Abstract

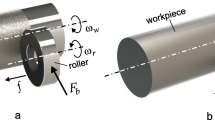

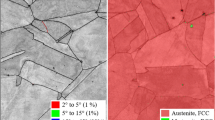

It is well known that apart from compressive residual stresses, smooth surface and microstructuring of the surface and subsurface layers are beneficial for enhancement of fatigue strength and load-carrying capacity of structural and machine components. This complex of properties can be achieved using surface severe plastic deformation. For symmetric rotational components made of high-strength aluminum alloys, slide burnishing is appropriate because of its simplicity and easy realization. The effect of the process parameters on the surface roughness, micro-hardness, and residual stresses obtained in slide burnishing of D16T aircraft aluminum alloy has been analyzed. The optimal values of the basic governing factors, which ensure minimum roughness (up to \(0.05\,\upmu\,{\text{m}}\)), have been established on the basis of a one-factor-at-the-time method, followed by a planned experiment and additional experiments. With the established combination of optimal values, the effect of number of passes and lubricant-cooler on the roughness, micro-hardness, and residual stresses in the surface being treated has been studied for two working schemes. To establish residual stress–depth profiles depending on the tool radius and burnishing force, FEM analysis of the slide burnishing process has been conducted. Thus, an evaluation of the effectiveness of slide burnishing as “mixed burnishing” has been made.

Similar content being viewed by others

References

El-Axir MH et al (2008) Improvements in out-of-roundness and microhardness of inner surfaces by internal ball burnishing process. J Mater Process Tech 196(1–3):120–128

John MRS, Vinayagam BK (2014) Optimization of nonlinear characteristics of ball burnishing process using Sugeno fuzzy neural system. J Braz Soc Mech Sci Eng 36:101–109

Basak H, Goktas HH (2009) Burnishing process on al-alloy and optimization of surface roughness and surface hardness by fuzzy logic. Mater Des 30(4):1275–1281

El-Taweel TA, El-Axir MH (2009) Analysis and optimization of the ball burnishing process through the Taguchi technique. Int J Adv Manuf Technol 41:301–310

El-Tayeb NSM et al (2009) On the surface and tribological characteristics of burnished cylindrical Al-6061. Tribol Int 42(2):320–326

El-Tayeb NSM et al (2007) Influence of roller burnishing contact width and burnishing orientation on surface quality and tribological behaviour of Aluminium 6061. J Mater Process Tech 186(1–3):272–278

Hua W et al (2008) Contact force studies of a burnishing slider. Tribol Int 41(1):60–66

El-Axir MH (2000) An investigation into roller burnishing. Int J Mach Tool Manu 40(11):1603–1617

Malleswara RJN et al (2010) The effect of roller burnishing on surface hardness and surface roughness on mild steel specimens. Int J Appl Eng Res 1(4):777–785

Shiou FJ, Cheng CH (2008) Ultra-precision surface finish of NAK80 mould tool steel using sequential ball burnishing and ball polishing processes. J Mater Process Tech 201(1–3):554–559

Shiou FJ, Hsu CC (2008) Surface finishing of hardened and tempered stainless tool steel using sequential ball grinding, ball burnishing and ball polishing processes on a machining centre. J Mater Process Tech 205(1–3):249–258

Shiou FJ, Ciou HS (2008) Ultra-precision surface finish of the hardened stainless mold steel using vibration-assisted ball polishing process. Int J Mach Tool Manu 48(7):721–732

Thamizhmanii S et al (2008) Surface roughness investigation and hardness by burnishing on titanium alloy. J Achiev Mater Manu Eng 28(2):139–142

Yeldose BC, Ramamoorthy B (2008) An investigation into the high performance of TiN-coated rollers in burnishing process. J Mater Process Tech 207(1–3):350–355

Schuha A et al (2007) Deep rolling of titanium rods for application in modular total hip arthroplasty. J Biomed Mater Res B Appl Biomat 81(2):330–335

Altenberg I et al (2012) On the effect of deep rolling and laser-peening on the stress-controlled low- and high-cycle fatigue behaviour of Ti-6Al-4 V at elevated temperatures up to 5500C. Int J Fatigue 44:292–302

Nalla RK et al (2003) On the influence of mechanical surface treatments—deep rolling and laser shock peening—on the fatigue behaviour of Ti-6Al-4 V at ambient and elevated temperatures. Mater Sci Eng A 355:216–230

Bozdana AT et al (2005) Deep cold rolling with ultrasonic vibrations—a new mechanical surface enhancement technique. Int J Mach Tool Manu 45(6):713–718

