Abstract

Alkali-activated materials and geopolymer are major sustainable alternative binding materials to ordinary Portland cement products with higher thermal resistance and often better durability properties. In lightweight form, they have an unmatched lowered thermal conductivity and insulating properties making them a perfect fit for optimized structural components with highest strength to density ratio and major energy savings in green buildings. For them to produce lightweight materials, generally either certain foaming agent or some types of lightweight aggregates in virgin, expanded, or recycled form are utilized that reduce the overall density through higher overall porosity. In accordance, this review provides an updated information on recent advances while stressing the sustainability of lightweight geopolymer materials over ordinary Portland cement products that are vastly in use. In the end, recent mechanical and durability properties developed and documented are reviewed and provided for future applications. Based on the result of this review, the most common lightweight aggregates used in literature are perlite, pumice, shale, ceramsite, and slate sand, in expanded and porous form, along with recycled thermosetting (e.g., rubber), or thermoplastic (e.g., polyethylene) materials. In foam form, chemical and mechanical foaming are the most commonly used foaming techniques to increase porosity of final materials. The pore mechanism of foam-based geopolymer is found to be different from that of lightweight aggregate-based geopolymer. This variation results in different physico-mechanical and durability properties such as better insulation properties (and lower thermal conductivity) for foam-based versus better mechanical properties for lightweight aggregate-based geopolymer.

Similar content being viewed by others

Data availability

The data gathered are available as the supplementary material.

Code availability

The authors declare that no code is used for the purpose of this article.

References

International Energy Agency (2020) Cement—Analysis—IEA

Elalaoui O, Ghorbel E, Ouezdou MB (2018) Influence of flame retardant addition on the durability of epoxy based polymer concrete after exposition to elevated temperature. Constr Build Mater 192:233–239. https://doi.org/10.1016/j.conbuildmat.2018.10.132

Laidoudi B, Flamin C, Crigny A, Ferrari J, Galzy G, Dupré B (2015) Bio based concrete with crushed rape straw, a good alternative to develop an affordable bio based concrete for construction and renovation. First Int Conf Bio Based Build Mater 33(2):23–30

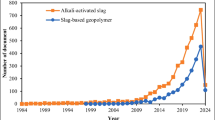

Nodehi M, Taghvaee VM (2021) Alkali-activated materials and geopolymer: a review of common precursors and activators addressing circular economy. Circ Econ Sustain. https://doi.org/10.1007/s43615-021-00029-w

Arrigoni A et al (2020) Life cycle greenhouse gas emissions of concrete containing supplementary cementitious materials: cut-off vs. substitution. J Clean Prod 263:121465. https://doi.org/10.1016/j.jclepro.2020.121465

Teixeira ER, Mateus R, Camões AF, Bragança L, Branco FG (2016) Comparative environmental life-cycle analysis of concretes using biomass and coal fly ashes as partial cement replacement material. J Clean Prod 112:2221–2230. https://doi.org/10.1016/j.jclepro.2015.09.124

Miller SA (2018) Supplementary cementitious materials to mitigate greenhouse gas emissions from concrete: can there be too much of a good thing? J Clean Prod 178:587–598. https://doi.org/10.1016/j.jclepro.2018.01.008

Nodehi M, Taghvaee VM (2021) Sustainable concrete for circular economy: a review on use of waste glass. Glass Struct Eng. https://doi.org/10.1007/s40940-021-00155-9

Purdon AO (1940) The action of alkalis on blast-furnace slag. J Soc Chem Ind 9(59):191–202

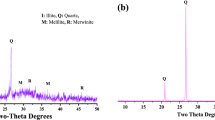

Kuenzel C, Grover LM, Vandeperre L, Boccaccini AR, Cheeseman CR (2013) Production of nepheline/quartz ceramics from geopolymer mortars. J Eur Ceram Soc 33(2):251–258. https://doi.org/10.1016/j.jeurceramsoc.2012.08.022

