Abstract

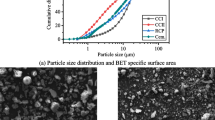

Grouting is a comprehensive technology used in the construction projects due to the rapid development of sub-surface urban infrastructures, the main reasons for grouting soils are strengthened the cohesion-less soils and increasing the shear stress (pure shear) of the grouted soils. Providing high flowability with high viscosity for the cement-based grout in the liquid stage (slurry) and high compressive strength of the cement-based grout in the hardened stage are significant challenges. In this study, the impact of two types of water reducer [polycarboxylate (PCE)] polymer on the rheological properties with the ultimate shear strength and compressive strength of cement-based grout with water-cement ratios (w/c) of 0.6 and 1.0 at two different temperatures 25 °C and 50 °C were studied. XRD and TGA were used to analysis the cement, polymers, and cement modified with polymers. The behavior of cement-based grout in the liquid phase (slurry) and hardened phase modified with different percentages of polymer up to 0.16% (by dry weight of cement) were investigated. The compressive strength of cement-based grout modified with polymer was tested from the young age up to 28 days of curing. Vipulanandan rheological model was used to predict the shear stress-shear strain behavior of cement-based grout slurry and compared to the Herschel–Bulkley (HB) model. The rheological and the compressive strength are increased with increasing the of PCE content. The polymer modification increased the yield stress, apparent viscosity and plastic viscosity of the cement grout by 19–136%, 32–319% and 58–367%, respectively based on the types of polymer, polymer content, w/c, and temperature. The compressive strength of the cement-based grout increased by 94–786% based on the types of polymer, polymer content, w/c and curing time. Increasing the temperature of cement-based grout slurry to 50 °C increased the maximum shear stresses by 110% and 107%, respectively. Effects of polymer content, w/c, curing time and the temperature of the plastic and hardened properties of cement-grout were modeled using a multiple nonlinear regression analysis.

Similar content being viewed by others

Data availability

No data, models, or code were generated or used during the study.

References

Eriksson, M. (2002). Prediction of grout spread and sealing effect (Doctoral dissertation, Byggvetenskap)

Funehag J (2007) Grouting of fractured rock with silica sol. Grouting design based on penetration length. Geologiska institutionen, Chalmers tekniska högskola, Göteborg

Abraham BM, Kumar TS, Sridharan A, Jose BT (2014) Strength improvement of loose sandy soils through cement grouting. Indian Geotech J 44(3):234–240. https://doi.org/10.1007/s40098-013-0073-3

Ibragimov MN (2005) Soil stabilization with cement grouts. Soil Mech Found Eng 42(2):67–72. https://doi.org/10.1007/s11204-005-0026-7

Bowen R (1981) Grouting in engineering practice. Apply Science Publication, London

Houlsby AC (1990) Construction and design of cement grouting: a guide to grouting in rock foundations, vol 67. Wiley, New York

Hatem M, Al-Ansari N, Pusch R, Knutsson S, Jonasson JE (2013) Rheological properties of low pH cement-palygorskite injection grout. J Adv Sci Eng Res 3(3):167–192

Mohammed A, Raof H, Salih A (2018) Vipulanandan constitutive models to predict the rheological properties and stress–strain behavior of cement grouts modified with metakaolin. J Test Eval 48

Montes D, Orozco W, Taborda EA, Franco CA, Cortés FB (2019) Development of nanofluids for perdurability in viscosity reduction of extra-heavy oils. Energies 12(6):1068

Bonavetti V, Donza H, Menendez G, Cabrera O, Irassar EF (2003) Limestone filler cement in low w/c concrete: a rational use of energy. Cem Concr Res 33(6):865–871

Matschei T, Lothenbach B, Glasser FP (2007) The role of calcium carbonate in cement hydration. Cem Concr Res 37(4):551–558

Vipulanandan C, Sunder S (2012) Effects of meta-kaolin clay on the working and strength properties of cement grouts. In: Grouting and deep mixing 2012, pp 1739–1747

Mesboua N, Benyounes K, Benmounah A (2018) Study of the impact of bentonite on the physico-mechanical and flow properties of cement grout. Cogent Eng 5(1):1446252

Vipulanandan C, Mohammed A, Ganpatye AS (2018) Smart cement performance enhancement with nanoAl 2 O 3 for real time monitoring applications using vipulanandan models. In: Offshore technology conference. Offshore technology conference

Vipulanandan C, Mohammed A (2015) Smart cement rheological and piezoresistive behavior for oil well applications. J Pet Sci Eng 135:50–58

