Highlights

-

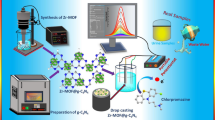

Various synthetic methods for the synthesis of NiCo2O4 nano-/microstructures in bare, doped, and composite/hybrid forms are reviewed.

-

Currents status and development prospects of NiCo2O4 nano-/microstructure-based electrochemical biosensors for bioanalytes such as glucose, urea, and H2O2, along with condition governing the electrochemical biosensor parameters, are summarized.

-

Also provide an insight into the key challenges and future perspectives about point-of-care monitoring of bioanalytes using NiCo2O4 nano-/microstructure-based biosensors.

Abstract

Non-enzymatic biosensors based on mixed transition metal oxides are deemed as the most promising devices due to their high sensitivity, selectivity, wide concentration range, low detection limits, and excellent recyclability. Spinel NiCo2O4 mixed oxides have drawn considerable attention recently due to their outstanding advantages including large specific surface area, high permeability, short electron, and ion diffusion pathways. Because of the rapid development of non-enzyme biosensors, the current state of methods for synthesis of pure and composite/hybrid NiCo2O4 materials and their subsequent electrochemical biosensing applications are systematically and comprehensively reviewed herein. Comparative analysis reveals better electrochemical sensing of bioanalytes by one-dimensional and two-dimensional NiCo2O4 nano-/microstructures than other morphologies. Better biosensing efficiency of NiCo2O4 as compared to corresponding individual metal oxides, viz. NiO and Co3O4, is attributed to the close intrinsic-state redox couples of Ni3+/Ni2+ (0.58 V/0.49 V) and Co3+/Co2+ (0.53 V/0.51 V). Biosensing performance of NiCo2O4 is also significantly improved by making the composites of NiCo2O4 with conducting carbonaceous materials like graphene, reduced graphene oxide, carbon nanotubes (single and multi-walled), carbon nanofibers; conducting polymers like polypyrrole (PPy), polyaniline (PANI); metal oxides NiO, Co3O4, SnO2, MnO2; and metals like Au, Pd, etc. Various factors affecting the morphologies and biosensing parameters of the nano-/micro-structured NiCo2O4 are also highlighted. Finally, some drawbacks and future perspectives related to this promising field are outlined.

Similar content being viewed by others

1 Introduction

Recently, spinel single-phase binary metal oxides containing two metal cations such as manganese cobaltate (MnCo2O4) [1], zinc cobaltate (ZnCo2O4) [2, 3], nickel ferrite (NiFe2O4) [4], copper manganate (CuMn2O4) [5], copper cobaltate (CuCo2O4) [6], cobalt manganate (CoMn2O4) [7], nickel cobaltate (NiCo2O4) [8] have attracted widespread attention from researchers worldwide due to their invariably better electrochemical properties as compared to individual metal oxides or a mixture of metal oxides. The excellent electrochemical performances of these single-phase binary metal oxides are attributed to the synergetic effects of properties of the individual metal oxide components [9]. Among various such single-phase binary metal oxides, NiCo2O4 is considered to be the best one as it possesses at least two times higher electronic conductivity as compared to corresponding individual metal oxides, viz. NiO and Co3O4 along with intrinsic-state redox couples of Ni3+/Ni2+ (0.58 V/0.49 V) and Co3+/Co2+ (0.53 V/0.51 V) [10,11,12]. Other key features are the exhibition of variable but sufficiently stable oxidation states by Ni (Ni2+, Ni3+) and Co (Co2+, Co3+, Co4+) and very high conductivity of 500 S cm−1 [13, 14].

Many transition metals, rare earth metals, non-metal-doped NiCo2O4, and conjugated polymer-modified NiCo2O4 materials have been reported in the literature with versatile applications. N- and P-doped NiCo2O4 with oxygen vacancies have been explored for electrochemical performance for supercapacitors, electro-catalyst for O2 and H2 evolution reaction [15,16,17,18], and anodic material for lithium-ion batteries [19]. Lin et al. [20] explored S-doped NiCo2O4 nanosheet arrays as the efficient and bifunctional electrode for overall water-splitting reactions. Compared with non-metal-doped NiCo2O4, transition metal and rare earth metal-doped NiCo2O4 are considered superior due to the latter’s excellent electrical conductivity. Zn- and Fe-doped NiCo2O4 showed electrocatalytic properties for oxygen evolution reactions and remarkable capacitive properties in asymmetric supercapacitors [21,22,23]. Ma et al. [24] synthesized highly porous hierarchical spinel Mn-doped NiCo2O4 nanosheets for high-performance anodes in lithium-ion batteries. Xia et al. [25] used Au–NiCo2O4 nanomaterials supported on 3D hierarchical porous graphene-like material as electro-catalyst for oxygen evolution reaction. Among the rare earth metal oxides, CeO2 is reported to be an excellent dopant for NiCo2O4 nanomaterials [26, 27]. Carbonaceous and polymer composite/hybrid NiCo2O4 nano-/microstructures are also found suitable for their potential applications in supercapacitors [28], fuel cells [29], Li-ion batteries [30], electro-catalyst for oxygen reduction reaction and oxygen evolution reaction [31], photo-detector [32], optoelectronic devices [33], perovskite solar cells [34], gas sensors [35,36,37] and biosensors [38, 39].

Facile, low-cost and eco-friendly synthetic methods lead to varieties of low dimensional nano-/micro-structured morphologies with excellent porosity and specifically large surface area, opportunities to synthesize composite/hybrid and ease of electrode fabrications for end-user applications. Spinel NiCo2O4 is a p-type semiconductor in which Ni occupies octahedral sites while Co is distributed in both octahedral and tetrahedral sites [13] (Fig. 1a, b). It shows a face-centered cubic arrangement and belongs to Fd3m space group with lattice constant ao = 8.269 Å [40].

Electrochemical sensing through miniaturized sensors based on nano-/micro-structured materials has taken over the conventional, expensive, laborious sensing techniques like lateral flow immunoassay, liquid chromatography, capillary electrophoresis, enzyme-linked immunosorbent assay, chemiluminescence, sequential injection analysis, gas chromatography–mass spectrometry and fluorescent methods [43,44,45,46,47,48]. Electrochemical biosensors can be categorized into amperometric and potentiometric sensors [49]. The amperometric biosensing involves a change in current response due to electrochemical redox reactions of the analytes when a potential is applied between the working and reference electrodes while the potentiometric biosensing makes use of ion-selective electrodes to transduce the biological reactions into a measurable electrical signal [43, 50].

Among the main classes of biosensors, the non-enzymatic biosensor is considered to be better, faster, and more convenient as compared to an enzymatic biosensor that involves complicated and multi-step enzyme immobilization processes and high specificity of the enzymes. Also, due to pH and temperature sensitiveness, the enzyme-based biosensors are highly unstable as enzymes undergo denaturation leading to biological inactivity beyond physiological conditions [51,52,53]. Nanomaterials not only provide high-density catalytic sites for the electro-oxidation or electro-reduction in the biomarkers but also provide large surface area for adsorption of biomarkers and facilitate an appropriate path for electron transport for electrochemical activity [54,55,56]. Since the crucial part in electrochemical biosensors is the modified electrode, much attention has been devoted to modulate the electrocatalytic behavior of the NiCo2O4 as electron mediator by engineering its composition, structure, specific surface area, and redox properties.

To date, many reviews have been reported for the applications of NiCo2O4 nano-/micro-structured materials including Li-ion batteries [10], supercapacitors [11, 57], fuel cells [58], and electro-catalyst for oxygen reduction, oxygen and hydrogen evolution reactions [59, 60]. The applications of the NiCo2O4-based non-enzymatic biosensors are aimed not only at the extension of the spectrum of target bioanalytes but also at the improvement in the biosensor performance in terms of sensitivity, selectivity, detection limits, long-term stability as well as reusability. Many new synthetic strategies and techniques have been developed for the fabrication of NiCo2O4-based non-enzymatic biosensors, but they are rarely summarized. Hence, it is an appropriate time to go through the periodical progress of NiCo2O4-based non-enzymatic biosensors. This review covers the crystal structure of the spinel NiCo2O4, various synthetic strategies employed for the synthesis of nano-/micro-structured NiCo2O4, electrochemical biosensing toward biomarkers such as glucose, H2O2, and urea, through the fabrication of modified electrodes. Various factors affecting the morphologies and biosensing parameters of the nano-/micro-structured NiCo2O4 are also reviewed.

2 General Biosensing Mechanism

Two types of strategies are generally involved in the electrochemical biosensing of biomarkers, i.e., enzyme based and enzyme-free [61, 62]. An enzymatic biosensor operates on three main components which include sensitive recognition element, signal transducer element, and data evaluation component [63,64,65,66]. Enzymes, antibodies, and nucleic acid are generally used as recognition components. Glucose oxidase and glucose dehydrogenase for glucose [67, 68], horseradish peroxidase for H2O2 [69], urease for urea [70], laccase and polyphenol oxidase for rutin [71], tryptophan oxidase for tryptophan [72], etc. act as sensitive recognition elements. The function of the signal transducer is to convert chemical changes into detectable and readable electronic signals which are finally transferred to the data evaluation component. Recent developments in the field of nanotechnology and nanoscience reveal the excellent efficiencies of the nanostructured materials as signal transducers. Biosensors based on nanostructured materials as artificial bioreceptors are used for early detection and diagnosis of diseases through the estimation of the levels of biomarkers [73,74,75]. The signal transducer behavior of the nanomaterials mainly depends upon the electrochemical redox properties, surface-to-volume ratio, crystal structure and phase, morphology, and the presence of some other conducting matrices along with the nanostructured materials [76,77,78]. In contrast, in enzyme-free biosensors, nanostructured materials are used as signal transducers as well as sensitive recognition elements.

