Abstract

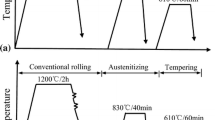

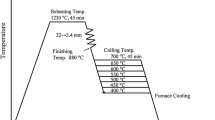

In this study, the effect of cooling rates on microstructures and mechanical properties in a Al-bearing hot-rolled transformation-induced plasticity steel was investigated. The experiments were carried out using hot simulation machine and hot rolling mill, where the samples were cooled at different cooling rates. The results showed that with the increase in cooling rates, film-like retained austenite gradually disappeared and only blocky retained austenite was retained at higher cooling rates. The volume fraction of retained austenite was 9–11% at cooling rates of 0.05–1 °C/s and 4–6% at cooling rates of 5–10 °C/s. In addition, martensite/austenite island was observed because of the heterogeneous carbon distribution. The samples cooled at 0.05 °C/s and 0.5 °C/s exhibited excellent mechanical properties, with tensile strengths of 712 MPa and 726 MPa, total elongations of 42% and 36% and strength and ductility balances of 29.91 GPa% and 26.15 GPa%, respectively. During plastic deformation, the instantaneous work hardening exponent of the sample cooled at 0.05 °C/s increased continuously until it reached the maximum value, while the instantaneous work hardening exponent of the sample cooled at 0.5 °C/s remained stable.

Similar content being viewed by others

References

C. Wang, H. Ding, M. Cai, B. Rolfe, Mater. Sci. Eng. A 610, 65 (2014)

M. De Meyer, B.C. De Cooman, D. Vanderschueren, Iron Steelmak. 27, 55 (2000)

J. Mahieu, B.C. De Cooman, J. Maki, S. Claessens, Iron Steelmak. 29, 29 (2002)

B. Mintz, Int. Mater. Rev. 46, 169 (2001)

K. Zhu, C. Mager, M. Huang, J. Mater. Sci. Technol. 33, 12 (2017)

V.S.Y. Injeti, Z.C. Li, B. Yu, R.D.K. Misra, Z.H. Cai, H. Ding, J. Mater. Sci. Technol. 34, 745 (2018)

H.Q. Huang, H.S. Di, N. Yan, J.C. Zhang, Y.G. Deng, R.D.K. Misra, J.P. Li, Acta Metall. Sin. (Engl. Lett.) 31, 503 (2018)

P.J. Jacques, E. Girault, A. Mertens, B. Verlinden, J. Van Humbeeck, F. Delannay, ISIJ Int. 41, 1068 (2001)

D.W. Suh, S.J. Park, C.S. Oh, S.J. Kim, Scr. Mater. 57, 1097 (2007)

J. Mahieu, B.C. De Cooman, J. Maki, Metall. Mater. Trans. A 33, 2573 (2002)

Y.J. Li, J. Kang, W.N. Zhang, D. Liu, X.H. Wang, G. Yuan, Mater. Sci. Eng. A 710, 181 (2018)

J. Chiang, J.D. Boyd, A.K. Pilkey, Mater. Sci. Eng. A 638, 132 (2015)

J. Chiang, B. Lawrence, J.D. Boyd, A.K. Pilkey, Mater. Sci. Eng. A 528, 4516 (2011)

A.Z. Hanzaki, R. Pandi, P.D. Hodgson, S. Yue, Metall. Mater. Trans. A 24, 2657 (1993)

S.M.K. Hosseini, A.Z. Hanzaki, M.J.Y. Panah, Mater. Sci. Eng. A 374, 122 (2004)

H.S. Wang, J. Kang, W.X. Dou, Y.X. Zhang, G. Yuan, G.M. Cao, R.D.K. Misra, G.D. Wang, Mater. Sci. Eng. A 702, 350 (2017)

N.H.V. Dijk, A.M. But, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, Acta Mater. 53, 5439 (2005)

D.J. Dyson, B. Holmes, ISIJ Int. 208, 469 (1970)

J.H. Hollomon, J. Member, Metall. Technol. 12, 268 (1945)

F.H. Akbary, J. Sietsma, G. Miyamoto, T. Furuhara, M.J. Santofimia, Acta Mater. 104, 72 (2016)

Z.Q. Liu, G. Miyamoto, Z.G. Yang, T. Furuhara, Acta Mater. 61, 3120 (2013)

X.C. Xiong, B. Chen, M.X. Huang, Scr. Mater. 68, 321 (2013)

Y.J. Li, D. Chen, X.L. Li, Steel Res. Int. 88, 11 (2017)

C. Wang, X. Wu, J. Liu, N. Xu, Mater. Sci. Eng. A 438, 267 (2006)

E.J. Seo, L. Cho, Y. Estrin, B.C. De Cooman, Acta Mater. 113, 124 (2016)

G.A. Thomas, J.G. Speer, D.K. Matlock, Metall. Mater. Trans. A 42A, 3652 (2011)

J. Zhao, W. Hu, X. Wang, J. Kang, G. Yuan, H. Di, R.D.K. Misra, Mater. Sci. Eng. A 666, 214 (2016)

A. Mertens, E.M. Bellhouse, J.R. Mcdermid, Mater. Sci. Eng. A 608, 249 (2014)

E.M. Bellhouse, J.R. Mcdermid, Metall. Mater. Trans. A 41, 1460 (2010)

J.R. Mcdermid, H.S. Zurob, Y. Bian, Metall. Mater. Trans. A 42, 3627 (2011)

E. Pereloma, H. Beladi, L. Zhang, I. Timokhina, Metall. Mater. Trans. A 43, 3958 (2012)

L. Li, X. Zhang, W. Yang, Metall. Mater. Trans. A 44, 4337 (2013)

D. De Knijf, T. Nguyen-minh, R.H. Petrov, L.A.I. Kestens, J.J. Jonas, J. Appl. Cryst. 47, 1261 (2014)

Acknowledgements

The authors acknowledge the support from the National Natural Science Foundation of China (No. 51504063). R.D.K. Misra also acknowledges for continued collaboration with Northeastern University as an honorary professor by providing guidance to students in research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Wang, XH., Kang, J., Li, YJ. et al. Effect of Cooling Rates in Coiling Process on Microstructures and Mechanical Properties in Al-Bearing Hot-Rolled TRIP Steel. Acta Metall. Sin. (Engl. Lett.) 32, 1207–1218 (2019). https://doi.org/10.1007/s40195-018-00868-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-00868-x