Abstract

Hardmetals are tungsten carbide (WC)-based composites, which are made of WC as a hard phase and transition metals such as Co, Fe, or/and Ni as ductile binder matrices. Their properties can be mainly tailored through the grain sizes of the sintered carbides and the amount of metallic binder. As successful tool materials, hardmetals are widely applied in metal cutting, wear applications, chipless forming, stoneworking, wood, and plastic working. In 2017, about two-thirds of tungsten consumption (including recycled materials) were produced for hardmetals in the world. This paper briefly introduces the development of manufacturing technology on WC–Co hardmetals from three aspects: powder preparation, bulk densification, and performance characterization. Two special WC–Co hardmetals are also described: cobalt-enrichment zone (CEZ) hardmetals, and binderless hardmetals. Furthermore, the development prospects for manufacturing techniques of hardmetals are also presented in the end.

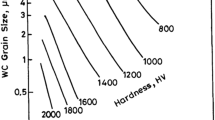

Reproduced with permission from Ref. [57] Copyright 2016 Elsevier

Reproduced with permission from Ref. [108] Copyright 2018 China Academic Journal Electronic Publishing House

Reproduced with permission from Ref. [108] Copyright 2018 China Academic Journal Electronic Publishing House

Similar content being viewed by others

Change history

21 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s42864-021-00115-4

References

Exner HE. Physical and chemical nature of cemented carbides. Int Met Rev. 1979;24(1):149.

Schubert WD, Lassner E. Cemented carbides—a success story. https://www.itia.info/assets/files/Newsletter_2010_06.pdf. Accessed 13 Sept 2019.

García J, Ciprés VC, Blomqvist A, Kaplan B. Cemented carbide microstructures: a review. Int J Refract Met Hard Mater. 2019;80:40.

Zeiler B. Tungsten and cobalt, the two key elements of the hardmetal industry. In: 11th international conference on the science of hard materials. Khao Lak. 2019.

Sarin VK, Mari D, Llanes L. Comprehensive hard materials. Kidlington: Elsevier; 2014. p. 32.

Vaishali J, Ramesh S, Sudarshana S, Shivashankar A. Reactive sintering of W–C–Co powder. In: 11th international conference on the science of hard materials, Khao Lak. 2019.

Armstrong RW. The hardness and strength properties of WC–Co composites. Materials. 2011;4(7):1287.

Fukatsu T, Kobori K, Ueki M. Micro-grained cemented carbide with high strength. Int J Refract Met Hard Mater. 1991;10(2):57.

Bock A, Zeiler B. Production and characterization of ultrafine WC powders. Int J Refract Met Hard Mater. 2002;20(1):23.

Tükör Z, Halwax E, Schubert WD, Bicher A, Bock A, Zeiler B. Structural analysis of submicron and ultrafine WC powders based on Rietveld refinements. In: 17th international plansee seminar, Reutte. 2009.

Miyake M, Hara A, Sho T. Direct production of WC from WO3 by using two rotary carburization furnaces. J Jpn Soc Powder Powder Metall. 1979;26(3):90.

Asada N, Yamamoto Y, Shimatani K, Honkawa S, Miyake M. Particle size of fine grain WC by the ‘continuous direct carburizing process’. Met Powder Rep. 1990;45:60.

Wang KF, Sun GD, Wu YD, Zhang GH. Fabrication of ultrafine and high-purity tungsten carbide powders via a carbothermic reduction–carburization process. J Alloys Compd. 2019;784:362.

Spriggs GE. A history of fine grained hardmetal. Int J Refract Met Hard Mater. 1995;13(5):241.

Farag S, Konyashin I, Ries B. The influence of grain growth inhibitors on the microstructure and properties of submicron, ultrafine and nano-structured hardmetals—a review. Int J Refract Met Hard Mater. 2018;77:12.

Adorjan A, Schubert WD, Schön A, Bock A, Zeiler B. WC grain growth during the early stages of sintering. Int J Refract Met Hard Mater. 2006;24:365.