Liew YM et al (2017) Formation of one-part-mixing geopolymers and geopolymer ceramics from geopolymer powder. Constr Build Mater 156:9–18. https://doi.org/10.1016/j.conbuildmat.2017.08.110

Bernal SA, Bejarano J, Garzón C, De Gutiérrez RM, Delvasto S, Rodríguez ED (2012) Performance of refractory aluminosilicate particle/fiber-reinforced geopolymer composites. Compos Part B Eng 43(4):1919–1928. https://doi.org/10.1016/j.compositesb.2012.02.027

Ohno M, Li VC (2014) A feasibility study of strain hardening fiber reinforced fly ash-based geopolymer composites. Constr Build Mater 57:163–168. https://doi.org/10.1016/j.conbuildmat.2014.02.005

Natali A, Manzi S, Bignozzi MC (2011) Novel fiber-reinforced composite materials based on sustainable geopolymer matrix. Procedia Eng 21:1124–1131. https://doi.org/10.1016/j.proeng.2011.11.2120

Provis JL, Bernal SA (2014) Binder chemistry—blended systems and intermediate Ca content. RILEM State-of-the-Art Reports, vol 13, pp 125–144. https://doi.org/10.1007/978-94-007-7672-2_5

Garcia-Lodeiro I, Palomo A, Fernández-Jiménez A (2015) An overview of the chemistry of alkali-activated cement-based binders. Woodhead Publishing Limited, Sawston

Provis JL, Van Deventer JSJ (2009) Geopolymers: structures, processing, properties and industrial applications. Woodhead pubishing, Sawston

Garcia-Lodeiro I, Palomo A, Fernández-Jiménez A, MacPhee DE (2011) Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O–CaO–Al2O3–SiO 2–H2O. Cem Concr Res 41(9):923–931. https://doi.org/10.1016/j.cemconres.2011.05.006

Shi C, Roy D, Krivenko P (2003) Alkali-activated cements and concretes. CRC Press, Boca Raton

Turner LK, Collins FG (2013) Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete. Constr Build Mater 43:125–130. https://doi.org/10.1016/j.conbuildmat.2013.01.023

Merikallio T, Mannonen R, Penttala V (1996) Drying of lightweight concrete produced from crushed expanded clay aggregates. Cem Concr Res 26(9):1423–1433. https://doi.org/10.1016/0008-8846(96)00116-0

Zhang M-H, Gjørv OE (1990) Pozzolanic reactivity of lightweight aggregates. Cem Concr Res 20(6):884–890. https://doi.org/10.1016/0008-8846(90)90050-8

Zhang MH, Gjørv OE (1990) Microstructure of the interfacial zone between lightweight aggregate and cement paste. Cem Concr Res 20(4):610–618. https://doi.org/10.1016/0008-8846(90)90103-5

Sarkar SL, Satish C, Leif B (1992) Interdependence of microstructure and strength of structural lightweight aggregate concrete. Cem Concr Compos 14(4):239–248. https://doi.org/10.1016/0958-9465(92)90022-N

Nyame BK, Buenfeld N (1986) Permeability of normal and lightweight mortars. Mag Concr Res 38(134):51–53. https://doi.org/10.1680/macr.1986.38.134.51

Akçaözoǧlu S, Atiş CD, Akçaözoǧlu K (2010) An investigation on the use of shredded waste PET bottles as aggregate in lightweight concrete. Waste Manag 30(2):285–290. https://doi.org/10.1016/j.wasman.2009.09.033

Topçu IB, Uygunoǧlu T (2007) Properties of autoclaved lightweight aggregate concrete. Build Environ 42(12):4108–4116. https://doi.org/10.1016/j.buildenv.2006.11.024

Babu DS, Ganesh Babu K, Wee TH (2005) Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem Concr Res 35(6):1218–1223. https://doi.org/10.1016/j.cemconres.2004.11.015

Zhang H (2011) Building materials in civil engineering. In: Zhang H (ed) Building materials in civil engineering. Elsevier, Amsterdam, pp 81–423

