Abstract

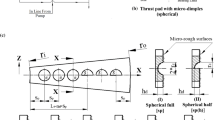

A numerical simulation is performed to investigate the synergizing influence of surface texture (micro-grooves) and electrically conducting lubricant on static and dynamic performance of hybrid thrust pad bearings operating under transverse magnetic field. Linear momentum and mass conservation equation are solved simultaneously to derive modified Reynolds equation for magnetohydrodynamic lubrication. Finite element approach has been used to obtain couple solution of modified Reynolds equation and restrictor (orifice) flow equation. A mass conserving algorithm (Jakobsson–Floberg–Olsson boundary condition) has been implemented to simulate cavitation phenomenon within micro-grooves. A parametric investigation (based on load-carrying capacity/fluid film pressure) is carried out to obtain optimum attributes for various micro-grooves shapes. Providing micro-groove on bearings surfaces results in a significant increase in load-carrying capacity, stiffness coefficient and reduction in frictional power loss of the bearing. Employing of electrically conducting lubricant is seen to be enhancing the load-carrying capacity and damping characteristics of the bearing.

Similar content being viewed by others

Abbreviations

- \( A_{\text{b}} \) :

-

Area of bearing; \( \left( {\pi r_{0}^{2} } \right) \), mm2

- \( A_{p} \) :

-

Area of recess; \( \left( {\pi r_{i}^{2} } \right) \), mm2

- \( \bar{A}_{\text{r}} \) :

-

Area ratio (\( A_{\text{b}} /A_{p} \))

- \( B_{o} \) :

-

Magnetic field [Tesla (T) (N/(m amp)]

- \( D \) :

-

Damping coefficient of fluid film, N s/m; \( \left( {\bar{D} = \frac{{h_{o}^{3} }}{{r_{o}^{4} \mu }}D} \right) \)

- \( \overline{\text{CS}}_{2} \) :

-

Restrictor (orifice) design parameter; \( \left( {\overline{\text{CS}}_{2} = \frac{{\pi d_{o}^{2} \mu }}{{4h_{o}^{3} }}\psi_{\text{d}} \left( {\frac{2}{{\rho p_{\text{s}} }}} \right)^{1/2} } \right) \)

- \( d_{\text{g}} \) :

-

Depth of micro-grooves, µm; \( \left( {\bar{d}_{\text{g}} = d_{\text{g}} /h_{\text{o}} } \right) \)

- \( d_{0} \) :

-

Diameter of the orifice, mm

- \( F_{o} \) :

-

Fluid film reaction, N; \( \bar{F}_{o} = \left( {\frac{{F_{o} }}{{p_{\text{s}} r_{o}^{2} }}} \right) \)

- F l :

-

Lorentz force, N/m3

- H :

-

Lubricant film thickness, mm; \( \left( {\bar{h} = h/h_{o} } \right) \)

- \( \dot{h} \) :

-

Squeeze velocity, mm/s; \( \left( {\bar{\dot{h}} = \frac{{\partial \bar{h}}}{{\partial \bar{t}}}} \right) \)

- \( h_{o} \) :

-

Reference film thickness, mm

- K :

-

Stiffness coefficient of fluid film, N/mm; \( \left( {\bar{K} = \frac{{h_{o} }}{{p_{\text{s}} r_{o}^{2} }}K} \right) \)

- \( L_{\text{g}} \) :

-

Length of groove \( \left( {L_{\text{g}} = r_{\text{go}} - r_{\text{gi}} } \right) \), mm; \( \left( {\bar{L}_{\text{g}} = \frac{{L_{\text{g}} }}{{r_{o} }}} \right) \)

- p :

-

Fluid film pressure, MPa; \( \left( {\bar{p} = \frac{{p - p_{\text{c}} }}{{p_{\text{s}} }}} \right) \)

- \( p_{\text{r}} \) :

-

Lubricant pressure in the recess \( \left( {\partial h/\partial t = 0} \right) \), MPa; \( \left( {\overline{p}_{\text{r}} = p_{\text{r}} /p_{\text{s}} } \right) \)

- \( p_{\text{c}} \) :

-

Cavitation pressure, MPa

- \( p_{\text{f}} \) :

-

Fluid film frictional power loss; N m/s; \( \left( {\bar{p}_{\text{fric}} = \frac{{p_{\text{f}} }}{{p_{\text{s}} h_{o} \omega r_{o}^{2} }}} \right) \)

- \( p_{\text{s}} \) :

-

Supply pressure, MPa

- Q :

-

Flow rate through the bearing, mm3/s

- \( Q_{\text{R}} \) :

