Management,34(9), 1210–1242.

Schütz, P., Tomasgard, A., & Ahmed, S. (2009). Supply chain design under uncertainty using sample average approximation and dual decomposition. European Journal of Operational Research,199(2), 409–419.

Seebacher, G., & Winkler, H. (2013). A citation analysis of the research on manufacturing and supply chain flexibility. International Journal of Production Research,51(11), 3415–3427.

Seebacher, G., & Winkler, H. (2015). A capability approach to evaluate supply chain flexibility. International Journal of Production Economics,167, 177–186.

Serrano-Bedia, A. M., López-Fernández, M. C., & Pérez-Pérez, M. (2013). Análisis de la relación entre flexibilidad en operaciones y performance empresarial mediante técnicas bibliométricas. Revista Española de Documentación Científica,36(4), 1–12.

Shah, T., & Sharma, M. (2014). Comprehensive view of logistics flexibility and its impact on customer satisfaction. International Journal of Logistics Systems and Management,19(1), 43–61.

Sharma, O. P., & Sushil. (2002). Issues in managing manufacturing flexibility: a review. Global Journal of Flexible Systems Management, 3(2–3), 11–29.

Shibin, K. T., Gunasekaran, A., Papadopoulos, T., Dubey, R., Singh, M., & Wamba, S. F. (2016). Enablers and barriers of flexible green supply chain management: A total interpretive structural modeling approach. Global Journal of Flexible Systems Management,17(2), 171–188.

Shukla, A. C., Deshmukh, S. G., & Kanda, A. (2010). Flexibility and Sustainability of supply chains: Are they together? Global Journal of Flexible Systems Management,11(1–2), 25–37.

Siddiqui, F., Haleem, A., & Sharma, C. (2012). The impact of supply chain management practices in total quality management practices and flexible system practices context: An empirical study in oil and gas industry. Global Journal of Flexible Systems Management,13(1), 11–23.

Siddiqui, F., Haleem, A., & Wadhwa, S. (2009). Role of supply chain management in context of total quality management in flexible systems: A state-of the-art literature review. Global Journal of Flexible Systems Management,10(3), 1–14.

Simangunsong, E., Hendry, L., & Stevenson, M. (2012). Supply-chain uncertainty: A review and theoretical foundation for future research. International Journal of Production Research,50(16), 4493–4523.

Simangunsong, E., Hendry, L., & Stevenson, M. (2016). Managing supply chain uncertainty with emerging ethical issues. International Journal of Operations & Production Management,36(10), 1272–1307.

Singh, R. K., & Acharya, P. (2013). Supply chain flexibility: A frame work of research dimensions. Global Journal of Flexible Systems Management,14(3), 157–166.

Singh, R. K., & Acharya, P. (2014). Identification and evaluation of supply chain flexibilities in Indian FMCG sector using DEMATEL. Global Journal of Flexible Systems Management,15(2), 91–100.

Singh, R., Koul, S., & Kumar, P. (2017). Analyzing the interaction of factors for flexibility in supply chains. Journal of Modelling in Management,12(4), 671–689.

Singh, R., & Sharma, M. (2014). Prioritising the alternatives for flexibility in supply chains. Production Planning & Control,25(2), 176–192.

Singh, D., Singh, J., & Singh, I. (2013). An empirical investigation of dynamic capabilities in managing strategic flexibility in manufacturing organizations. Management Decision,51(7), 1442–1461.

Slack, N. (2005a). The flexibility of manufacturing systems. International Journal of Operations & Production Management,25(12), 1190–1200.

Slack, N. (2005b). The changing nature of operations flexibility. International Journal of Operations & Production Management,25(12), 1201–1210.

Solke, N. S., & Singh, T. P. (2018). Analysis of relationship between manufacturing flexibility and lean manufacturing using structural equation modelling. Global Journal of Flexible Systems Management,19(2), 139–157.

Song, J., Chen, W., & Lei, L. (2018). Supply chain flexibility and operations optimisation under demand uncertainty: A case in disaster relief. International Journal of Production Research,56(10), 1–15.

Song, H., & Song, Y. (2009). Impact of inventory management flexibility on service flexibility and performance: Evidence from mainland Chinese firms. Transportation Journal,48(3), 7–19.

Soon, Q., & Udin, Z. (2011). Supply chain management from the perspective of value chain flexibility: An exploratory study. Journal of Manufacturing Technology Management,22(4), 506–526.