Huang SG, Liu RL, Li L, Van der Biest O, Vleugels J. NbC as grain growth inhibitor and carbide in WC–Co hardmetals. Int J Refract Met Hard Mater. 2008;26:389.

Brookes KJA. Fine-structured hardmetals and grain-growth inhibitors. Met Powder Rep. 2016;71(2):92.

Pötschke J, Richter V, Gestrich T, Säuberlich T, Meese-Marktscheffel JA. Grain growth inhibition in ultrafine hardmetals. Int J Refract Met Hard Mater. 2017;66:95.

Pötschke J, Gestrich T, Richter V. Grain growth inhibition of hardmetals during initial heat-up. Int J Refract Met Hard Mater. 2018;72:117.

Richter V, Pötschke J, Holke R, Michaelis A. Nanoscaled hardmetals—fiction or reality? In: 18th international Plansee seminar, Reutte. 2013.

Liu X, Song X, Wang H, Liu X, Tang F, Lu H. Complexions in WC–Co cemented carbides. Acta Mater. 2018;149:164.

Meingast A, Coronel E, Blomqvist A, Norgren S, Wahnström G, Lattemann M. High resolution STEM investigation of interface layers in hardmetals. Int J Refract Met Hard Mater. 2018;72:135.

McCandlish LE, Kear BH, Kim BK. Processing and properties of nanostructured WC–Co. Nanostruct Mater. 1992;1(2):119.

Kear BH, McCandlish LE. Chemical processing and properties of nanostructured WC–Co materials. Nanostruct Mater. 1993;3(1–6):19.

Ouyang Y, Wu Y, Peng Z. Fluidization synthesis of WC–Co composite powder and its application. China Tungsten Ind. 1999;14:210.

Yi Z, Shao G, Duan X, Sun P, Shi X, Xiong Z, Guo J. Preparation of WC–Co powder by direct reduction and carbonization. China Part. 2005;3(5):286.

Liu W, Song X, Zhang J, Yin F, Zhang G. A novel route to prepare ultrafine-grained WC–Co cemented carbides. J Alloys Compd. 2008;458(1–2):366.

Liu W, Song X, Zhang J, Zhang G, Liu X. Preparation of ultrafine WC–Co composite powder by in situ reduction and carbonization reactions. Int J Refract Met Hard Mater. 2009;27(1):115.

Liu W, Song X, Wang K, Zhang J, Liu X. A novel rapid route for synthesizing WC–Co bulk by in situ reactions in spark plasma sintering. Mater Sci Eng A. 2009;499(1–2):476.

Wei C, Song X, Zhao S, Zhang L, Liu W. In-situ synthesis of WC–Co composite powder and densification by sinter-HIP. Int J Refract Met Hard Mater. 2010;28(5):567.

Fievet F. New spherical monodisperse and non-agglomerated cobalt powders. In: international conference on advances in hardmaterials production, Bonn. 1992.

Pasquazzi A, Weissenbacher R, Oehlers M. Improvement of the compressibility of cobalt powders for the cemented carbide industry. Int J Refract Met Hard Mater. 2017;62(Part B):118.

Neikov O, Naboychenko S, Murashova I. Production of cobalt and cobalt-alloy powders. In: Handbook of non-ferrous metal powders. 2nd ed. Amsterdam: Elsevier; 2019. p. 669.

Wu CH, Chen SS, Nie HB, Lin GA, Wu QS. Continuous dynamically controlled low-temperature combustion synthesis of ultrafine Co3O4 powders: experiment and theoretical analysis. Int J SHS. 2012;21(4):217.

Wu C, Xiao M, Chen S, Xie H. Application of fluidization technology in productions of cemented carbides. Int J Refract Met Hard Mater. 2014;46:188.

Brookes KJA. Gühring’s ‘elite’ hardmetals plant. Met Powder Rep. 1991;46:46.

Friedrichs K. Transition from HSS tools to solid carbide tools in the field of shaft tools and the development of new types of carbides. In: 15th international Plansee seminar, Reutte. 2001.

Brookes K. Leading Europe in extruded carbide. Met Powder Rep. 2002;57(1):26.