Electrochemical biosensors are mainly based on the output electrical signals changes incurred from either the oxidation or the reduction of the target bioanalyte on the surface of the transducer (Fig. 2) [79,80,81]. These redox reactions are catalyzed by signal transducer enzymes and nanostructured materials in enzyme-based and enzyme-free biosensors, respectively. The strength of the electrical signals is significantly affected by the concentrations of target bioanalytes, temperature, pH, and the presence of the interfering species [82,83,84,85].

3 Synthesis of Nano-/Micro-Structured NiCo2O4

3.1 Hydrothermal/Solvothermal Method

Hydrothermal synthesis involves heterogeneous reactions in an aqueous medium within a temperature range of 100–200 °C and high pressure. To achieve these conditions, the reaction is usually carried out in Teflon-lined sealed steel autoclaves. Alkali metal hydroxide or NH3 is added to convert the precursor metal salts into their respective hydroxides at basic pH conditions [86, 87]. An initial nucleation phase is followed by the directed crystal growth along appropriate crystal planes. The morphology, surface, and the structural features of the materials synthesized through hydrothermal method depend upon the conditions like temperature, pH of the solution, concentration of the precursor, nature of the solvent, and the presence of the templates [88]. NiCo2O4 nano-/microstructures of various shapes and morphologies have been prepared hydrothermally. Nano-/micro-structured NiCo2O4 of morphologies such as urchin shaped [89], coral-like [90], core–ring-structured nanoplatelets [91], porous coral-like nanospheres [36], hollow nanospheres [92], nanospheres [93], urchin-like spheres [94], mesoporous nanoparticles [95], mesoporous nanoneedles [96, 97], 3D network-like mesoporous nanostructures [98], 3D hierarchical tremella-like, flower-like, urchin-like and pine needle-like [99], nanoflakes [100], nanowalls [101], etc. are reported.

Ni and Co precursor salt solutions with molar atomic ratio of 1:2 are taken during hydrothermal growth since Ni and Co atoms are present in the 1:2 atomic ratio. Liu et al. [94] used 1 mmol Ni(NO3)2·6H2O and 2 mmol Co(NO3)2·6H2O solution to prepare urchin-like NiCo2O4 spheres. Yang et al. [102] mixed 1 mmol of Ni(CH3COO)2·4H2O and 2 mmol of Co(CH3COO)2·4H2O for the preparation of NiCo2O4 nanospheres. Yu et al. [96] used 0.5 mmol Ni(NO3)2·6H2O, 1 mmol Co(NO3)2·6H2O for the synthesis of NiCo2O4 mesoporous nanoneedles. Zhu et al. [98] mixed 0.225 mmol of Ni(CH3COO)2·4H2O and 0.45 mmol of Co(CH3COO)2·4H2O for the synthesis of 3-D network-like mesoporous nanostructures. For the initial formation of binary metal hydroxides or metal carbonate hydroxides, reagents like NH3, urea, NaOH, NH4HCO3, NH4F, hexamethylenetetramine (HMTA) [103], diethylene glycol (DEG), cetyltrimethylammonium bromide (CTAB) [104], sodium dodecyl sulfate (SDS) [105], poly(diallyldimethylammonium chloride) (PDDA) [106], glycine [107], methyl glycerate [108], and ethylene glycol are added in the reaction mixture. The combination of some polar solvents such as ethanol, ethanol, propanol, ethylene glycol, and acetone along with water has also been found to facilitate the morphological characteristics [109]. Water:polar solvent ratio also significantly affects the growth mechanism. In Fig. 3a–d, different morphologies for the NiCo2O4 nanostructures are shown for water:ethanol ratios 1:0, 3:1, 1:1, and 1:3. More porous, denser, and thinner sheets were formed for the synthesized 3D flower-like NiCo2O4 nanostructures as the composition of ethanol was increased.

Reproduced with permission from Ref. [109]. Copyright © 2017 Elsevier B.V.

FESEM image of NiCo2O4 samples using water: ethanol ratios a 1:0, b 3:1, c 1:1, and d 1:3.

In the hydrothermal growth, the temperature is also a key factor in controlling the morphology of the nanostructures. Urchin- and sheaf-like NiCo2O4 nanostructures were synthesized by Umeshbabu et al. [104] using CTAB as a surfactant under hydrothermal conditions at 120 °C and 200 °C temperatures, respectively. Different morphologies were attributed to different degrees of crystal splitting and anisotropic crystal growth at different growth temperatures [110]. Further, the temperature also affects the magnitude of the van der Waals forces, hydrogen bonding, hydrophobic attraction, crystal field attraction, and intrinsic crystal contraction which subsequently control the Ostwald ripening process [111, 112].

Nayak et al. [89] mixed Ni(NO3)2·6H2O and Co(NO3)2·6H2O salts in a 1:2 atomic ratio along with urea which produced OH− ions in the reaction mixture according to Eqs. 1–3.

Ni2+ and Co2+ on reaction with these OH− ions formed Ni–Co bimetallic hydroxide [NiCo2(OH)6] which were finally converted into NiCo2O4 nanoneedles after crystal growth and calcinations. However, according to some reports, in the presence of urea, metal carbonate hydroxides are initially formed instead of bimetallic hydroxides (Eqs. 4–7) [113].

Even ethanol as the solvent can also initiate the formation of metal carbonate hydroxides. Two-dimensional porous NiCo2O4 nanodisks were synthesized by a low-temperature hydrothermal method by Jain et al. [114] (Eqs. 8, 9). Figure 4 proposes the initial formation of Ni2(CO3)(OH)2 and Co2(CO3)(OH)2. Subsequent hydrothermal treatment in basic medium followed by calcination at 500 oC formed two-dimensional porous NiCo2O4 nanodisks.

Reproduced with permission from Ref. [114], Copyright © 2018 Elsevier B.V.

Schematic diagram for the synthesis of two-dimensional porous nanodisks of NiCo2O4.

The nature of alkali source, capping agent, and other additives significantly affects the morphology of the NiCo2O4 nanostructures. Wang et al. [99] reported tremella-like NiCo2O4 nanostructures in the presence of HMTA, which transformed into flower-like nanostructures when NH4F was also added along with HMTA. However, when HMTA was replaced with urea, urchin-like and pine needle-like NiCo2O4 nanostructures were formed, respectively, in the absence and presence of NH4F additive [99]. HMTA is hydrolyzed to produce NH3 which finally produces OH− ions as stated earlier in this section (Eq. 10).

It was suggested that the F− ions released from NH4F stimulate the initially formed nanosheets and nanoneedles to produce more active sites to further activate nucleation, more mass loading of active material per unit area, firm binding between the active material, and hence more crystal growth [115,116,117]. The possible set of reactions elaborating the role of F− ions released from NH4F is shown as follows [118] (Eqs. 11–13).

Further, different concentrations of the NH4F also stimulated the initially formed nanostructures to acquire more versatile morphologies. For 3, 9, and 12 mmol concentrations of NH4F, various morphologies of the NiCo2O4 nanostructures are shown in Fig. 5. With an increase in concentration from 3 to 9 mmol, aggregation of the neighboring nanosheets occured. Further increase in concentration to 12 mmol, rhombus-shaped architectures were formed [117].

Reproduced with permission from Ref. [117]. Copyright © 2014 Elsevier Ltd.

FESEM images representing the effect of concentration of NH4F on the morphologies of NiCo2O4 nanostructures: a–c 3 mmol NH4F; d–f 9 mmol NH4F; g–i 12 mmol NH4F.

Deng et al. [119] prepared novel urchin-like peapoded NiCo2O4@C nanostructures as a bifunctional catalyst for the water-splitting reaction. A three-phase process was proposed which included the initial hydrothermal synthesis of nanoneedles self-assembled microsphere followed by coating with polymerized glucose as green carbon source onto NiCo2O4 microsphere. The final stage was the calcination of the coated NiCo2O4 microsphere under N2 atmosphere to give urchin-like peapoded NiCo2O4@C. The fabrication process of urchin-like peapoded NiCo2O4@C is pictorially demonstrated in Fig. 6.

Reproduced with permission from Ref. [119], Copyright © 2017 Elsevier B.V.

Schematic diagram of the process of urchin-like peapoded NiCo2O4@C.

Still another way of engineering the morphology, porosity, and growth of the crystals along the particular oriented crystal planes of the nanomaterials, is the use of non-aqueous solvents. The modified method is named as solvothermal instead of hydrothermal. Solvents with different solubilities and polarities can significantly affect the degree of supersaturation, the diffusion rates of the chemical species to the surface of the growing crystals, the interfacial surface energy, etc. [120, 121]. Fu et al. [122] synthesized 1D porous NiCo2O4 microrods (using metal acetate salts) (Fig. 7a) and microspheres (using metal nitrate salts) (Fig. 7b) in aqueous and isopropanol media, respectively, under similar conditions of temperature and reaction time. In 1:1 ethanol:water medium, spindle-like hierarchical architectures composed of closely packed microplates aligned along one direction with sizes of 3–5 μm were formed (Fig. 7c). In pure ethanol microspheres composed of nanosheets, interweave together with an average diameter of 8 μm were formed (Fig. 7d). However, in diethylene glycol, irregular aggregates with sheet-like structures were synthesized (Fig. 7e).

