Abstract

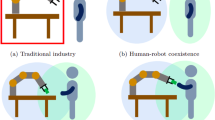

New industrial revolution - “The 4th industrial revolution” must be a remarkable milestone for the second decade of the twenty-first century. Many countries are competing to innovate their manufacturing chains for eco-friendly and energy-efficient productions. Although this green or sustainable manufacturing system evolves under the support of cyber-physical system (or digital twin) based on ICT technology, industrial robots also play important roles in this speedy, flexible and effective manufacturing chains. Recently, low-cost industrial robots or collaborative robots, are rising in a highly interactive environment with humans. Although an industrial robot consists of many important components such as mechanical parts (kinematic structure and reducer) and electric parts (servo motor, driver, sensors, and controller), precision reducer takes approximately 25% of material-cost and governs important performance indices of industrial robots. This paper presents review of high precision reducers (HPRs) for industrial robots driving 4th industrial revolution. First, we provide HPRs market along with industrial robots. According to previous studies, HPRs for industrial robots can be classified based on their principles: planetary reducer, cycloid reducer, and harmonic drive (HD). Then, principle, characteristics, and three main performances (hysteresis, rotational transmission error (RTE) and efficiency) of HPRs are discussed. In addition, compensation methods overcoming accuracy limits of HPRs are summarized. Finally, other applications of HPRs except industrial robots are presented.

Similar content being viewed by others

References

Kwon, J., Park, H. W., Park, Y.-B., and Kim, N., “Potentials of Additive Manufacturing with Smart Materials for Chemical Biomarkers in Wearable Applications,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 3, pp. 335–347, 2017.

Ullah, S. M. S., Muhammad, I., and Ko, T. J., “Optimal Strategy to Deal with Decision Making Problems in Machine Tools Remanufacturing,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 3, No. 1, pp. 19–26, 2016.

Dornfeld, D. A., “Green Manufacturing: Fundamentals and Applications,” Springer Science & Business Media, pp. 1–23, 2012.

Lee, C.-M., Choi, Y.-H., Ha, J.-H., and Woo, W.-S., “Eco-Friendly Technology for Recycling of Cutting Fluids and Metal Chips: A Review,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 4, pp. 457–468, 2017.

Lee, C.-M., Woo, W.-S., and Roh, Y.-H., “Remanufacturing: Trends and Issues,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 1, pp. 113–125, 2017.

Yoon, H.-S., Kim, M.-S., Jang, K.-H., and Ahn, S.-H., “Future Perspectives of Sustainable Manufacturing and Applications Based on Research Databases,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 9, pp. 1249–1263, 2016.

Lee, J., Kim, H.-C., Choi, J.-W., and Lee, I. H., “A Review on 3D Printed Smart Devices for 4D Printing,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 3, pp. 373–383, 2017.

Beier, G., Niehoff, S., Ziems, T., and Xue, B., “Sustainability Aspects of a Digitalized Industry-A Comparative Study from China and Germany,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 2, pp. 227–234, 2017.

Matsumoto, M., Yang, S., Martinsen, K., and Kainuma, Y., “Trends and Research Challenges in Remanufacturing,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 3, No. 1, pp. 129–142, 2016.

Davim, J. P., “Green Manufacturing Processes and Systems,” Springer, 2013.

Vijayaraghavan, A., Yuan, C., Diaz, N., Fleschutz. T, Helu, M., “Green Manufacturing: Fundamentals and Applications-Closed-Loop Production Systems,” Springer, pp. 117–152, 2013.

Sun, Z. and Li, L., “Opportunity Estimation for Real-Time Energy Control of Sustainable Manufacturing Systems,” IEEE Transactions on Automation Science and Engineering, Vol. 10, No. 1, pp. 38–44, 2013.

Chen, G., Zhang, L., Arinez, J., and Biller, S., “Energy-Efficient Production Systems Through Schedule-Based Operations,” IEEE Transactions on Automation Science and Engineering, Vol. 10, No. 1, pp. 27–37, 2013.