Sreedevi, R., & Saranga, H. (2017). Uncertainty and supply chain risk: The moderating role of supply chain flexibility in risk mitigation. International Journal of Production Economics,193, 332–342.

Stank, T., Scott, K., & Closs, D. (2001). Performance benefits of supply chain logistical integration. Transportation Journal,41(2/3), 32–46.

Stevenson, M. (2013). The role of services in flexible supply chains: An exploratory study. International Journal of Agile Systems and Management,6(4), 307–323.

Stevenson, M., & Spring, M. (2007). Flexibility from a supply chain perspective: Definition and review. International Journal of Operations & Production Management,27(7), 685–713.

Stevenson, M., & Spring, M. (2009). Supply chain flexibility: An inter-firm empirical study. International Journal of Operations & Production Management,29(9), 946–971.

Swafford, M., Ghosh, S., & Murthy, N. (2006a). The antecedents of supply chain agility of a firm: Scale development and model testing. Journal of Operations Management,24(2), 170–188.

Swafford, M., Ghosh, S., & Murthy, N. (2006b). A framework for assessing value chain agility. International Journal of Operations & Production Management,26(2), 118–140.

Swafford, M., Ghosh, S., & Murthy, N. (2008). Achieving supply chain agility through IT integration and flexibility. International Journal of Production Economics,116(2), 288–297.

Tachizawa, M., & Gimenez, C. (2009). Assessing the effectiveness of supply flexibility sources: An empirical research. International Journal of Production Research,47(20), 5791–5809.

Tachizawa, M., & Giménez, C. (2010). Supply flexibility strategies in Spanish firms: Results from a survey. International Journal of Production Economics,124(1), 214–224.

Tachizawa, M., & Thomson, C. (2007). Drivers and sources of supply flexibility: An exploratory study. International Journal of Operations & Production Management,27(10), 1115–1136.

Tang, C., & Tomlin, B. (2008). The power of flexibility for mitigating supply chain risks. International Journal of Production Economics,116(1), 12–27.

Tanrisever, F., Morrice, D., & Morton, D. (2012). Managing capacity flexibility in make-to-order production environments. European Journal of Operational Research,216(2), 334–345.

Teich, E., & Claus, T. (2017). Measurement of load and capacity flexibility in manufacturing. Global Journal of Flexible Systems Management,18(4), 291–302.

Thomé, A., Scavarda, S., Ceryno, P., & Klingebiel, K. (2014). A multi-tier study on supply chain flexibility in the automotive industry. International Journal of Production Economics,158, 91–105.

Tipu, S., & Fantazy, K. (2014). Supply chain strategy, flexibility, and performance: A comparative study of SMEs in Pakistan and Canada. The International Journal of Logistics Management,25(2), 399–416.

Tiwari, A., Tiwari, A., & Samuel, C. (2015). Supply chain flexibility: A comprehensive review. Management Research Review,38(7), 767–792.

Tomlin, B. (2006). On the value of mitigation and contingency strategies for managing supply chain disruption risks. Management Science,52(5), 639–657.

Treville, S., Schürhoff, N., Trigeorgis, L., & Avanzi, B. (2014). Optimal sourcing and lead-time reduction under evolutionary demand risk. Production and Operations Management,23(12), 2103–2117.

Tse, Y., Zhang, M., Akhtar, P., & MacBryde, J. (2016). Embracing supply chain agility: An investigation in the electronics industry. Supply Chain Management: An International Journal,21(1), 140–156.

Um, J. (2017). Improving supply chain flexibility and agility through variety management. The International Journal of Logistics Management,28(2), 464–487.

Um, J., Lyons, A., Lam, H., Cheng, T., & Dominguez-Pery, C. (2017). Product variety management and supply chain performance: A capability perspective on their relationships and competitiveness implications. International Journal of Production Economics,187, 15–26.

Verbeek, A., Debackere, K., Luwel, M., & Zimmermann, E. (2002). Measuring progress and evolution in science and technology—The multiple uses of bibliometric indicators. International Journal of Management Reviews,4(2), 179–211.

Vickery, S. N., Calantone, R., & Dröge, C. (1999). Supply chain flexibility: An empirical study. Journal of Supply Chain Management,35(2), 16–24.

Wadhwa, S., Ducq, Y., Saxena, A., & Prakash, A. (2008a). Supply chain as a flexible system: A KM focused competence. Global Journal of Flexible Systems Management,9(2–3), 15–30.

Wadhwa, S., Mishra, M., & Saxena, A. (2007). A network approach for modeling and design of agile supply chains using a flexibility construct. International Journal of Flexible Manufacturing Systems,19(4), 410.