Reproduced with permission from Ref. [122]. Copyright © 2017 American Chemical Society

FESEM images of NiCo2O4 architectures prepared solvothermally using different solvents a water, b isopropanol, c 1:1 ethanol: water, d pure ethanol, and e diethylene glycol.

Wang et al. [123] in an interesting stepwise hydrothermal growth synthesized layers of NiCo2O4 nanosheets on the surface of NiCo2O4 nanocones precursor to give highly ordered 3D hierarchical NiCo2O4@NiCo2O4 core–shell nanocone arrays on nickel foams (Fig. 8). Different morphologies were engineered by controlling the reaction time and the temperature during stepwise hydrothermal growth. Further, NiCo2O4 nanocones arrays on Ni foam were synthesized in the absence of HMTA while the NiCo2O4 nanosheets growth on NiCo2O4 nanocones was guided by the presence of HMTA.

Reproduced with permission from Ref. [123], Copyright © 2018 Elsevier B.V.

Schematic illustration for the formation of highly ordered 3D hierarchical NiCo2O4@NiCo2O4 core–shell nanocones arrays on nickel foams.

3.2 Templated Solution Growth Method

The morphology, size, shape, and surface area of nanostructures can be designed through template-based synthesis to produce nanostructures with controlled physical, chemical, electrical, and electronic properties essential in notable applications and are also quite different from those of the bulk materials. Generally, three stages, viz., template preparation, directed synthesis of the desired material using the template, and the template removal, are described in the overall growth process of nanostructures [124]. The chemical nature, structure, concentration, and growth temperature are some of the important environmental factors affecting the growth of nanomaterials. Template-based methodologies are reported in the literature which govern the synthesis of NiCo2O4 nanomaterials with versatile morphologies including nanospheres, hollow spheres, nanocages, hollow submicron spheres, hollow irregular octahedra-like cages, flower-like nanostructure, microspheres with highly ordered mesoporous structures, nanowires, etc. With the development of new methods for synthesizing mesoporous binary NiCo2O4 metal oxides, the combination of template method with other methods such as hydrothermal/solvothermal, sol–gel has been widely used. In one such study, Ren et al. [125] prepared mesoporous NiCo2O4 microspheres using a mesoporous silica (KIT-6) template. The KIT-6 template was added into the metal nitrate precursor solution prepared in ethanol. The schematic illustration of the formation of mesoporous NiCo2O4 microspheres is shown in Fig. 9a. The high porosity of the synthesized mesospheres was ascertained by FESEM and TEM images (Fig. 9b, c). The template was finally removed by etching with 2 M NaOH solution [125].

Reproduced with permission from Ref. [125]. Copyright © Authors

a Schematic illustration of the formation of mesoporous NiCo2O4 microspheres, b high-magnification FESEM image, and c TEM image of the mesoporous NiCo2O4 microspheres.

Yuan et al. [126] utilized silica spheres as hard templates prepared by the modified Stöber method [127], for the synthesis of hierarchical mesoporous hollow NiCo2O4 submicron spheres with uniform size and mesoporous textual property. These submicron spheres were composed of ultrathin nanosheets with a thickness of a few nanometers. The NaOH solution was used for the in situ removal of silica spheres. Dopamine—a biomolecule containing amine functional groups is capable of self-polymerize under alkaline conditions. It forms a layer of the polydopamine which attracts various metal ions including Co2+ and Ni2+ cations due to strong electrostatic interactions. Further, the alkalinity of the medium results in the formation of –OH–Ni–OH–Co–OH– complex networks. This property has been explored for the synthesis of NiCo2O4 nanostructures by Veeramani et al. [128]. FESEM images shown in Fig. 10 are demonstrating the effect of dopamine on the morphology of the NiCo2O4 nanostructures. Flower-like dopamine derived NiCo2O4 nanostructures were formed.

Reproduced with permission from Ref. [128], Copyright © 2016 American Chemical Society

Schematic illustration of the synthesis of dopamine-free and dopamine-NiCo2O4 nanostructures.

In another significant strategy, Xiong et al. [129] used mollusk shell-based macroporous carbon material (MSBPC), as a template to grow NiCo2O4 nanowires hydrothermally (Fig. 11a, b). The MSBPC was obtained from mollusc shells by removing calcium carbonate crystal and other biomacromolecules by acid treatment and carbonization. It was observed that there was uniform and dense growth of the NiCo2O4 nanowires on the inner walls of MSBPC channels. The average length of the NiCo2O4 nanowires was about 1.5 µm. Li et al. [130] reported the synthesis of composite C@NiCo2O4 hollow microspheres via a two-step strategy of hard template-induced hydrothermal synthesis followed by calcination. SiO2@RF (resorcinol–formaldehyde resin, RF) sphere was used as a hard template, whereas HMTA was used as precipitant. The template SiO2@RF was synthesized via a one-pot sol–gel process under alkaline condition using an alcohol–water mixed solvent [131]. The SiO2 core was removed by treating the prepared material with 2 M NaOH at room temperature for 12 h. The SiO2@RF template was having a core–shell structure with an average diameter of 350 nm (Fig. 11c). The NiCo2O4 nanoflakes were grown and assembled on the carbon surface of the SiO2@RF spheres (Fig. 11d). Recently, novel micron-sized NiCo2O4 pompon was prepared by templated growth using polyvinylpyrrolidone (PVP) non-ionic polymer and cationic surfactant CTAB as co-template [132]. Columbic and coordinative forces between template, co-template, and the metal ions help to form a stable “hairball” structure which finally was converted into a micron-sized pompon-like product on annealing (Fig. 11e). In contrast, in the absence of co-template CTAB, mesoporous NiCo2O4 hollow submicron spheres with a uniform diameter of 400–500 nm were obtained through a soft template method assisted by PVP (Fig. 11f). Further, in the absence of even PVP, solid submicron spheres were obtained [133].

FESEM images of a MSBPC, b NiCo2O4 nanowires grown on MSBPC. Reproduced with permission from Ref. [129]. Copyright © 2014 American Chemical Society. c TEM image of SiO2@RF spheres, d TEM image of NiCo2O4 nanoflakes grown on SiO2@RF spheres. Reproduced with permission from Ref. [130]. Copyright © 2018 Elsevier B.V. e FESEM image of micron-sized NiCo2O4 pompon. Reproduced with permission from Ref. [132]. Copyright © 2019 Elsevier B.V. f FESEM image of NiCo2O4 hollow submicron spheres. Reproduced with permission from Ref. [133]. Copyright © 2015 Elsevier B.V.

Qi et al. [131] also used RF microspheres as templates for the synthesis of NiCo2O4 hollow microspheres with tunable shell numbers and shell thickness. The shell numbers were controlled by adjusting the solvent ratio (DI water: ethylene glycol) and heating ramp rate, whereas the shell thickness and porosity were controlled by adjusting the metal ion concentrations (Fig. 12). For total molar concentrations of Ni2+ and Co2+ of 0.05 and 0.1 M, thin and thick shells, respectively, were formed. NiCo2O4 hollow microspheres with double and triple shells were formed at a heating ramp rate of 2 and 5 °C min−1, respectively, in EG as a solvent. With the increase in the ramp rate, the increased temperature gradient of the infused RF microspheres along the radial direction favors the separation of adjacent NiCo2O4 layers and the infused RF cores, thereby transforming double shell to triple shells [134]. Furthermore, EG prevents the formation of the metal aqua ions, and thus, the penetration of the metal ions into RF microspheres is accelerated which is essential for the formation of multi-shell NiCo2O4 hollow microspheres [135, 136]. Additionally, the final calcination process also results in some adhesion force in the outward direction and the contraction force by decomposition of the inner core which segregates the outer NiCo2O4 shell and the inner infused RF [131].

Reproduced with permission from Ref. [131]. Copyright © 2016 Elsevier B.V.

Pictorial representation for the formation of NiCo2O4 hollow microspheres with tunable numbers and shell thickness.

In addition to templates of organic origin, inorganic metal oxides have also been reported as template materials for the synthesis of NiCo2O4 nano-/microarchitectures [137]. Lv et al. [138] synthesized hollow NiCo2O4 octahedral nanocages via a Cu2O-templated strategy in combination with a coordination reaction. Uniform Cu2O octahedral crystals were prepared by reducing a copper-citrate complex solution with ascorbic acid in the presence of PVP. Initially, amorphous (NiCox)O(OH) was deposited onto the Cu2O octahedral crystals through a precipitation method. Cu2O octahedral crystals were etched according to a “coordinating etching and precipitating” (CEP) using Na2S2O3 as coordinating etchant [139] (Eqs. 14, 15). After that, the product was annealed at 400 °C for 2 h to get the hollow NiCo2O4 nanocages. In a similar study, Huang et al. [140] reported the synthesis of highly porous NiCo2O4 hollow nanospheres through a polycrystalline Cu2O-templated route based on “coordinating etching and precipitating” process. The excellent electron transfer capability, large specific surface area, and intrinsic redox couples of Ni2+/Ni3+ and Co2+/Co3+ ions, and superior electrocatalytic activity of NiCo2O4 hollow nanospheres were explored for glucose sensing by cyclic voltammetry and electrochemical impedance spectroscopy. NiCo2O4 hollow nanosphere-modified glassy carbon electrode (GCE) exhibited a high sensitivity of 1917 μA mM−1 cm−2, linear dynamic ranges of 0.01–0.30 mM and 0.30–2.24 mM, and very low detection limit of 0.6 μM (S/N = 3). Solid CuO octahedral is also reported as template materials for the synthesis of hollow octahedra-like NiCo2O4 cages. However, CuO templates can be simply removed by dissolving with a diluted NH4OH solution [141].

