Abstract

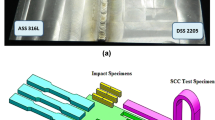

Inconel 625 nickel alloy and UNS S32205 duplex stainless steel (DSS) were welded with ER2209 filler metal using MIG (Metal Inert Gas) welding method. The weld metal obtained by DSS filler metal was subjected to mechanical and microstructural evaluation. Toughness and hardness properties had been examined by mechanical and microstructural characterization of weld metal, fusion line, and HAZ (Heat Affected Zone) region, and precipitations were investigated by light microscopy (LM), scanning electron microscopy (SEM), and energy-dispersive spectrometry (EDS). Corrosion behavior of base metals and face and root of weld metal were examined by using potentiodynamic polarization test. Additionally, detailed elemental analysis and mapping of weld metal with both optical emission spectrometer (OES) and X-Ray spectrometer were attained. Results demonstrate a significant decrease in toughness of the welding due to the presence of Nb and Mo rich intermetallic precipitations in the Inconel HAZ and root region, although there is no significant increase in hardness. Potentiodynamic polarization test shows that the dilution-induced microstructural transformation in the root of weld has the worst corrosion resistance in the weld metal. Therefore, this dissimilar welding does not have optimum properties for neither toughness nor corrosion.

Similar content being viewed by others

References

DuPont NJ, Lippold CJ, Kiser DS (2009) Welding metallurgy and weldability of nickel based alloys Wiley, Hoboken

Kangazian J, Shamanian M, Ashrafi A (2017) Dissimilar welding between SAF 2507 stainless steel and Incoloy 825 Ni-based alloy: the role of microstructure on corrosion behavior of the weld metals. J Manuf Process 29:376–388. https://doi.org/10.1016/j.jmapro.2017.08.012

Kangazian J, Shamanian M (2018) Characterization of structure–property relationship of Incoloy 825 and SAF 2507 dissimilar welds. Trans Indian Inst Metals 71:1747–1757. https://doi.org/10.1007/s12666-018-1309-9

Sridhar R, Devendranath Ramkumar K, Arivazhagan N (2014) Characterization of microstructure, strength, and toughness of dissimilar weldments of inconel 625 and duplex stainless steel SAF 2205. Acta Metall Sin (English Lett) 27:1018–1030. https://doi.org/10.1007/s40195-014-0116-5

Karahan T, Mert T, Tümer M, Kerimak ZM Microstructural analysis of Inconel 625 nickel alloy / UNS S31803 duplex stainless steel dissimilar weldments. pp 4–8

Ramkumar KD, Sridhar R, Periwal S et al (2015) Investigations on the structure – property relationships of electron beam welded Inconel 625 and UNS 32205. Mater Des 68:158–166. https://doi.org/10.1016/j.matdes.2014.12.032

Ramkumar KD, Oza S, Periwal S et al (2015) Characterization of weld strength and toughness in the multi-pass welding of Inconel 625 and Super-duplex stainless steel UNS S32750. Cienc Tecnol dos Mater 27:41–52. https://doi.org/10.1016/j.ctmat.2015.04.004

Mohammed GR, Ishak M, Aqida SN, Abdulhadi HA (2017) Effects of heat input on microstructure , corrosion and mechanical characteristics of welded austenitic and duplex stainless steels : a review https://doi.org/10.3390/met7020039

Wang S, Ma Q, Li Y (2011) Characterization of microstructure , mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR. Mater Des 32:831–837. https://doi.org/10.1016/j.matdes.2010.07.012

Gunn R (1997) Duplex stainless steels: microstructure, properties and applications. Abingt Publ 219

Yıldızlı K (2015) Investigation on the microstructure and toughness properties of austenitic and duplex stainless steels weldments under cryogenic conditions. Mater Des 77:83–94. https://doi.org/10.1016/j.matdes.2015.04.008

Yılmaz R, Tümer M (2013) Microstructural studies and impact toughness of dissimilar weldments between AISI 316 L and AH36 steels by FCAW. Int J Adv Manuf Technol 67:1433–1447. https://doi.org/10.1007/s00170-012-4579-0

Huang B-S, Yang J, Lu D-H, Bin W-J (2016) Study on the microstructure, mechanical properties and corrosion behaviour of S355JR/316L dissimilar welded joint prepared by gas tungsten arc welding multi-pass welding process. Sci Technol Weld Join 21:381–388. https://doi.org/10.1080/13621718.2015.1122152

Kumar KG, Ramkumar KD, Arivazhagan N (2015) Characterization of metallurgical and mechanical properties on the multi-pass welding of Inconel 625 and AISI 316L. J Mech Sci Technol 29:1039–1047. https://doi.org/10.1007/s12206-014-1112-4

Ramkumar KD, Kumar PSG, Krishna VR et al (2016) Influence of laser peening on the tensile strength and impact toughness of dissimilar welds of Inconel 625 and UNS S32205. Mater Sci Eng A 676:88–99. https://doi.org/10.1016/j.msea.2016.08.104

