Abstract

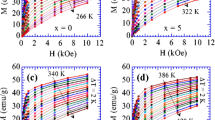

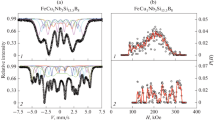

The influence of the partial substitution of Fe by Si and thermal treatments on the structural, magnetic and magnetostrictive properties of the Fe67.5Pd30.5Si2 rapidly solidified ribbons has been investigated. A remarkable decrease in the martensite transformation temperature, with ~ 65 K lower than that of the Fe–Pd archetype alloy, is observed in the as-prepared ribbons. The thermal treatments shift the martensite transformation temperatures upward, with approximately 13 K for the higher thermal treatment. Also, these induce an improvement in the crystallinity in these ribbons with high texture and an increase in the crystallite size as a result of reducing the internal defects and stress. The thermodynamic considerations discussed in the frame of the Clapeyron–Clausius relation by using the calorimetric and thermomagnetic measurements (up to 7 T) reveal a weak influence of the magnetic fields on the martensitic transformation temperatures (~ 0.5 K/T). The magnetostriction decrease with temperature under small magnetic fields was discussed, beside an unusual behaviour in the technically saturated domain. This behaviour is based on the coexistence of the ordinary and forced magnetostrictions, the last one increasing faster with the temperature decreasing.

Similar content being viewed by others

References

R. Oshima, M. Sugiyama, J. Phys. Colloq. 43(C4), 383–389 (1982). https://doi.org/10.1051/jphyscol:1982456

Y. Ma, M. Zink, S.G. Mayr, Appl. Phys. Lett. 96, 213703 (2010). https://doi.org/10.1063/1.3435260

K. Ullakko, JMEP 5, 405–409 (1996). https://doi.org/10.1007/BF02649344

E.W. Lee, Rep. Prog. Phys. 18, 184 (1955)

K. Ullakko, J.K. Huang, C. Kantner, R.C. O’Handley, Appl. Phys. Lett. (1996). https://doi.org/10.1063/1.117637

T. Yamamoto, M. Taya, Y. Sutou, Y. Liang, T. Wada, L. Sorensen, Acta Mater. 52, 5083–5091 (2004). https://doi.org/10.1016/j.actamat.2004.07.014

J. Cui, T.W. Shield, R.D. Muto, Acta Mater. 52, 35–47 (2004). https://doi.org/10.1016/j.actamat.2003.08.024

R.D. James, M. Wuttig, Philos. Mag. A 77(5), 1273 (1998). https://doi.org/10.1080/01418619808214252

M. Matsui, K. Adachi, Phys. B 161, 53–59 (1989). https://doi.org/10.1016/0921-4526(89)90102-6

S. Muto, R. Oshima, F.E. Fujita, Acta Metall. 38, 685–694 (1990). https://doi.org/10.1016/0956-7151(90)90224-5

T. Sakamoto, T. Fukuda, T. Kakeshita, T. Takeuchi, K. Kishio, J. Appl. Phys. 93, 8647–8649 (2003). https://doi.org/10.2320/matertrans.44.2495

T. Kakeshita, T. Fukuda, T. Takeuchi, Mater. Sci. Eng. A 438–440, 12–17 (2006). https://doi.org/10.1016/j.msea.2006.02.193

A. Arabi-Hashemi, Y. Ma, A. Setzer, P. Esquinazi, S.G. Mayr, Scripta Mater. 104, 91–94 (2015). https://doi.org/10.1016/j.scriptamat.2015.04.010

R. Kainuma, Y. Imano, W. Ito, Y. Sutou, H. Morito, S. Okamoto, O. Kitakami, K. Oikawa, A. Fujita, T. Kanomata, K. Ishida, Nature 439, 957 (2006). https://doi.org/10.1038/nature04493