Vipulanandan C, Krishnamoorti R, Mohammed A, Boncan V, Narvaez G, Head B, Pappas JM (2015) Iron nanoparticle modified smart cement for real time monitoring of ultra deepwater oil well cementing applications. In: Offshore technology conference. Offshore technology conference

Vipulanandan C, Mohammed A (2015) Effect of nanoclay on the electrical resistivity and rheological properties of smart and sensing bentonite drilling muds. J Pet Sci Eng 130:86–95

Vipulanandan C, Mohammed A, Samuel RG (2018) Fluid loss control in smart bentonite drilling mud modified with nanoclay and quantified with Vipulanandan fluid loss model. In: Offshore technology conference. Offshore technology conference

Vipulanandan C, Mohammed A (2019) Magnetic field strength and temperature effects on the behavior of oil well cement slurry modified with iron oxide nanoparticles and quantified with vipulanandan models. J Test Eval 48(6)

Mohammed AS (2018) Electrical resistivity and rheological properties of sensing bentonite drilling muds modified with lightweight polymer. Egypt J Pet 27(1):55–63

Qadir W, Ghafor K, Mohammed A (2019) Regression analysis and vipulanandan model to quantify the effect of polymers on the plastic and hardened properties with the tensile bonding strength of the cement mortar. Results Mater 1:100011

Burhan L, Ghafor K, Mohammed A (2019) Modeling the effect of silica fume on the compressive, tensile strengths and durability of NSC and HSC in various strength ranges. J Build Pathol Rehabil 4(1):19

Mohammed A, Mahmood W (2019) Estimating the efficiency of the sandy soils-cement based grout interactions from particle size distribution (PSD). Geomech Geoeng. https://doi.org/10.1080/17486025.2019.1645361

Abdalla LB, Ghafor K, Mohammed A (2019) Testing and modeling the young age compressive strength for high workability concrete modified with PCE polymers. Results Mater 1:100004

Ashikhmen VA, Pronina LÉ (1986) Rheological properties of dispersed cement grouts. Power Technol Eng (Formerly Hydrotechn Constr) 20(10):598–603

Rosquoët F, Alexis A, Khelidj A, Phelipot A (2003) Experimental study of cement grout: rheological behavior and sedimentation. Cem Concr Res 33(5):713–722. https://doi.org/10.1016/S0008-8846(02)01036-0

Christodoulou DN, Droudakis AI, Pantazopoulos IA, Markou IN, Atmatzidis DK (2009) Groutability and effectiveness of microfine cement grouts. In: Proceedings of the 17th international conference on soil mechanics and geotechnical engineering. https://doi.org/10.3233/978-1-60750-031-5-2232

Lim SK, Tan CS, Chen KP, Lee ML, Lee WP (2013) Effect of different sand grading on strength properties of cement grout. Constr Build Mater 38:348–355

Benyounes K, Benmounah A (2014) Effect of bentonite on the rheological behavior of cement grout in presence of superplasticizer. Int J Civ Architect Struct Constr Eng 8(11):1095–1098

Chen JJ, Li LG, Ng PL, Kwan AKH (2017) Effects of superfine zeolite on strength, flowability and cohesiveness of cementitious paste. Cement Concr Compos 83:101–110

Konsta-Gdoutos MS, Metaxa ZS, Shah SP (2010) Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem Concr Compos 32(2):110–115

Akbulut S, Saglamer A (2002) Estimating the groutability of granular soils: a new approach. Tunn Undergr Space Technol 17(4):371–380

Vipulanandan C, Mohammed A, Samuel RG (2017) Smart bentonite drilling muds modified with iron oxide nanoparticles and characterized based on the electrical resistivity and rheological properties with varying magnetic field strengths and temperatures. In: Offshore technology conference. Offshore technology conference

Cheung J, Jeknavorian A, Roberts L, Silva D (2011) Impact of admixtures on the hydration kinetics of Portland cement. Cem Concr Res 41(12):1289–1309

Ezziane K, Ngo TT, Kaci A (2014) Evaluation of rheological parameters of mortar containing various amounts of mineral addition with polycarboxylate superplasticizer. Constr Build Mater 70:549–559

Jolicoeur C, Simard MA (1998) Chemical admixture-cement interactions: phenomenology and physico-chemical concepts. Cem Concr Compos 20(2–3):87–101

Plank J, Hirsch C (2007) Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem Concr Res 37(4):537–542. https://doi.org/10.1016/j.cemconres.2007.01.007

Gallias JL, Kara-Ali R, Bigas JP (2000) The effect of fine mineral admixtures on water requirement of cement pastes. Cem Concr Res 30(10):1543–1549

