Abstract

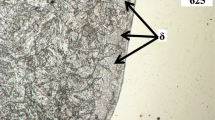

Use of a buttering deposit on ferritic steel in dissimilar metal weld (DMW) joint is a common practice in nuclear plants to connect pressure vessel components (ferritic steel) to pipelines (austenitic stainless steel). Carbon migration and metallurgical changes near fusion interface (ferritic steel–austenitic stainless steel) lead to a steeper gradient in material properties, and minimizing this gradient is the major challenge in the manufacturing of DMW joints. Inconel 82 is often deposited on ferritic steel material as buttering to reducing the gradient of physical and attaining material compatibility. Inconel 82/182 fillers are used to minimize the carbon migration, but the results are not truly adequate. In this paper, Ni–Fe alloy (chromium-free) has been used as the intermediate buffer layer in the weld buttering deposit to address the issue of carbon migration and subsequent metallurgical deterioration. The weld pads with and without buffer layers of Ni–Fe alloy have been investigated and compared in detail for metallurgical properties and carbon diffusivities. Ni–Fe buffer layer can significantly control the carbon migration which resists the metallurgical deterioration. It showed the better results in post-weld heat treatment and thermally aged conditions. The buttering deposit with Ni–Fe buffer layer could be the better choice for DMW joints requirements.

Similar content being viewed by others

References

R. Miteva, N.G. Taylor, in E. Commission (Ed.) NESC Report, Institute for Energy, Netherland (2006)

A.K. Bhaduri, S. Venkadesan, P. Rodriguez, P.G. Mukunda, Int. J. Press. Vessels Pip. 58, 251 (1994)

C.D. Lundin, Weld. Res. Suppl. 61, 58s (1982)

M. Sireesha, S.K. Albert, V. Shankar, S. Sundaresan, J. Nucl. Mater. 279, 65 (2000)

A. Celik, A. Alsaran, Mater. Charact. 43, 311 (1999)

M. Sireesha, V. Shankar, S.K. Albert, S. Sundaresan, Mater. Sci. Eng. A 292, 74 (2000)

C.R. Das, A.K. Bhaduri, G. Srinivasan, V. Shankar, S. Mathew, J. Mater. Process. Technol. 209, 1428 (2009)

Y.Y. Ying, S.R. Kae, S.R. Haur, C. Chun, J. Mater. Sci. Lett. 20, 1429 (2001)

R. Anand, C. Sudha, V.T. Paul, S. Saroja, Suppl. Weld. J. 89, 65s (2010)

D.W. Rathod, S. Aravindan, P.K. Singh, S. Pandey, ISIJ Int. 54, 1866 (2014)

H.-L. Ming, Z.-M. Zhang, P.-Y. Xiu, J.-Q. Wang, E.-H. Han, W. Ke, M.-X. Su, Acta Metall. Sin. (Engl. Lett.) 29, 848 (2016)

J.N. DuPont, S. Babu, S. Liu, Metall. Mater. Trans. A 44A, 3385 (2013)

J.N. Dupont, C.S. Kusko, Weld. J. 86, 51s (2007)

D.W. Rathod, P.K. Singh, S. Pandey, S. Aravindan, Mater. Sci. Eng. A 666, 100 (2016)

R.E. Avery, in, Nickel Development Institute, Reprinted with permission from Chemical Engineering Progress May 1991, American Institute of Chemical Engineers, NiDI reprint series No 14018, (1991)

D.W. Rathod, S. Pandey, P.K. Singh, R. Prasad, Mater. Sci. Eng. A 639, 259 (2015)

D.W. Rathod, S. Pandey, P.K. Singh, R. Prasad, J. Press. Vessel Technol. 138, 011403 (2016)

J.C. Lippold, D.J. Kotecki, Welding metallurgy and weldability of stainless steels, 1st edn. (Hoboken, New Jersey: John Wiley & Sons, Wiley Interscience Publication, 2005)

W.H. Minnick, M.A. Prosser, Manual welding of dissimilar metals, in Gas Tungsten Arc Welding Handbook, 6th ed. (Goodheart-Willcox Publisher, 2013), pp. 203–212

J.N. DuPont, J.C. Lippold, S.D. Kiser, Welding Metallurgy and Weldability of Nickel-Base Alloys, 1st edn. (Wiley Publications, Hoboken, 2009)

J.N. DuPont, R.E. Mizia, Review of dissimilar metal welding for the NGNP helical coil steam generator, Idaho National Laboratory, Idaho Falls, Idaho, INL/EXT-10-18459, (2010)

J.N. Dupont, S.W. Banovic, A.R. Marder, Weld. J. 82(6), 125s (2003)

R. Dehmolaei, M. Shamanian, A. Kermanpur, Mater. Charact. 59, 1447 (2008)

G. Srinivasan, A.K. Bhaduri, in Proceedings of 63rd Annual Assembly & International Conference of the International Institute of Welding, Istanbul, Turkey, 2010, pp. 81–87

B.J. Lee, H.D. Kim, J.H. Hong, Metall. Mater. Trans. A 29A, 1441 (1998)

Acknowledgments

The authors acknowledge the support given by Board of Research in Nuclear Sciences, Department of Atomic Energy (India) for present work (No. 2008/36/107-BRNS/4038A). Authors are also thankful to the Defense Metallurgical Research Laboratory (Ministry of Defense, India) for providing EPMA facility in diffusion-related study. The help extended by Mr. Paul English, Specialist Welder, MTRL, UoM is also highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Rathod, D.W., Pandey, S., Aravindan, S. et al. Metallurgical Behaviour and Carbon Diffusion in Buttering Deposits Prepared With and Without Buffer Layers. Acta Metall. Sin. (Engl. Lett.) 30, 120–132 (2017). https://doi.org/10.1007/s40195-016-0487-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-016-0487-x