Mallick PK (2010) Thermoplastics and thermoplastic-matrix composites for lightweight automotive structures. In: Mater. Des. Manuf. Light. Veh., pp 174–207, doi: https://doi.org/10.1533/9781845697822.1.174

Oderji SY, Chen B, Ahmad MR, Shah SFA (2019) Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: effect of slag and alkali activators. J Clean Prod 225:1–10. https://doi.org/10.1016/j.jclepro.2019.03.290

Gao X, Yu QL (2019) Effects of an eco-silica source based activator on functional alkali activated lightweight composites. Constr Build Mater 215:686–695. https://doi.org/10.1016/j.conbuildmat.2019.04.251

Yang SL, Millard SG, Soutsos MN, Barnett SJ, Le TT (2009) Influence of aggregate and curing regime on the mechanical properties of ultra-high performance fibre reinforced concrete (UHPFRC). Constr Build Mater 23(6):2291–2298. https://doi.org/10.1016/j.conbuildmat.2008.11.012

Boarder RFW, Owens PL, Khatib JM (2016) In: The sustainability of lightweight aggregates manufactured from clay wastes for reducing the carbon footprint of structural and foundation concrete, Second edn., Elsevier Ltd

Sataloff RT, Johns MM, Kost KM (2015) Advanced concrete technology. Geriatric Otolaryngology, ISBN:9781626239777

Yoon JY, Kim JH, Hwang YY, Shin DK (2015) Lightweight concrete produced using a two-stage casting process. Materials 8(4):1384–1397. https://doi.org/10.3390/ma8041384 (Basel)

Bhatnagar N, Asija N (2016) Durability of high-performance ballistic composites. In: Lightweight ballistic composites. Elsevier, pp 231–283

Colangelo F et al (2018) Mechanical and thermal properties of lightweight geopolymer composites. Cem Concr Compos 86:266–272. https://doi.org/10.1016/j.cemconcomp.2017.11.016

Rashad AM (2016) A synopsis about perlite as building material—A best practice guide for civil engineer. Constr Build Mater 121:338–353. https://doi.org/10.1016/j.conbuildmat.2016.06.001

Tsaousi GM, Douni I, Panias D (2016) Characterization of the properties of perlite geopolymer pastes. Mater Constr 66(324):1–8. https://doi.org/10.3989/mc.2016.10415

Anwar Hossain KM (2004) Properties of volcanic pumice based cement and lightweight concrete. Cem Concr Res 34(2):283–291. https://doi.org/10.1016/j.cemconres.2003.08.004

Restuccia F, Ptak N, Rein G (2017) Self-heating behavior and ignition of shale rock. Combust Flame 176:213–219. https://doi.org/10.1016/j.combustflame.2016.09.025

Dong S, Yang W, Ge Y, Jiang S, Sun T, Deng J (2015) Mechanical properties of concrete containing ceramsite sand. In: ICTE 2015, Sep. 2015, pp 1259–1265. https://doi.org/10.1061/9780784479384.158

Chen Y, Hui Q, Zhang H, Zhu Z, Wang C, Zhao J (2020) Experiment and application of ceramsite concrete used to maintain roadway in coal mine. Meas Control 53(9–10):1832–1840. https://doi.org/10.1177/0020294020947134 (United Kingdom)

Yang J, Huang W, Luo B (2018) Silt ceramsite mechanical properties for reduction of solid waste pollution. Chem Eng Trans 71:1411–1416. https://doi.org/10.3303/CET1871236

Wichert J (2020) Properties of slate. In: Wichert J (ed) Slate as dimension stone: origin, standards, properties, mining and deposits. Springer International Publishing, Cham, pp 61–134

Rowe DB, Monterusso MA, Rugh CL (2006) Assessment of heat-expanded slate and fertility requirements in green roof substrates. HortTechnology 16(3):471–477. https://doi.org/10.21273/horttech.16.3.0471

