Abstract

3-Hydroxypropionaldehyde (3-HPA) forms, together with HPA-hydrate and HPA-dimer, a dynamic, multi-component system (HPA system) used in food preservation, as a precursor for many modern chemicals such as acrolein, acrylic acid, and 1,3-propanediol (1,3-PDO), and for polymer production. 3-HPA can be obtained both through traditional chemistry and bacterial fermentation. To date, 3-HPA has been produced from petrochemical resources as an intermediate in 1,3-PDO production. In vivo, glycerol is converted in one enzymatic step into 3-HPA. The 3-HPA-producing Lactobacillus reuteri is used as a probiotic in the health care of humans and animals. The biotechnological production of 3-HPA from renewable resources is desirable both for use of 3-HPA in foods and for the production of bulk chemicals. The main challenge will be the efficient production and recovery of pure 3-HPA.

Similar content being viewed by others

References

Abeles RH, Brownstein AM, Randles CH (1960) β-Hydroxypropionaldehyde, an intermediate in the formation of 1,3-propanediol by Aerobacter aerogenes. Biochim Biophys Acta 41:530–531

Arntz D, Wiegand N (1991) Method of preparing 1,3-propanediol. US Patent 5 015 789

Ashton FM, Crafts AS (1981) Mode of action of herbicides. Wiley, New York

Axelsson L, Chung TC, Dobrogosz WJ, Lindgren SE (1988) Production of a broad-spectrum antimicrobial substance produced by Lactobacillus reuteri. Microb Ecol Health Dis 2:131–136

Barbirato F, Grivet JP, Soucaille P, Bories A (1996) 3-Hydroxypropionaldehyde, an inhibitory metabolite of glycerol fermentation to 1,3-propanediol by enterobacterial species. Appl Environ Microbiol 62:1448–1451

Berzelius J (1839) Lehrbuch der Chemie. Dresden und Leipzig

Biebl H, Menzel K, Zeng AP, Deckwer WD (1999) Microbial production of 1,3-propanediol. Appl Microbiol Biotechnol 52:289–297

Boer AL de, Schmidt-Dannert C (2003) Recent efforts in engineering microbial cells to produce new chemical compounds. Curr Opin Chem Biol 7:273–278

Bowmer KH, Higgins ML (1976) Some aspects of the persistence and fate of acrolein herbicide in water. Arch Environ Contam Toxicol 5:87–96

Bowmer KH, Sainty E (1977) Management of aquatic plants with acrolein. J Aquat Plant Manage 15:40–46

Brossmer C, Arntz D (2000) Process for the production of 1,3-propanediol. US Patent 6 140 543

Burridge A (2002) Product profile: acrylic acid. European Chemical News 16–22 September, Reed Business Information

Cameron DC, Altaras NE, Hoffman ML, Shaw AJ (1998) Metabolic engineering of propanediol pathways. Biotechnol Prog 14:116–125

Casas IA, Dobrogosz WJ (1997) Lactobacillus reuteri: overview of a new probiotic for humans and animals. Microbiol Ther 26:221–231

Casas IA, Dobrogosz WJ (2000) Validation of the probiotic concept: Lactobacillus reuteri confers broad-spectrum protection against disease in humans and animals. Microb Ecol Health Dis 12:285

CEP (2003) Engineering 1,3-carbon molecules. AIChE, New York, www.cepmagazine.org. Cited 14 February 2003

Chen CN, Sung HW, Liang HF, Chang WH (2002) Feasibility study using a natural compound (reuterin) produced by Lactobacillus reuteri in sterilizing and crosslinking biological tissues. J Biomed Mater Res 61:360–369

Chevreul ME (1823) In: Levrault (ed) Recherches sur les corps gras d’origine animale. Paris

Circle SJ, Stone L, Boruff CS (1945) Acrolein determination by means of tryptophan. Ind Eng Chem 17:259–262

Claisse O, Lonvaud-Funel A (2001) Primers and a specific DNA probe for detecting lactic acid bacteria producing 3-hydroxypropionaldehyde from glycerol in spoiled ciders. J Food Prot 64:833–837

Daeschel MA (1989) Antimicrobial substances from lactic acid bacteria for use as food preservatives. Food Technol 43:164–167

Daniel R, Bobik TA, Gottschalk G (1999) Biochemistry of coenzyme B12-dependent glycerol and diol dehydratases and organization of the encoding genes. FEMS Microbiol Rev 22:553–566