Formisano A, Caraviello A, Carrino L, Durante M, Langella A. Rheological characterization and finite element modeling of an extrusion process of a WC–Co compound. Int J Refract Met Hard Mater. 2015;50:93.

Laoui T, Froyen L, Kruth JP. Effect of mechanical alloying on selective laser sintering of WC-9Co powder. Powder Metall. 1999;42(3):203.

Pötschke J, Berger C, Richter H, Scheithauer U, Weingarten S. Additive manufacturing of hardmetals. In: Euro PM2017 congress & exhibition, Milan. 2017.

Brookes K. 3D-printing style additive manufacturing for commercial hardmetals. Met Powder Rep. 2015;70(3):137.

Li CW, Chang KC, Yeh AC. On the microstructure and properties of an advanced cemented carbide system processed by selective laser melting. J Alloys Compd. 2019;782:440.

Zhang X, Guo Z, Chen C, Yang W. Additive manufacturing of WC-20Co components by 3D gel-printing. Int J Refract Met Hard Mater. 2018;70:215.

Enneti R, Prough K, Wolfe T, Klein A, Studley N, Trasorras J. Sintering of WC-12% Co processed by binder jet 3D printing (BJ3DP) technology. Int J Refract Met Hard Mater. 2018;71:28.

Lengauer W, Duretek I, Fürst M, Schwarz V, Gonzalez-Gutierrez J, Schuschnigg S, Kukla C, Kitzmantel M, Neubauer E, Lieberwirth C, Morrison V. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int J Refract Met Hard Mater. 2019;82:141.

Yang MJ, German RM. Nanophase and superfine cemented carbides processed by powder injection molding. Int J Refract Met Hard Mater. 1998;16(2):107.

Rödiger K, van den Berg H, Dreyer K, Kassel D, Orths S. Near-net-shaping in the hardmetal industry. Int J Refract Met Hard Mater. 2000;18(2–3):111.

Zhu B, Qu X, Tao Y. Powder injection molding of WC-8%Co tungsten cemented carbide. Int J Refract Met Hard Mater. 2002;20(5–6):89.

Brookes K. MIM marches on into hardmetal tool manufacture. Met Powder Rep. 2005;60:14.

Micski A, Andersson KM, Jansson CÅ, Olofsson K, Samuelson P. Simulation points way towards economic hardmetal moulding. Met Powder Rep. 2008;63(8):56.

Fayyaz A, Muhamad N, Sulong AB. Microstructure and physical and mechanical properties of micro cemented carbide injection moulded components. Powder Tech. 2018;326:151.

Xie XC, Lin CG, Jia CC, Cao RJ. Effects of process parameters on quality of ultrafine WC/12Co injection molded compacts. Int J Refract Met Hard Mater. 2015;48:305.

Fais A. A faster FAST: electro-sinter-forging. Met Powder Rep. 2017;73(2):80.

Upadhyaya A, Sarathy D, Wagner G. Advances in sintering of hard metals. Mater Des. 2001;22:499.

Oliver C, Álvarez E, García J. Kinetics of densification and grain growth in ultrafine WC–Co composites. Int J Refract Met Hard Mater. 2016;59:121.

Gestrich T, Kaiser A, Pötschke J, Meinl J, Höhn S. Thermal behaviour of cermets and hardmetals during debinding and sintering. Int J Refract Met Hard Mater. 2018;73:210.

Ferstl H, Wilson D, Rough S. Quantifying the convective drying behaviour of hardmetal paste extrudates. Powder Tech. 2019;351:212.

Freytag J, Exner HE. The influence of tungsten and carbon additions on the sintering and the magnetic properties of WC-12Co hardmetals. In: international powder metallurgy conference, Chicago. 1977. p. 511.

Gille G, Szesny B, Leitner G. A new 0.4 μm WC powder as well as powder-related properties and sintering behaviour of 0.6 to 30 μm WC–Co hardmetals. J Adv Mater. 1999;31:9.

Wang H, Webb T, Bitler J. Different effects of Cr3C2 and VC on the sintering behavior of WC–Co materials. Int J Refract Met Hard Mater. 2015;53:117.

