Abstract

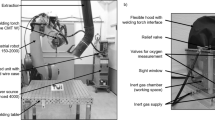

By extrapolating knowledge in multipass welding and developing multiaxial robot solutions, the wire deposit in 3D or wire arc additive manufacturing (WAAM) can be an innovative solution to propose a credible alternative for rough cast parts with a large size and a quite complex geometry such as different components for naval application. In the framework of the Joint Laboratory of Marine Technology (JLMT), DCNS Research and Ecole Centrale de Nantes (ECN) are associated to develop especially additive manufacturing activities for large components. In this experimental study, the authors propose to investigate for two different metallic materials the conditions of the filler material deposit by the CMT® process and the consequences on the manufacturing time. Moreover, the in-service performance (mechanical and corrosion properties) is evaluated. In a first approach, austenitic stainless steel and copper-aluminum alloys have been evaluated.

Similar content being viewed by others

References

Kazanas P, Deherkar P, Almeida P, Lockett H, Williams S (2012) Fabrication of geometrical features using wire and arc additive manufacture. Proc Inst Mech Eng B J Eng Manuf 226(6):1042–1051. https://doi.org/10.1177/0954405412437126

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (Apr 2015) Wire + arc additive manufacturing. Mater Sci Technol 32(7):641–647

Posch G, Kalchgruber F, Hackl H, Chladil H (2014) Manufacturing of turbine blades by shape giving CMT-welding, Metal Additive Manufacturing Conference, Vienna, Austria

Ding D, Pan Z, Cuiuri D, Li H (2015) A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot Comput Integr Manuf 31:101–110. https://doi.org/10.1016/j.rcim.2014.08.008

Bureau Veritas–Marine & offshore Division (2014) Rules on materials and welding for the classification of marine units NR 216 DT R07 E, p 120

Kou S (1987) Welding metallurgy. John Wiley & Sons, Inc, p 218

Donghong D, Zengxi P, Van Duin S, Huijun L, Chen S (2016) Fabricating superior NiAl bronze components through wire arc additive manufacturing, MDPI, Materials 2016, 9, 652

Lorimer GW, Hasan F, Iqbal J, Ridley N (1986) Observation of microstructure and corrosion behaviour of some aluminium bronzes. Br Corros J 21(4):244–248

Acknowledgments

This study had been performed in the frameworks of the Joint Laboratory of Marine Technology between Ecole Centrale de Nantes and DCNS. The authors wish to thank the team for their contributions to the presented works.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the collection Welding, Additive Manufacturing and Associated NDT

Rights and permissions

About this article

Cite this article

Queguineur, A., Rückert, G., Cortial, F. et al. Evaluation of wire arc additive manufacturing for large-sized components in naval applications. Weld World 62, 259–266 (2018). https://doi.org/10.1007/s40194-017-0536-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0536-8