-

Lubricant flow rate through the, mm3/s; \( \left( {\bar{Q}_{\text{R}} = \frac{12\mu }{{p_{\text{s}} h_{o}^{3} }}Q_{\text{R}} } \right) \)

- \( r_{i} \) :

-

Recess radius, mm

- \( r_{\text{gi}} , r_{\text{go}} \) :

-

Radius for groove commencement and end, mm; \( \left( {\bar{r}_{\text{gi}} = \frac{{r_{\text{gi}} }}{{r_{o} }};\bar{r}_{\text{go}} = \frac{{r_{\text{go}} }}{{r_{o} }}} \right) \)

- \( r_{o} \) :

-

External radius of pad (stationary surface), mm

- u, v, w :

-

Velocity of fluid in x, y and z directions, mm/s

- U, V, W :

-

Velocity component of runner (moving surface) in x, y and z directions, mm/s

- x, y, z :

-

Cartesian coordinates; \( \left( {\bar{x} = \frac{x}{{r_{o} }};\bar{z} = \frac{z}{{r_{o} }};\bar{y} = \frac{y}{{h_{o} }}} \right) \)

- \( \theta_{\text{gi}} , \theta_{\text{go}} \) :

-

Angle for groove commencement and end, Radian

- \( \theta_{\text{g}} \) :

-

Circumferential angle/width of micro-grooves, Radian; \( \left( {\theta_{\text{g}} = \theta_{\text{go}} - \theta_{\text{gi}} } \right) \)

- \( \rho_{\text{c}} \) :

-

Effective density of lubricant in cavitation zone, kg/m3

- \( \sigma \) :

-

Lubricant electrical conductivity (siemens/metre)

- \( \psi_{\text{d}} \) :

-

Coefficient of discharge for an orifice restrictor

References

Khonsari MM, Booser ER (2008) Applied tribology: bearing design and lubrication. Wiley, Hoboken

Roberts W (1981) Tribology in nuclear power generation. Tribol Int 14(1):17–28

Sinhasan R, Jain S (1984) Lubrication of orifice-compensated flexible thrust pad bearings. Tribol Int 17(4):215–221

Osman T, Dorid M, Safar Z et al (1996) Experimental assessment of hydrostatic thrust bearing performance. Tribol Int 29(3):233–239

Liu ZF, Zhan CP, Cheng Q et al (2016) Thermal and tilt effects on bearing characteristics of hydrostatic oil pad in rotary table. J Hydrodynam 28(4):585–595

Etsion I (2005) State of the art in laser surface texturing. Trans ASME F J Tribol 127(1):248–253

Yang H, Ratchev S, Turitto M et al (2009) Rapid manufacturing of non-assembly complex micro-devices by microstereolithography. Tsinghua Sci Technol 14:164–167

Yu TH, Sadeghi F (2001) Groove effects on thrust washer lubrication. J Tribol 123(2):295–304

Brizmer V, Kligerman Y, Etsion I (2003) A laser surface textured parallel thrust bearing. Tribol Trans 46(3):397–403

Uddin MS, Ibatan T, Shankar S (2017) Influence of surface texture shape, geometry and orientation on hydrodynamic lubrication performance of plane-to-plane slider surfaces. Lubr Sci 29(3):153–181

Etsion I, Halperin G, Brizmer V et al (2004) Experimental investigation of laser surface textured parallel thrust bearings. Tribol Lett 17(2):295–300

Cupillard S, Cervantes MJ, Glavatskih S (2008) Pressure buildup mechanism in a textured inlet of a hydrodynamic contact. J Tribol 130(2):021701

Syed I, Sarangi M (2018) Combined effects of fluid–solid interfacial slip and fluid inertia on the hydrodynamic performance of square shape textured parallel sliding contacts. J Br Soc Mech Sci Eng 40(6):314

Kumar V, Sharma SC (2018) Influence of dimple geometry and micro-roughness orientation on performance of textured hybrid thrust pad bearing. Meccanica 53(14):3579–3606

Tala-Ighil N, Fillon M, Maspeyrot P (2011) Effect of textured area on the performances of a hydrodynamic journal bearing. Tribol Int 44(3):211–219

Ronen A, Etsion I, Kligerman Y (2001) Friction-reducing surface-texturing in reciprocating automotive components. Tribol Trans 44(3):359–366

Kadirgama K, Ramasamy D, El-Hossein KA (2017) Assessment of alternative methods of preparing internal combustion engine cylinder bore surfaces for frictional improvement. J Br Soc Mech Sci Eng 39(9):3591–3605

Etsion I, Sher E (2009) Improving fuel efficiency with laser surface textured piston rings. Tribol Int 42(4):542–547