Danner H, Braun R (1999) Biotechnology for the production of commodity chemicals from biomass. Chem Soc Rev 28:395–405

Danner H, Ürmös M, Gartner M, Braun R (1998) Biotechnological production of acrylic acid out of biomass. Appl Biochem Biotechnol 70–72:887–894

Dobrogosz WJ, Lindgren SE (1988) Antibiotic reuterin. US Patent PCT/US88/01423

Dobrogosz WJ, Casas IA, Pagano GA, Sjöberg B-M, Talarico TL, Karlsson M (1989) Lactobacillus reuteri and the enteric microbiota. In: Grubb R, Midtvedt T, Norin E (eds) The regulatory and protective role of the normal microflora. MacMillan, London, pp 283–292

El-Ziney MG, Debevere J (1998) The effect of reuterin on Listeria monocytogenes and Escherichia coli O157:H7 in milk and cottage cheese. J Food Prot 61:1275–1280

El-Ziney MG, Arneborg N, Uyttendaele M, Debevere J, Jakobsen M (1998) Characterization of growth and metabolite production of Lactobacillus reuteri during glucose/glycerol cofermentation in batch and continuous cultures. Biotechnol Lett 20:913–916

El Ziney MG, van den Tempel T, Debevere J, Jakobsen M (1999) Application of reuterin produced by Lactobacillus reuteri 12002 for meat decontamination and preservation. J Food Prot 62:257–261

Emptage MH, Sharon L, Laffend LA, Pucci JP, Whited G (2003) Process for the biological production of 1,3-propanediol with high titer. US Patent 6 514 733

Etzkorn WG, Brockwell JL, Young MA, Maher JM, Warren BK (2000) Production of 1,3-propanediol from 3-hydroxypropionaldehyde. US Patent 6 166 263

Freund A (1881) Über die Bildung und Darstellung von Trimethylenalkohol aus Glycerin. Monatsh Chem 2:636–641

Gänzle MG, Vogel RF (2003) Studies on the mode of action of reutericyclin. Appl Environ Microbiol 69:1305–1307

Geoffroy CJ (1742) Method of making soap-lees and hard soap, for medicinal uses. Phil Trans R Soc London 42:71–77

Ghilarducci DP, Tjeerdema RS (1995) Fate and effects of acrolein. Rev Environ Contam Toxicol 95–146

Gokarn RR, Selifonova OV, Jessen HJ, Gort SJ, Selmer T, Buckel W (2002) 3-Hydroxypropionic acid and other organic compounds. Canadian Patent 2429039

Hall RH, Stern ES (1950) Acid-catalysed hydration of acrylaldehyde: kinetics of the reaction and isolation of β-hydroxypropaldehyde. J Chem Soc 490–498

Hess LG, Kurtz AN, Stanton DB (1978) Acrolein and derivatives. In: Grayson M, Eckroth D (eds) Kirk-Othmer encyclopedia of chemical technology. Wiley, New York, pp 277–297

Holtzel A, Gänzle MG, Nicholson GJ, Hammes WP, Jung G (2000) The first low molecular weight antibiotic from lactic acid bacteria: reutericyclin, a new tetramic acid. Angew Chem Int Ed Eng 39:2766–2768

Humphreys FB (1924) Formation of acrolein from glycerol by B. welchii. J Inf Dis 35:282–290

Inverizon International (1998) Technology Roadmap for Plant/Crop-Based Renewable Resources 2020. Inverizon International, Chesterfield, Mo., http://www.oit.doe.gov/agriculture/pdfs/technology_roadmap.pdf

Kabuki T, Saito T, Kawai Y, Uemura J, Itoh T (1997) Production, purification and characterization of reutericin 6, a bacteriocin with lytic activity produced by Lactobacillus reuteri LA6. Int J Food Microbiol 34:145–156

Kehrer JS, Biswal SS (2000) The molecular effects of acrolein. Toxicol Sci 57:6–15

Kissel CL, Brady JL, Guerra AM, Pau JK, Rockie BA, Caserio FF Jr (1978) Analysis of acrolein in aged aqueous media. Comparison of various analytical methods with bioassays. J Agric Food Chem 26:1338–1343

Klantschitsch T, Spillmann H, Puhan Z (1996) Lactobacillus reuteri: Ein milchwirtschaftlicher Neuling. DMZ Lebensm-Ind Milchwirtsch 17:790–797