Yang et al. [142] reported NiCo2O4 hollow nanorods prepared by the sacrificial template-accelerated acid hydrolysis of ZnO (Eq. 16).

3.3 Sol–gel Method

The sol–gel process represents the chemical conversion of the liquid “sol” to the network “gel” phase, subsequently post-treatment into solid metal oxides with microcrystalline ultrafine particles. It is superior to other methods because it can better control the texture and surface properties of synthesized nanomaterials. The sol–gel method for the synthesis of nanomaterials is affected by numerous factors including pH, temperature, nature of solvent, growth time, agitations time, presence of capping agents, template, etc. With the consideration of these factors and potential applications, many protocols have been used to design materials of different sizes and features, including nano-, micro-, meso-, and macro-materials. To get excellent porosity and conductivity for potential electrochemical applications, the addition of polymers stuffs such as PVP [143], organic solvents/additives like propionic acid [144], citric acid [145, 146], N,N-dimethylformamide (DMF) [147], and epoxides like propylene oxide [148, 149], during the post-annealing process is suggested. Significantly the additive/metal ion molar ratio is very important in controlling the pore size and pore volume. Traditional use of SiO2 is avoided as its addition decreases the conductivity and limits the connection of the film with conducting substrate in thin film forms of NiCo2O4 [143]. In a typical sol–gel method, the NiCo2O4 spinel oxide was prepared by mixing appropriate amounts of metal salt precursors along with citric acid. The resulting solution was magnetically stirred at 80 °C for 2 h to get a gelatinous matrix. Finally, the matrix was calcined at 550 °C for 5 h to get the desired product [146]. Citric acid was also used as a chelating ligand for the synthesis of highly porous coral-like crystalline NiCo2O4 nanoparticles with submicron sizes via a facile sol–gel method in H2O-DMF mixture as solvent [147]. Liu et al. prepared nanoporous NiCo2O4 thin films deposited on ITO glass. The precursor solutions for NiCo2O4 nanospheres were prepared via a sol–gel method in glacial acetic acid and ethanol as solvents, and ethylene glycol and CTAB were used as a viscosity modifier template, respectively [150]. Thus, the sol–gel process is a proven and important method for preparing NiCo2O4 nanoparticles.

3.4 Co-precipitation Method

Better stoichiometric control and high purity of the metal oxide nanomaterials can be easily achieved through the coprecipitation method which involves simultaneous precipitation from a homogeneous solution of two or more cations. Simultaneous occurrence of nucleation, growth, coarsening, Ostwald ripening, and aggregation dramatically affect the size, morphology, and properties of the metal oxide nanoparticles. The technique has been applied for the synthesis of NiCo2O4 nanomaterials. NiCo2O4 hexagonal nanostructures were prepared by Bhagwan et al. [151] using Ni and Co chlorides and 6 M KOH as the precipitating agent. The schematic illustration for the formation of NiCo2O4 hexagonal is shown in Fig. 13a. It was suggested that the strong alkaline environment in the growth solution caused nickel and cobalt ions to precipitate and nucleate together, forming nickel–cobalt hydroxide which was subsequently converted into NiCo2O4 hexagonal after calcination at 300 °C. Liang et al. [152] reported hierarchical NiCo2O4 nanosheets@halloysite nanotubes (Fig. 13b). The initial formation of NiCo precursor@halloysite nanotubes was assisted by HMTA and dehydrated citric acid trisodium salt.

a Schematic representation for the synthesis of hexagonal NiCo2O4 nanosheets, Reproduced with permission from Ref. [151]. Copyright © 2019 Elsevier Ltd. and b hierarchical NiCo2O4 nanosheets@halloysite nanotubes via co-precipitation method. Reproduced with permission from Ref. [152]. Copyright © 2014 American Chemical Society

A stepwise co-precipitation template free method was designed by Chen et al. [153] for the synthesis of hierarchical urchin-like NiCo2O4 hollow nanospheres. Urea-assisted mesoporous urchin-like NiCo2O4 nanostructures were prepared by Jadhav et al. [154] by an easy, viable, and cost-effective co-precipitation method. Yu et al. [155] explored the structure-stabilizing properties of PVP, which can bind the metal ions through electrostatic interaction with the –N and/or C=O functional groups, for the formation of Ni–Co precursor particles with tetragonal prism-like shapes by a modified coprecipitation method. The yolk–shell Ni–Co oxide nanoprisms with a highly porous interior core structure consisting of numerous polycrystalline primary particles were obtained finally after annealing. Other stabilizing and precipitating agents like ethylene glycol (EG) [156], urea [157], NaOH, NH4OH, NH4HCO3, H2C2O4 [158, 159] and NaHCO3 [153] are reported in the literature. Organic stabilizers such as EG are supposed to form a protective layer around the particle surface through interactions with hydroxyl groups preventing the aggregation. Moreover, EG also acts as a bidentate chelating ligand for solvated metal ions [160]. Another important factor that controls the morphology, shape, and size of the nanoparticles is the pH of the reaction medium during coprecipitation. Wan et al. [159] observed the change in morphology of the NiCo2O4 precursors from the cubic to the fibrous along the axial direction. The fibrous morphology was maintained at a still higher pH value of 8.4; however, the aspect ratio was increased (Fig. 14a–d). A dynamic equilibrium was suggested to exist between metal ammoniated complexes and the coprecipitation of Ni2+ and Co2+ as their oxalates.

Reproduced with permission from Ref. [159]. Copyright © 2018 Elsevier Ltd.

FESEM images NiCo2O4 precursor powders prepared at a pH = 3, b pH = 7, c pH = 8 and d pH = 8.4.

The post-annealing temperature is also an important factor for controlling the morphology of the NiCo2O4 spinel structures. The homogeneous dark blue-colored suspension which was obtained by mixing the metal nitrates and NaOH solution was initially evaporated under rotation and reduced pressure conditions by a cost-effective rotary evaporation method. Hexagonal column-like mesoporous loose architectures and hexagonal dense blocks were obtained at 200 and 400 °C calcination temperatures, respectively (Fig. 15) [161].

Reproduced with permission from Ref. [161]. Copyright © 2018 Elsevier Ltd and Techna Group S.r.l.

Schematic illustration of the synthesis of hexagonal mesoporous structured NiCo2O4 (HMS-NCO) and NiCo2O4 calcined at 400 °C (NCO-400).

3.5 Electro-Deposition

Electro-deposition is considered a very useful, versatile, and flexible tool for the deposition of dendritic hierarchical structures, thin and thick films, nanosheet, nanofoil, nanotubes, nanowires, and many well-ordered transition metal oxides on conducting surfaces. Potentiostatic, galvanostatic, and pulse plating are the three main techniques employed for electro-deposition [162, 163]. The basic principle of electro-deposition involves three steps, viz. preparation of a metal ions precursor solution, co-electro-deposition, and final thermal decomposition [164]. Recently, this technique has also been used for the preparation of NiCo2O4 spinel structures for various applications, including supercapacitors, anode materials for Li-ion batteries, gas sensors, biosensors, etc. Wu et al. [165] deposited nanostructured cauliflower-like NiCo2O4 film through galvanostatic electro-deposition combined with annealing treatment (Fig. 16). Galvanostatic electro-deposition was performed using a three-electrode compartment comprising a stainless steel disk as a working electrode. An Ag/AgCl saturated with KCl and a platinum plate were used as the reference and counter electrodes, respectively. Hydroxide-SiO2 template transformed nanoflakes to cauliflower-like NiCo2O4 nanoparticles. Under cathodic potential, the generated OH− ions catalyzed the sol–gel process for the formation of SiO2. The generated OH− ions facilitated the formation of Ni(OH)2 and Co(OH)2. Heat treatment of the deposited at 250 °C in air for 2 h converts the metal hydroxides into NiCo2O4 films.

Reproduced with permission from Ref. [165]. Copyright © 2017 Hydrogen Energy Publications LLC. Published by Elsevier Ltd

Schematic illustration of the formation of cauliflower-like NiCo2O4 film.

Wang et al. [166] reported the electro-deposition of the nickel/cobalt/zinc ternary alloy layer on ultrafine nickel wire. Removal of the zinc by dealloying with NaOH solution followed by oxidation at the atmospheric environment resulted in mesoporous NiCo2O4 film on the surface of ultrafine nickel wire. Zhao et al. [167] grew NiCo2O4 nanosheet networks on carbon cloth through a simple cathodic electro-deposition process followed by post-annealing at 300 °C in an air atmosphere for 120 min. The average mass loadings for NiCo2O4 nanosheet networks grown on carbon cloth at different electro-deposition times 200, 400, and 600 s were 0.4, 0.6, and 0.9 mg cm−2, respectively. The \({\text{NO}}_{ 3}^{ - }\) ions from the metal salts were reduced to \({\text{NO}}_{ 2}^{ - }\) and \({\text{NH}}_{ 4}^{ + }\) ions at the cathode. This reduction also resulted in the formation of OH− ions which combined with the Ni2+ and Co2+ to form amorphous binary metal hydroxide NiCo2(OH)6 nanosheet networks [168]. Post-annealing transforms the NiCo2(OH)6 into NiCo2O4 nanosheet networks [57, 169] (Eqs. 17–20).