Gille G, Bredthauer J, Gries B, Mende B, Heinrich W. Advanced and new grades of WC and binder powder—their properties and application. Int J Refract Met Hard Mater. 2000;18:87.

Göthelid M, Haglund S, Ågren J. Influence of O and Co on the early stages of sintering of WC–Co: a surface study by AES and STM. Acta Mater. 2000;48:4357.

Macedo H, Silva A, Melo D. The spreading of cobalt, nickel and iron on tungsten carbide and the first stage of hard metal sintering. Mater Lett. 2003;57:3924.

Laptev A. Theory and technology of sintering, thermal and chemicothermal treatment. Powder Metall Met Ceram. 2007;46(7–8):317.

Froschauer L, Fulrath R. Direct observation of liquid-phase sintering in the system tungsten carbide-cobalt. J Mater Sci. 1976;11:142.

Haglund S, Ågren J, Uhrenius B. Solid state sintering of cemented carbides: an experimental study. Z Metallkd. 1998;89:316.

Silva A, Schubert WD, Lux B. The role of the binder phase in the WC–Co sintering. Mater Res. 2001;4:59.

Gille G, Szesny B, Dreyer K, Berg H, Schmidt J, Gestrich T, Leitner G. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts. Int J Refract Met Hard Mater. 2002;20:3.

Nie H, Zeng Q, Zheng J, Wen X, Yu Y. The preparation, preparation mechanism and properties of extra coarse-grained WC–Co hardmetals. Met Powder Rep. 2017;72:188.

Kumar A, Watabe M, Kurokawa K. The sintering kinetics of ultrafine tungsten carbide powders. Ceram Int. 2011;37:2643.

Bounhoure V, Lay S, Coindeau S, Norgren S, Pauty E, Missiaen J. Effect of Cr addition on solid state sintering of WC–Co alloys. Int J Refract Met Hard Mater. 2015;52:21.

Konyashin I, Zaitsev A, Sidorenko D, Levashov E, Levashov E, Ries B, Konischev S, Sorokin M, Mazilkin A, Herrmann M, Kaiser A. Wettability of tungsten carbide by liquid binders in WC–Co cemented carbides: is it complete for all carbon contents? Int J Refract Met Hard Mater. 2017;62:134.

Konyashin I, Ries B, Lachmann F, Fry A. Gradient WC–Co hardmetals: theory and practice. Int J Refract Met Hard Mater. 2013;36:10.

Janisch D, Lengauer W, Rödiger K, Dreyer K, Berg H. Cobalt capping: why is sintered hardmetal sometimes covered with binder? Int J Refract Met Hard Mater. 2010;28:466.

Guo J, Fan P, Wang X, Fang Z. Formation of Co-capping during sintering of straight WC-10wt% Co. Int J Refract Met Hard Mater. 2010;28:317.

Sachet E, Schubert WD, Mühlbauer G, Yukimura J, Kubo Y. On the formation and in situ observation of thin surface layers of cobalt on sintered cemented carbides. Int J Refract Met Hard Mater. 2012;31:96.

Konyashin I, Hlawatschek S, Ries B, Lachmann F, Vukovic M. Cobalt capping on WC–Co hardmetals. Part I: a mechanism explaining the presence or absence of cobalt layers on hardmetal articles during sintering. Int J Refract Met Hard Mater. 2014;42:142.

García J, Englund S, Haglöf F. Controlling cobalt capping in sintering process of cermets. Int J Refract Met Hard Mater. 2017;62:126.

Raether F, Klimera A, Baber J. In situ measurement and simulation of temperature and stress gradients during sintering of large ceramic components. Ceram Int. 2008;34(2):385.

Baber J, Klimera A, Raether F. In situ measurement of dimensional changes and temperature fields during sintering with a novel thermooptical measuring device. J Eur Ceram Soc. 2007;27:701.

Ponomarev S, Shatov A, Mikhailov A, Firstov S. Carbon distribution in WC based cemented carbides. Int J Refract Met Hard Mater. 2014;49:42.