Knifton JF, Slaugh LH, Weider PR, James TG, Powell JB, Allen KD, Williams TS (2003) One step process for preparing a 1,3-diol. US Patent 6 518 466

Lörcks J (2000) Biologisch abbaubare Werkstoffe. Fachagentur Nachwachsende Rohstoffe, Gülzow, Germany

Lüthi-Peng Q, Dileme FB, Puhan Z (2002a) Effect of glucose on glycerol bioconversion by Lactobacillus reuteri. Appl Microbiol Biotechnol 59:289–296

Lüthi-Peng Q, Schärer S, Puhan Z (2002b) Production and stability of 3-hydroxypropionaldehyde in Lactobacillus reuteri. Appl Microbiol Biotechnol 60:73–80

Mao J, Doane R, Kovacs MF Jr (1994) Separation of acrolein and its possible metabolites using different modes of high performance liquid chromatography. J Liquid Chrom 17:1811–1819

Matagrin A (1925) Chevreul et la bougie stéarique. Ind Chim 12:400–402

Mickelson MN, Werkman CH (1940) The dissimilation of glycerol by coli-aerogenes intermediates. J Bacteriol 39:709–715

Mills E, Baugh WD, Conner HA (1954) Studies on the formation of acrolein in distillery mashes. Appl Microbiol 2:9–13

Mittendorf V, Robertson EJ, Leech RM, Kruger N, Steinbüchel A, Poirier Y (1998) Synthesis of medium-chain-length polyhydroxyalkanoates in Arabidopsis thaliana using intermediates of peroxisomal fatty acid beta-oxidation. Proc Natl Acad Sci USA 95:13397–13402

Morris RC, Snider AV (1950) Polymers of trimethylene glycol. US Patent 2 520 733

Mukai T, Asasaka T, Sato E, Mori K, Matsumoto M, Ohori H (2002) Inhibition of binding of Helicobacter pylori to the glycolipid receptors by probiotic Lactobacillus reuteri. FEMS Immunol Med Microbiol 32:105–110

Nagasawa T, Nakamura T, Yamada H (1990) Production of acrylic acid and methacrylic acid using Rhodococcus rhodochrous J1 nitrilase. Appl Microbiol Biotechnol 34:322–324

Narayanasamy K, Shukla S, Parekh LJ (1990) Utilization of acrylonitrile by bacteria isolated from petrochemical waste waters. Indian J Exp Biol 28:968–971

Nawaz MS, Franklin W, Cerniglia CE (1993) Degradation of acrylamide by immobilized cells of a Pseudomonas sp. and Xanthomonas maltophilia. Can J Microbiol 39:207–212

Nawaz MS, Franklin W, Cerniglia CE (1994) Degradation of aliphatic amide mixture by immobilized and nonimmobilized cells of Pseudomonas sp. Environ Sci Technol 28:1106–1109

Nef JU (1904) Dissociationsvorgänge in der Glycol-Glycerinreihe. Ann Chem 335:191–245

Nielsen AT, Moore DW, Schuetze Jr (1981) A 13C and 1H NMR study of formaldehyde reactions with acetaldehyde and acrolein. Synthesis of 2-(hydroxymethyl)-1,3-propanediol. Pol J Chem 55:1393–1403

Noble A (1999) Why do wines taste bitter and feel astringent? In: Waterhouse AL, Ebeler SE (eds) Chemistry of wine flavor. Am Chem Soc, Washington, D.C., pp 156–165

O’Loughlin, Bowmer KH (1975) Dilution and decay of aquatic herbicides in flowing channels. J Hydrol 26:217–235

Otsuka K (2003) Studies on the mechanism of glycerol metabolism by microbes. Bull Res Inst Ferment Yamanashi Univ 5:1–58

Pasteur L (1858a) Nouvelles recherches sur la fermentation alcoolique. C R Acad Sci XLVII:224

Pasteur L (1858b) Production constante de glycérine dans la fermentation alcoolique. C R Acad Sci XLVI:857

Pasteur L (1866) Etudes sur le vin, ses maladies; causes qui les provoquent, procédées nouveaux pour le conserver et pour le vieillir. Masson, Paris

Pressman D, Lucas HJ (1942) Hydration of unsaturated compounds. XI. Acrolein and acrylic acid. J Am Chem Soc 64:1953–1957

Rasch M (2002) The influence of temperature, salt and pH on the inhibitory effect of reuterin on Escherichia coli. Int J Food Microbiol 72:225–231