Wadhwa, S., & Rao, K. S. (2004). A unified framework for manufacturing and supply chain flexibility. Global Journal of Flexible Systems Management,5(1), 29–36.

Wadhwa, S., Saxena, A., & Chan, F. (2008b). Framework for flexibility in dynamic supply chain management. International Journal of Production Research,46(6), 1373–1404.

Wang, Y. (2008). Evaluating flexibility on order quantity and delivery lead time for a supply chain system. International Journal of Systems Science,39(12), 1193–1202.

Wang, I. (2012). Lead-time: A case study of flexible printed circuit boards. Journal of Applied Sciences,12(3), 271–278.

Wang, H., Mastragostino, R., & Swartz, C. (2016). Flexibility analysis of process supply chain networks. Computers & Chemical Engineering,84(4), 409–421.

Wang, T., Tai, J., & Wei, H. (2006). A virtual integration theory of improved supply-chain performance. Journal of Management Information Systems,23(2), 41–64.

Weeks, K., Guiffrida, A., & Safa, M. (2018). The efficacy of routing and flexibility on financial performance within an international manufacturing setting. International Journal of Productivity and Performance Management,67(2), 341–365.

Willis, G., Genchev, S., & Chen, H. (2016). Supply chain learning, integration, and flexibility performance: An empirical study in India. The International Journal of Logistics Management,27(3), 755–769.

Wong, C., Sakun, B., & Wong, C. (2011). The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. Journal of Operations Management,9(6), 604–615.

Xiao, Y. (2015). Flexibility measure analysis of supply chain. International Journal of Production Research,53(10), 3161–3174.

Yang, J. (2014). Supply chain agility. Securing performance for Chinese manufacturers. International Journal of Production Economics,150, 104–113.

Yang, C., Lin, C., & Sheu, C. (2007). Developing manufacturing flexibility through supply chain activities: Evidence from the motherboard industry. Total Quality Management,18(9), 957–972.

Yi, C., Ngai, E., & Moon, K. (2011). Supply chain flexibility in an uncertain environment: Exploratory findings from five case studies. Supply Chain Management: An International Journal,16(4), 271–283.

Yu, K., Cadeaux, J., & Luo, B. (2015). Operational flexibility: Review and meta-analysis. International Journal of Production Economics,169, 190–202.

Yu, K., Cadeaux, J., & Song, H. (2012). Alternative forms of fit in distribution flexibility strategies. International Journal of Operations & Production Management,32(10), 1199–1227.

Yu, K., Cadeaux, J., & Song, H. (2013). Distribution channel network and relational performance: The intervening mechanism of adaptive distribution flexibility. Decision Sciences,44(5), 915–950.

Yu, K., Luo, B., Feng, X., & Liu, J. (2018). Supply chain information integration, flexibility, and operational performance: An archival search and content analysis. The International Journal of Logistics Management,29(1), 340–364.

Zainol, N., Al-Mamun, A., & Permarupan, Y. (2013). Effects of demand, manufacturing flexibility, cost and supply chain on product modularity: A study in Malaysia. Asian Social Science,9(17), 167–179.

Zhang, Q., & Tseng, M. (2009). Modelling and integration of customer flexibility in the order commitment process for high mix low volume production. International Journal of Production Research,47(22), 6397–6416.

Zhang, Q., Vonderembse, M. A., & Lim, J. S. (2003). Manufacturing flexibility: Defining and analyzing relationships among competence, capability, and customer satisfaction. Journal of Operations Management,21(2), 173–191.

Zhang, Q., Vonderembse, M., & Lim, J. (2005). Logistics flexibility and its impact on customer satisfaction. The International Journal of Logistics Management,16(1), 71–95.

Zhao, L., Huo, B., Sun, L., & Zhao, X. (2013). The impact of supply chain risk on supply chain integration and company performance: A global investigation. Supply Chain Management: An International Journal,18(2), 115–131.

Acknowledgements

The authors are grateful to anonymous reviewers and Editor-in-Chief for their suggestions during review process.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pérez-Pérez, M., Kocabasoglu-Hillmer, C., Serrano-Bedia, A.M. et al. Manufacturing and Supply Chain Flexibility: Building an Integrative Conceptual Model Through Systematic Literature Review and Bibliometric Analysis. Glob J Flex Syst Manag 20 (Suppl 1), 1–23 (2019). https://doi.org/10.1007/s40171-019-00221-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40171-019-00221-w