Abstract

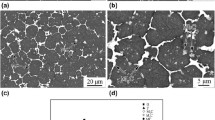

In this paper, ASP2030 (A30) high speed steel (HSS) was produced by spray forming and the microstructure was studied by optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), electron probe microanalysis (EPMA) and X-ray diffraction (XRD). The spray formed A30 (SF A30) steel exhibited a very uniform and fine microstructure consisting of martensite, retained austenite and uniformly distributed network carbides. Microstructure refining can be explained in terms of the rapid solidification of spray forming. M2C, MC and M6C type carbides were found in the as-sprayed A30 HSS by XRD and TEM. A uniform distribution of carbides was obtained after forging and annealing. The microstructure properties of SF A30 steel indicate that spray forming can be considered as a cost-effective route for the production of A30 steels and other highly alloyed steels.

Similar content being viewed by others

References

Moon HK, Lee KB, Kwon H (2008) Influences of Co addition and austenitizing temperature on secondary hardening and impact fracture behavior in P/M high speed steels of W-Mo-Cr-V(-Co) system. Mater Sci Eng A 474:328–334

Mesquita RA, Barbosa CA (2004) Spray forming high speed steel—properties and processing. Mater Sci Eng A 383:87–95

Zhou B, Shen Y, Chen J, Cui ZS (2011) Breakdown behavior of eutectic carbides in high speed steel during hot compression. J Iron Steel Res Int 18:41–48

Hetzner DW (2001) Refining carbide size distributions in M1 high speed steel by processing and alloying. Mater Charact 46:175–182

Wronski AS, Wright CS, Bolton JD, Bienvenu Y, Jeandin M, Smith AB (1991) PM HSS for aerospace automotive and cutting tool applications. Met Powder Rep 46(50–51):53–55

Grant PS (1995) Spray forming. Prog Mater Sci 39:497–545

Rodenburg C, Krzyzanowski M, Beynon JH, Rainforth WM (2004) Hot workability of spray-formed AISI M3:2 high-speed steel. Mater Sci Eng A 386:420–427

Schulz A, Uhlenwinkel V, Escher C, Kohlmann R, Kulmburg A, Montero MC, Rabitsch R, Schützenhöfer W, Stocchi D, Viale D (2008) Opportunities and challenges of spray forming high-alloyed steels. Mater Sci Eng A 477:69–79

Bhargava AK, Tiwari AN (1992) Effect of rapid solidification and heat treatment on D2 steel. Int J Rapid Solidif 7:51–66

Zhang JG (2003) Research in spray forming technology and its applications in metallurgy. J Mater Process Technol 138:357–360

Zhang JG, Xu HB, Shi HS, Wu JS, Sun DS (2003) Microstructure and properties of spray formed Cr12MoV steel for rolls. J Mater Process Technol 111:79–84

Ikawa Y, Itami T, Kumagai K, Kawashima Y, Leatham AG, Coombs JS (1990) Spray deposition method and its application to the production of mill rolls. ISIJ Int 30:756–763

Lee ES, Park WJ, Baik KH, Ahn S (1998) Different carbide types and their effect on bend properties of a spray-formed high speed steel. Scr Mater 39:1133–1138

Zhang Y, Zhang GQ, Li Z, Li ZD, Yuan H, Xu WY, Liu N, Tian SF (2007) Analysis of twin-nozzle-scanning spray forming process and spray formed high speed steel (HSS). J Iron Steel Res Int 14:7–10

Yan F, Xu Z, Shi HS, Fan JF (2008) Microstructure of the spray formed Vanadis 4 steel and its ultrafine structure. Mater Charact 59:592–597

Cui CS, Fritsching U, Schulz A, Tinscher R, Bauckhage K, Mayr P (2005) Spray forming of homogeneous 100Cr6 bearing steel billets. J Mater Process Technol 168:496–504

Yu FX, Cui JZ, Ranganathan S, Dwarakadasa ES (2001) Fundamental differences between spray forming and other semisolid processes. Mater Sci Eng A 304–306:621–626

Wei SZ, Zhu JH, Xu LJ (2005) Research on wear resistance of high speed steel with high vanadium content. Mater Sci Eng A 404:138–145

Zhou H, Wang JG, Jia SS, Keisaku OGI (1997) Solidified microstructures and phases of high speed steels containing different V and C content. Acta Metall Sin 33:838–843

Luan YK, Song NN, Bai YL, Kang XH, Li DZ (2010) Effect of solidification rate on the morphology and distribution of eutectic carbides in centrifugal casting high-speed steel rolls. J Mater Process Technol 210:536–541

Lee ES, Park WJ, Jung JY (1998) Solidification microstructure and M2C carbide decomposition in a spray-formed high-speed steel. Metall Mater Trans 29A:1395–1404

Xu Q, Lavernia EJ (1999) Microstructure evolution during the initial stages of spray atomization and deposition. Scr Mater 41:535–540

Pan FS, Wang WQ, Tang AT (2011) Phase transformation refinement of coarse primary carbides in M2 high speed steel. Prog Nat Sci 21:180–186

Večko Pirtovšek T, Kugler G, Godec M, Terčelj M (2011) Microstructural characterization during the hot deformation of 1.17C-11.3Cr-1.48V-2.24W-1.35Mo ledeburitic tool steel. Mater Charact 62:189–197

Meurling F, Melander A, Tidesten M, Westin L (2001) Influence of carbide and inclusion contents on the fatigue properties of high speed steels and tool steels. Int J Fatigue 23:215–224

Acknowledgments

This research was financially supported by Baosteel Research Institute, People’s Republic of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, SL., Fan, JF., Zhang, JY. et al. High speed steel produced by spray forming. Adv. Manuf. 4, 115–122 (2016). https://doi.org/10.1007/s40436-016-0137-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-016-0137-6