The dissolution of the ions decreases near the electrode due to the formation of the OH− ions and an increase in pH near the electrode is observed. Since the solubility constants of Ni(OH)2 (8.2 × 10−16) and Co(OH)2/3 (2.5 × 10−16) are very low and comparable, their simultaneous precipitations occur which finally gives NiCO2(OH)6 [170, 171]. Ramadoss et al. [169] electrodeposited highly porous and binder-free 3D flower-like NiCo2O4/Ni nanostructures on Ni wire and explored their supercapacitor applications (Fig. 17a). The high porosity of the nanostructures was attributed to the presence of H2 bubbles produced by hydrogen evolution reaction during electro-deposition. Furthermore, H2 bubbles also acted as a template for the construction of a 3D flower-like NiCo2O4/Ni with dendritic walls on the Ni wire. Nanoforest hierarchical composites Co3O4@NiCo2O4 nanowire arrays were synthesized by Zhang et al. [172]. Co3O4 nanowires were initially grown on Ni foam through a facile hydrothermal method. After that, NiCo2O4 was electrochemically deposited in the Co3O4 nanowires to avoid the conventional aggregation (Fig. 17b). Mirzaee et al. [173] proposed a two-step method involving initial electro-deposition followed by thermal treatment at 300 °C with a ramping rate of 1 °C min−1 to form flower-like arrays of NiCo2O4 on electrochemically reduced graphene oxide (ERGO) which itself was deposited on nickel–nickel oxide foam.

a Electrodeposited 3D flower-like NiCo2O4/Ni nanostructures on Ni-wire. Reproduced with permission from Ref. [169], Copyright © 2016 The Royal Society of Chemistry. b Schematic representation of the formation of nanoforest hierarchical composites Co3O4@NiCo2O4 nanowire arrays. Reproduced with permission from Ref. [172]. Copyright © 2013 Elsevier Ltd.

In addition to these, NiCo2O4 architectures of versatile morphologies have been electrochemically deposited on a variety of conducting surfaces. Some of these include honeycomb-shaped NiCo2O4 on carbon cloth [174], ultrathin NiCo2O4 nanosheets on three-dimensional interwoven nitrogen-doped carbon nanotubes [175], ultrathin porous NiCo2O4 nanosheet arrays on flexible carbon fabric, 3D vertically aligned carbon nanotubes/NiCo2O4 core/shell structures [176], hybrid composite Ni(OH)2@NiCo2O4 on carbon fiber paper [177], 3D hierarchical NiCo2O4@MnO2 hybrid nanomaterial on stainless steel mesh [178], freestanding bowl-like NiCo2O4 on carbon fiber paper [179], network-like holey NiCo2O4 nanosheet arrays on Ni foam [180], NiCo2O4@ carbon nanofibers [181], and many more.

3.6 Combustion Method

Combustion synthesis, also referred to as self-propagating high-temperature synthesis is one of the most versatile, convinced, convenient, cost-effective, and fast method for the synthesis of nanomaterials. It involves a thermally induced redox reaction between precursor salt as oxidizers and an organic fuel [182,183,184]. Glucose, fructose, tartaric acid, sucrose, glycine, citric acid, hydrazine, urea, and oxalic acid are generally used as organic fuels. However, if metal oxalate or acetate salts are used, the combustion process can be directly conducted in the absence of fuel [185]. Byproduct gases like CO2, H2O, N2, oxides of N (NOx) and S (SOx), etc. are evolved during the combustion process [186]. The release of these gases promotes the expansion of the product and rapid fall in temperature after the reaction ceases. This provides a solid product with a high degree of porosity and good dispersibility [187]. As compared to solid-state combustion, liquid phase combustion synthesis has proved to be the most suitable one as oxidizers and fuel are well dissolved in aqueous or alcoholic solutions [188]. Ni(NO3)2·6H2O, Co(NO3)2·6H2O (in 1:2 molar ratio) as oxidizers and tartaric acid as fuel were dissolved in acidified 2-methoxy ethanol solution. The resulting solution was combusted at 250 °C for 1 h to prepare NiCo2O4 nanoparticles [189]. Sucrose assisted combustion of the Ni and Co nitrates also resulted in NiCo2O4 nanoparticles when the combustion process was carried out at 350 °C for 6 h [190]. The oxalate precursors were directly decomposed into NiCo2O4 powders by heating in an air ambient atmosphere at 320 °C for 10 h [185]. Citric acid assisted combustion at 400 °C for 4 h resulted in highly porous NiCo2O4 nanomaterials [191]. Urea-assisted combustion was processed at 400 °C for 2 h in ethyl acetate as a solvent [192]. In each case, a viscous gel is obtained initially by heating the reaction solution at low temperature followed by auto-ignition resulting in the formation of highly fluffy mass which is finally calcined at high temperature. Direct calcination of the metal nitrate salts in the presence of alkalis without any fuel has also been reported for the synthesis of the NiCo2O4 nanorods [41].

Though it is a fast and low-cost method for the synthesis of NiCo2O4 powders, it suffers from some major drawbacks including less control over morphological uniformity and particle size, the simultaneous formation of a variety of crystal phases, the formation of highly agglomerated structures, complex and uncertain growth mechanism, and critically very low possibilities of formation of a versatile and wide range of morphological structures as those of in hydrothermal and other solution methods.

3.7 Electro-Spinning Method

Many electrospun carbonaceous materials such as carbon nanofibers, single-walled carbon nanotubes, multi-walled carbon nanotubes, etc. prepared from oxidation and carbonization of polymers like PVP, PAN, PVA have been used as templates for the growth and deposition of NiCo2O4 nanostructures with versatile morphologies. In one synthetic way, there is simultaneous growth of NiCo2O4 nanostructures and electro-spinning of template material [193, 194]. In another strategy, NiCo2O4 nanostructures are grown through other synthetic methods like hydrothermal, sol–gel, coprecipitation, etc. on pre-electrospun carbonaceous templates [39]. Electro-spinning setup comprises a high-voltage system, spinneret, and collector which results in the formation of continuous nanofibers with diameters ranging from nanometer to micrometer [195,196,197]. The deposition of NiCo2O4 nanostructures on these carbonaceous materials not only improves the electrical and electronic properties but also enhances the thermal, mechanical and chemical stabilities which are the important prerequisite characteristics for the biosensing and other applications. The composition of the precursor solution, presence of additives like templates and capping agents, modification in the electro-spinning setup, post-annealing, electrospun voltage are some of the major factors which control the thickness, porosity, and morphology of the deposited NiCo2O4 films. Lai et al. [198] through electro-spinning, co-deposition, redox deposition fabricated NiCo2O4-doped carbon nanofiber@MnO2 nanosheet and nanorod hybrid membranes. Busacca et al. [199] prepared NiCo2O4/carbon nanofibers composites and investigated their oxygen evolution reaction in alkaline electrolyte. Metal acetate salt precursor in a molar ratio 1:2 was mixed in PAN (as carbon source) and DMF. The electrospun layer was thermally oxidized at 270 °C in air for 30 min followed by subsequent carbonization at 900 °C for 1 h under a helium gas flow. Li et al. [193] fabricated porous one-dimensional NiCo2O4 nanostructures via a single-spinneret electro-spinning method. Stoichiometric amounts of Ni and Co nitrates were homogeneously mixed in a solution prepared by dissolving PVP in ethanol and N,N-dimethylformamide. Metallic precursor concentration: PVP (M: PVP) ratio was significant in determining the morphologies of the electrospun one-dimensional NiCo2O4 nanostructures. For 0.44:1, 0.61:1, and 0.87:1 M: PVP ratios, NiCo2O4 nanofibers, nanotubes, and nanobelts were formed. The versatility in morphologies was attributed to the fast water evaporation and burning off of PVP during annealing. Guan et al. [194] synthesized spinel NiCo2O4 nanofibers with diameters of 50–100 nm through electro-spinning of the PVA/cobalt acetate/nickel acetate composite precursor followed by annealing at high temperatures ranging from 400 to 800 °C. Liu et al. [39] demonstrated the surfactant-assisted hydrothermal uniform growth NiCo2O4 nanoneedle on electrospun carbon nanofiber (ECF) and explored their glucose sensing properties non-enzymatically. ECF film was prepared through initial electro-spinning and subsequent oxidation and carbonization of PAN (Fig. 18a–c). Xu et al. [200] instead of PAN used PVP as a carbon source to produce NiCo2O4 nanotubes. These nanotubes were used as scaffolds for hydrothermal growth of MnO2 nanosheets for the additional improvement in electronic conductivity and electrochemical activity for supercapacitor applications (Fig. 18d–f). Copolymers like poly (acrylonitrile-co-methylhydrogen itaconate) [201] and biobased polymer composites such as PAN/lignin [202] are also reported in the literature for the formation of flexible carbon nanofibers. The hollow carbon nanofibers were used as a template for the hydrothermal growth of NiCo2O4 with uniform dandelion-like morphology consisting of densely grown nanoneedle (Fig. 18g, h) [203]. The above discussion thus reveals that the proper combination and the composition of the polymers can result in the formation of carbonaceous materials with versatile structural features with high surface area necessary for potential applications.

a Fabrication procedure of NiCo2O4/ECF nanohybrids, b FESEM image of ECF and c FESEM image of NiCo2O4 nanoneedles grown on ECF. Reproduced with permission from Ref. [39]. Copyright © 2017 Elsevier B.V. d The fabrication procedure for NiCo2O4@MnO2 composites, e FESEM image of NiCo2O4 nanotubes and f FESEM image of MnO2 nanosheets grown of NiCo2O4 nanotubes. Reproduced with permission from Ref. [200]. Copyright © 2016 Elsevier B.V. g, h Low- and high-magnification FESEM images, respectively, of NiCo2O4 with uniform dandelion-like morphologies. Reproduced with permission from Ref. [203]. Copyright © 2019 Elsevier Ltd.

