Abstract

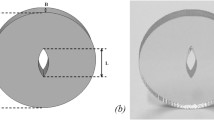

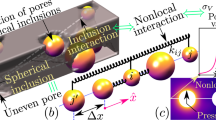

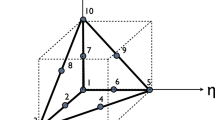

The physical visualisation of a three-dimension (3D) stress field is a promising method for quantitatively analysing and revealing the stress distribution and evolution of a porous solid, and it significantly contributes to the understanding of the governing effects of stress fields on the mechanical behaviours of complex porous solids. However, experimental limitations regarding the manufacture of complex porous models and the extraction of the stress distributions in matrices inhibit the accurate visualisation of the 3D stress fields of porous structures. This paper presents a method of experimentally visualising and elucidating the 3D structures and stress fields of porous solids using photopolymer materials, 3D printing, the frozen-stress method, and photoelastic tests. Transparent thick discs containing various randomly distributed pores were produced using photopolymer materials and 3D printing technology. Experimental measures, including the frozen-stress method, photoelastic testing, and the phase-shifting method, were applied to quantitatively characterise the 3D stress fields distributed throughout the porous discs under radial-direction compressive loads. The temperature for ‘freezing’ stresses in the photopolymer materials was experimentally determined. The effects of pore distribution and population on the stress-field characteristics were investigated. The experimental results were used to validate the numerical analysis of the stress-field characteristics of the porous models. The visualisation test results agreed well with those of the numerical simulations. The proposed method can be used to visually quantify the characteristics and evolution of the 3D stress fields of porous solids.

Similar content being viewed by others

References

Baghbanan A, Jing L (2008) Stress effects on permeability in a fractured rock mass with correlated fracture length and aperture. Int J Rock Mech Min Sci 45:1320–1334. doi:10.1016/j.ijrmms.2008.01.015

Chasset C, Jarsj J, Erlstrom M, Cvetkovic V, Destouni G (2011) Scenario simulations of CO2 injection feasibility, plume migration and storage in a saline aquifer, Scania, Sweden. Nrnaonal Jornal of Grnho Ga Onrol, 5: 1303–1318. doi:1310.1016/j.ijggc.2011.1306.1003

Liu J, Wang JG, Gao F, Ju Y, Zhang X, Zhang LC (2016) Flow consistency between non-darcy flow in fracture network and nonlinear diffusion in matrix to gas production rate in fractured shale gas reservoirs. Trans Porous Media, 111: 97–121. doi:110.1007/s11242-11015-10583-11249

Zhang Q, Ju Y, Gong W, Zhang L, Sun H (2015) Numerical simulations of seepage flow in rough single rock fractures. Petroleum, 1: 200–205. doi: http://dx.doi.org/210.1016/j.petlm.2015.1009.1003

Roberts PM, Abdel-Fattah AI (2009) Seismic stress stimulation mobilizes colloids trapped in a porous rock. Earth Planet Sci Lett 284:538–543. doi: http://dx.doi.org/510.1016/j.epsl.2009. 1005. 1017

Roshan H, Rahman SS (2011) A fully coupled chemo-poroelastic analysis of pore pressure and stress distribution around a wellbore in water active rocks. Rock Mech Rock Eng 44:199–210. doi:110.1007/s00603-00010-00104-00607.

Xie HP, Li LY, Ju Y, Peng RD, Yang YM (2011) Energy analysis for damage and catastrophic failure of rocks. Sci China Technol Sci 54:199–209. doi:110.1007/s11431-11011-14639-y

Mazumder S, Wolf KH (2008) Differential swelling and permeability change of coal in response to CO2 injection for ECBM. Int J Coal Geol 74:123–138. doi:10.1016/j.coal.2007.11.001

Schroeder K, Ozdemir E, Morsi BI (2002) Sequestration of carbon dioxide in coal seams. Gas 2:2–10

Ju Y, Liu HB, Liu JH, Tian KP, Wei S, Hao S (2011) Investigation on thermophysical properties of reactive powder concrete. Sci China Technol Sci 54:3382–3403. doi:3310.1007/s11431-11011-14536-11434

Li Y, Bao J, Guo Y (2010) The relationship between autogenous shrinkage and pore structure of cement paste with mineral admixtures. Constr Build Mater 24:1855–1860. doi: http://dx. doi.org/ 1810.1016/j.conbuildmat.2010.1804.1018

Lieske H (2013) An investigation on micro pore structures and the vapor pressure mechanism of explosive spalling of RPC exposed to high temperature. Sci China Technol Sci 56:458–470. doi:410.1007/s11431-11012-15110-11434

Ikeda Y, Nagano Y, Kawamoto H, Takano N (2004) 3D modeling of porous ceramics by high-resolution X-ray CT for stress analyses. Key Eng Mater 270-273:28–34. doi:10.4028/www.scientific.net/ KEM.4270-4273.4028

Ju Y, Yang Y M, Mao Y Z, Liu H B, Wang H J (2009) Laboratory investigation on mechanisms of stress wave propagations in porous media. Sci China Technol Sci 52:1374–1389. doi:1310.1007/ s11431-11009-10128-y

