Abstract

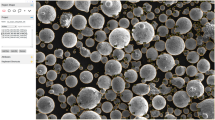

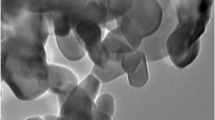

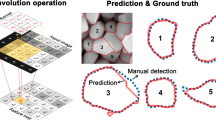

Research concerned with the identification as well as quantification of satellites found within metallic powders has recently demonstrated the promise of implementing Mask R-CNNs, instance segmentation, and transfer learning. Though the original research and development of such an approach demonstrated the functionality of the data-driven image analysis framework, questions remained in regards to the scale-ability of the Mask R-CNN-based model. Accordingly, the present work demonstrates the fact that the originally formulated model can be expanded to include scanning electron micrographs to various powder types at variate magnifications (rather than the original case of micrographs of a single powder type at a single magnification). Moreover, the present work establishes a process that enables users to specifically target which images will have most impact on increasing generalize-ability and performance in order to optimize maximum improvement of the model with the least amount of images annotated. Beyond this, we also outline a method of auto-labeling satellites in images by using a trained model to increase its own training set size.

Similar content being viewed by others

References

DebRoy T, Wei H, Zuback J, Mukherjee T, Elmer J, Milewski J, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components-process, structure and properties. Prog Mater Sci 92:112–224

du Plessis A (2019) Effects of process parameters on porosity in laser powder bed fusion revealed by X-ray tomography. Addit Manuf 30:100871

Riener K, Albrecht N, Ziegelmeier S, Ramakrishnan R, Haferkamp L, Spierings AB, Leichtfried GJ (2020) Influence of particle size distribution and morphology on the properties of the powder feedstock as well as of ALSI10mg parts produced by laser powder bed fusion (LPBF). Addit Manuf 34:101286

Anderson IE, White EMH, Dehoff R (2018) Feedstock powder processing research needs for additive manufacturing development. Curr Opin Solid State Mater Sci 22(1):8–15. 10.1016/j.cossms.2018.01.002.https://www.sciencedirect.com/science/article/pii/S1359028617302334

Haferkamp L, Haudenschild L, Spierings A, Wegener K, Riener K, Ziegelmeier S, Leichtfried GJ (2021) The influence of particle shape, powder flowability, and powder layer density on part density in laser powder bed fusion. Metals 11(3):418

Cunningham R, Nicolas A, Madsen J, Fodran E, Anagnostou E, Sangid MD, Rollett AD (2017) Analyzing the effects of powder and post-processing on porosity and properties of electron beam melted Ti-6Al-4V. Mater Res Lett 5(7):516–525

Cunningham R, Narra SP, Montgomery C, Beuth J, Rollett A (2017) Synchrotron-based x-ray microtomography characterization of the effect of processing variables on porosity formation in laser power-bed additive manufacturing of Ti-6Al-4V. JOM 69(3):479–484

Cordova L, Bor T, de Smit M, Campos M, Tinga T (2020) Measuring the spreadability of pre-treated and moisturized powders for laser powder bed fusion. Addit Manuf 32:101082

Özbilen S (1999) Satellite formation mechanism in gas atomised powders. Powder Metall 42(1):70–78

Cohn R, Anderson I, Prost T, Tiarks J, White E, Holm E (2021) Instance segmentation for direct measurements of satellites in metal powders and automated microstructural characterization from image data. JOM 73(7):2159–2172

Cohn R, Anderson I, Prost T, Tiarks J, White E, Holm E (2021) Instance segmentation for direct measurements of satellites in metal powders and automated microstructural characterization from image data. arXiv preprint arXiv:2101.01585

He K, Gkioxari G, Dollár P, Girshick R (2017) Mask r-cnn. In: Proceedings of the IEEE international conference on computer vision, pp 2961–2969

Roy P, Ghosh S, Bhattacharya S, Pal U (2018) Effects of degradations on deep neural network architectures. arXiv preprint arXiv:1807.10108

Clayton J (2014) Optimising metal powders for additive manufacturing. Metal Powder Rep 69(5):14–17

Zhang Q, Wang W, Zhu SC (2018) Examining cnn representations with respect to dataset bias. In: Proceedings of the AAAI Conference on Artificial Intelligence, vol 32