Zipf MS, Pinheiro IG, Conegero MG (2016) Simplified greywater treatment systems: slow filters of sand and slate waste followed by granular activated carbon. J Environ Manag 176:119–127. https://doi.org/10.1016/j.jenvman.2016.03.035

Arulrajah A, Piratheepan J, Disfani MM, Bo MW (2013) Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J Mater Civ Eng 25(8):1077–1088. https://doi.org/10.1061/(asce)mt.1943-5533.0000652

Valore RC (1961) Foam and gas concretes

Zhang Z, Provis JL, Reid A, Wang H (2014) Geopolymer foam concrete: an emerging material for sustainable construction. Constr Build Mater 56:113–127. https://doi.org/10.1016/j.conbuildmat.2014.01.081

Dhasindrakrishna K, Pasupathy K, Ramakrishnan S, Sanjayan J (2021) Progress, current thinking and challenges in geopolymer foam concrete technology. Cem Concr Compos 116(November 2020):103886. https://doi.org/10.1016/j.cemconcomp.2020.103886

Erdoğan ST (2015) Inexpensive intumescent alkali-activated natural pozzolan pastes. J Eur Ceram Soc 35(9):2663–2670. https://doi.org/10.1016/j.jeurceramsoc.2015.03.017

Onutai S, Jiemsirilers S, Thavorniti P, Kobayashi T (2016) Fast microwave syntheses of fly ash based porous geopolymers in the presence of high alkali concentration. Ceram Int 42(8):9866–9874. https://doi.org/10.1016/j.ceramint.2016.03.086

Jones MR, McCarthy A (2006) Heat of hydration in foamed concrete: effect of mix constituents and plastic density. Cem Concr Res 36(6):1032–1041. https://doi.org/10.1016/j.cemconres.2006.01.011

Le VS et al (2020) Mechanical properties of geopolymer foam at high temperature. Sci Eng Compos Mater 27(1):129–138. https://doi.org/10.1515/secm-2020-0013

Hassan HS, Abdel-Gawwad HA, García SRV, Israde-Alcántara I (2018) Fabrication and characterization of thermally-insulating coconut ash-based geopolymer foam. Waste Manag 80:235–240. https://doi.org/10.1016/j.wasman.2018.09.022

Dhasindrakrishna K, Pasupathy K, Ramakrishnan S, Sanjayan J (2020) Effect of yield stress development on the foam-stability of aerated geopolymer concrete. Cem Concr Res 138(September):106233. https://doi.org/10.1016/j.cemconres.2020.106233

Lertcumfu N, Kaewapai K, Jaita P, Tunkasiri T, Sirisoonthorn S, Rujijanagul G (2020) Effects of olive oil on physical and mechanical properties of ceramic waste-based geopolymer foam. J Reinf Plast Compos 39(3–4):111–118. https://doi.org/10.1177/0731684419896852

Han L et al (2020) Synthesis of fly ash-based self-supported zeolites foam geopolymer via saturated steam treatment. J Hazard Mater 393(March):122468. https://doi.org/10.1016/j.jhazmat.2020.122468

Dhasindrakrishna K, Pasupathy K, Ramakrishnan S, Sanjayan J (2020) Effect of yield stress development on the foam-stability of aerated geopolymer concrete. Cem Concr Res 138(April):106233. https://doi.org/10.1016/j.cemconres.2020.106233

Dhasindrakrishna K, Pasupathy K, Ramakrishnan S, Sanjayan J (2021) Progress, current thinking and challenges in geopolymer foam concrete technology. Cem Concr Compos 116(September 2020):103886. https://doi.org/10.1016/j.cemconcomp.2020.103886

Masi G, Rickard WDA, Vickers L, Bignozzi MC, Van Riessen A (2014) A comparison between different foaming methods for the synthesis of light weight geopolymers. Ceram Int 40(9 PART A):13891–13902. https://doi.org/10.1016/j.ceramint.2014.05.108