Liu, H., Zhao, Q., Huang, N., and Zhao, X., “A Simulation-Based Tool for Energy Efficient Building Design for a Class of Manufacturing Plants,” IEEE Transactions on Automation Science and Engineering, Vol. 10, No. 1, pp. 117–123, 2013.

Hoang, K. D. and Ahn, H.-J., “Both Energy and Cost-Effective Semi-Active RFC (Reaction Force Compensation) Method for Linear Motor Motion Stage,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 1, pp. 73–78, 2017.

Kim, M., Shin, Y.-J., Lee, J.-Y., Chu, W.-S., and Ahn, S.-H., “Pulse Width Modulation as Energy-Saving Strategy of Shape Memory Alloy Based Smart Soft Composite Actuator,” International Journal of Precision Engineering and Manufacturing, Vol. 18, No. 6, pp. 895–901, 2017.

Yang, L., Liu, Z., and Zhang, Y., “Energy-Efficient Yaw Moment Control for Humanoid Robot Utilizing ARMS Swing,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 9, pp. 1121–1128, 2016.

Park, H.-S., Nguyen, T.-T., and Dang, X.-P., “Multi-Objective Optimization of Turning Process of Hardened Material for Energy Efficiency,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 12, pp. 1623–1631, 2016.

Lee, G., Sul, S.-K., and Kim, J., “Energy-Saving Method of Parallel Mechanism by Redundant Actuation,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 2, No. 4, pp. 345–351, 2015.

Jani, J. M., Leary, M., Subic, A., and Gibson, M. A., “A Review of Shape Memory Alloy Research, Applications and Opportunities,” Materials & Design, Vol. 56, pp. 1078–1113, 2014.

Shah, A. U. R., Prabhakar, M., and Song, J.-I., “Current Advances in the Fire Retardancy of Natural Fiber and Bio-Based Composites-A Review,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 2, pp. 247–262, 2017.

Wager, J. F. and Hoffman, R., “Thin, Fast, and Flexible,” IEEE Spectrum, Vol. 48, No. 5, 2011.

Shin, D.-G., Kim, T.-H., and Kim, D.-E., “Review of 4D Printing Materials and their Properties,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 3, pp. 349–357, 2017.

Ahn, D.-G., “Direct Metal Additive Manufacturing Processes and Their Sustainable Applications for Green Technology: A Review,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 3, No. 4, pp. 381–395, 2016.

Kang, H. S., Lee, J. Y., Choi, S., Kim, H., Park, J. H., et al., “Smart Manufacturing: Past Research, Present Findings, and Future Directions,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 3, No. 1, pp. 111–128, 2016.

Herrmann, C., Schmidt, C., Kurle, D., Blume, S., and Thiede, S., “Sustainability in Manufacturing and Factories of the Future,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 1, No. 4, pp. 283–292, 2014.

Leondes, C., “Artificial Intelligence and Robotics in Manufacturing,” CRC Press, 2001.

Knight, W., “China Wants to Replace Millions of Workers with Robots,” MIT Technology Review, https://doi.org/www.technologyreview.com/s/544201/china-wants-to-replace-millions-of-workers-withrobots, 2015. (Accessed 6 JUL 2018)

Lee, S.-D. and Song, J.-B., “Sensorless Collision Detection Based on Friction Model for a Robot Manipulator,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 1, pp. 11–17, 2016.

Kim, S. M., Yi, B.-J., Chung, J.-H., Cheong, J., and Kim, W., “Development of a New Neurosurgical 5-DOF Parallel Robot for Stereotactic DBS Operations,” International Journal of Precision Engineering and Manufacturing, Vol. 18, No. 3, pp. 333–343, 2017.

Nguyen, Q. C., Kim, Y., Park, S., and Kwon, H., “End-Effector Path Planning and Collision Avoidance for Robot-Assisted Surgery,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 12, pp. 1703–1709, 2016.

Choi, Y., Kim, D., Hwang, S., Kim, H., Kim, N., et al., “Dual-Arm Robot Motion Planning for Collision Avoidance Using B-Spline Curve,” International Journal of Precision Engineering and Manufacturing, Vol. 18, No. 6, pp. 835–843, 2017.