3.8 Microwave-Assisted Method

Microwaves are the electromagnetic radiations having a frequency range between 300 MHz and 300 GHz and a wavelength range of 1 m–1 mm. Microwave-assisted synthesis of nano-/microstructures is superior to the conventional methods described above because it requires a very short reaction duration, is energy efficiency, cost-effectiveness, and gives an excellent yield of highly porous materials. Microwaves result in volumetric heating as they can penetrate throughout the volume of reactants [204]. This volumetric heating is caused by various types of polarization in the medium, including electron polarization, atomic polarization, directional polarization, and space charge polarization [205]. To obtain better morphological results, microwave-assisted synthesis of nanomaterials is usually combined with other synthetic methods such as sol–gel, co-precipitation, and hydro/solvothermal, etc. Recently, the improvement in the hydrothermal method in harmony with microwave assistance has been studied to synthesize NiCo2O4 nano-/microstructures. Other ways of engineering the structural aspects of the NiCo2O4 are the use of a template, capping agents, organic solvents, ionic solvents, and addition of other growth additives. The microwave-assisted hydrothermal method was applied by Zhang et al. [206] to prepare NiCo2O4 double-shelled hollow spheres with an outer and inner shell thickness of ~ 20 and ~ 70 nm, respectively. A mixture of isopropanol and glycerol was used to prepare a reaction solution (Fig. 19a). Glycerol molecules were supposed to form a self-assembled quasi-emulsions in isopropanol that serve as a soft template for the growth of Ni–Co double hydroxides. In the absence of glycerol, solid microspheres with diameters of ~ 1 µm were formed, demonstrating the templated role of glycerol in the synthesis of a double-shelled hollow nanostructure (Fig. 19b–d). In the presence of microwaves, the reaction mixture is heated due to dielectric loss, which significantly accelerates the reaction kinetics. Additionally, the presence of microwaves improves uniformity in terms of dispersion and size distributions.

Reproduced with permission from Ref. [206]. Copyright © 2017 Springer Nature

a Pictorial representation of the microwave-assisted hydrothermal synthesis of NiCo2O4 double-shelled hollow spheres. b FESEM and c TEM images of NiCo2O4 hollow spheres prepared in the presence of glycerol and d FESEM image of the NiCo2O4 structures prepared in the absence of glycerol.

Shanmugavani et al. [207] analyzed the effect of reaction times on the morphology of the NiCo2O4/NiO nanocomposites. The reaction was carried out in the presence of oxalic acid at an operating frequency of 2.45 GHz and 800 W output power. It was proposed that the initially formed nanoparticles are converted into bundled-like structures as the reaction time was increased. Recently, Sun et al. [103] reported novel porous nanoscale NiO/NiCo2O4 heterostructure through two-stage calcination of nickel–cobalt bimetallic hydroxide precursors (NiCo precursors) which were initially synthesized using a microwave-assisted hydrothermal method in the presence of HMTA and NH4F. Notably, F− ions were supposed to act as functional template agents. Prolonged irradiation significantly affects the morphology of NiCo2O4 materials. When the irradiation time was increased from 5 to 40 min, the incompletely self-assembled and non-uniform 2D nanosheets are converted into more optimized and thickened 3D frameworks with large open spaces (Fig. 20a–i).

Reproduced with permission from Ref. [103]. Copyright © 2019 Elsevier Inc.

FESEM images of bimetal Ni-Co-precursors obtained under various microwave-assisted hydrothermal reaction times. a 5 min, b, c 10 min, d 15 min, e 20 min, f 25 min, g 30 min, h 35 min, and i 40 min.

Nakate et al. [208] prepared nanocrystalline NiCo2O4 nanoplates in the surfactant-free environment using metal chloride salts precursors through microwave irradiation. Gu et al. [209] reported 3D nanosphere-like NiCo2O4 nanostructure composed of intertwined 2D ultrathin mesoporous nanosheets having large specific surface area 146.5 m2 g−1. The reaction solution was exposed to microwaves (power 560 W) for 6 min. Su et al. [210] reported highly crystalline NiCo2O4 supported on carbon black via a simple, one step intermittent microwave heating method avoiding the calcination process. However, in a contrary study, Tao et al. [211] analyzed the effect of post-annealing temperature on the morphologies of the NiCo2O4. Ni–Co double hydroxide was initially prepared through a microwave-assisted method using a tertbutanol solution (98%). Flower-shaped morphology of the Ni–Co double hydroxide was completely converted into unique coral-like morphology on calcination. As the post-annealing temperature was increased from 400 to 700 °C, individual ultrathin nanosheets shrink to smaller nano-sized crystal grains which finally self-assembled to form coral-like NiCo2O4 architectures.

For greener perspectives, ionic solvents like [1-butyl-3-methylimidazolium][BF4] {[Bmim][BF4]}, [Bmim]FeCl4, [Bmim]Cl [212], and non-ionic glucose-based polymeric surfactant, β-C10Alkyl Poly Glucoside [213] are also reported in the literature for the synthesis of NiCo2O4 architectures with versatile morphologies.

3.9 Spray Pyrolysis Method

In spray pyrolysis technique, an aerosol of various precursor components is prepared in suitable solvent and is sprayed on the substrate. After that, sequential evaporation of the solvent from the surface of the substrate, heating to precipitate out the solute, high-temperature annealing, formation of microporous particles, and finally, sintering of solid particles is carried out [214]. NiCo2O4 nanostructures with morphologies hollow nanosphere [215], hollow microspheres [216], dried plum-like particles [217], yolk–shell microspheres [218], nanoaggregates [219], thin films with uniform particle distribution size 20–30 nm [220], etc. are reported (Fig. 21a–e).

Morphologies of various NiCo2O4 nanostructures a hollow nanosphere. Reproduced with permission from Ref. [215]. Copyright © 2017 The Korean Society of Industrial and Engineering Chemistry, Published by Elsevier B.V. b hollow microspheres. Reproduced with permission from Ref. [216]. Copyright © 2019 Elsevier Ltd and Techna Group S.r.l. c yolk–shell microspheres. Reproduced with permission from Ref. [218]. Copyright © 2017 Elsevier Ltd. d nanoaggregates. Reproduced with permission from Ref. [219]. Copyright © 2015 Elsevier Inc. and e thin films with uniform particle distribution size 20–30 nm. Reproduced with permission from Ref. [220]. Copyright © 2016 Elsevier Ltd.

Similar to the electro-spinning method, carbonaceous materials such as reduced graphene oxide, carbon nanotubes, carbon nanofibers are also mixed in the precursor solution to improve the electrochemical properties of NiCo2O4. Park et al. [221] synthesized three-dimensional macroporous multi-walled carbon nanotubes microspheres densely loaded with NiCo2O4 hollow nanospheres via spray pyrolysis process. The schematic illustration depicting the formation mechanism is shown in Fig. 22a. The polystyrene nanobeads added in the solution improved the structural uniformity and the dispersion of CNT microspheres. The similarity in the atomic radii of the Ni and Co ions resulted in the Kirkendall diffusion into the outer surface of the where they were oxidized to form NiCo2O4 (Fig. 22b).

Reproduced with permission from Ref. [221]. Copyright © 2017 Elsevier Ltd.

Formation mechanism of 3D macroporous multi-walled carbon nanotubes microspheres densely loaded with NiCo2O4 hollow nanospheres.

4 Biosensor Applications of Nano-/Micro-structured NiCo2O4

4.1 Glucose Biosensors

Non-enzymatic glucose sensing is considered to be a better, fast, and convenient way as compared to the enzymatic method since the later is a complicated and multi-step process involving immobilization of enzyme bioreceptor such as glucose oxidase, glucose dehydrogenase, and quinoprotein glucose dehydrogenase onto the electrode surface [51, 52]. Furthermore, maintaining the enzyme stability under non-physiological conditions of observations is another major issue related to enzymatic glucose biosensing. Most of the biosensing measurements are based on cyclic voltammetry (CV) and amperometric analysis. Better biosensing behavior and electrochemical activity using NiCo2O4 nano-/microstructure-modified electrodes are adjudged by broader redox peaks with larger area coverage in the CV curves. Since the spinel NiCo2O4 comprises binary intrinsic-state redox couples of Ni3+/Ni2+ (0.58 V/0.49 V) and Co3+/Co2+ (0.53 V/0.51 V), only a pair of redox peaks in the CV curves is generally observed due to almost similar redox potential values for NiO and Co3O4 [142, 222, 223]. In alkaline medium, NiCo2O4 is oxidized to Ni and Co perhydroxides which finally convert glucose into gluconolactone (Eqs. 21–26) [224].