Delair S et al (2012) Durability of inorganic foam in solution: the role of alkali elements in the geopolymer network. Corros Sci 59:213–221. https://doi.org/10.1016/j.corsci.2012.03.002

Huang Y, Gong L, Shi L, Cao W, Pan Y, Cheng X (2018) Experimental investigation on the influencing factors of preparing porous fly ash-based geopolymer for insulation material. Energy Build 168:9–18. https://doi.org/10.1016/j.enbuild.2018.02.043

Bai C, Conte A, Colombo P (2017) Open-cell phosphate-based geopolymer foams by frothing. Mater Lett 188:379–382. https://doi.org/10.1016/j.matlet.2016.11.103

Al Saadi THA, Badanoiu AI, Nicoara AI, Stoleriu S, Voicu G (2017) Synthesis and properties of alkali activated borosilicate inorganic polymers based on waste glass. Constr Build Mater 136:298–306. https://doi.org/10.1016/j.conbuildmat.2017.01.026

Haq EU, Padmanabhan SK, Licciulli A (2015) Microwave synthesis of thermal insulating foams from coal derived bottom ash. Fuel Process Technol 130(C):263–267. https://doi.org/10.1016/j.fuproc.2014.10.017

Zhao Y et al (2010) Preparation of sintered foam materials by alkali-activated coal fly ash. J Hazard Mater 174(1–3):108–112. https://doi.org/10.1016/j.jhazmat.2009.09.023

Cui Y, Wang D (2019) Effects of water on pore structure and thermal conductivity of fly ash-based foam geopolymers. Adv Mater Sci Eng. https://doi.org/10.1155/2019/3202794

Ranjani IS, Ramamurthy K (2010) Relative assessment of density and stability of foam produced with four synthetic surfactants. Mater Struct Constr 43(10):1317–1325. https://doi.org/10.1617/s11527-010-9582-z

He J, Gao Q, Song X, Bu X, He J (2019) Effect of foaming agent on physical and mechanical properties of alkali-activated slag foamed concrete. Constr Build Mater 226:280–287. https://doi.org/10.1016/j.conbuildmat.2019.07.302

Jones MR, Zheng L, Ozlutas K (2016) Stability and instability of foamed concrete. Mag Concr Res 68(11):542–549. https://doi.org/10.1680/macr.15.00097

Fameau AL, Salonen A (2014) Effect of particles and aggregated structures on the foam stability and aging. Comptes Rendus Phys 15(8–9):748–760. https://doi.org/10.1016/j.crhy.2014.09.009

Hou L, Li J, Lu Z, Niu Y, Jiang J, Li T (2019) Effect of nanoparticles on foaming agent and the foamed concrete. Constr Build Mater 227:116698. https://doi.org/10.1016/j.conbuildmat.2019.116698

Huang Z, Zhang T, Wen Z (2015) Proportioning and characterization of Portland cement-based ultra-lightweight foam concretes. Constr Build Mater 79:390–396. https://doi.org/10.1016/j.conbuildmat.2015.01.051

Hajimohammadi A, Ngo T, Provis JL, Kim T, Vongsvivut J (2019) High strength/density ratio in a syntactic foam made from one-part mix geopolymer and cenospheres. Compos Part B Eng 173(February):106908. https://doi.org/10.1016/j.compositesb.2019.106908

Posi P et al (2013) Lightweight geopolymer concrete containing aggregate from recycle lightweight block. Mater Des 52:580–586. https://doi.org/10.1016/j.matdes.2013.06.001

Pimraksa K, Chindaprasirt P, Rungchet A, Sagoe-Crentsil K, Sato T (2011) Lightweight geopolymer made of highly porous siliceous materials with various Na2O/Al2O3 and SiO2/Al2O3 ratios. Mater Sci Eng A 528(21):6616–6623. https://doi.org/10.1016/j.msea.2011.04.044

Huiskes DMA, Keulen A, Yu QL, Brouwers HJH (2016) Design and performance evaluation of ultra-lightweight geopolymer concrete. Mater Des 89:516–526. https://doi.org/10.1016/j.matdes.2015.09.167

