Abstract

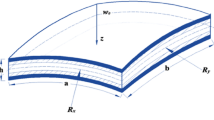

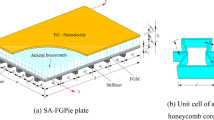

In this research, semi-active control of sandwich plates with electro-rheological (ER) core and carbon nanotubes-reinforced composite facesheets using smart ER dampers is studied. Sandwich plate is subjected to the external electric field and rested on orthotropic visco-Pasternak foundation. The material properties of ER core and nanocomposite facesheets are obtained by Yalcintas model and Eshelby–Mori–Tanaka approach, respectively. The governing equations of motion are solved by a combination between finite element and Newmark methods for clamped and simply supported boundary condition. The effects of various parameters such as applied voltage, controlled electric field and initial gap of the electrodes on the vibration suppression time are discussed. The results show that the settling time of system introduced in this work is much less than previous researches in this field which is a very important advantage.

Similar content being viewed by others

References

Preumont A (2002) Vibration control of active structures–an introduction, 2nd edn. Kluwer Academic Publishers, London

Kim YS, Wang KW, Lee HS (1992) Feedback control of ER-fluid-based structures for vibration suppression. Smart Mater Struct 1:139–145

Lou Z, Ervin RD, Filisko FE (1994) A preliminary parametric study of electrorheological dampers. J Fluids Eng 116(3):570–576

Stanway R, Sproston JL, El Wahed AK (1996) Applications of electro-rheological fluids in vibration control: a survey. Smart Mater Struct 5:464–482

Makris N, Burton SA, Hill D, Jordan M (1996) Analysis and design of ER damper for seismic protection of structures. J Eng Mech 122:1003–1011

Vavreck AN, Wang KW (1997) A new hybrid model for electrorheological fluid dampers and application to dynamic vibration absorption. J Acoust Soc Am 101(5):3109

Lindler J, Wereley NM (1999) Analysis and testing of electrorheological bypass dampers. J Intell Mater Syst Struct 10(5):363–376

Oh HU, Onoda J, Minesugi K (2000) Characteristics of a liquid-crystal type ER-fluid variable damper for semiactive vibration suppression. J Vib Acoust 122(4):412–419

Xu YL, Qu WL, Ko JM (2000) Seismic response control of frame structures using magnetorheological/electrorheological dampers. Earthquake Eng Struct Dyn 29(5):557–575

Lee HG, Choi SB (2002) Dynamic properties of an ER fluid under shear and flow modes. Mater Des 23:69–76

Jung WJ, Jeong WB, Hong SR, Choi SB (2004) Vibration control of a flexible beam structure using squeeze-mode ER mounts. J Sound Vib 273:185–199

Shawkatul Islam ASM, Ahmed AKW (2006) A comparative study of advanced suspension dampers for vibration and shock isolation performance of road vehicle. Int J Passenger Cars Mech Syst 115(6):1–12

Pahlavan L, Rezaeepazhand J (2007) Dynamic response analysis and vibration control of a cantilever beam with a squeeze-mode electrorheological damper. Smart Mater Struct 16:2183–2189

Nguyen QH, Choi SB (2009) Dynamic modeling of an electrorheological damper considering the unsteady behavior of electrorheological fluid flow. Smart Mater Struct 18:055016–055018

Nguyen QH, Choi SB (2009) A new approach for dynamic modeling of an electrorheological damper using a lumped parameter method. Smart Mater Struct 18:115020

Wang J, Xie F, Wang Y, Guo C (2012) Study on electro rheological fluid shock damper and adjustable damping performance. In: Proceedings of the FISITA 2012 world automotive congress vol 7, pp 919–926

Lopez CAV, Alcantara DH, Menendez RM, Mendoza RAR, Garza HA (2015) Method for modeling electrorheological dampers using its dynamic characteristics. Math Prob Eng 2015:1–15

Hoseinzadeh M, Rezaeepazhand J (2014) Vibration suppression of composite plates using smart electrorheological dampers. Int J Mech Sci 84:31–40

Hoseinzadeh M, Rezaeepazhand J (2016) Dynamic stability of laminated composite plates with an external smart damper. J Solid Mech 8(1):45–57

Choi YT, Cho JU, Choi SB, Wereley NM (2005) Constitutive models of electrorheological and magnetorheological fluids using viscometers. Smart Mater Struct 14:1025–1036

Yeh JY, Chen LW (2004) Vibration of a sandwich plate with a constrained layer and electrorheological fluid core. Compos Struct 65(2):251–258

Snamina J (2011) Optimal location of an active segment of magnetorheological fluid layer in a sandwich plate. In: 12th international carpathian control conference (ICCC) https://doi.org/10.1109/carpathiancc.2011.5945880

Soleymani MM, Hajabasib MA, Elahi Mahani S (2015) Free vibrations analysis of a sandwich rectangular plate with electrorheological fluid core. J Comput Appl Res Mech Eng 5(1):71–81

Ghorbanpour Arani A, Jamali SA, BabaAkbar Zarei H (2017) Differential quadrature method for vibration analysis of electro-rheological sandwich plate with CNT reinforced nanocomposite facesheets subjected to electric field. Compos Struct 180:211–220

Ke LL, Liu C, Wang YS (2015) Free vibration of nonlocal piezoelectric nanoplates under various boundary conditions. Physica E 66:93–106

Ghorbanpour Arani A, Jamali M, Ghorbanpour Arani AH, Kolahchi R, Mosayyebi M (2016) Electro-magneto wave propagation analysis of viscoelastic sandwich nanoplates considering surface effects. J Mech Eng Sci 231(2):387–403

Manoharan R, Vasudevan R, Jeevanantham AK (2014) Vibration analysis of a partially treated laminated composite magnetorheological fluid sandwich plate. Smart Mater Struct 23:025022

Lu H, Meng G (2006) An experimental and analytical investigation of the dynamic characteristics of a flexible sandwich plate filled with electrorheological fluid. Int J Adv Manuf Technol 28:1049–1055

Ghorbanpour Arani A, Haghparast E, BabaAkbar Zarei H (2016) Nonlocal vibration of axially moving graphene sheet resting on orthotropic visco-Pasternak foundation under longitudinal magnetic field. Phys B 495:35–49

Yeh JY, Chen LW (2005) Dynamic stability of a sandwich plate with a constraining layer and electrorheological fluid core. J Sound Vib 285:637–652

Yeh JY, Chen LW (2006) Dynamic stability analysis of a rectangular orthotropic sandwich plate with an electrorheological fluid core. Compos Struct 72:33–41

Manoharan R, Vasudevan R, Jeevanantham AK (2014) Vibration analysis of a partially treated laminated composite magnetorheological fluid sandwich plate. J Vib Control 22(3):869–895

Newmark NM (1959) A method of computation for structural dynamics. J Eng Mech 85:67–94

Yalcintas M, Coulter JP (1995) Electrorheological material based adaptive beams subjected to various boundary conditions. J Intell Mater Syst Struct 6:700–717

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Cezar Negrao, PhD.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2

Rights and permissions

About this article

Cite this article

Ghorbanpour Arani, A., BabaAkbar-Zarei, H. & Jamali, S.A. Application of smart electro-rheological dampers in semi-active control of electro-rheological sandwich plates with nanocomposite facesheets rested on orthotropic visco-Pasternak foundation. J Braz. Soc. Mech. Sci. Eng. 41, 426 (2019). https://doi.org/10.1007/s40430-019-1903-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1903-8