Abstract

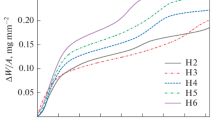

NiTi Shape Memory Alloys (SMAs) orthodontic wires are subject to complex chemical loading in oral cavities. In the worst case, fractures are observed. Hydrogen effects are suspected, by analogy with the hydrogen embrittlement in Ti alloy systems. Several mechanisms have been observed for the case of steels, including hydride formations, hydrogen-enhanced-strain-induced vacancies (HESIV), hydrogen-enhanced-decohesion (HEDE), and hydrogen-enhanced-localized-plasticity (HELP). A degradation of the mechanical properties of NiTi arches appears due to the presence of hydrogen. Hydrogen atoms, which come from the chemical environment of buccal cavity, are supposed to diffuse in the interstitial sites naturally present in the crystallographic structure of NiTi SMAs as the same way than in steels. For instance, the maximum strain decreases, the area of the hysteresis becomes smaller with the increasing of hydrogen concentration in SMA archwires and fatigue life becomes shorter. Accounting for effects of hydrogen diffusion on the NiTi behavior, a coupled chemo-thermomechanical constitutive model needs to be formulated. The work of Lachiguer et al. (in: Smart Mater Struct 25(11):1–11, 2016) proposes material parameter dependencies to the normalized concentration of hydrogen in a NiTi constitutive law. The main limitation of this model is that the hydrogen concentration can only be considered as homogeneous. Nano-indentation tests carried out on NiTi wires charged with hydrogen highlighted an heterogeneous distribution of hardness (which is related to the hydrogen concentration). It becomes then necessary to take into account the gradient of hydrogen distribution. To this end, the weak form of equilibrium equations for each field (thermal, mechanical and chemical) through 2D domain is discretized and numerically solved by finite element method. A special finite element with coupled degrees of freedom (displacements, temperature, and hydrogen concentration) is developed and implemented in the Abaqus finite element software through the UEL subroutine. Numerical tests with complex loadings are carried out. Obtained results are discussed showing the relevance of the adopted approach.

Similar content being viewed by others

References

Miura F, Mogi M, Ohura Y, Hamanaka H (1986) The super-elastic property of the Japanese NiTi alloy wire for use in orthodontics. Am J Orthod Dentofac Orthop 90(1):1–10

Yokoyama K, Hamada K, Moriyama K, Asaoka K (2001) Degradation and fracture of Ni–Ti superelastic wire in an oral cavity. Biomaterials 22(16):2257–2262

Lachiguer A, Bouby C, Gamaoun F, Bouraoui T, Ben Zineb T (2016) Modeling of hydrogen effect on the superelastic behavior of Ni–Ti shape memory alloy wires. Smart Mater Struct 25(11):1–11

Wade N, Adachi Y, Hosoi Y (1990) A role of hydrogen in shape memory effect of Ni–Ti alloys. Scr Metall Mater 24:1051–1055

Yokoyama K, Ogawa T, Asaoka K, Sakai J, Nagumo M (2003) Degradation of tensile strength of Ni–Ti superelastic alloy due to hydrogen absorption in methanol solution containing hydrochloric acid. Mater Sci Eng A 360(1–2):153–159

Yokoyama K, Kaneko K, Moriyama K, Asaoka K, Sakai J, Nagumo M (2004) Delayed fracture of Ni–Ti superelastic alloys in acidic and neutral fluoride solutions. J Biomed Mater Res Part A 69(1):105–113

Sheriff J, Pelton AR, Pruitt LA (2004) Hydrogen effects on NITINOL fatigue. In: Proceedings of the international conference on shape memory and superelastic technologies, pp 111–116

House K, Sernetz F, Dymock D, Sandy JR, Ireland AJ (2008) Corrosion of orthodontic appliances—should we care? Am J Orthod Dentofac Orthop 133(4):584–592

Patoor E, Lagoudas DC, Entchev PB, Brinson LC, Gao X (2006) Shape memory alloys, Part I: general properties and modeling of single crystals. Mech Mater 38(5–6):391–429