Since the rates of oxidation of Ni2+ and Co2+ ions on the electrode surface during anodic scan determine the rate of sensing of glucose, NiCo2O4 nano-/microstructures with versatile morphologies having large specific surface area, permeability, and most importantly short electron and ion diffusion pathways are synthesized. Ni3+ and Co3+ ions are reduced back to Ni2+ and Co2+ ions by the electrons lost by the oxidation of glucose to gluconolactone. According to Hussain et al. [225], H2O2 is formed as one of the products along with gluconolactone if the electrochemical sensing is performed in the presence of oxygen. Glucose undergoes a spontaneous reaction with water and O2 to form gluconolactone which is further oxidized into gluconic acid (Eqs. 27, 28). In a slightly basic medium (pH = 7.4), gluconic acid ionizes to gluconate ions which act as mobile charge carriers on the surface of the NiCo2O4 nanostructures producing a strong electrical signal (Eq. 29). Elakkiya et al. [226] reported highly porous flower-like NiCo2O4 nanostructures synthesized via a facile hydrothermal method for excellent electrocatalytic activity in alkaline electrolyte for the oxidation of glucose and lactic acid.

The binary spinel NiCo2O4 architecture exhibits better intrinsic electronic conductivity as compared to pure NiO and Co3O4 which is attributed to the doping of Ni3+ ions in the octahedral sites of the Co3O4 crystal lattice which accelerates the electron hopping process [227]. Huang et al. [140] compared the electron transfer resistance (Ret) through electrochemical impedance spectroscopy for GCE modified with NiCo2O4, NiO, and Co3O4. Nyquist plots for all the modified GCE consisted of two portions; an inclined line at low frequencies and a semicircular portion at high frequencies. However, the lowest Ret of NiCo2O4/GCE was an indication of the enhanced conductivity for NiCo2O4 (Fig. 23a). Broader redox peaks NiCo2O4/GCE as compared to NiO/GCE and Co3O4/GCE confirmed the better biosensing behavior of the NiCo2O4 as compared to Co3O4 and NiO (Fig. 23b).

Reproduced with permission from Ref. [140]. Copyright © 2016 Elsevier B.V.

a Nyquist plots of NiCo2O4, Co3O4, and NiO-modified GCE in 0.1 M NaOH. b CV curves for NiCo2O4, Co3O4, and NiO-modified GCE in 0.2 M NaOH without glucose.

Spinel NiCo2O4 hollow nanocages were prepared by using Co-based zeolite imidazole frameworks (ZIF-67) as a template and precursor by Feng et al. [228]. Morphological characterization revealed that the thickness of the cage shell was about 30 nm. The outer surface of the nanocages was covered with small nanosheets. A wide linear dynamic range 0.18 μΜ–5.1 mM, high sensitivity 1306 μA mM−1 cm−2, a fast response time of 1 s, and limit of detection 27 nM were observed for NiCo2O4 hollow nanocage-based modified GCE.

NiCo2O4 nanoplates interconnected through MoS2 nanosheets performed excellent electrocatalytic behavior toward glucose. NiCo2O4 nanoplates and MoS2 nanosheets illustrated a significance synergic effect. Though not an active catalyst for the oxidation of glucose, the highly active edge of vein-like MoS2 nanosheets inhibited the agglomeration of NiCo2O4 nanoplates and formed long conducting chains which provide an alternative pathway with lower electrical resistance [229] (Fig. 24a, b). The fabricated glucose biosensor exhibited a high sensitivity of 1748.58 μA mM−1 cm−2 and a very low detection limit of 0.152 μM. MoS2 nanosheets have also been reported as support material for the fabrication of NiCo2O4/MoS2 nanocomposites through a simple ionothermal method in deep eutectic solvent (choline chloride (ChCl)-urea mixture) [230]. Deep eutectic solvents consist of simple eutectic-based ionic liquids prepared by eutectic mixing of ChCl and some hydrogen bond donors like acids, amides, alcohols, etc. [231]. These solvents have excellent thermal stability, high surface tensions, negligible vapor pressure, and most importantly biodegradability [232,233,234,235,236]. The NiCo2O4-MoS2/chitosan/GCE-modified electrode was used as an electrochemical sensor for glucose in red wine and honey [230].

Reproduced with permission from Ref. [229]. Copyright © 2017 Elsevier B.V.

a Electrocatalytic activities of MoS2-NiCo2O4/GCE in 0.1 M NaOH at a scan rate of 50 mV s−1. b Amperometric response curves for MoS2-NiCo2O4/GCE.

Analysis of non-enzymatic glucose sensing properties of NiCo2O4 nanosheets showed linear response with respect to the change in glucose concentration varying from 5 to 65 μM. The high sensitivity of 6.69 μA μM−1 cm−2 with a LOD value of 0.38 μM and liquid of quantification of 1.27 μM was observed. During CV measurements, scan rates increased the oxidation and reduction peak currents as well as peak-to-peak separations [224]. The electrochemical kinetics of the NiCo2O4 hollow nanorods grown on stainless steel via a sacrificial template showed similar trends during glucose sensing in 0.1 M NaOH solution with scan rates ranging from 5 to 100 mV s−1 (Fig. 25a). Amperometric studies revealed a steady-state current optimization within 2 s of glucose addition. Calculated sensitivity, linear detection range, and detection limit were 1685.1 µA mM−1 cm−2, 0.0003–1.0 mM, and 0.16 µM (S/N = 3), respectively (Fig. 25b) [142]. Cui et al. [237] prepared rectangular flake-like mesoporous NiCo2O4 via a facile hydrothermal method and observed glucose biosensing sensitivity of 662.31 µA mM−1 cm−2 and very low detection limit of 0.3 nM at S/N = 3. The other optimized operational parameters were: 0.2 M KOH, + 0.5 V applied potential and 1.0 mg mL−1 loading of meso-NiCo2O4 in the suspensions. Dry rod-like NiCo2O4 synthesized through a facile hydrothermal reaction followed by subsequently microwave treatment. The non-enzymatic glucose sensor fabricated using these rod-like features showed a high sensitivity of 431.29 µA mM−1 cm−2 [238]. The microwave treatment completely removed the water and made the material highly porous for exhibiting excellent biosensing applications. One-dimensional porous NiCo2O4 nanowires array grown on nickel foam (NiCo2O4 NWs/NF) via a facile hydrothermal method exhibit highly efficient glucose sensitivity of 5916 μA mM−1 cm−2, a detection limit of 1 μM–3.987 mM and LOD of 0.94 μM (S/N = 3) [239]. As conducting substrate, nickel foam not only provides the large electrochemically active surface area due to three-dimensional interconnected features, but also directs the growth of one-dimensional NiCo2O4 porous nanowires [240]. Besides, the one-dimensional porous NiCo2O4 nanowires array provided sufficient transport channels for ions and abundant active sites for redox reactions. Carbon cloth has also been used as a potential conducting surface for the growth of porous NiCo2O4 nanowires. As fabricated enzyme-free NiCo2O4 porous nanowire arrays supported on carbon cloth-based electrode for glucose sensing exhibited a linear dynamic range of 1 μM–0.63 mM, the sensitivity of 4.12 mA mM−1 cm−2, and low detection limit of 0.5 μM [241].

Reproduced with permission from Ref. [142]. Copyright © 2015 Elsevier B.V.

a CV curves of NiCo2O4 hollow nanorods with various scan rates. Inset: redox peak currents as a function of the scan rates, b variation in response current for NiO (curve a), Co3O4 (curve b), and NiCo2O4 hollow nanorods (curve c) as a function of glucose concentrations. Inset: calibration curve of NiCo2O4 hollow nanorods.

One of the main disadvantages of using bare NiCo2O4 is its poor electrical conductivity. However, this limitation can be overcome by forming its composite/hybrid materials. It has been reported that the electrical conductivity and hence the electrochemical biosensing performance of NiCo2O4 can be improved by making its composites with conducting carbonaceous materials like graphene, reduced graphene oxide, carbon nanotubes (single and multi-walled), carbon nanofibers; conducting polymers like polypyrrole (PPy), polyaniline (PANI); metal oxides NiO, Co3O4, SnO2, MnO2; and metals like Au, Pd, etc. Among these, the carbonaceous materials are considered to be potential candidates as compared to others due to their excellent electrical conductivities, good mechanical strength, thermal and chemical stabilities, and resistance to oxidation–reduction reactions. Besides, these carbonaceous materials provide a large specific surface area for better adsorption of analytes, which ultimately results in very high sensitivity and very low detection limits.

The two-dimensional one-atom-thick layered structure of graphene has been extensively used for making composites with NiCo2O4 due to its high specific surface area of 2670 m2 g−1 and excellent conductivity [242, 243]. Studies have revealed a higher specific surface area for the NiCo2O4/reduced graphene oxide composites as compared to bare NiCo2O4 nanoparticles (Fig. 26a) [244]. Even the pore width was less in the case of NiCo2O4/reduced graphene oxide composites. Various glucose-sensing scans are given in Fig. 26b–d. The enhanced redox peak current density for NiCo2O4/reduced graphene oxide composites as compared to pure NiCo2O4 was attributed to the lesser extent of aggregation of graphene sheets due to the interception of the NiCo2O4 nanoparticles on graphene surface causing weakening of π–π interaction between individual graphene sheets, faster diffusion rates and electron transfer between the glucose molecules and the electrode surface [245].

Reproduced with permission from Ref. [244]. Copyright © 2016 Elsevier B.V.

a Adsorption–desorption hysteresis loop, specific surface area (SSA), average pore width, and total pore volume of the synthesized pure NiCo2O4 and NiCo2O4/graphene nanohybrids. b CV for NiCo2O4/graphene hybrid-modified electrode. c Effect of scan rates scan rate for the solution with 0.1 mM glucose in 0.1 M NaOH. d Linear sweep voltammetric curves for glucose in the concentration of 0–0.14 mM and calibration plot (Inset).