Read RR (2002) β-Hydroxypropionic acid. Org Synth 1:321

Redtenbacher J (1843) Über die Zerlegungsprodukte des Glycerinoxydes durch trockene Destillation. Ann Chem Pharm 47:113–148

Redtenbacher J (1846) Über eine neue Entstehungsweise der Metacetonsäure. Ann Chem Pharm 57:170

Reid G (1999) The scientific basis for probiotic strains of Lactobacillus. Appl Environ Microbiol 65:3763–3766

Rentschler H, Tanner H (1951) Das Bitterwerden der Rotweine. Mitt Lebensm-Unters Hyg 42:463–475

Reymolds H, Hoehn WM, Werkman CH (1939) Occurrence of acrolein as an intermediate during the fermentation of glycerol by the coli-aerogenes bacteria. Iowa State Coll J Sci 13:277

Sauvageot N, Gouffi K, Laplace JM, Auffray Y (2000) Glycerol metabolism in Lactobacillus collinoides: production of 3-hydroxypropionaldehyde, a precursor of acrolein. Int J Food Microbiol 55:167–170

Schauenstein E, Esterbauer H, Zollner H (1977) Saturated aldehydes. In: Schauenstein E, Esterbauer H, Zollner H (eds) Aldehydes in biological systems their natural occurrence and biological activities. Pion, London, pp 9–24

Scheele CW (1931) On the peculiar saccharine principle in expressed oils and fats. The collected papers of CW Scheele 255–258

Schoenberger CR (2003) Greenhouse effect. Forbes Magazine (http://www.forbes.com/forbes/2003/0203/054_print.html)

Schütz H, Radler F (1984) Anaerobic reduction of glycerol to propanediol-1.3 by Lactobacillus brevis and Lactobacillus buchneri. Syst Appl Microbiol 5:169–178

Serjak WC, Day WH, Van Lanen JM, Boruff CS (1954) Acrolein production by bacteria found in distillery grain mashes. Appl Microbiol 2:14–20

Shornikova AV, Casas IA, Isolauri E, Mykkanen H, Vesikari T (1997) Lactobacillus reuteri as a therapeutic agent in acute diarrhea in young children. J Pediatr Gastroenterol Nutr 24:399–404

Slininger PJ, Bothast RJ (1985) Optimizing aerobic conversion of glycerol to 3-hydroxypropionaldehyde. Appl Environ Microbiol 50:1444–1450

Slininger PJ, Bothast RJ, Smiley KL (1983) Production of 3-hydroxypropionaldehyde from glycerol. Appl Environ Microbiol 46:62–67

Smiley KL, Sobolov M (1962) A cobamide-requiring glycerol dehydrase from an acrolein-forming Lactobacillus. Arch Biochem Biophys 97:538–543

Sobolov M, Smiley KL (1960) Metabolism of glycerol by an acrolein-forming Lactobacillus. J Bacteriol 79:261–266

Sponholz W-R (1993) Wine spoilage by microorganisms. In: Fleet GH (ed) Wine microbiology and biotechnology. Harwood, Chur, pp 395–420

Stepanow A, Schtschukin M (1927) Über die Aldolkondensation von Formaldehyde und Acetaldehyde. Chem Zentralbl D 1167

Sung HW, Chen CN, Chang Y, Liang HF (2002) Biocompatibility study of biological tissues fixed by a natural compound (reuterin) produced by Lactobacillus reuteri. Biomaterials 23:3203–3214

Sung HW, Chen CN, Liang HF, Hong MH (2003) A natural compound (reuterin) produced by Lactobacillus reuteri for biological-tissue fixation. Biomaterials 24:1335–1347

Talarico TL, Dobrogosz WJ (1989) Chemical characterization of an antimicrobial substance produced by Lactobacillus reuteri. Antimicrob Agents Chemother 33:674–679

Talarico TL, Casas IA, Chung TC, Dobrogosz WJ (1988) Production and isolation of reuterin, a growth inhibitor produced by Lactobacillus reuteri. Antimicrob Agents Chemother 32:1854–1858

Tannock GW (1999) Probiotics: a critical review. Horizon, Wymondham

Thiman KV (1955) The life of bacteria their growth, metabolism, and relationships. MacMillan, New York

Toba T, Samant SK, Yoshioka E, Itoh T (1991) Reutericin-6, a new bacteriocin produced by Lactobacillus reuteri La-6. Lett Appl Microbiol 13:281–286