Hwang, S., Kim, H., Choi, Y., Shin, K., and Han, C., “Design Optimization Method for 7 DOF Robot Manipulator Using Performance Indices,” International Journal of Precision Engineering and Manufacturing, Vol. 18, No. 3, pp. 293–299, 2017.

Brumson, B., “Going Green with Robotics,” https://doi.org/www.robotics.org/content-detail.cfm/Industrial-Robotics-Industry-Insights/Going-Green-with-Robotics/content_id/1517 (Accessed 6 JUL 2018)

Choi, T., Do, H., Park, C., Chung, K., Park, D., et al., “Advanced Manufacturing with Robot,” Proc. of 12th International Conference on Control, Automation and Systems International Conference, pp. 2207–2209, 2012.

Harmonic drive, “Improve the Productivity of Your Factory Automation Systems with Lightweight Gears and Actuators,” www.harmonicdrive.net (Accessed 6 JUL 2018)

Kircanski, N. M. and Goldenberg, A. A., “An Experimental Study of Nonlinear Stiffness, Hysteresis, and Friction Effects in Robot Joints with Harmonic Drives and Torque Sensors,” The International Journal of Robotics Research, Vol. 16, No. 2, pp. 214–239, 1997.

Warnecke, H. and Schiele, G., “Performance Characteristics and Performance Testing of Industrial Robots—State of the Art,” Robot Technology and Applications, pp. 5–17, 1985.

IFR Press, “World Robotics Report 2016,” International Federation of Robotics, https://doi.org/ifr.org/ifr-press-releases/news/world-roboticsreport-2016 (Accessed 6 JUL 2018)

Global Market Insights, “Precision Gearbox Market Size By Product (Parallel, Right Angle, Planetary), By Application (Military & Aerospace, Food Beverage & Tobacco, Machine Tools, Material Handling, Packaging, Robotics, Medical), Industry Analysis Report, Regional Outlook (U.S., Canada, Germany, UK, France, Russia, China, Japan, South Korea, India, Brazil, Mexico), Growth Potential, Price Trends, Competitive Market Share & Forecast, 2016–2024,” https://doi.org/www.gminsights.com/industry-analysis/precisiongearbox-market (Accessed 9 AUG 2018)

Research In China, “Global and China Industrial Robot Speed Reducer Industry Report, 2015–2018,” https://doi.org/www.researchinchina.com/Htmls/Report/2016/10214.html (Accessed 6 JUL 2018)

Nidec-Shimpo Co., “High Precision Gear Technology -Product Catalog,” https://doi.org/www.drives.nidec-shimpo.com/wp-content/uploads/2017/12/pdf/Precision_Gear_Technology_Catalog.pdf (Accessed 9 AUG 2018)

Sumitomo Drive Technology, “Fine Cyclo-Zero Backlash Precision Gearboxes,” Catalogue 991333 EN, https://doi.org/www.sumitomodrive.com/uploads/product/files/file-2662.pdf (Accessed 23 JUL 2018)

Spinea, “Twinspin-High Precision Reduction Gear,” https://doi.org/www.spinea.com/en/products/twinspin/index (Accessed 23 JUL 2018)

Nabtesco, “Precision Reduction Gear RV: E Series / C Series / Original Series,” https://doi.org/www.nabtescomotioncontrol.com/pdfs/rv-ec-series.pdf (Accessed 9 AUG 2018)

Nabtesco, “Precision Reduction Gear RV: N Series,” https://doi.org/precision.nabtesco.com/en/products/detail/RV-N, 2016.

Harmonic Drive System, “Harmonic Drive Reducers-Speed Reducers for Precision Motion Control,” https://doi.org/www.harmonicdrive.net/_hd/content/documents/reducer_catalog.pdf (Accessed 23 JUL 2018)

Maurice, P., Padois, V., Measson, Y., and Bidaud, P., “Human-Oriented Design of Collaborative Robots,” International Journal of Industrial Ergonomics, Vol. 57, pp. 88–102, 2017.