Kligerman Y, Etsion I (2001) Analysis of the hydrodynamic effects in a surface textured circumferential gas seal. Tribol Trans 44(3):472–478

Qiu Y, Khonsari MM (2009) On the prediction of cavitation in dimples using a mass-conservative algorithm. J Tribol 131(4):041702

Qiu Y, Khonsari MM (2011) Performance analysis of full-film textured surfaces with consideration of roughness effects. J Tribol 133(2):021704

Elrod HG (1981) A cavitation algorithm. ASME J Lubr Technol 103:350

Vijayaraghavan D, Keith JT (1989) Development and evaluation of a cavitation algorithm. Tribol Trans 32(2):225–233

Vijayaraghavan D (1996) An efficient numerical procedure for thermohydrodynamic analysis of cavitating bearings. Trans Am Soc Mech Eng J Tribol 118(3):555–563

Brito F (2009) Thermohydrodynamic performance of twin groove journal bearings considering realistic lubricant supply conditions: a theoretical and experimental study. University of Minho, Braga

Elco R, Hughes W (1962) Magnetohydrodynamic pressurization of liquid metal bearings. Wear 5(3):198–212

Kuzma D, Maki E, Donnelly R (1964) Magnetohydrodynamic squeeze films. J Basic Eng 86(3):441–444

Kuzma D (1964) The finite magnetohydrodynamic journal bearing. J Basic Eng 86(3):445–448

Lin JR (2010) MHD steady and dynamic characteristics of wide tapered-land slider bearings. Tribol Int 43(12):2378–2383

Lin JR, Lu RF (2010) Dynamic characteristics for Magneto-hydrodynamic wide slider bearings with an exponential film profile. J Mar Sci Technol 18(2):268–276

Naduvinamani N, Siddangouda A, Siddharam P (2017) A comparative study of static and dynamic characteristics of parabolic and plane inclined slider bearings lubricated with MHD couple stress fluids. Tribol Trans 60(1):1–11

Lin JR (2001) Magneto-hydrodynamic squeeze film characteristics between annular disks. Ind Lubr Tribol 53(2):66–71

Fathima ST, Naduvinamani N, Hanumagowda B et al (2015) Modified Reynolds equation for different types of finite plates with the combined effect of MHD and couple stresses. Tribol Trans 58(4):660–667

Kumar V, Sharma SC (2018) Dynamic characteristics of compensated hydrostatic thrust pad bearing subjected to external transverse magnetic field. Acta Mech 229(3):1251–1274

Kumar V, Sharma SC (2018) Finite element method analysis of hydrostatic thrust pad bearings operating with electrically conducting lubricant. Proc Inst Mech Eng Part J J Eng Tribol 232(10):1318–1331

Kumar V, Sharma SC (2019) Magneto-hydrostatic lubrication of thrust bearings considering different configurations of recess. Ind Lubr Tribol. https://doi.org/10.1108/ILT-10-2018-0370

http://www.indium.com/technical-documents/product-data-sheets/download.php?docid=622

Acknowledgements

This research received no specific grant from any funding agency in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Vivek Kumar and Satish C. Sharma declare that they have no conflict of interest.

Additional information

Technical Editor: Jader Barbosa Jr., PhD.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Derivation for modified Reynolds equation

Assumptions: steady-state flow\( ; \frac{\partial p}{\partial t} = 0 \). Inertia and body forces (except Lorentz force) are assumed to be neglected. The momentum conservation equation and mass conservation equations are as follows:

Here, \( \vec{F}_{\text{l}} \) is a body force known as Lorentz force and defined as force felt by a charge particle passing through an external magnetic field (Bo). Mathematically, Lorentz force is expressed as cross-product of current density \( \left( {\vec{J}} \right) \) and magnetic field \( \left( {\vec{B}} \right) \), i.e. \( \overrightarrow { F}_{\text{l}} = \left( {\vec{J} \times \vec{B}} \right) \); the current density is expressed as: \( \vec{J} = \sigma \left( {\vec{E} + \left( {\vec{v} \times \vec{B}} \right)} \right) \). Navier–Stokes equation (12) along the three axes of Cartesian co-ordinate system is as follows:

\( E_{z} \) and \( E_{x} \) represent the magnitude of induced/generated electric field and the subscript denotes the direction. The bearing surfaces are assumed non-conducting. The magnitude of induced electric field can be obtained by setting net current flow to be zero, i.e.

