Abstract

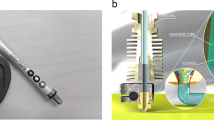

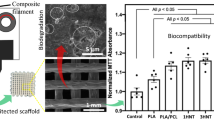

Personalized medicine suitable for individual patients in tissue engineering is a significant challenge. Owing to the recent growth of 3D printing, various methods of building objects have been proposed. However, there is very little information about the mechanical properties of the pieces obtained by controlling the process variables using composite filaments. Fused deposition modeling (FDM) technology was used to fabricate new scaffolds with infill patterns, interconnected channel networks, controllable porosity, and size. Polylactic acid (PLA)/carbon nanotube (CNT) filaments were synthesized using the melt extrusion technique. An improvement in the mechanical properties was observed in composites compared with the pure polymer. Moreover, no toxicity was expressed by stem cells after 24 h of incubation in the presence of composite filaments for a high CNT concentration. Our results will aid in the scaffold design of composite filaments through the modeling of process parameters and mechanical properties.

Similar content being viewed by others

References

F. Asghari., Samiei, M., Adibkia, K., Akbarzadeh., A. and Davaran, S. 2017. Biodegradable and biocompatible polymers for tissue engineering application: a review. Artificial Cells, Nanomedicine, and Biotechnology 45:185–192. doi: https://doi.org/10.3109/21691401.2016.1146731.

Ayutsede, J., Gandhi, M., Sukigara, S., Micklus, M., Chen, H.-E., & Ko, F. (2005). Regeneration of bombyx mori silk by electrospinning. Part 3: characterization of electrospun nonwoven mat. Polymer, 46, 1625–1634. https://doi.org/10.1016/j.polymer.2004.11.029.

Bacakova, L., Novotná, K., & Parizek, M. (2014). Polysaccharides as cell carriers for tissue engineering: the use of cellulose in vascular wall reconstruction. Physiological Research, 63, S29–S47 PMID: 24564664 (DOI not available).

De la Paz Orozco, A., Vega, F. J., Martel-Estrada, S., Aguilar, A. H., Mendoza-Duarte, M., Chavarría-Gaytán, M., et al. (2016). Development of chitosan/poly (L-lactide)/multiwalled carbon nanotubes scaffolds for bone tissue engineering. Open Journal of Regenerative Medicine, 5, 14–23. https://doi.org/10.4236/ojrm.2016.51002.

Do, A. V., Khorsand, B., Geary, S. M., & Salem, A. K. (2015). 3D printing of scaffolds for tissue regeneration applications. Advanced Healthcare Materials, 4, 1742–1762. https://doi.org/10.1002/adhm.201500168.

Dondero, W. E., & Gorga, R. E. (2006). Morphological and mechanical properties of carbon nanotube/polymer composites via melt compounding. Journal of Polymer Science Part B: Polymer Physics, 44, 864–878. https://doi.org/10.1002/polb.20743.

Fernández-Tresguerres, I., Hernández-Gil, I., Alobera Gracia, M. A., Canto Pingarrón, M. D., & Blanco Jerez, L. (2006). Bases fisiológicas de la regeneración ósea II: El proceso de remodelado. Medicina Oral, Patología Oraly Cirugía Bucal (Internet), 11(DOI not available), 151–157.

Fernandez-Vicente, M., Calle, W., Ferrandiz, S., & Conejero, A. (2016). Effect of infill parameters on tensile mechanical behavior in desktop 3D printing. 3D Printing and Additive Manufacturing, 3, 183–192. https://doi.org/10.1089/3dp.2015.0036.

Gorga, R. E., & Cohen, R. E. (2004). Toughness enhancements in poly (methyl methacrylate) by addition of oriented multiwall carbon nanotubes. Journal of Polymer Science Part B: Polymer Physics, 42, 2690–2702. https://doi.org/10.1002/polb.20126.

Gregor, A., Filová, E., Novák, M., Kronek, J., Chlup, H., Buzgo, M., Blahnová, V., Lukášová, V., Bartoš, M., Nečas, A., & Hošek, J. (2017). Designing of PLA scaffolds for bone tissue replacement fabricated by ordinary commercial 3D printer. Journal of Biological Engineering, 11, 31–51. https://doi.org/10.1186/s13036-017-0074-3.

Gupta, B., Revagade, N., & Hilborn, J. (2007). Poly (lactic acid) fiber: an overview. Progress in Polymer Science, 32, 455–482. https://doi.org/10.1016/j.progpolymsci.2007.01.005.