Li J, Liang X, Shen S, Xu T, Feng J, Yan S (2018) Scale-aware fast R-CNN for pedestrian detection. IEEE Trans Multimed 20(4):985–996. https://doi.org/10.1109/TMM.2017.2759508

Garshev A, Kozlov D, Evdokimov P, Filippov YY, Orlov N, Putlyaev V, Chetvertukhin A, Petrov A (2019) Analysis of aluminum alloy powders for additive manufacturing fabricated by atomization. Inorg Mater: Appl Res 10(4):901–905

Chen G, Zhao S, Tan P, Wang J, Xiang C, Tang H (2018) A comparative study of Ti-6Al-4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol 333:38–46

Hunter JD (2007) Matplotlib: A 2d graphics environment. Comput Sci Eng 9(3):90–95. https://doi.org/10.1109/MCSE.2007.55

Zhou Y, Shi J, Yang X, Wang C, Wei S, Zhang X (2019) Rotational objects recognition and angle estimation via kernel-mapping CNN. IEEE Access 7:116505–116518

Zhang, Z., Chen, X., Liu, J., Zhou, K. (2019) Rotated feature network for multi-orientation object detection. arXiv preprint arXiv:1903.09839

Dutta, A., Zisserman, A. (2019) The via annotation software for images, audio and video. In: Proceedings of the 27th ACM international conference on multimedia, pp 2276–2279

Ren S, He K, Girshick R, Sun J (2015) Faster R-CNN: Towards real-time object detection with region proposal networks. Adv Neural Inf Process Syst 28:91–99

Wu, Y., Kirillov, A., Massa, F., Lo, W.Y., Girshick, R. (2019) Detectron2

Paszke A, Gross S, Massa F, Lerer A, Bradbury J, Chanan G, Killeen T, Lin Z, Gimelshein N, Antiga L et al (2019) Pytorch: an imperative style, high-performance deep learning library. Adv Neural Inf Process Syst 32:8026–8037

Massar C, Tsaknopoulos K, Sousa BC, Grubbs J, Cote DL (2020) Heat treatment of recycled battlefield stainless-steel scrap for cold spray applications. JOM 72(9):3080–3089. https://doi.org/10.1007/s11837-020-04259-5

Reyes, E., Estévez, P.A., Reyes, I., Cabrera-Vives, G., Huijse, P., Carrasco, R., Forster, F. (2018) Enhanced rotational invariant convolutional neural network for supernovae detection. In: 2018 International Joint Conference on Neural Networks (IJCNN), pp 1–8. 10.1109/IJCNN.2018.8489627

Cheng G, Zhou P, Han J (2016) Learning rotation-invariant convolutional neural networks for object detection in VHR optical remote sensing images. IEEE Trans Geosci Remote Sens 54(12):7405–7415. https://doi.org/10.1109/TGRS.2016.2601622

Taylor, L., Nitschke, G. (2018) Improving deep learning with generic data augmentation. In: 2018 IEEE Symposium Series on Computational Intelligence (SSCI), pp 1542–1547. 10.1109/SSCI.2018.8628742

Shorten C, Khoshgoftaar TM (2019) A survey on image data augmentation for deep learning. J Big Data 6(1):1–48

McGuinness, K., OGara, S. (2019) Comparing data augmentation strategies for deep image classification. DORAS

Long, J., Shelhamer, E., Darrell, T. (2015) Fully convolutional networks for semantic segmentation. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 3431–3440

ASTM, B. 214: standard test method for sieve analysis of metal powders. ASTM Int 1, 1–4

Acknowledgments

This work is in part funded by the United States Army Research Laboratory under grant number W911NF-10-2-0098. This work used the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by National Science Foundation grant number DMR200035. We also thank WPI students Grace Fitzpatrick-Schmidt for capturing a portion of the SEM images, as well as Ashley M. Schuliger and Christopher S. Vieira for their helpful insights.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Price, S.E., Gleason, M.A., Sousa, B.C. et al. Automated and Refined Application of Convolutional Neural Network Modeling to Metallic Powder Particle Satellite Detection. Integr Mater Manuf Innov 10, 661–676 (2021). https://doi.org/10.1007/s40192-021-00240-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-021-00240-5