Fluid film velocity profile is derived by using following Boundary conditions:

The value of induced electric field (Ez and Ex) obtained by solving equations (17 and 18) is substituted into Eq. (14 and 15), and subsequently these equations are solved using boundary condition provided in Eqs. (19 and 20). The fluid film velocity profile along Cartesian axes x and z are governed by following expressions:

where H denotes Hartmann number, a non-dimensional parameter representing relative magnitude of electro-magnetic force to viscous force, i.e. \( H = B_{o} h_{o} \left( {\sigma /\mu } \right)^{1/2} \); here, symbol \( \sigma \) is used to represent lubricant electrical conductivity. Now, substituting the expression of fluid film velocity (21 and 22) in mass conservation Eq. (13) and performing integration w.r.t film thickness direction, modified Reynolds equation for electrically conducting lubricant can be obtained as follows:

where \( \emptyset \left( {h,M} \right) = \frac{{6h_{o}^{2} }}{{h^{2} H^{2} }}\left\{ {\left( {\frac{Hh}{{h_{o} }}} \right)coth\left( {\frac{Hh}{{2h_{o} }}} \right) - 2} \right\} \) is magnetohydrodynamic function.

The lubricant is fed in recess of the bearing by means of an orifice restrictor (compensating element). Under steady-state operation of bearing, the total lubricant input flow through the restrictor will be same as that of summation of lubricant flow rate through nodes located at recess boundary. The lubricant flow rate through orifice restrictor is governed by the following expression:

1.2 Cavitation parameters for JFO boundary conditions

Film zone/location | Boundary condition | Value of switch functions | |

|---|---|---|---|

Full film zone | \( \bar{p} > 0 \) | \( g = 1;\lambda = 1;\gamma = 1 \) | (25) |

Film rupture location | \( \bar{p} = 0;\left[ { \frac{{\partial \bar{p}}}{{\partial \bar{x}}} \& \frac{{\partial \bar{p}}}{{\partial \bar{z}}}} \right] = 0 \) | \( g = 1;\lambda = 1;\gamma = 1 \) | (26) |

Cavitation Zone | \( \bar{p} < 0 \) | \( g = 0;0 \le \lambda \le 1;\gamma = 0 \) | (27) |

Film reformation location | \( \bar{p} = 0; \left[ { \frac{{\partial \bar{p}}}{{\partial \bar{x}}} \& \frac{{\partial \bar{p}}}{{\partial \bar{z}}}} \right] > 0 \) | \( g = 0;0 \le \lambda \le 1;\gamma = 0 \) | (28) |

1.3 Fluid film thickness expression for groove having different cross-sectional shapes (Refer Fig. 1c)

Groove Shape | Fluid film expression | Domain | Eqs. |

|---|---|---|---|

(I) Circular (Cir) | \( \bar{h} = \bar{h}_{0} + \bar{d}_{\text{g}} \sqrt {1 - 4\left( {\frac{{\theta - \left( {\theta_{\text{gi}} + 0.5*\theta_{\text{g}} } \right)}}{{\theta_{\text{g}} }}} \right)^{2} } \) | \( \theta_{\text{gi}} \le \theta \le \theta_{\text{go}} \) | (29) |

(II) Rectangular (Rect) | \( \bar{h} = \bar{h}_{0} + \bar{d}_{\text{g}} \) | \( \theta_{\text{gi}} \le \theta \le \theta_{\text{go}} \) | (30) |

(III) Triangular (Tri) | \( \bar{h} = \bar{h}_{0} + 2*\bar{d}_{\text{g}} *\frac{{\left( {\theta - \theta_{\text{gi}} } \right)}}{{\theta_{\text{g}} }}; \) | \( \theta_{\text{gi}} \le \theta < \left( {\theta_{\text{gi}} + 0.5*\theta_{\text{g}} } \right) \) | (31) |

\( \bar{h} = \bar{h}_{0} - 2*\bar{d}_{\text{g}} *\frac{{\left( {\theta - \left( {\theta_{\text{gi}} + \theta_{\text{g}} } \right)} \right)}}{{\theta_{\text{g}} }} \) | \( \left( {\theta_{\text{gi}} + 0.5*\theta_{\text{g}} } \right) \le \theta \le \theta_{\text{go}} \) | (32) | |

(IV)Trapezoidal (Trap) | \( \bar{h} = \bar{h}_{0} + 4*\bar{d}_{\text{g}} *\frac{{\left( {\theta - \theta_{\text{gi}} } \right)}}{{\theta_{\text{g}} }} \) | \( \theta_{\text{gi}} \le \theta < \left( {\theta_{\text{gi}} + 0.25*\theta_{\text{g}} } \right) \) | (33) |