Cisse C, Zaki W, Ben Zineb T (2016) A review of constitutive models and modeling techniques for shape memory alloys. Int J Plasticity 76:244–284

Oriani R (1970) The diffusion and trapping of hydrogen steel. Acta Metall 18(1):147–157

Sofronis P, McMeeking RM (1989) Numerical analysis of hydrogen transport near a blunting crack tip. J Mech Phys Solids 37(3):317–350

Koyama M, Tasan CC, Akiyama E, Tsuzaki K, Raabe D (2014) Hydrogenassisted decohesion and localized plasticity in dual-phase steel. Acta Mater 70:174–187

Lufrano J, Sofronis P, Birnbaum HK (1996) Modeling of hydrogen transport and elastically accommodated hydride formation near a crack tip. J Mech Phys Solids 44(2):179–205

Nagumo M, Yagi T, Saitoh H (2000) Deformation-induced defects controlling fracture toughness of steel revealed by tritium desorption behaviors. Acta Mater 48(4):943–951

Troiano AR (2016) The role of hydrogen and other interstitials in the mechanical behavior of metals. Metallogr Microstruct Anal 5(6):557–569

Oriani R (1978) Hydrogen embrittlement of steels. Annu Rev Mater Sci 8:327–357

Hirth JP (1980) Effects of hydrogen on the properties of iron and steel. Metall Trans A 11(6):861–890

Birnbaum HK, Sofronis P (1994) Hydrogen-enhanced localized plasticity—a mechanism for hydrogen-related fracture. Mater Sci Eng 176:191–202

Robertson IM, Birnbaum HK (1986) An HVEM study of hydrogen effects on the deformation and fracture of nickel. Acta Metall 34(3):353–366

Von Pezold J, Lymperakis L, Neugebeauer J (2011) Hydrogen-enhanced local plasticity at dilute bulk H concentrations: the role of H–H interactions and the formation of local hydrides. Acta Mater 59(8):2969–2980

Maxelon M, Pundt A, Pyckhout-Hintzen W, Barker J, Kirchheim R (2001) Interaction of hydrogen and deuterium with dislocations in palladium as observed by small angle neutron scattering. Acta Mater 49(14):2625–2634

Aslan O (2015) Numerical modeling of hydrogen diffusion in metals accounting for large deformations. Int J Hydrogen Energy 40(44):15227–15235

Peultier B, Ben Zineb T, Patoor E (2006) Macroscopic constitutive law of shape memory alloy thermomechanical behaviour. Application to structure computation by FEM. Mech Mater 38(5–6):510–524

Peultier B, Ben Zineb T, Patoor E (2008) A simplified micromechanical constitutive law adapted to the design of shape memory applications by finite element methods. Mater Sci Eng A 481–482:384–388

Chemisky Y, Duval A, Patoor E, Ben Zineb T (2011) Constitutive model for shape memory alloys including phase transformation, martensitic reorientation and twins accommodation. Mech Mater 43(7):361–376

Barrera O, Tarleton E, Tang HW, Cocks AC (2016) Modelling the coupling between hydrogen diffusion and the mechanical behaviour of metals. Comput Mater Sci 122:219–228

Halphen B, Nguyen QS (1974) Plastic and visco-plastic materials with generalized potential. Mech Res Commun 1(1):43–47

Lemaitre J, Chaboche J-L, Benallal A, Desmorat R (2009) Mécanique des matériaux solides, 3rd edn. Dunod, Paris

Cottrell A (1975) An introduction to metallurgy, 2nd edn. Edward Arnold, London

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ulff, N., Bouby, C., Lachiguer, A. et al. Modeling of Hydrogen Effects on the Thermomechanical Behavior of NiTi-Based Shape Memory Alloys. Shap. Mem. Superelasticity 5, 206–217 (2019). https://doi.org/10.1007/s40830-019-00224-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-019-00224-7