Mortezaie A, Shamanian M (2014) An assessment of microstructure, mechanical properties and corrosion resistance of dissimilar welds between Inconel 718 and 310S austenitic stainless steel. Int J Press Vessel Pip 116:37–46. https://doi.org/10.1016/j.ijpvp.2014.01.002

Sayiram G, Arivazhagan N (2015) Microstructural characterization of dissimilar welds between Incoloy 800H and 321 Austenitic Stainless Steel. Mater Charact 102:180–188. https://doi.org/10.1016/j.matchar.2015.03.006

Sireesha M, Shankar V, Albert SK, Sundaresan S (2000) Microstructural features of dissimilar welds between 316LN austenitic stainless steel and alloy 800. Mater Sci Eng A 292:74–82. https://doi.org/10.1016/S0921-5093(00)00969-2

Devendranath Ramkumar K, Patel SD, Sri Praveen S et al (2014) Influence of filler metals and welding techniques on the structure-property relationships of Inconel 718 and AISI 316L dissimilar weldments. Mater Des 62:175–188. https://doi.org/10.1016/j.matdes.2014.05.019

Kangazian J, Shamanian M (2017) Mechanical and microstructural evaluation of SAF 2507 and incoloy 825 dissimilar welds. J Manuf Process 26:407–418. https://doi.org/10.1016/j.jmapro.2017.03.006

Shankar V, Gill TPS, Mannan SL, Sundaresan S (2003) Solidification cracking in austenitic stainless steel welds. Sadhana 28:359–382. https://doi.org/10.1007/BF02706438

Lippold JC, Kotecki DJ (2005) Welding metallurgy and weldability of stainless steels

Ranjbar K, Dehmolaei R, Amra M, Keivanrad I (2018) Microstructure and properties of a dissimilar weld between alloy 617 and A387 steel using different filler metals. Weld World 62:1121–1136. https://doi.org/10.1007/s40194-018-0610-x

Li G, Huang J, Wu Y (2014) An investigation on microstructure and properties of dissimilar welded Inconel 625 and SUS 304 using high-power CO2 laser. Int J Adv Manuf Technol 76:1203–1214. https://doi.org/10.1007/s00170-014-6349-7

Xu F, Lv Y, Liu Y et al (2013) Microstructural evolution and mechanical properties of Inconel 625 alloy during pulsed plasma arc deposition process. J Mater Sci Technol 29:480–488. https://doi.org/10.1016/j.jmst.2013.02.010

Xu FJ, Lv YH, Xu BS et al (2013) Effect of deposition strategy on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by pulsed plasma arc deposition. Mater Des 45:446–455. https://doi.org/10.1016/j.matdes.2012.07.013

Devendranath Ramkumar K, Jagat Sai R, Santhosh Reddy V et al (2015) Effect of filler wires and direct ageing on the microstructure and mechanical properties in the multi-pass welding of Inconel 718. J Manuf Process 18:23–45. https://doi.org/10.1016/j.jmapro.2015.01.001

Ramkumar KD, Kumar BM, Krishnan MG et al (2015) Studies on the weldability, microstructure and mechanical properties of activated flux TIG weldments of Inconel 718. Mater Sci Eng A 639:234–244. https://doi.org/10.1016/j.msea.2015.05.004

Liao MT, Chen WJ (1998) The influence of shielding gas on notch toughness of stainless steel weld metals. Mater Manuf Process 13:565–573. https://doi.org/10.1080/10426919808935276

Tümer M, Yılmaz R (2016) Characterization of microstructure, chemical composition, and toughness of a multipass welded joint of austenitic stainless steel AISI316L. Int J Adv Manuf Technol:1–13. https://doi.org/10.1007/s00170-016-8614-4

Liao MT, Chen WJ (1998) The effect of shielding-gas compositions on the microstructure and mechanical properties of stainless steel weldments. Mater Chem Phys 55:145–151. https://doi.org/10.1016/S0254-0584(98)00134-5

Mukhopadhyay S, Pal TK (2006) Effect of shielding gas mixture on gas metal arc welding of HSLA steel using solid and flux-cored wires. Int J Adv Manuf Technol 29:262–268. https://doi.org/10.1007/s00170-005-2510-7

Evangeline A, Sathiya P (2019) Cold metal arc transfer (CMT) metal deposition of Inconel 625 superalloy on 316L austenitic stainless steel: microstructural evaluation, corrosion and wear resistance properties. Mater Res Express 6:1–2. https://doi.org/10.1016/j.vetmic.2007.04.014

Acknowledgements

The authors would like to acknowledge the welding consumables support from Gedik Welding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Tumer, M., Karahan, T. & Mert, T. Evaluation of microstructural and mechanical properties of dissimilar Inconel 625 nickel alloy–UNS S32205 duplex stainless steel weldment using MIG welding. Weld World 64, 21–35 (2020). https://doi.org/10.1007/s40194-019-00825-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00825-x