Ju Y, Yang Y M, Song Z D, Xu W J (2008) A statistical model for porous structure of rocks. Sci China Technol Sci 51:2040–2058. doi: 2010.1007/s11431-11008-10111-z

Ju Y, Wang H J, Yang Y M (2010) Numerical simulation of mechanisms of deformation,failure and energy dissipation in porous rock media subjected to wave stresses. Sci China Technol Sci 53:1098–1113. doi: 1010.1007/s11431-11010-10126-11430

Babu PRDK, Ramesh K (2010) Development of photoelastic fringe plotting scheme from 3D FE results. Commun Numer Methods Eng 22: 809–821. doi:810.1002/cnm.1853

Lei Z, Yun H, Kang Y (2009) Automatic evaluation of photoelastic fringe constant by the nonlinear least-squares method. Opt Laser Technol 41:985–989. doi: http://dx.doi.org/910.1016/j.optlastec. 2009.1004.1010

Pathak P M, Ramesh K (1999) Validation of finite element modelling through photoelastic fringe contours. Commun Numer Methods Eng 15:229–238. doi:210.1002/(SICI)1099-0887(199904)199915:199904<199229::AID-CNM199236>199903.199900.CO;199902-L

Hecker FW, Morche B (1986) Computer-aided measurement of relative retardations in plane photoelasticity. Exp Stress Anal. Springer, pp 535–542. doi:510.1007/1978-1094-1009-4416-1009_1058

Ajovalasit A, Pitarresi G, Zuccarello B (2007) Limitation of carrier fringe methods in digital photoelasticity. Opt Lasers Eng 45: 631–636. doi:10.1016/j.optlaseng.2006.08.008

Ramesh K, Kasimayan T, Simon BN (2011) Digital photoelasticity – a comprehensive review. J Strain Anal Eng Des 46:245–266. doi:210.1177/0309324711401501

Ramesh K, Tamrakar DK (2000) Improved determination of retardation in digital photoelasticity by load stepping. Opt Lasers Eng 33:387–400. doi: http://dx.doi.org/310.1016/S0143-8166 (1000)00076-00072

Ramji M, Ramesh K (2010) Adaptive quality guided phase unwrapping algorithm for whole-field digital photoelastic parameter estimation of complex models. Strain 46: 184–194. doi: https://doi.org/ 110.1111/j.1475-1305.2008.00431.x

Yoneyama S, Morimoto Y, Matsui R (2003) Photoelastic fringe pattern analysis by real-time phase-shifting method. Opt Lasers Eng 39:1–13. doi:10.1016/S0143-8166(1002)00098-00092

Zhang D, Han Y, Zhang B, Arola D (2007) Automatic determination of parameters in photoelasticity. Opt Lasers Eng 45:860–867. doi: http://dx.doi.org/810.1016/j.optlaseng.2007.1002.1002

Bignardi C, Bertetto AM, Mazza L (1999) Photoelastic measurements and computation of the stress field and contact pressure in a pneumatic lip seal. Tribol Int 32:1–13. doi:10.1016/S0301-1679X(1098)00106-00106

Rispler A R, Steven G P, Tong L (2000) Photoelastic evaluation of metallic inserts of optimised shape. Compos Sci Technol 60:95–106. doi: http://dx.doi.org/110.1016/S0266-3538(1099)00107-00104

Smith CW (1980) Photoelasticity in fracture mechanics. Exp Mech 20:390–396. doi:310.1007/BF02321014

Cernosek J (1980) Three-dimensional photoelasticity by stress freezing. Exp Mech 20: 417–426. doi:410.1007/BF02320882

Daniel IM (1983) Experimental methods in applied mechanics. J Appl Mech 50:963–976. doi:910.1115/1111.3167209

Wijerathne MLL, Oguni K, Hori M (2003) 3D stress field tomography based on photoelasticity. Comput Fluid Solid Mech 746–750. doi: http://dx.doi.org/710.1016/B1978-008044046-008044040.008050183-008044044

Yoneyama S, Morimoto Y, Kawamura M (2005) Two-dimensional stress separation using phase-stepping interferometric photoelasticity. Meas Sci Technol 16:1329. doi:1310.1088/ 0957-0233/1316/1326/1014

Pinit P, Umezaki E (2005) Full-field determination of principal-stress directions using photoelasticity with plane-polarized RGB lights. Opt Rev 12:228–232. doi:210.1007/s10043-10005-10228-10042

Swain D, Philip J, Pillai SA (2014) A modified regularized scheme for isochromatic demodulation in RGB photoelasticity. Opt Lasers Eng 61:39–51. doi:10.1016/j.optlaseng.2014.04.009

Zhang YT, Huang MJ, Liang HR, Lao FY (2012) Branch cutting algorithm for unwrapping photoelastic phase map with isotropic point. Opt Lasers Eng 50:619–631. doi:10.1016/j.optlaseng.2011.10.013