Posi P, Ridtirud C, Ekvong C, Chammanee D, Janthowong K, Chindaprasirt P (2015) Properties of lightweight high calcium fly ash geopolymer concretes containing recycled packaging foam. Constr Build Mater 94:408–413. https://doi.org/10.1016/j.conbuildmat.2015.07.080

Wongsa A, Sata V, Nematollahi B, Sanjayan J, Chindaprasirt P (2018) Mechanical and thermal properties of lightweight geopolymer mortar incorporating crumb rubber. J Clean Prod 195:1069–1080. https://doi.org/10.1016/j.jclepro.2018.06.003

Wongsa A, Sata V, Nuaklong P, Chindaprasirt P (2018) Use of crushed clay brick and pumice aggregates in lightweight geopolymer concrete. Constr Build Mater 188:1025–1034. https://doi.org/10.1016/j.conbuildmat.2018.08.176

Mohseni E, Kazemi MJ, Koushkbaghi M, Zehtab B, Behforouz B (2019) Evaluation of mechanical and durability properties of fiber-reinforced lightweight geopolymer composites based on rice husk ash and nano-alumina. Constr Build Mater 209:532–540. https://doi.org/10.1016/j.conbuildmat.2019.03.067

Ismail N, El-Hassan H (2018) Development and characterization of fly ash-slag blended geopolymer mortar and lightweight concrete. J Mater Civ Eng 30(4):04018029. https://doi.org/10.1061/(asce)mt.1943-5533.0002209

Mermerdaş K, Algın Z, Ekmen Ş (2020) Experimental assessment and optimization of mix parameters of fly ash-based lightweight geopolymer mortar with respect to shrinkage and strength. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101351

Rożek P, Król M, Mozgawa W (2020) Lightweight geopolymer-expanded glass composites for removal of methylene blue from aqueous solutions. Ceram Int 46(12):19785–19791. https://doi.org/10.1016/j.ceramint.2020.05.011

Peyne J, Gautron J, Doudeau J, Rossignol S (2018) Development of low temperature lightweight geopolymer aggregate, from industrial Waste, in comparison with high temperature processed aggregates. J Clean Prod 189:47–58. https://doi.org/10.1016/j.jclepro.2018.04.038

Alghamdi H, Neithalath N (2018) Novel synthesis of lightweight geopolymer matrices from fly ash through carbonate-based activation. Mater Today Commun 17(September):266–277. https://doi.org/10.1016/j.mtcomm.2018.09.014

Top S, Vapur H (2018) Effect of basaltic pumice aggregate addition on the material properties of fly ash based lightweight geopolymer concrete. J Mol Struct 1163:10–17. https://doi.org/10.1016/j.molstruc.2018.02.114

Riyap HI et al (2019) Microstructure and mechanical, physical and structural properties of sustainable lightweight metakaolin-based geopolymer cements and mortars employing rice husk. J Asian Ceram Soc 7(2):199–212. https://doi.org/10.1080/21870764.2019.1606140

Sanjayan JG, Nazari A, Chen L, Nguyen GH (2015) Physical and mechanical properties of lightweight aerated geopolymer. Constr Build Mater 79:236–244. https://doi.org/10.1016/j.conbuildmat.2015.01.043

Top S, Vapur H, Altiner M, Kaya D, Ekicibil A (2020) Properties of fly ash-based lightweight geopolymer concrete prepared using pumice and expanded perlite as aggregates. J Mol Struct 1202:127236. https://doi.org/10.1016/j.molstruc.2019.127236

Wang Y, Zheng T, Zheng X, Liu Y, Darkwa J, Zhou G (2020) Thermo-mechanical and moisture absorption properties of fly ash-based lightweight geopolymer concrete reinforced by polypropylene fibers. Constr Build Mater 251:118960. https://doi.org/10.1016/j.conbuildmat.2020.118960