Meyer D et al (2011) Surface hardening by cryogenic deep rolling. Procedia Eng 19:258–263

Lin YC et al (2013) Modeling the creep behaviour of 2024-T3 Al alloy. Comput Mater Sci 67:243–248

Fattouh M, El-Khabeery MM (1989) Residual stress distribution in burnishing solution treated and aged 7075 aluminium alloy. Int J Mach Tool Manu 29(1):153–160

Luo H et al (2006) Study of the burnishing process with cylindrical polycrystalline diamond tool. J Mater Process Tech 180:9–16

Luo H et al (2001) Study on the aluminum alloy burnishing processing and the existence of the outstripping phenomenon. J Mater Process Tech 116:88–90

Luo H et al (2005) Investigation of the burnishing process with PCD tool on non-ferrous metals. Int J Adv Manuf Technol 25:454–459

Yua X, Wangb L (1999) Effect of various parameters on the surface roughness of an aluminium alloy burnished with a spherical surfaced polycrystalline diamond tool. Int J Mach Tool Manu 39:459–469

Nestler A, Schubert A (2015) Effect of machining parameters on surface properties in slide diamond burnishing of aluminium matrix composites. Mater Today Proc 2S:S156–S161

Hou Y et al (2015) Effect of processing parameters on surface roughness in ultrasonic deep rolling 6061-T6 aluminum alloy with longitudinal-torsional vibration. Appl Mech Mater 722:60–63

Ye X et al (2011) Effects of ultrasonic deep rolling on fatigue performance of pre-corroded 7A52 aluminum alloy. Adv Mater Res 189–193:897–900

Zhuanga W et al (2014) Deep surface rolling for fatigue life enhancement of laser clad aircraft aluminium alloy. Appl Surf Sci 320:558–562

Majzoobi GH et al (2009) The effects of deep rolling and shot peening on fretting fatigue resistance of Aluminum-7075-T6. Mater Sci Eng A 516:235–247

Beghini M et al (2014) Experimental parameter sensitivity analysis of residual stresses induced by deep rolling on 7075-T6 aluminium alloy. Surf Coat Tech 254:175–186

Al Quran FMF (2015) The effect of roller burnishing on surface hardness and roughness of aluminum alloy. Int J Mech Appl 5(2):37–40

Jinlong L, Hongyun L (2013) Effect of surface burnishing on texture and corrosion behavior of 2024 aluminum alloy. Surf Coat Tech 235:513–520

Nakamura Y et al (2014) Improvement of fatigue properties in a cast aluminum alloy by roller burnishing and friction stir processing. Adv Mater Res 891–892:662–667

Mishra RS et al (1999) High strain rate superplasticity in a friction stir processed 7075 al alloy. Scr Mater 42(2):163–168

Mishra RS et al (2003) Friction stir processing: a novel technique for fabrication of surface composite. Mater Sci Eng A 341:307–310

Sharma SR, Mishra RS (2008) Fatigue crack growth behavior of friction stir processed aluminum alloy. Scr Mater 59(4):395–398

Sharma SR et al (2004) Effect of friction stir processing on fatigue behavior of A356 alloy. Scr Mater 51(3):237–241

Ma ZY et al (2010) Superplastic deformation mechanism of an ultrafine-grained aluminum alloy produced by friction stir processing. Acta Mater 58(14):4693–4704

Ma ZY et al (2006) Effect of multiple-pass friction stir processing on microstructure and tensile properties of a cast aluminum–silicon alloy. Scr Mater 54(9):1623–1626

Vuchkov IN, Vuchkov II (2009) QStatLab Professional, v. 5.5—Statistical Quality Control Software. User’s Manual, Sofia

Korzynski M (2007) Modelling and experimental validation of the force-surface roughness relation for smoothing burnishing with a spherical tool. Int J Mach Tool Manu 47(12):1956–1964

Acknowledgments

This work was supported by the Bulgarian Ministry of Education and Science and the Technical University of Gabrovo under Contract No. D1601M. The authors extend their special acknowledgements to Dr Yosiph Mitev for his collaboration with the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Maximov, J.T., Anchev, A.P., Duncheva, G.V. et al. Influence of the process parameters on the surface roughness, micro-hardness, and residual stresses in slide burnishing of high-strength aluminum alloys. J Braz. Soc. Mech. Sci. Eng. 39, 3067–3078 (2017). https://doi.org/10.1007/s40430-016-0647-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-016-0647-y