Stephen, M., “Comparing Cycloidal and Planetary Gear Boxes,” https://doi.org/www.machinedesign.com/news/comparing-cycloidal-andplanetary-gearboxes, 2011. (Accessed 6 JUL 2018)

Norton, R. L., “Design of Machinery,” 2nd Edition, McGraw-Hill, 2009.

LéVai, Z. N., “Structure and Analysis of Planetary Gear Trains,” Journal of Mechanisms, Vol. 3, No. 3, pp. 131–148, 1968.

Bagci, C., “Efficient Methods for the Synthesis of Compound Planetary Differential Gear Trains for Multiple Speed Ratio Generation,” Gear Technol, Vol. 7, pp. 14–35, 1990.

Walton, M. C., “Strain Wave Gearing,” Google Patents, https://doi.org/patentimages.storage.googleapis.com/b1/c0/2d/5fe78bb0c8a415/US2906143.pdf, 1959 (Accessed 6 JUL 2018)

Walton, M. C., “Breakthrough in Mechanical Drive Design: The Harmonic Drive,” Machine Design, pp. 160–173, https://doi.org/insidepenton.com/MD/TheHarmonicDrive.pdf (Accessed 6 JUL 2018)

Ueura, K. and Slatter, R., “Actuators: Development of the Harmonic Drive Gear for Space Applications,” Proc. of the 8th Space Mechanisms and Tribology Symposium, Vol. 438, pp. 259–264, 1999.

Róbert, K., “Development of Flat Wheel Harmonic Drives,” Ph.D. Thesis, Budapest University, 2009.

Pohlau, I. F., “Compact Harmonic Drive Actuators Made of Thermoplastics,” Proc. of Technical Aids for Rehavilitation European Symposium, pp. 59–60, 2007.

Perez-Diaz, J. L., Diez-Jimenez, E., Valiente-Blanco, I., Cristache, C., Alvarez-Valenzuela, M.-A., et al., “Performance of Magnetic-Superconductor Non-Contact Harmonic Drive for Cryogenic Space Applications,” Machines, Vol. 3, No. 3, pp. 138–156, 2015.

Blanche, J. and Yang, D., “Cycloid Drives with Machining Tolerances,” Journal of Mechanisms, Transmissions, and Automation in Design, Vol. 111, No. 3, pp. 337–344, 1989.

Yang, D. and Blanche, J., “Design and Application Guidelines for Cycloid Drives with Machining Tolerances,” Mechanism and Machine Theory, Vol. 25, No. 5, pp. 487–501, 1990.

Pham, A. D. and Ahn, H.-J., “Lost Motion Analysis of One Stage Cycloid Reducer Considering Tolerances,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 8, pp. 1009–1016, 2016.

Ren, Z.-Y., Mao, S.-M., Guo, W.-C., and Guo, Z., “Tooth Modification and Dynamic Performance of the Cycloidal Drive,” Mechanical Systems and Signal Processing, Vol. 85, pp. 857–866, 2017.

Hishida, T., Wang, H., Ishida, T, Matsumoto, K., and Hashimoto, M., “Rotational Transmission Error of K-H-V Planetary Gears with Cycloid Gear-1st Report, Analytical Method of the Rotational Transmission Error,” Trans. of the Japan Society of Mechanical Engineers Series C, Vol. 60, No. 570, pp. 645–653, 1994.

Hishida, T., Wang, H., Ishida, T, and Hashimoto, M., “Rotational Transmission Error of K-H-V Planetary Gears with Cycloid Gear-2nd Report, Effects of Manufacturing and Assembly Errors on Rotational Transmission Error,” Trans. of the Japan Society of Mechanical Engineers Series C, Vol. 60, No. 578, pp. 3510–3517, 1994.

Hishida, T., Wang, H., Ishida, T, Ishida, T, Hashimoto, M., “Rotational Transmission Error of K-H-V Planetary Gears with Cycloid Gear-3rd Report, Mutual Effects of Errors of the Elements on the Rotational Transmission Error,” Trans. of the Japan Soc. of mechanical Eng.-series C, Vol. 60, No. 578, pp. 3518–3525, 1994.

Tuttle, T. D. and Seering, W. P., “A Nonlinear Model of a Harmonic Drive Gear Transmission,” IEEE Transactions on Robotics and Automation, Vol. 12, No. 3, pp. 368–374, 1996.