Toraya T (2000) Radical catalysis of B12 enzymes: structure, mechanism, inactivation, and reactivation of diol and glycerol dehydratases. Cell Mol Life Sci 57:106–127

Ulmer C, Deckwer W-D, Zeng A-P (2002) Zweistufiger Prozess zur Herstellung von 1,3-Propandiol und 3-Hydroxypropionaldehyde aus Glycerin. Chem Ing Tech 74:674

Valerius G, Zhu X, Hofmann H, Arntz D, Haas T (1996) Modelling of a trickle-bed reactor 2. The hydrogenation of 3-hydroxypropanal to 1,3-propanediol. Chem Eng Proc 35:11–19

Valeur N, Engel P, Ladefoged K (2002) Immunomodulation in the human GI tract by the probiotic Lactobacillus reuteri (ATCC 55730/SD2112). Am J Gastroent 97:S76

Vancauwenberge JE, Slininger PJ, Bothast RJ (1990) Bacterial conversion of glycerol to beta-hydroxypropionaldehyde. Appl Environ Microbiol 56:329–332

Voisenet ME (1910) Formation d’acroléine dans la maladie de l’amertume des vins. C R Acad Sci 150:1614–1616

Voisenet ME (1914a) Sur un ferment, contenu dans les eaux, agent de déshydratation de la glycérine. C R Acad Sci 158:195–197

Voisenet ME (1914b) Sur un ferment, contenu dans les eaux, agent de déshydratation de la glycérine. Ann Inst Pasteur 28:807–818

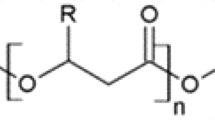

Vollenweider S, Grassi G, König I, Puhan Z (2003) Purification and structural characterization of 3-hydroxypropionaldehyde and its derivatives. J Agric Food Chem 51:3287–3293

WHO (1992) Acrolein. Environ Health Crit 127

Widmer A, Müller A (2003) Glycerin überschwemmt Europa. Chem Rundschau 10:4–6

Wittlich P (2001) Biotechnische Herstellung von 1,3-Propandiol aus Glycerin mit immobilisierten Zellen von Clostridium butyricum NRRL B-1024 und thermophilen Mikroorganismen. Dissertation, Technische Universität Braunschweig, Germany

Wolf BW, Garleb KA, Ataya DG, Casas IA (1995) Safety and tolerance of Lactobacillus reuteri in healthy adult male subjects. Microb Ecol Health Dis 8:41–50

Wolf BW, Wheeler KB, Ataya DG, Garleb KA (1998) Safety and tolerance of Lactobacillus reuteri supplementation to a population infected with the human immunodeficiency virus. Food Chem Toxicol 36:1085–1094

WSSA (1983) Herbicide Handbook of the Weed Science Society of America

Yunmbam MK, Roberts JF (1992) The in vitro efficacy of reuterin on the culture and bloodstream forms of Trypanosoma brucei brucei. Comp Biochem Physiol C 101:235–238

Yunmbam MK, Roberts JF (1993) In vivo evaluation of reuterin and its combinations with suramin, melarsoprol, dl-alpha-difluoromethylornithine and bleomycin in mice infected with Trypanosoma brucei brucei. Comp Biochem Physiol C 105:521–524

Zeng AP, Biebl H (2002) Bulk chemicals from biotechnology: the case of 1,3-propanediol production and the new trends. Adv Biochem Eng Biotechnol 74:239–259

Acknowledgements

We thank Prof. Dr. Puhan for critical advice. We thank Prof. Hsing-Wen Sung, Mr. Donald B. Appleby (Procter & Gamble Chemicals), and Mr. Valéry Desroches (HB International S.A.), for kindly providing data for the figures presented in this work. We thank Mr. Heinz Trogemann (Stockhausen GmbH & Co. KG) and Mrs. Albrecht (Celanese AG) for providing information on the price of acrylic acid, and Joseph W. Carroll (DuPont Co.) for helpful discussions. The authors would like to offer special thanks to Annemieke Ijpenberg and Janice Sych for critical review.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vollenweider, S., Lacroix, C. 3-Hydroxypropionaldehyde: applications and perspectives of biotechnological production. Appl Microbiol Biotechnol 64, 16–27 (2004). https://doi.org/10.1007/s00253-003-1497-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-003-1497-y