Abstract.

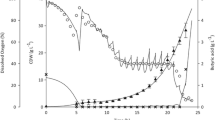

The main objective of this work was the optimization of the production of the β-ketolase, acetopyruvate hydrolase, from Pseudomonas putida O1. Orcinol was used as an inducer for enzyme production. The growth medium was optimized in two steps. In the first step, screening for optimal glucose concentration was performed. In the second step, a central composite design was used to optimize carbon and nitrogen sources in the medium. After this optimization procedure, a medium was obtained which produced seven times more biomass than the initial medium. Acetopyruvate hydrolase enzyme production was optimized by determining the optimal time of feed and amount of orcinol, using statistical methods. In a subsequent step, the maximal orcinol-degradation rate was determined. The results obtained were used to find an optimal feeding profile for enzyme production. By using the optimized fed-batch process, acetopyruvate hydrolase activity was enhanced from 10 units l–1 to 400 units l–1, in comparison with previously reported fermentation experiments. Productivity could even be increased by a factor of 75, to a value of 20 units l–1 h–1.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Electronic Publication

Rights and permissions

About this article

Cite this article

Hofer, .H., Mandl, .T. & Steiner, .W. Acetopyruvate hydrolase production by Pseudomonas putida O1 – optimization of batch and fed-batch fermentations. Appl Microbiol Biotechnol 60, 293–299 (2002). https://doi.org/10.1007/s00253-002-1133-2

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s00253-002-1133-2