Gandhi, P. S., “Modeling and Control of Nonlinear Transmission Attributes in Harmonic Drive Systems,” Ph. D. Thesis, Rice University, 2001.

Seyfferth, W., Maghzal, A., and Angeles, J., “Nonlinear Modeling and Parameter Identification of Harmonic Drive Robotic Transmissions,” Proc. of Robotics and Automation, International Conference, pp. 3027–3032, 1995.

Taghirad, H. and Belanger, P., “Modeling and Parameter Identification of Harmonic Drive Systems,” Journal of Dynamic Systems, Measurement, and Control, Vol. 120, No. 4, pp. 439–444, 1998.

Taghirad, H. and Belanger, P., “An Experimental Study on Modelling and Identification of Harmonic Drive Systems”, Proc. of Conference on Decision and Control, Conference, pp. 4725–4730, 1996.

Zhou, J., Sun, W., and Yuan, L., “Nonlinear Vibroimpact Characteristics of a Planetary Gear Transmission System,” Shock and Vibration, Vol. 2016, Article ID4304525, pp. 1–11, 2016.

Park, J., Ha, J. M., Oh, H., Youn, B. D., Choi, J.-H., et al., “Model-Based Fault Diagnosis of a Planetary Gear: A Novel Approach Using Transmission Error,” IEEE Transactions on Reliability, Vol. 65, No. 4, pp. 1830–1841, 2016.

August, R., “Dynamics of Planetary Gear Trains,” National Aeronautics and Space Administration, pp. 1–289, 1984.

Meng, Y., Wu, C., and Ling, L., “Mathematical Modeling of the Transmission Performance of 2K-H Pin Cycloid Planetary Mechanism,” Mechanism and Machine Theory, Vol. 42, No. 7, pp. 776–790, 2007.

Blagojević, M., “Analysis of Clearances and Deformations at Cycloid Disc,” Machine Design, Vol. 6, No. 3, pp. 79–84, 2014.

Kumar, N., “Investigation of Drive-Train Dynamics of Mechanical Transmissions Incorporating Cycloidal Drives,” Ph.D. Thesis, School of Queensland University of Technology, 2015.

Zhang, J., Chen, B., and Lyu, S.-K., “Mathematical Model and Analysis on Cycloid Planetary Gear,” Proc. of the 2nd Mechanic Automation and Control Engineering International Conference, pp. 400–403, 2011.

Hong-Liu, Y., Jin-Hua, Y., Xin, H., and Ping, S., “Study on Teeth Profile Modification of Cycloid Reducer Based on Non-Hertz Elastic Contact Analysis,” Mechanics Research Communications, Vol. 48, pp. 87–92, 2013.

Kim, K.-H., Lee, C.-S., and Ahn, H.-J., “Torsional Rigidity of a Cycloid Drive Considering Finite Bearing and Hertz Contact Stiffness,” Proc. of American Society of Mechanical Engineers International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Vol. 6, pp. 125–130, 2009.

Pham, A. D. and Ahn, H.-J., “Hysteresis Curve Analysis of a Cycloid Reducer Using Non-Linear Spring with a Dead Zone,” International Journal of Precision Engineering and Manufacturing, Vol. 18, No. 3, pp. 375–380, 2017.

Zhang, H., Ahmad, S., and Liu, G., “Modeling of Torsional Compliance and Hysteresis Behaviors in Harmonic Drives,” IEEE/ASME Trans. Mechatronics, Vol. 20, No. 1, pp. 178–185, 2015.

Dhaouadi, R., Ghorbel, F. H., and Gandhi, P. S., “A New Dynamic Model of Hysteresis in Harmonic Drives,” IEEE Transactions on Industrial Electronics, Vol. 50, No. 6, pp. 1165–1171, 2003.

Rhéaume, F., Champliaud, H., and Liu, Z., “Understanding and Modelling the Torsional Stiffness of Harmonic Drives Through Finite-Element Method,” Proc. of the Institution of Mechanical Engineering Science Part C, Vol. 223, No. 2, pp. 515–524, 2009.