Khudhair MH, Elharfi A, El-Youbi MS (2018) The effect of polymeric admixtures of water reduce of superplasticizer and setting accelerator on physical properties and mechanical performance of mortars and concretes. J Environ Res 1(1):4

Mikanovic N, Jolicoeur C (2008) Influence of superplasticizers on the rheology and stability of limestone and cement pastes. Cem Concr Res 38(7):907–919. https://doi.org/10.1016/j.cemconres.2008.01.015

Khudhair MHR, Elyoubi MS, Elharfi A (2017) Study of the influence of water reducing and setting retarder admixtures of polycarboxylate “superplasticizers” on physical and mechanical properties of mortar and concrete. J Mater Environ Sci. https://doi.org/10.26872/jmes.2018.9.1.7

Mohammed AS (2018) Property correlations and statistical variations in the geotechnical properties of (CH) clay soils. Geotech Geol Eng 36(1):267–281

Livescu S (2012) Mathematical modeling of thixotropic drilling mud and crude oil flow in wells and pipelines—a review. J Pet Sci Eng 98:174–184

Mohammed AS (2017) Effect of temperature on the rheological properties with shear stress limit of iron oxide nanoparticle modified bentonite drilling muds. Egypt J Pet 26(3):791–802

Vipulanandan C, Mohammed AS (2014) Hyperbolic rheological model with shear stress limit for acrylamide polymer modified bentonite drilling muds. J Pet Sci Eng 122:38–47

Afolabi RO, Orodu OD, Seteyeobot I (2018) Predictive modelling of the impact of silica nanoparticles on fluid loss of water based drilling mud. Appl Clay Sci 151:37–45

Vipulanandan C, Mohammed A (2015) Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Mater Struct 24(12):125020

Vipulanandan C, Mohammed A (2015) XRD and TGA, swelling and compacted properties of polymer treated sulfate contaminated CL soil. J Test Eval 44(6):2270–2284

Vipulanandan C, Mohammed A (2017) Rheological properties of piezoresistive smart cement slurry modified with iron-oxide nanoparticles for oil-well applications. J Test Eval 45(6):2050–2060

Vipulanandan C, Mohammed A (2018) New Vipulanandan failure model and property correlations for sandstone, shale and limestone rocks. IFCEE 2018:365–376

Mohammed AS (2019) Vipulanandan models to predict the mechanical properties, fracture toughness, pulse velocity and ultimate shear strength of shale rocks. Geotech Geol Eng 37(2):625–638

Mohammed AS, Vipulanandan C (2014) Compressive and tensile behavior of polymer treated sulfate contaminated CL soil. Geotech Geol Eng 32(1):71–83

Mohammed A, Vipulanandan C (2015) Testing and modeling the short-term behavior of lime and fly ash treated sulfate contaminated CL soil. Geotech Geol Eng 33(4):1099–1114

Vipulanandan C, Mohammed A (2018) Smart cement compressive piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Eval 47(2)

Mohammed A, Mahmood W (2018) Statistical variations and new correlation models to predict the mechanical behavior and ultimate shear strength of gypsum rock. Open Eng 8(1):213–226

Mohammed A, Mahmood W (2018) Vipulanandan failure models to predict the tensile strength, compressive modulus, fracture toughness and ultimate shear strength of calcium rocks. Int J Geotech Eng. https://doi.org/10.1080/19386362.2018.1468663

Mohammed A, Mahmood W (2019) New Vipulanandan pq model for particle size distribution and groutability limits for sandy soils. J Test Eval 48(5)

Qadir W, Ghafor K, Mohammed A (2019) Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv Civ Eng. https://doi.org/10.1155/2019/7013908

Halim JG, Kusuma OC, Hardjito D (2017) Optimizing polycarboxylate based superplasticizer dosage with different cement type. Proc Eng 171:752–759. https://doi.org/10.1016/j.proeng.2017.01.442

Mohammed MH, Pusch R, Knutsson S, Hellström G (2014) Rheological properties of cement-based grouts determined by different techniques. Engineering 6(05):217

Lee D, Choi M (2018) Standard reference materials for cement paste: part II—determination of mixing ratios. Materials 11(5):861

Acknowledgements

University of Sulaimani, Civil Engineering Department, Gasin Cement Co. and Zarya Construction Co. supported this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammed, A., Mahmood, W. & Ghafor, K. Shear stress limit, rheological properties and compressive strength of cement-based grout modified with polymers. J Build Rehabil 5, 3 (2020). https://doi.org/10.1007/s41024-019-0069-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-019-0069-1