Abstract

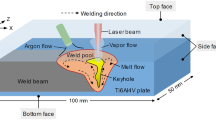

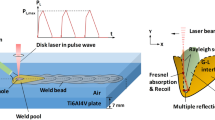

For a practical pulse laser beam welding (PLBW) process of metal sheets assembled in butt joint configuration, the precise control of the assembling clearance has been a challenge. The existence of machining burrs and assembly errors will lead to forming severe defects, such as misalignment, welding leakage, and penetrating. In this paper, a pair of Ti6Al4V plates with a 0.2-mm air gap was tested by an improved PLBW process. A three-dimensional multi-phase and multi-physical field coupling model of the Ti6Al4V plate with a reserved air gap was established according to the weld profile, and the dynamic behavior of the keyhole and molten pool was simulated. The transient temperature field, velocity field, keyhole size, and liquid bridge connection were calculated by using different welding heat input parameters. The results showed that the weld profile simulated by the CFD model is in good agreement with the experimental results, and the deviation is between 0.68 and 7.95%. After the laser power reaches the peak value, the metal steam eruption weakens and the obvious Marangoni vortex appears in the molten pool. The simulated keyhole is always in three stages, that is, the keyhole appears and then gradually forms the through-hole. The through-hole keeps oscillating, and finally, the keyhole shrinks and disappears when the laser power drops to zero. With the increase of laser peak power, the keyhole shape becomes more curved, indicating that the keyhole oscillation is enhanced. With the increase in welding speed, the stability of the molten pool is improved, and the area of the liquid bridge rises more regularly.

Similar content being viewed by others

References

Fabrizia C, Vittorio A, Gaetano C, Francesco C, Vincenzo S (2013) Investigation and optimization of laser welding of Ti-6Al-4V titanium alloy plates. J Manuf Sci Eng 135(6):061012

Auwal ST, Ramesh S, Yusof F, Manladan SM (2018) A review on laser beam welding of titanium alloys. Int J Adv Manuf Technol 97:1071–1098

Gope DK, Kumar U, Chattopadhyaya S, Mandal S (2018) Experimental investigation of pug cutter embedded TIG welding of Ti-6Al-4V titanium alloy. J Mech Sci Technol 32:2715–2721

Ghaini FM, Hamedi MJ, Torkamany MJ, Sabbaghzadeh J (2007) Weld metal microstructural characteristics in pulsed Nd: YAG laser welding. Scr Mater 56:955–958

Mohid Z, Rafai NH, Ibrahim MR, Rahim EA (2017) Melted zone shapes transformation in titanium alloy welded using pulse wave laser. Mater Sci Forum 882:8–12

Junaid M, Baig MN, Shamir M, Khan FN, Rehman K, Haider J (2016) A comparative study of pulsed laser and pulsed TIG welding of Ti-5Al-2.5Sn titanium alloy sheet. J Mater Process Technol 242:24–38

Gao XL, Zhang LJ, Liu J, Zhang JX (2014) Effects of weld cross-section profiles and microstructure on properties of pulsed Nd: YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72:895–903

Kumar U, Patel D, Zaffar Z, Gope DK, Chattopadhyaya S, Das AK, Biswal MK (2018) Experimental and numerical investigation of temperature distribution and analysis of mechanical properties during pulsed Nd-YAG laser welding of thin Ti6Al4V alloy. Mater Sci Eng 377:012158

Aalderink BJ, Pathiraj B, Aarts KM (2010) Seam gap bridging of laser based processes for the welding of aluminum sheets for industrial applications. Int J Adv Manuf Technol 48:143–154

Satyanarayana G, Narayana KL, Nageswara BR, Slobodyan MS, Elkin MA, Kiselev AS (2019) Numerical simulation of the processes of formation of a welded joint with a pulsed ND:YAG laser welding of ZR–1%NB alloy. Thermal Eng 66:210–218

Pang SY, Chen WD, Wang W (2014) A quantitative model of keyhole instability induced porosity in laser welding of titanium alloy. Metall Mater Trans 45:2808–2818

Drobniak P, Otto A, Vázquez RG, Arias RM, Arias JL (2020) Simulation of keyhole laser welding of stainless steel plates with a gap. Procedia CIRP 94:731–736

Hao HC, Gao JQ, Huang HS (2020) Numerical simulation for dynamic behavior of molten pool in tungsten inert gas welding with reserved gap. J Manuf Processes 58:11–18

Katayama S, Kawahito Y (2009) Elucidation of phenomena in high power fiber laser welding, development of prevention procedures of welding defects. Proc SPIE 7195:71951R-R71955

Chang B, Allen C, Blackburn J, Hilton P, Du D (2015) Fluid flow characteristics and porosity behavior in full penetration laser welding of a titanium alloy. Metall Mater Trans B 46:906–918

Lei Z, Wu S, Cao B (2020) Role of thermal fluid dynamics in alloying element distribution and weld porosity in powder feeding-based laser welding of Al alloy. Appl Therm Eng 171:115081

Pang SY, Chen LL, Zhou JX, Yin YJ, Chen T (2011) A three-dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding. J Phys D 44:25301

Chen JC, Ouyang ZP, Du XW, Wei YH (2022) Weld pool dynamics and joining mechanism in pulse wave laser beam welding of Ti-6Al-4V titanium alloy sheets assembled in butt joint with an air gap. Opt Laser Technol 146:107558

Pilliod JE, Puckett EG (2004) Second-order accurate volume-of-fluid algorithms for tracking material interfaces. J Comput Phys 199:465–502

Osher S, Fedkiw R, Piechor K (2004) Level set methods and dynamic implicit surfaces. Appl Mech Rev 57:B15–B15

Sussman M, Smereka P, Osher S (1994) A level set approach for computing solutions to incompressible two-phase flow. J Comput Phys 114:146–159

Qian LG, Wei YH, Xiao F (2018) Coupled THINC and level set method: a conservative interface capturing scheme with high-order surface representations. J Comput Phys 373:284–303

Chen JC, Chen XM, Liu XJ, Wei YH (2022) Numerical investigation on keyhole collapsing and rebuilding behavior during pulsed laser beam welding of Ti6Al4V titanium alloy under various pulse frequencies. Appl Phys A 128:140–155

Yang Z, Tao W, Li L, Chen Y, Shi C (2017) Numerical simulation of heat transfer and fluid flow during double-sided laser beam welding of T-joints for aluminum aircraft fuselage panels. Opt Laser Technol 91:120–129

Li ZX, Rostam K, Panjehpour A, Akbari M, Karimipour A, Rostamis S (2020) Experimental and numerical study of temperature field and molten pool dimensions in dissimilar thickness laser welding of Ti6Al4V alloy. J Manuf Process 49:438–436

Pariona MM, Taques AF, Wojciechowski LA (2018) The Marangoni effect on microstructure properties and morphology of laser-treated Al-Fe alloy with single track by FEM: varying the laser beam velocity. Int J Heat Mass Tran 119:10–19

Chang B, Allen C, Blackburn J, Hilton P, Du D (2015) Fluid flow characteristics and porosity behavior in full penetration laser welding of a titanium alloy. Metall Mater Trans B 46:906–918

Funding

The research is funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and China Postdoctoral Science Foundation No. 2020M671479.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors declare their consent to participate.

Consent for publication

The authors declare their consent for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kong, B., Wei, Y., Tang, F. et al. Effect of welding heat input conditions on the dynamic behavior of pulse laser beam welding molten pool for Ti6Al4V thin plate with clearance. Int J Adv Manuf Technol 125, 629–644 (2023). https://doi.org/10.1007/s00170-022-10740-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10740-z