Persson T, Schwind M. Correlation of WC grain size distribution to hardness and coercivity. In: 18th international Plansee seminar, Reutte. 2013.

Fang Z, Easan J. Nondestructive evaluation of WC–Co composites using magnetic properties. Int J Powder Met. 1993;29:259.

Liu X, Wang H, Song X, Moscatelli R. Elastic modulus of nanocrystalline cemented carbide. Trans Nonferr Met Soc China. 2018;28(5):966.

Roa JJ, Jiménez-Piqué E, Tarragó JM, Sandoval DA, Mateo A, Fair J, Llanes L. Hall–Petch strengthening of the constrained metallic binder in WC–Co cemented carbides: experimental assessment by means of massive nanoindentation and statistical analysis. Mater Sci Eng A. 2016;676:487.

Duszová A, Halgaš R, Bľanda M, Hvizdoš P, Lofaj F, Dusza J, Morgiel J. Nanoindentation of WC–Co hardmetals. J Eur Ceram Soc. 2013;33:2227.

Csanádi T, Bľanda M, Chinh N, Hvizdoš P, Dusza J. Orientation-dependent hardness and nanoindentation-induced deformation mechanisms of WC crystals. Acta Mater. 2015;83:397.

Roa J, Phani P, Oliver W, Llanes L. Mapping of mechanical properties at microstructural length scale in WC–Co cemented carbides assessment of hardness and elastic modulus by means of high speed massive nanoindentation and statistical analysis. Int J Refract Met Hard Mater. 2018;75:211.

Tarragó J, Roa J, Jiménez-Piqué E, Keown E, Fair J, Llanes L. Mechanical deformation of WC–Co composite micropillars under uniaxial compression. Int J Refract Met Hard Mater. 2016;54:70.

Sandoval D, Rinaldi A, Tarragó J, Roa J, Fair J, Llanes L. Scale effect in mechanical characterization of WC–Co composites. Int J Refract Met Hard Mater. 2018;72:157.

Sandoval D, Rinaldi A, Notargiacomo A, Ther O, Tarrés E, Roa J, Llanes L. Influence of specimen size and microstructure on uniaxial compression of WC–Co micropillars. Ceram Int. 2019;45:15934.

Trueba M, Aramburu A, Rodríguez N, Iparraguirre I, Elizalde M, Ocaña I, Martínez-Esnaola J. “In-situ” mechanical characterisation of WC–Co hardmetals using microbeam testing. Int J Refract Met Hard Mater. 2014;43:236.

Elizalde M, Ocaña I, Alkorta J, Sánchez-Moreno J. Mechanical strength assessment of single WC–WC interfaces present in WC–Co hardmetals through micro-beam bending experiments. Int J Refract Met Hard Mater. 2018;72:39.

Glühmann J, Schneeweiß M, Berg H, Kassel D, Rödiger K, Dreyer K, Lengauer W. Functionally graded WC–Ti(C, N)–(Ta, Nb)C–Co hardmetals: metallurgy and performance. Int J Refract Met Hard Mater. 2013;36:38.

Janisch D, Garel M, Eder A, Lengauer W, Dreyer K, Berg H. Sintering, characterisation, and analysis of functional gradient hardmetals. Int J Refract Met Hard Mater. 2008;26:179.

Königshofer R, Eder A, Lengauer W, Dreyer K, Kassel D, Daub H-W, Berg H. Growth of the graded zone and its impact on cutting performance in high-pressure nitrogen modified functionally gradient hardmetals. J Alloys Compd. 2004;366:228.

Tang J, Xiong J, Guo Z, Yang T, Zheng Q. Microstructure and properties of CVD coated on gradient cemented carbide with different WC grain size. Int J Refract Met Hard Mater. 2016;61:128.

Frykholm R, Jansson B, Andrén H-O. The influence of carbon content on formation of carbo-nitride free surface layers in cemented carbides. Int J Refract Met Hard Mater. 2002;20:345.