Islam, M., Rojas, E., Bergey, D., Johnson, A., & Yodh, A. (2003). High weight fraction surfactant solubilization of single-wall carbon nanotubes in water. Nano Letters, 3, 269–273. https://doi.org/10.1021/nl025924u.

Kim, J.-W., Kotagiri, N., Kim, J.-H., & Deaton, R. (2006). In situ fluorescence microscopy visualization and characterization of nanometer-scale carbon nanotubes labeled with 1-pyrenebutanoic acid, succinimidyl ester. Applied Physics Letters, 88, 213110. https://doi.org/10.1063/1.2206875.

Kim, J., Kim, S. W., Choi, S. J., Lim, K. T., Lee, J. B., Seonwoo, H., Choung, P. H., Park, K., Cho, C. S., Choung, Y. H., & Chung, J. H. (2011). A healing method of tympanic membrane perforations using three-dimensional porous chitosan scaffolds. Tissue Engineering Parts A, 17, 2763–2772. https://doi.org/10.1089/ten.TEA.2010.0533.

Kim, H.-B., Seo, Y.-R., Chang, K.-J., Park, S.-B., Seonwoo, H., Kim, J. W., et al. (2017). Mechanical and biological characteristics of reinforced 3D printing filament composites with agricultural by-product. Food Engineering Progress., 21, 233–241. https://doi.org/10.13050/foodengprog.2017.21.3.233.

Koh, Y.-H., Jun, I.-K., & Kim, H.-E. (2006). Fabrication of poly (ε-caprolactone)/hydroxyapatite scaffold using rapid direct deposition. Materials Letters, 60, 1184–1187. https://doi.org/10.1016/j.matlet.2005.10.103.

Lee, H., Ahn, S., Bonassar, L. J., & Kim, G. (2013). Cell (MC3T3-E1)-printed poly (ϵ-caprolactone)/alginate hybrid scaffolds for tissue regeneration. Macromolecular Rapid Communications, 34, 142–149. https://doi.org/10.1002/marc.201200524.

Lee, J.-S., Hong, J. M., Jung, J. W., Shim, J.-H., Oh, J.-H., & Cho, D.-W. (2014). 3D printing of composite tissue with complex shape applied to ear regeneration. Biofabrication, 6, 024103. https://doi.org/10.1088/1758-5082/6/2/024103.

Lim, K.-T., Jin, H., Seonwoo, H., Kim, H.-B., Kim, J., Kim, J.-W., Renji, C., Choung, P. H., & Chung, J. H. (2016). Physical stimulation-based osteogenesis: effect of secretion in vitro on fluid dynamic shear stress of human alveolar bone-derived mesenchymal stem cells. IEEE Transactions on Nanobioscience, 15, 881–890. https://doi.org/10.1109/TNB.2016.2627053.

McCullen, S. D., Stevens, D. R., Roberts, W. A., Clarke, L. I., Bernacki, S. H., Gorga, R. E., et al. (2007). Characterization of electrospun nanocomposite scaffolds and biocompatibility with adipose-derived human mesenchymal stem cells. International Journal of Nanomedicine, 2, 253–263 PMCID: PMC2673972 (DOI not available).

Mozdzen, L. C., Rodgers, R., Banks, J. M., Bailey, R. C., & Harley, B. A. (2016). Increasing the strength and bioactivity of collagen scaffolds using customizable arrays of 3D-printed polymer fibers. Acta Biomaterialia, 33, 25–33. https://doi.org/10.1016/j.actbio.2016.02.004.

Polo-Corrales, L., Latorre-Esteves, M., & Ramirez-Vick, J. E. (2014). Scaffold design for bone regeneration. Journal of Nanoscience and Nanotechnology, 14, 15–56 PMCID: PMC3997175 (DOI not available.

Zein, I., Hutmacher, D. W., Tan, K. C., & Teoh, S. H. (2002). Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials, 23, 1169–1185. https://doi.org/10.1016/S0142-9612(01)00232-0.

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (No. 2018R1A6A1A03025582) and the National Research Foundation of Korea (NRF-2016R1D1 A3B03932921).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All protocols for human tissue processing were developed in accordance with the legal regulatory guidelines for human tissues and organs in the experimental protocol approved by the Seoul National University (Seoul, South Korea) Institutional Review Board (IRB No. CRI05008)

Conflict of Interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 331 kb)

Rights and permissions

About this article

Cite this article

Kim, HB., Patel, D.K., Seo, YR. et al. 3D-Printed Scaffolds with Reinforced Poly (Lactic Acid)/Carbon Nanotube Filaments Based on Melt Extrusion. J. Biosyst. Eng. 44, 120–127 (2019). https://doi.org/10.1007/s42853-019-00011-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-019-00011-3