Abdulkareem OA, Mustafa Al Bakri AM, Kamarudin H, Khairul Nizar I, Saif AA (2014) Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr Build Mater 50:377–387. https://doi.org/10.1016/j.conbuildmat.2013.09.047

Liu MYJ, Alengaram UJ, Jumaat MZ, Mo KH (2014) Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build 72:238–245. https://doi.org/10.1016/j.enbuild.2013.12.029

Vickers L, van Riessen A, Rickard W (2015) Fire-resistant geopolymers: role of fibres and fillers to enhance thermal properties. Springer, Singapore

Ahmad MR, Chen B, Shah SFA (2020) Influence of different admixtures on the mechanical and durability properties of one-part alkali-activated mortars. Constr Build Mater 265:120320. https://doi.org/10.1016/j.conbuildmat.2020.120320

Temuujin J, Williams RP, van Riessen A (2009) Effect of mechanical activation of fly ash on the properties of geopolymer cured at ambient temperature. J Mater Process Technol 209(12–13):5276–5280. https://doi.org/10.1016/j.jmatprotec.2009.03.016

Chindaprasirt P, Rattanasak U, Taebuanhuad S (2013) Role of microwave radiation in curing the fly ash geopolymer. Adv Powder Technol 24(3):703–707. https://doi.org/10.1016/j.apt.2012.12.005

Chindaprasirt P, Rattanasak U, Taebuanhuad S (2013) Resistance to acid and sulfate solutions of microwave-assisted high calcium fly ash geopolymer. Mater Struct Constr 46(3):375–381. https://doi.org/10.1617/s11527-012-9907-1

Yost JR, Radlińska A, Ernst S, Salera M (2013) Structural behavior of alkali activated fly ash concrete. Part. Mixture design, material properties and sample fabrication. Mater Struct Constr 46(3):435–447. https://doi.org/10.1617/s11527-012-9919-x

Provis JL (2018) Alkali-activated materials. Cem Concr Res 114:40–48. https://doi.org/10.1016/j.cemconres.2017.02.009

Rehman MU, Rashid K, Zafar I, Alqahtani FK, Khan MI (2020) Formulation and characterization of geopolymer and conventional lightweight green concrete by incorporating synthetic lightweight aggregate. J Build Eng 31(August 2019):101363. https://doi.org/10.1016/j.jobe.2020.101363

Wang S, Li H, Zou S, Zhang G (2020) Experimental research on a feasible rice husk/geopolymer foam building insulation material. Energy Build 226:110358. https://doi.org/10.1016/j.enbuild.2020.110358

Zhang Z, Provis JL, Reid A, Wang H (2015) Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem Concr Compos 62:97–105. https://doi.org/10.1016/j.cemconcomp.2015.03.013

Łach M, Korniejenko K, Mikuła J (2016) Thermal insulation and thermally resistant materials made of geopolymer foams. Procedia Eng 151:410–416. https://doi.org/10.1016/j.proeng.2016.07.350

Phavongkham V, Wattanasiriwech S, Cheng TW, Wattanasiriwech D (2020) Effects of surfactant on thermo-mechanical behavior of geopolymer foam paste made with sodium perborate foaming agent. Constr Build Mater 243:118282. https://doi.org/10.1016/j.conbuildmat.2020.118282

Łach M, Mierzwiński D, Korniejenko K, Mikuła J (2018) Geopolymer foam as a passive fire protection. In: MATEC Web Conf., vol 247, p 00031. https://doi.org/10.1051/matecconf/201824700031

Cui Y, Wang D, Zhao J, Li D, Ng S, Rui Y (2018) Effect of calcium stearate based foam stabilizer on pore characteristics and thermal conductivity of geopolymer foam material. J Build Eng 20(March):21–29. https://doi.org/10.1016/j.jobe.2018.06.002

Nadeem M, Haq EU, Ahmed F, Rafiq MA, Awan GH, Zain-ul-Abdein M (2020) Effect of microwave curing on the construction properties of natural soil based geopolymer foam. Constr Build Mater 230:117074. https://doi.org/10.1016/j.conbuildmat.2019.117074