\( \bar{h} = \bar{h}_{0} + \bar{d}_{\text{g}} \) | \( \left( {\theta_{\text{gi}} + 0.25*\theta_{\text{g}} } \right) \le \theta < \left( {\theta_{\text{gi}} + 0.75*\theta_{\text{g}} } \right) \) | (34) | |

\( \bar{h} = \bar{h}_{0} - 4*\bar{d}_{\text{g}} *\frac{{\left( {\theta - \left( {\theta_{\text{gi}} + \theta_{\text{g}} } \right)} \right)}}{{\theta_{\text{g}} }} \) | \( \left( {\theta_{\text{gi}} + 0.75*\theta_{\text{g}} } \right) \le \theta < \theta_{\text{go}} \) | (35) | |

Smooth surface | \( \bar{h} = \bar{h}_{0} ; \) | \( \left( {\theta < \theta_{\text{gi }} } \right)\;{\text{or}}\; \left( {\theta > \theta_{\text{go}} } \right) \) | (36) |

1.4 Finite element formulation

Using approximation of fluid film pressure (Eq. 4) in Eq. 3, residue will be obtained:

Integrating residue over fluid film domain (weak formulation)

Assembled global flow governing equation:

The matrix terms eth element in the above equation is expressed as follows:

Fluidity term matrix:

Flow term matrix:

Hydrodynamic term matrix

Squeeze term matrix:

For obtaining dynamic characteristics, the local derivative of nodal pressure w.r.t film thickness and squeeze velocity is defined as:

The numerical integration of aforementioned matrix terms (40–43) is obtained using Gauss–Legendre Quadrature. The shape function for four-noded isoparametric element is defined as:

The derivative of shape function w.r.t \( \xi \) and \( \eta \) can be obtained using chain rule of partial differentiation

The above partial derivatives in matrix form can be expressed as:

where \( \left[ J \right] \) represent Jacobian Matrix. Determinants of Jacobian Matrix are defined as: \( {\text{d}}\bar{x}{\text{d}}\bar{z} = J{\text{d}}\xi {\text{d}}\eta \). Substituting the value of \( \frac{{\partial N_{i} }}{{\partial \bar{x}}} \) and \( \frac{{\partial N_{i} }}{{\partial \bar{z}}} \) from (48) in expression for \( \overline{ F}_{ij}^{e} \)

Similarly the expression for \( \left( { \overline{\text{RH}}_{i}^{e} } \right) \) and \( \left( {\overline{\text{RS}}_{i}^{e} } \right) \) matrix terms for the eth element are described as

Integrand for flow matric term (\( \bar{Q}_{i}^{e} \)) is expressed as

Using \( n_{x} {\text{d}}\varGamma^{e} = {\text{d}}\bar{z} \) and \( n_{z} {\text{d}}\varGamma^{e} = {\text{d}}\bar{x} \) in the above equation

The expression for flow term \( {\bar{\mathbf{Q}}}_{i}^{e} \) is obtained by performing one-dimensional numerical integration as follows:

where \( \left| {\bar{J}_{L1} } \right| = \left| {\frac{{\partial \bar{x}}}{\partial \xi }} \right|, \left| {\bar{J}_{L2} } \right| = \left| {\frac{{\partial \bar{y}}}{\partial \eta }} \right| \)

The expression in A.3.18 should be integrated over the nodes located at inner radius (ri) or at outer radius (ro) of thrust pad. This will provide lubricant flow rate through 1/32nd model of thrust pad. The total lubricant flow through entire bearing would be 32 times of this lubricant flow rate. The restrictor flow Eq. (24) should be coupled with the element system Eq. (39) to yield simultaneous solution of modified Reynolds equation for nodal pressure vector. Elemental matrix equation (39) is obtained for each element and is assembled to generate global system of equations, as expressed as follows:

The above Eq. (55) has been used to compute nodal pressure vector, which depends on nodes coordinates, film thickness at a node and squeeze velocity. In order to obtained steady-state pressure, the squeeze velocity is set to zero. Thus, the above equation in steady state reduces to:

The numerical solution of hybrid thrust pad bearing requires coupling of the above-mentioned Eq. (56) with restrictor flow equation. This can be achieved by setting the value of nodal pressures, located on the recess radius (ri) equal to recess pressure and algebraic sum of fluid flow rate (for 1/32nd model) through these nodes equal to flow through orifice restrictor.

Rights and permissions

About this article

Cite this article

Kumar, V., Sharma, S.C. Effect of geometric shape of micro-grooves on the performance of textured hybrid thrust pad bearing. J Braz. Soc. Mech. Sci. Eng. 41, 508 (2019). https://doi.org/10.1007/s40430-019-2016-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-2016-0