Ma et al. [246] developed NiCo2O4 nanowrinkles/reduced graphene oxide hybrid-based modified GCE for non-enzymatic glucose detection at the physiological level. As far as the concentration of the glucose is concerned, the oxidation potential of glucose decreased while oxidation peak current increased proportionally to a greater extent for NiCo2O4 nanowrinkles/reduced graphene oxide hybrid-based modified GCE as compared to single component Co3O4, NiO and bare NiCo2O4 at a scan rate of 100 mV s−1 in 0.1 M NaOH (Fig. 27a–d). The results confirmed the crucial role of reduced graphene oxide in improving the electrocatalytic biosensing performance of the NiCo2O4 spinel for different concentrations of glucose.

Reproduced with permission from Ref. [246]. Copyright © 2016 Elsevier Ltd.

CV plots for different glucose concentrations (1–4 mM) in 0.1 M NaOH a Co3O4, b NiO, c NiCo2O4, and d NiCo2O4 nanowrinkles/reduced graphene oxide-modified GCE.

In addition to two-dimensional graphene, Wu et al. [245] reported the synthesis of three-dimensional graphene foam (3DGF) through a chemical vapor deposition technique. The 3DGF provides additional stability and large porous surface as well as high conductivity to the hierarchical NiCo2O4 composites. NiCo2O4 hierarchical nanoneedles were deposited onto the surface of 3DGF via a hydrothermal method. The synergism between hierarchical NiCo2O4 nanoneedles and 3DGF exhibited a high sensitivity of 2524 μA mM−1 cm−2 and a limit of detection 0.38 μM (S/N = 3). Further, as fabricated electrode showed excellent selectivity for glucose even in the presence of interfering compounds like dopamine, ascorbic acid, lactose, d-Fructose, and urea as negligible current responses were observed on their additions as compared to glucose. NiCo2O4 nanospheres/reduced graphene oxide composite prepared by a template-based method using the Cu2O/GO template achieved a high sensitivity of 2082.57 μA mM−1 cm−2, the detection range of 0.04–1.28 mM, and low detection limit of 0.7 μM [137]. Ni et al. [247] reported a reduced graphene oxide supported NiCo2O4 nanorods composite prepared via an ionothermal method using deep eutectic solvents. The modified GCE exhibited superior electrocatalytic biosensing of glucose with a wide double-linear range from 1 μM to 25 mM and a very low detection limit of 0.35 μM (S/N = 3). The presence of a large number of small interconnected nanoparticles on the surface of the NiCo2O4 nanorods provided the dense electrocatalytic active site in coordination with reduced graphene oxide which provided large surface area and excellent electrical conductivity (Fig. 28a).

a Proposed mechanism of glucose sensing using NiCo2O4 nanorods/rGO/Nafion composite-modified GCE. Reproduced with permission from Ref. [247]. Copyright © 2018 Elsevier Ltd. b Schematic presentation of the synthesis of the NHGH/NiCo2O4 electro-catalyst for non-enzymatic glucose sensing, Reproduced with permission from Ref. [38]. Copyright © 2019 Elsevier B.V.

Another way of preventing the aggregation of graphene sheets, which reduces the specific surface area and inhibits the fast mass transfer, is the nitrogen doping. This nitrogen doping is not only supposed to facilitates the charge transfers between adjacent carbon atoms but also suppresses the electrons and holes recombination necessary for better electrical conductivity and electrocatalytic oxidation of glucose [248, 249]. Detailed characterization revealed that in the course of hydrothermal reactions, the graphene was reduced to nitrogen-doped reduced graphene oxide when glycine acted as a source of nitrogen. Further, the nitrogen-doped reduced graphene was self-assembled into hydrogels with interconnected 3D porous network structure resulted from an increased extent of π–π stacking interactions. This 3D form provides a sufficiently large surface area and active sites for the better adsorption of the analyte species. To ascertain this, Lu et al. [38] explored the interactions of flower-like NiCo2O4 and 3D nitrogen-doped holey graphene hydrogel (NHGH)-modified GCE for electrochemical biosensing of glucose (Fig. 28b).

Similar to graphene, carbon nanofibers also possess excellent dimensional, thermal and chemical stability as well as good electrical conductivity. Recently, these fibers have attracted wide attention and have been widely explored in fields such as electrochemical cells, catalysis, adsorption, structure enhancement, biosensors, gas sensors, and nanodevices [250, 251]. Among various synthetic methods, electro-spinning is considered to be the most suitable low-cost and simple method for synthesizing carbon nanofibers [252, 253]. Liu et al. [39] explored the glucose-sensing behavior of NiCo2O4 nanoneedle-decorated electrospun carbon nanofiber nanohybrids. Faster electrocatalytic oxidation of glucose was reported for nanohybrids as compared to bare NiCo2O4 nanoneedle and electrospun carbon nanofiber-modified GCEs. The fact was supported by a large increase in the anode peak current and a positive shift in the anode peak potential.

Novel metals such as Au, Ag, and Pd, have also been used to prepare NiCo2O4 composites to improve the biosensing capabilities. Recently, dealloying has been used as a convenient method for preparing nanoporous metals with a 3D bicontinuous structure, which is characterized by open nanopores with adjustable sizes [254,255,256]. These 3D nanoporous metals act as conductive surfaces for the deposition of biosensors electrocatalytic materials such as NiCo2O4 since they provide high conductivity and large surface area. Disposable needle-type hybrid electrode comprising a stainless steel core modified with a 3D nanoporous Au/NiCo2O4 nanowall hybrid structure-modified electrochemical non-enzymatic glucose sensor showed a linear response of 0.01–21 mM glucose, high sensitivity of 0.3871 μA μM−1 cm−2, detection limit of 1 μM within a response time of < 1 s [257]. Naik et al. [258] compared the bare NiCo2O4/Ni foam, NiCo2O4–Ag/Ni foam and NiCo2O4–Au/Ni foam nanosheets electrodes. The calculated sensitivity for pure NiCo2O4, NiCo2O4–Ag, and NiCo2O4–Au nanosheets electrodes in the linear range 5–45 μM and 45–465 μM were 20.8, 29.86, and 44.86 μA μM−1 cm−2 and 6.2, 11.5, and 13.96 μA μM−1 cm−2, respectively. The respective limits of detection were 9.33, 5.82, and 2.64 μM. DFT studies confirmed strong binding between Au and NiCo2O4 as compared to Ag. Further, the binding energy of glucose was more for the NiCo2O4–Au surface compared to the NiCo2O4–Ag surface. The enhanced density of states near the Fermi level improved the conductivity of the NiCo2O4–Au nanosheet than NiCo2O4–Ag that caused superior glucose sensing performance. In a similar type of report, the sensitivities for pure NiCo2O4 and NiCo2O4–Pd nanosheets electrodes in the linear range 5–90 μM and 70–450 μM were 27.5 and 40.03 μA μM−1 cm−2 and 8.53 and 8.23 μA μM−1 cm−2, respectively [259].

Similar to metals, conducting polymers also possess the electronic, electrical, and optical properties, easy synthesis, excellent mechanical stabilities and most importantly the low toxicity and biodegradability, the issues which are generally associated with metals. Moreover, the noble metals are easily poisoned by some intermediates produced during the oxidation of glucose. Among various conducting polymers, polyaniline and polypyrrole have gained much attention due to their superior thermal and oxidative stabilities [260, 261]. Constructing a core–shell nanostructure comprising conductive polymer coating as the outer walls of metal oxides is the most important strategy for enhancing the conductivities [262]. NiCo2O4@PANI nanoparticles with an average particle size 25 nm shortened the ion transport pathway and the modified GCE exhibited a sensitivity of 4.55 mA mM−1 cm−2, a detection limit of 0.3833 μM and linear dynamic range of 0.0150–4.7350 mM (Fig. 29a, b) [263]. The PANI core–shell provided more effective electrical contact between redox-active centers and the electrolyte resulting in good contact and small diffusion distances for electron transports which subsequently improved the sensor activity. NiCo2O4@Ppy nanowires grown on Ni foam were synthesized via hydrothermal growth and oxidant-induced polymerization process (Fig. 29c–e). The fabricated glucose sensor showed high sensitivity 3059 μA mM−1 cm−2, low detection limit 0.22 μM, and wide linear dynamic range 0.001–20 mM. The excellent electrocatalytic behavior was attributed to the synergism due to bimetallic oxide, the significant role of Ppy in transmitting charges among electrode material due to its excellent conductivity, non-collapsing and non-agglomeration of the NiCo2O4 due to Ppy coating, and absence of any adhesive or conductive agent during electrode fabrication [264].

a HRTEM image of NiCo2O4@PANI nanocomposite and b CV plots for different GCE electrodes in the absence and presence of 4 mM glucose in 0.1 M NaOH solution at scan rate = 50 mV s−1. Reproduced with permission from Ref. [263]. Copyright © 2015 Elsevier B.V. c Schematic illustration of the preparation of core–shell NiCo2O4@Ppy on Ni foam substrate. d FESEM image of bare NiCo2O4. e FESEM image of NiCo2O4@Ppy composite, Reproduced with permission from Ref. [264]. Copyright © 2019 Elsevier B.V.