Gu G, Xu F, Ruan S, Huang X, Zhu J, Peng C (2020) Influence of precast foam on the pore structure and properties of fly ash-based geopolymer foams. Constr Build Mater 256:119410. https://doi.org/10.1016/j.conbuildmat.2020.119410

Ibrahim WMW, Hussin K, Abdullah MMAB, Kadir AA, Deraman LM, Sandu AV (2017) Influence of foaming agent/water ratio and foam/geopolymer paste ratio to the properties of fly ash-based lightweight geopolymer for brick application. Rev Chim 68(9):1978–1982. https://doi.org/10.37358/rc.17.9.5805

Nambiar EKK, Ramamurthy K (2007) Air-void characterisation of foam concrete. Cem Concr Res 37(2):221–230. https://doi.org/10.1016/j.cemconres.2006.10.009

Ma C, Zhao B, Guo S, Long G, Xie Y (2019) Properties and characterization of green one-part geopolymer activated by composite activators. J Clean Prod 220:188–199. https://doi.org/10.1016/j.jclepro.2019.02.159

Mo KH, Alengaram UJ, Jumaat MZ (2016) Bond properties of lightweight concrete—a review. Constr Build Mater 112:478–496. https://doi.org/10.1016/j.conbuildmat.2016.02.125

Hassanpour M, Shafigh P, Mahmud HB (2012) Lightweight aggregate concrete fiber reinforcement—a review. Constr Build Mater 37:452–461. https://doi.org/10.1016/j.conbuildmat.2012.07.071

Sturm P, Gluth GJG, Brouwers HJH, Kühne HC (2016) Synthesizing one-part geopolymers from rice husk ash. Constr Build Mater 124:961–966. https://doi.org/10.1016/j.conbuildmat.2016.08.017

Chaipanich A, Chindaprasirt P (2015) The properties and durability of autoclaved aerated concrete masonry blocks. In: Eco-efficient masonry bricks and blocks. Elsevier, pp 215–230

Nath P, Sarker PK (2017) Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr Build Mater 130:22–31. https://doi.org/10.1016/j.conbuildmat.2016.11.034

Islam A, Alengaram UJ, Jumaat MZ, Ghazali NB, Yusoff S, Bashar II (2017) Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymer concrete. Constr Build Mater 152:964–977. https://doi.org/10.1016/j.conbuildmat.2017.06.092

Lizcano M, Gonzalez A, Basu S, Lozano K, Radovic M (2012) Effects of water content and chemical composition on structural properties of alkaline activated metakaolin-based geopolymers. J Am Ceram Soc 95(7):2169–2177. https://doi.org/10.1111/j.1551-2916.2012.05184.x

Steins P, Poulesquen A, Diat O, Frizon F (2012) Structural evolution during geopolymerization from an early age to consolidated material. Langmuir 28(22):8502–8510. https://doi.org/10.1021/la300868v

Nodehi M (2021) A review of Epoxy, Polyester and Vinyl ester-based polymer concrete: fresh, mechanical and durability properties. Innov Infrastruct Solut

Criado M, Palomo A, Fernández-Jiménez A (2005) Alkali activation of fly ashes. Part 1: effect of curing conditions on the carbonation of the reaction products. Fuel 84(16):2048–2054. https://doi.org/10.1016/j.fuel.2005.03.030

Acknowledgements

The graphics in this article are sketched through a licensed Adobe Photoshop express and Bio render.

Funding

This research did not receive any specific grant or funding from agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to publish

The authors declare their consent to publish this article in the journal of Innovative Infrastructure Solutions (IIS).

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nodehi, M. A comparative review on foam-based versus lightweight aggregate-based alkali-activated materials and geopolymer. Innov. Infrastruct. Solut. 6, 231 (2021). https://doi.org/10.1007/s41062-021-00595-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00595-w