Shi L, Yang J, Huang J, Zhou T, Zhang Y. Microstructure evolution and formation mechanism of graded cemented carbide with cubic-carbide-free layer prepared with TiN or Ti(C, N) free powder mixture. Int J Refract Met Hard Mater. 2017;66:198.

Ekroth M, Frykholm R, Lindholm M, Andrén H-O, Ågren J. Gradient zones in WC–Ti(C, N)–Co-based cemented carbides: experimental study and computer simulations. Acta Mater. 2000;48:2177.

Garcia J, Lindwall G, Prat O, Frisk K. Kinetics of formation of graded layers on cemented carbides: experimental investigations and DICTRA simulations. Int J Refract Met Hard Mater. 2011;29:256.

Chen W, Xie W, Zhang L, Chen L, Wang S. Diffusion-controlled growth of fcc-free surface layers on cemented carbides: experimental measurements coupled with computer simulation. Int J Refract Met Hard Mater. 2013;41:531.

Zhang W, Du Y, Peng Y, Xie W, Wen G, Wang S. Experimental investigation and simulation of the effect of Ti and N contents on the formation of fcc-free surface layers in WC–Ti(C, N)–Co cemented carbides. Int J Refract Met Hard Mater. 2013;41:638.

Kenemitsu Y, Nishimura T, Yoshino H, Takao K, Masumoto Y. Effect of hot isostatic pressing on binderless cemented carbide. Int J Refract Met Hard Mater. 1982;1:66.

Shushi I. Ultrafine particle binderless cemented carbide. Met Powder Rep. 1992;47:32.

Zhang T, Nie H, Li W, Zheng W, Cai X. Research progress and application of binderless cemented carbides. China Tungsten Ind. 2018;33:22.

Poetschke J, Richter V, Michaelis A. Fundamentals of sintering nanoscaled binderless hardmetals. Int J Refract Met Hard Mater. 2015;49:124.

Brookes K. Plansee Seminar 2017: opening session—global hardmetal trends. Met Powder Rep. 2017;72:301.

Liu L. Reflections on the high quality development of tungsten industry in China. China Tungsten Ind. 2019;34:10.

Ginting A, Skeina R, Cuaca D, Herdianto, Pieter, Masyithah Z. The characteristics of CVD- and PVD-coated carbide tools in hard turning of AISI 4340. Measurement. 2018;129:548.

Fieandt L, Johansson K, Larsson T, Boman M, Lindahl E. On the growth, orientation and hardness of chemical vapor deposited Ti(C, N). Thin Solid Films. 2018;645:19.

Selinder T, Coronel E, Wallin E, Helmersson U. α -Alumina coatings on WC/Co substrates by physical vapor deposition. Int J Refract Met Hard Mater. 2009;27:507.

Connelly R, Pattanaik A, Sarin V. Development of moderate temperature CVD Al2O3 coatings. Int J Refract Met Hard Mater. 2005;23:317.

Reineck I, Sjöstrand M, Karner J, Pedrazzini M. Diamond coated cutting tools. Int J Refract Met Hard Mater. 1996;14:187.

Lux B, Colombier C, Altena H, Stjernberg K. Preparation of alumina coatings by chemical vapour deposition. Thin Solid Films. 1986;138:49.

Mehrotra Pankaj K. Reduction of environmental impact in hardmetal technologies. Met Powder Rep. 2017;72:267.

Li M, Xi X, Nie Z, Ma L, Liu Q. Recovery of tungsten from WC–Co hard metal scraps using molten salts electrolysis. J Mater Res Technol. 2019;8:1440.

European Powder Metallurgy Association (EPMA). Vision 2025—future developments for the European PM Industry. https://www.epma.com/epma-free-publications/product/vision-2025-high-res. Accessed 19 June 2019.

Acknowledgements

The work was financially supported by the Major Special Projects of Fujian Science and Technology Plan (Grant No. 2017HZ0001-1). The authors are grateful to Prof. Yang Mingchuan of SLU for his WC–Co composite powder.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nie, H., Zhang, T. Development of manufacturing technology on WC–Co hardmetals. Tungsten 1, 198–212 (2019). https://doi.org/10.1007/s42864-019-00025-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-019-00025-6