Campbell TA, Ivanova OS (2013) 3D printing of multifunctional nanocomposites. Nano Today 8:119–120. doi: http://dx.doi.org/110.1016/j.nantod.2012.1012.1002

Kruth JP, Leu MC, Nakagawa T (1998) Progress in additive manufacturing and rapid prototyping. CIRP Ann Manuf Technol 47:525–540. doi: http://dx.doi.org/510.1016/S0007-8506(1007) 63240-63245

Miller B W, Moore J W, Barrett H H, Fryé T, Adler S, et al. (2011) 3D printing in X-ray and Gamma-Ray Imaging: a novel method for fabricating high-density imaging apertures. Nucl Instrum Methods Phys Res 659:262. doi: http://dx.doi.org/210.1016/j.nima.2011.1008.1051

Ju Y, Xie H, Zheng Z, Lu J, Mao L, Gao F, et al. (2014a) Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Sci Bull 59:5354–5365. doi:5310.1007/ s11434-11014-10579-11439

Wang L, Ju Y et al (2017) The mechanical and photoelastic properties of 3D printable stress-visualized materials. Sci Rep (in revision)

Ju Y, Wang L, Xie H, Ma G, Zheng Z, Mao L (2017) Visualization and transparentization of the structure and stress field of aggregated geomaterials through 3D printing and photoelastic techniques. Rock Mech Rock Eng 1–25. doi:10.1007/s00603-017-1171-9

Ramesh K, Lewis G (2002) Digital photoelasticity: advanced techniques and applications. Appl Mech Rev 55(4): B69–B71. doi:10.1007/978-3-642-59723-7

Ju Y, Zheng J, Epstein M, Sudak L, Wang J, Zhao X (2014b) 3D numerical reconstruction of well-connected porous structure of rock using fractal algorithms. Comput Methods Appl Mech Eng 279:212–226. doi: http://dx.doi.org/210.1016/j.cma.2014.1006.1035

Jacobs PF, Reid DT (1992) Rapid prototyping & manufacturing—fundamentals of StereoLithography. McGraw-Hill, Society of Manufacturing Engineers

Dally JW, Riley WF, Kobayashi AS (1982) Experimental stress analysis. McGraw-Hill, 45:481–485

Frocht MM, Mayer WG (1964) Photoelasticity. Phys Today 17:58. doi:10.1063/1.3051413

Heywood, RolandBryon (1969) Photoelasticity for designers. Pergamon Press 5:238–238

Shin DC, Hawong JS (2011) Development of a hybrid method of reflection photoelasticity for crack problems in anisotropic plates. Exper Mech 51:183–198. doi:110.1007/s11340-11010-19348-11340

Epstein JS, Post D, Smith CW (1984) Three-dimensional photoelastic measurements with very thin slices. Exp Tech 8:34–37. doi:10.1111/j.1747-1567.1984.tb01861.x

Patterson EA, Wang ZF (1991) Towards full field automated photoelastic analysis of complex components. Strain 27:49–53. doi:10.1111/j.1475-1305.1991.tb00752.x

Wang ZF, Patterson EA (1995) Use of phase-stepping with demodulation and fuzzy sets for birefringence measurement. Opt Lasers Eng 22:91–104. doi:http://dx.doi.org/ 110.1016/ 0143-8166(1094)00024-00025.

Ajovalasit A, Petrucci G, Scafidi M (2015) Review of RGB photoelasticity. Opt Lasers Eng 68:58–73. doi:10.1016/j.optlaseng.2014.1012.1008

Ramakrishnan V, Ramesh K (2016) Scanning schemes in white light photoelasticity – part I: critical assessment of existing schemes. Opt Lasers Eng doi: 10.1016/j.optlaseng.2016.1006.1016

Quiroga JA, González-Cano A (1997) Phase measuring algorithm for extraction of isochromatics of photoelastic fringe patterns. Appl Opt 36:8397–8402. doi: https://doi.org/8310.1364/AO.8336.008397

Quiroga JA, González-Cano A (2000) Separation of isoclinics and isochromatics from photoelastic data with a regularized phase-tracking technique. Appl Opt 39:2931–2940. doi:https://doi.org/2910.1364 /AO. 2939.002931

Acknowledgements

The authors gratefully acknowledge the financial support received from the National Natural Science Foundation of China (Grant Nos. 51374213, 51674251), the State Key Research Development Program of China (Grant No. 2016YFC0600705), the National Natural Science Fund for Distinguished Young Scholars (Grant No. 51125017), the Science Fund for Creative Research Groups of the National Natural Science Foundation of China (Grant No. 51421003), the Fund for Creative Research and Development Group Program of Jiangsu Province (Grant No. 2014-27) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (Grant No. PAPD-2014). Especially, the authors would also like to express their gratitude to the editors and the anonymous reviewers for their valuable comments, which have greatly improved this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ju, Y., Zheng, Z., Xie, H. et al. Experimental Visualisation Methods for Three-Dimensional Stress Fields of Porous Solids. Exp Tech 41, 331–344 (2017). https://doi.org/10.1007/s40799-017-0178-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-017-0178-1