Abstract

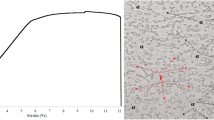

A novel plasma-MIG hybrid welding process, which combines the advantages of plasma arc and MIG welding, can improve the welding efficiency of aluminum alloy thick plates and reduce defects. The effects of plasma-MIG hybrid welding parameters on the penetration capability, tensile strength, weld bead microstructure, and hot cracking susceptibility of 5083 aluminum alloy 6-mm-thick butt-joint specimens were investigated. In this study, hybrid welding parameters such as plasma arc current, distance between plasma arc torch and base metal, torch travel speed, and plasma arc argon flow rate were selected. The results demonstrated that specimens produced with a higher plasma arc welding current at 163 A could improve the penetration capability but reduced the hot cracking susceptibility of specimens. The specimens produced at a higher torch travel speed of 340 mm/min had better tensile strength and lower hot cracking susceptibility. Using a lower plasma arc argon flow rate at 3.7 L/min during the plasma-MIG hybrid welding process not only improve penetration capability, but also increase the tensile strength of the 5083 aluminum alloy weld to 265.2 MPa.

Similar content being viewed by others

Availability of data and material

All data are presented in this published article.

Code availability

Not applicable.

References

Huang L, Hua X, Wu D, Jiang Z, Li F, Wang H, Shi S (2017) Microstructural characterization of 5083 aluminum alloy thick plates welded with GMAW and twin wire GMAW processes. Int J Adv Manuf Technol 93:1809–1817

Yang M, Lu J, Wang H, Liu Y, Yang H, Zhang W, Tan J, Chen J (2021) Effect of the laser power on the microstructure and mechanical properties of the laser-MIG hybrid welding joints of the 2195 Al–Li alloy. Sci Technol Weld Joining 26(1):75–83

Huang L, Hua X, Wu D (2018) Relationship between the weld pool convection and metallurgical and mechanical properties in hybrid welding for butt joint of 10-mm-thick aluminum alloy plate. Welding in the World 62:895–903

Huang L, Hua X, Wu D, Fang L (2019) Experimental investigation and numerical study on the elimination of porosity in aluminum alloy laser welding and laser–GMA welding. J Mater Eng Perform 28:1618–1627

Subashini L, Prabhakar KVP, Gundakaram RC, Ghosh S, Padmanabham G (2016) Single pass laser-arc hybrid welding of maraging steel thick sections. Mater Manuf Processes 31:2186–2198

Bunaziv I, Akselsen OM, Salminen A, Unt A (2016) Fiber laser-MIG hybrid welding of 5 mm 5083 aluminum alloy. J Mater Process Technol 233:107–114

Wang L, Liu Y, Yang C, Gao M (2021) Study of porosity suppression in oscillating laser-MIG hybrid welding of AA6082 aluminum alloy. J Mater Process Technol 292:117053

Guo Y, Pan H, Ren L, Quan G (2018) An investigation on plasma-MIG hybrid welding of 5083 aluminum alloy. Int J Adv Manuf Technol 98:1433–1440

Han Y, Tong J, Hong H, Sun Z (2019) The influence of hybrid arc coupling mechanism on GMAW arc in VPPA-GMAW hybrid welding of aluminum alloys. Int J Adv Manuf Technol 101:989–994

Cheng CM, Chou CP, Lee IK, Lin HY (2005) Hot cracking of welds on heat treatable aluminium alloys. Sci Technol Weld Joining 10(3):344–352

Chang CC, Chen CL, Wen JY, Cheng CM, Chou CP (2012) Characterization of hot cracking due to welding of high-strength aluminum alloys. Mater Manuf Processes 27:658–663

Lin HL, Wang WK (2016) Effect of activating flux on the A356 and 6061 aluminum alloy GMA welds. Appl Mech Mater 835:161–166

Miao H, Yu G, He X, Li S, Chen X (2017) Comparative study of hybrid laser–MIG leading configuration on porosity in aluminum alloy bead-on-plate welding. Int J Adv Manuf Technol 91:2681–2688

Yang T, Xiong J, Chen H (2016) Effect of process parameters on tensile strength in plasma-MIG hybrid welding for 2219 aluminum alloy. Int J Adv Manuf Technol 84:2413–2421

Vyskoč M, Sahul M, Sahul M (2018) Effect of shielding gas on the properties of AW 5083 aluminum alloy laser weld joints. J Mater Eng Perform 27:2993–3006

Wu L, Yang B, Han X, Ma G, Xu B, Liu Y, Song X (2022) The microstructure and mechanical properties of 5083, 6005A and 7N01 aluminum alloy gas metal arc-welded joints for high-speed train: a comparative study. Metals 12:213

Liu Y, Wang W, Xie J, Sun S, Wang L, Qian Y, Meng Y, Wei Y (2012) Microstructure and mechanical properties of aluminum 5083 weldments by gas tungsten arc and gas metal arc welding. Mater Sci Eng, A 549:7–13

Ma M, Lai R, Qin J, Wang B, Liu H, Yi D (2021) Effect of weld reinforcement on tensile and fatigue properties of 5083 aluminum metal inert gas (MIG) welded joint: experiments and numerical simulations. Int J Fatigue 144:106046

Funding

This published article was financially supported by the Ministry of Science and Technology (MOST) of Taiwan under the project No. MOST 109–2221-E-017–002.

Author information

Authors and Affiliations

Contributions

Hsuan-Liang Lin designed the MOST project and the main conceptual ideas of this research and conducted experimental discussions. Guan-Ching Chen performed all welding experiments and verified the experimental results using tensile testing, OM, and SEM. Ching-Min Cheng proposed in a discussion with Hsuan-Liang Lin to analyze the hot crack susceptibility of the specimens by a spot vare-straint testing machine. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable. This published article involves no studies on human or animal subjects.

Consent to participate

Not applicable. This published article involves no studies on human subjects.

Consent for publication

Not applicable. This published article involves no studies on human subjects.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, HL., Chen, GC. & Cheng, CM. Effects of plasma-MIG hybrid welding parameters on performance and hot cracking susceptibility of 5083 Al alloy butt-joint welds. Int J Adv Manuf Technol 122, 4055–4064 (2022). https://doi.org/10.1007/s00170-022-10159-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10159-6