Kikuchi, M., Nitta, R., Kiyosawa, Y., and Zhang, X. Y., “Stress Analysis of Cup Type Strain Wave Gearing,” Key Engineering Materials, pp. 129–134, 2003.

Dong, H., Wang, D., and Ting, K.-L., “Elastic Kinematic and Geometric Model of Harmonic Gear Drives,” Proc. of American Society of Mechanical Engineers International Design Engineering Technical Conferences and Computers and Information Engineering Conference, pp. 717–725, 2008.

Dong, H., Wang, D., and Ting, K.-L., “Kinematic Effect of the Compliant Cup in Harmonic Drives,” Journal of Mechanical Design, Vol. 133, No. 5, Paper No. 051004, 2011.

Dong, H. and Wang, D., “Elastic Deformation Characteristic of the Flexspline in Harmonic Drive,” Proc. of Reconfigurable Mechanisms and Robots of ASME/IFToMM International Conference, pp. 363–369, 2009.

Csobán, A., “Tooth Friction Loss in Simple Planetary Gears,” Scientific Bulletin Series C: Fascicle Mechanics, Tribology, Machine Manufacturing Technology, Vol. 21, p. 153, 2007.

Concli, F. and Gorla, C., “Influence of Lubricant Temperature, Lubricant Level and Rotational Speed on the Churning Power Losses in an Industrial Planetary Speed Reducer: Computational and Experimental Study,” International Journal Computational Methods and Experimental Measurements, Vol. 1, No. 4, pp. 353–366, 2013.

Mihailidis, A., Athanasopoulos, E., and Agouridas, K., “EHL Film Thickness and Load Dependent Power Loss of Cycloid Reducers,” Proceedings of the Institution of Mechanical Engineers Part C of Journal of Mechanical Engineering Science, Vol. 230, Nos. 7–8, pp. 1303–1317, 2016.

Schafer, I., Bourlier, P., Hantschack, F., Roberts, E., Lewis, S., et al., “Space Lubrication and Performance of Harmonic Drive Gears,” Proc. of 11th European Space Mechanisms and Tribology Symposium, pp. 65–72, 2005.

Gorla, C., Davoli, P., Rosa, F., Longoni, C., Chiozzi, F., et al., “Theoretical and Experimental Analysis of a Cycloidal Speed Reducer,” Journal of Mechanical Design, Vol. 130, No. 11, Paper No. 112604, 2008.

Neagoe, M., Diaconescu, D., Pascale, L., and Săulescu, R., “On the Efficiency of a Cycloidal Planetary Reducer with a Modified Structure,” Proc. of International Economic Engineering and Manufacturing Systems, Vol. 8, No. 3, pp. 544–549, 2007.

Csoban, A. and Kozma, M, “Influence of the Oil Churning, the Bearing and the Tooth Friction Losses on the Efficiency of Planetary Gears,” Journal of Mechanical Engineering., Vol. 56, No. 4, pp. 231–238, 2010.

Wang, R.-J., Matthee, A., Gerber, S., and Tlali, P., “Calculation of Torque Performance of a Novel Magnetic Planetary Gear,” IEEE Magnetics Letters, Vol. 7, Article No. 1303805, pp. 1–5, 2016.

Kosse, V., “Using Hysteresis Loop and Torsional Shock Loading to Assess Damping and Efficiency of Cyclodrives,” Proc. of 14th International Congress on Sound and Vibration Conference, 2007.

Pham, A.-D. and Ahn, H.-J., “Efficiency Analysis of a Cycloid Reducer Considering Tolerance,” Journal of Friction and Wear, Vol. 38, No. 6, pp. 490–496, 2017.

Bao, J. and He, W., “Parametric Design and Efficiency Analysis of the Output-Pin-Wheel Cycloid Transmission,” International Journal of Control and Automation, Vol. 8, No. 8, pp. 349–362, 2015.

Malhotra, S. and Parameswaran, M., “Analysis of a Cycloid Speed Reducer,” Mechanism and Machine Theory, Vol. 18, No. 6, pp. 491–499, 1983.

