Abstract

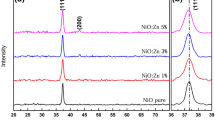

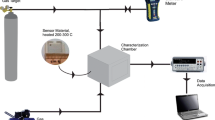

Rhombohedral structure of chromium oxide (Cr2O3) thin-film doped hexagonal zinc oxide (ZnO) nanoparticles have been prepared using pulsed laser deposition technique at a different weight percent of ZnO from 0 to 9 wt%. The results of X-ray diffraction analysis shown that the doped films are polycrystalline, and the average crystallite size of the synthesized thin films is found to be dependent on the ZnO concentration. The surface morphology of the prepared thin films was characterized by atomic force microscopy. The optical properties are investigated using ultraviolet–visible light (UV–Vis) absorption spectroscopy. The optical bandgap ranged from 2.45 to 2.68 eV, showing the shift towards longer-wavelength compared to bulk Cr2O3 (~ 3 eV). The sensitivity, response, and recovery times of the sensor towards nitrogen dioxide (NO2) gas were studied and discussed. The sensitivity increase with increasing the doping concentration, and started to decrease when ZnO concentrations reach 7 wt%. The optimal ZnO concentrations for NO2 gas sensitivity is 5 wt%, which attain maximum sensitivity of 87.5% at temperature of 523 K.

Similar content being viewed by others

References

M. Maaza, B.D. Ngom, M. Achouri, K. Manikandan, Vacuum 114, 172 (2015)

S.A. Makhlouf, J. Magn. Magn. Mater. 272–276, 1530 (2014)

H. Cao, X. Qiu, Y. Liang, M. Zhao, Q. Zhu, Appl. Phys. Lett. 88, 241112 (2006)

Y. Zhou, X. Weng, L. Yuan, L. Deng, J. Ceram. Soc. Jpn. 122, 311 (2014)

Y.C. Pu, M.G. Kibria, Z. Mi, J.Z. Zhang, J. Phys. Chem. Lett. 60, 2649 (2015)

B.K. Miremadi, R.C. Singh, Z. Chen, S.R. Morrison, K. Colbow, Sens. Actuators B 21, 1 (1994)

C.H. Hsu, D.H. Huang, W.Y. Ho, L.T. Huang, C.L. Chang, Mater. Sci. Eng. A 429, 212 (2006)

D. Zhang, X. Li, B. Qin, X. Li, X. Guo, C. Lai, J. Am. Ceram. Soc. 97, 3413 (2014)

Y. Wang, X. Yuan, X. Liu, J. Ren, W. Tong, Y. Wang, G. Lu, Solid State Sci. 10, 1117 (2008)

M.N.H. Mia, M.F. Pervez, M.K. Hossain, M.R. Rahman, M.J. Uddin, M.A. Al Mashud, H.K. Ghosh, M. Hoq, Results Phys. 7, 2683 (2017)

J. Sengupta, A. Ahmed, R. Labar, Mater. Lett. 109, 265 (2013)

D. Niemeyer, D.E. Williams, P. Smith, K.F.E. Pratt, B. Slater, C.R.A. Catlow, A.M. Stoneham, J. Mater. Chem. 12, 667 (2002)

K.J. Choi, H.W. Jang, Sensors 10, 4083 (2010)

M.H. Suhail, A.A. Ramadan, S.B. Aziz, O.G. Abdullah, J. Sci. Adv. Mater. Devices 2, 301 (2017)

M.H. Suhail, H.S. Al-Jumily, O.G. Abdullah, SN Appl. Sci. 1, 69 (2019)

N. Barsan, M.S. Berberich, W. Gopel, Fresenius J. Anal. Chem. 365, 287 (1999)

M.H. Suhail, O.G. Abdullah, G.A. Kadhim, J. Sci. Adv. Mater. Devices 4, 143 (2019)

T.K.H. Starke, G.S.V. Coles, IEEE Sens. J. 2, 14 (2002)

H. Du, P. Yao, Y. Sun, J. Wang, H. Wang, N. Yu, Sensors 17, 1822 (2017)

N. Zhang, X. Ma, Y. Yin, Y. Chen, C. Li, J. Yin, S. Ruan, Inorg. Chem. Front. 6, 238 (2019)

O.G. Abdullah, J. Mater. Sci. Mater. Electron. 27, 12106 (2016)

A.M. Babeer, Silicon 9, 847 (2017)

M. Suchea, N. Katsarakis, S. Christoulakis, S. Nikolopoulou, G. Kiriakidis, Sens. Actuators B 118, 135 (2006)

N.G. Deshpande, Y.G. Gudage, R. Sharma, J.C. Vyas, J.B. Kim, Y.P. Lee, Sens. Actuators B 138, 76 (2009)

X.Q. Pan, L. Fu, J. Electroceram. 7, 35 (2001)

A.H. Mohamad, S.R. Saeed, O.G. Abdullah, Mater. Res. Express 6, 115332 (2019)

O.G. Abdullah, S.A. Saleem, J. Electron. Mater. 45, 5910 (2016)

S.F. Bdewi, O.G. Abdullah, B.K. Aziz, A.A.R. Mutar, J. Inorg. Organomet. Polym. Mater. 26, 326 (2016)

S.B. Aziz, O.G. Abdullah, M.A. Brza, A.K. Azawy, D.A. Tahir, Results Phys. 15, 102776 (2019)

M.F. Al-Kuhaili, S.M.A. Durrani, Opt. Mater. 29, 709 (2007)

G. Goodlet, S. Faty, S. Cardoso, P.P. Freitas, A.M.P. Simoes, M.G.S. Ferreira, M.D.C. Belo, Corros. Sci. 46, 1479 (2004)

O.G. Abdullah, D.A. Tahir, K. Kadir, J. Mater. Sci. Mater. Electron. 26, 6939 (2015)

A.H. Mohamad, O.G. Abdullah, S.R. Saeed, Results Phys. 16, 102898 (2020)

Z. Liao, H. Zhang, Y. Zhou, J. Xu, J. Zhang, D. Yu, Phys. Lett. A 372, 4505 (2008)

A.F. Abdulameer, M.H. Suhail, O.G. Abdullah, I.M. Al-Essa, J. Mater. Sci. Mater. Electron. 28, 13472 (2017)

C. Wang, L. Yin, L. Zhang, D. Xiang, R. Gao, Sensors 10, 2088 (2010)

L. Filipovic, S. Selberherr, Sensors 15, 7206 (2015)

M. Kumar, V. Bhatt, A.C. Abhyankar, J. Kim, A. Kumar, S.H. Patil, J. Yun, Sci. Rep. 8, 8079 (2018)

N. Jayababu, M. Poloju, J. Shruthi, M.V.R. Reddy, RSC Adv. 9, 13765 (2019)

G.F. Fine, L.M. Cavanagh, A. Afonj, R. Binions, Sensors 10, 5469 (2010)

Acknowledgements

The authors would wish to express their grateful appreciation to the Department of Physics, College of Science, at the University of Baghdad, for the facility in their laboratories and the support given to this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Suhail, M.H., Adehmash, I.K., Abdul Kareem, S.M. et al. Construction of Cr2O3:ZnO Nanostructured Thin Film Prepared by Pulsed Laser Deposition Technique for NO2 Gas Sensor. Trans. Electr. Electron. Mater. 21, 355–365 (2020). https://doi.org/10.1007/s42341-020-00182-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42341-020-00182-3