Sensinger, J. W. and Lipsey, J. H., “Cycloid vs. Harmonic Drives for Use in High Ratio, Single Stage Robotic Transmissions,” Proc. of Robotics and Automation International Conference pp. 4130–4135, 2012.

Kim, J.-G., Park, Y.-J., Lee, G.-H., and Kim, J.-H., “An Experimental Study on the Effect of Carrier Pinhole Position Errors on Planet Gear Load Sharing,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 10, pp. 1305–1312, 2016.

Gandhi, P. S. and Ghorbel, F. H., “Closed-Loop Compensation of Kinematic Error in Harmonic Drives for Precision Control Applications,” IEEE Transactions on Control Systems Technology, Vol. 10, No. 6, pp. 759–768, 2002.

Tjahjowidodo, T., Al-Bender, F., and Van Brussel, H., “Theoretical Modelling and Experimental Identification of Nonlinear Torsional Behaviour in Harmonic Drives,” Mechatronics, Vol. 23, No. 5, pp. 497–504, 2013.

Iwasaki, M., Yamamoto, M., Hirai, H., Okitsu, Y., Sasaki, K., et al., “Modeling and Compensation for Angular Transmission Error of Harmonic Drive Gearings in High Precision Positioning,” Proc. of Advanced Intelligent Mechatronics IEEE/ASME International Conference, pp. 662–667, 2009.

Han, B., Ma, J., and Li, H., “Research on Nonlinear Friction Compensation of Harmonic Drive in Gimbal Servo-System of DGCMG,” International Journal of Control, Automation and Systems, Vol. 14, No. 3, pp. 779–786, 2016.

Harmonic Drive, “Harmonic Drive: Applications,” https://doi.org/harmonicdrive.de/en/applications/ (Accessed 10 JUL 2018)

Intelligent Control Systems Laboratory, “Application Example: A Helicopter Transmission-ICSL,” Georgia Institute of Technology School of Electrical and Computer Engineering, https://doi.org/icsl.gatech.edu/application_example_a_helicopter_transmission/ (Accessed 10 JUL 2018)

Fan, L., Wang, S., Wang, X., Han, F., and Lyu, H., “Nonlinear Dynamic Modeling of a Helicopter Planetary Gear Train for Carrier Plate Crack Fault Diagnosis,” Chinese Journal of Aeronautics, Vol. 29, No. 3, pp. 675–687, 2016.

Qiu, J., Liu, B., Dong, H., and Wang, D., “Type Synthesis of Gear-Box in Wind Turbine,” Procedia Computer Science, Vol. 109, pp. 809–816, 2017.

Carley, L., “The Inner Workings of Variable Valve Timing,” https://doi.org/www.enginebuildermag.com/2014/01/the-inner-workings-of-variablevalve-timing/, Engine Builder (Accessed 10 JUL 2018)

Del Pio, G., Pennestrì, E., and Valentini, P. P., “Kinematic and Power-Flow Analysis of Bevel Gears Planetary Gear Trains with Gyroscopic Complexity,” Mechanism and Machine Theory, Vol. 70, pp. 523–537, 2013.

Nabtesco, “Applications: Precision Reaches a New Level,” https://doi.org/www.nabtescomotioncontrol.com/applications.php (Accessed 10 JUL 2018)

Tsubaki Group, “Products for Machine Tools: Gear Reducers,” https://doi.org/tsubakimoto.com/products/application-products-datail/machine-tool/reducer/ (Accessed 10 JUL 2018)

Ho, L. M., “Application of Adaptive Thresholds in Robust Fault Detection of an Electro-Mechanical Single-Wheel Steering Actuator,” Proc. of the 8th Supervision and Safety of Technical Processes IFAC Conference, Vol. 45, No. 20, pp. 259–264, 2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pham, AD., Ahn, HJ. High Precision Reducers for Industrial Robots Driving 4th Industrial Revolution: State of Arts, Analysis, Design, Performance Evaluation and Perspective. Int. J. of Precis. Eng. and Manuf.-Green Tech. 5, 519–533 (2018). https://doi.org/10.1007/s40684-018-0058-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-018-0058-x