J. Steiner, A. Lisfi, T. Kakeshita, T. Fukuda, M. Wuttig, Sci Rep. 6, 34259 (2016). https://doi.org/10.1038/srep34259

D. Vokoun, T. Goryczkaand, C.T. Hu, Smart Mater. Struct. 12, 242–248 (2003). https://doi.org/10.1088/0964-1726/12/2/312

T. Wada, T. Tagawa, M. Taya, Scr. Mater. 48, 207–211 (2003)

K. Tsuchiya, T. Nojiri, H. Ohtsuka, M. Umemoto, Mater. Trans. 44(12), 2499–2502 (2003). https://doi.org/10.2320/matertrans.44.2499

V. Sánchez-Alarcos, V. Recarte, J.I. Pérez-Landazábal, M.A. González, J.A. Rodriguez-Velamazan, Acta Mat. 57, 4224–4232 (2009). https://doi.org/10.1016/j.actamat.2009.05.020

M. Sofronie, M. Enculescu, A.D. Crisan, F. Tolea, Rom Rep Phys 72(2), 502 (2020)

D. Vokoun, C.T. Hu, Y.H. Lo, A. Lančok, O. Heczko, Mater Today Proc 2S, S845–S848 (2015). https://doi.org/10.1016/j.matpr.2015.07.414

M.E. Gruner, S. Hamann, H. Brunken, A. Ludwig, P. Entel, J. Alloys Compd. 577S, S333–S337 (2013). https://doi.org/10.1016/j.jallcom.2012.02.033

M. Sofronie, F. Tolea, M. Tolea, B. Popescu, M. Valeanu, J. Phys. Chem. Solids 142, 109446 (2020). https://doi.org/10.1016/j.jpcs.2020.109446

S. Hamann, M.E. Gruner, Acta Mater. 58, 5949–5961 (2010). https://doi.org/10.1016/j.actamat.2010.07.011

H.Y. Yasuda, N. Komoto, M. Ueda, Y. Umakoshi, Sci. Technol. Adv. Mater. 3, 165–169 (2002). https://doi.org/10.1016/S1468-6996(02)00012-8

O.A. Golovnia, G.A. Popov, N.I. Vlasova, A.V. Protasov, V.S. Gaviko, V.V. Popov Jr., A. Kashyap, J. Magn. Magn. Mater. 481, 212–220 (2019). https://doi.org/10.1016/j.jmmm.2019.03.017

M. He, L. Ma, X. Zhou, T. Liu, L. Li, Q. Yao, Z. Gu, Mater. Res. Express 6, 046406 (2019). https://doi.org/10.1088/2053-1591/aafc04

M. Sofronie, F. Tolea, V. Kuncser, M. Valeanu, G. Filoti, IEEE Trans. Mag. 51, 2500404 (2015). https://doi.org/10.1109/TMAG.2014.235922

J. Liu, N. Scheerbaum, D. Hinz, O. Gutfleisch, Acta Mater. 56(13), 3177–3186 (2008). https://doi.org/10.1016/j.actamat.2008.03.008

D. Vokoun, C.T. Hu, J. Alloys Compd. 346, 147–153 (2002). https://doi.org/10.1016/S0925-8388(02)00494-2

G. Petculescu, P.K. Lambert, A.E. Clark, K.B. Hathaway, Q. Xing, T.A. Lograsso, J.B. Restorff, M. Wun-Fogle, J. Appl. Phys. 111, 07A921 (2012). https://doi.org/10.1063/1.3673857

R. Oshima, M. Suguyama, F.E. Fujita, Metall. Mater. Trans. A 19, 803–810 (1988). https://doi.org/10.1007/BF02628361

K. Seki, H. Kura, T. Sato, T. Taniyama, J. App. Phys. 103, 063910 (2008). https://doi.org/10.1063/1.2890143

P.J. Webster, K.R.A. Ziebeck, S.L. Town, M.S. Peak, Philos Mag B 49, 295 (1984). https://doi.org/10.1080/13642817408246515

V.A. Chernenko, V.A. L’vov, T. Kanomata, T. Kakeshita, K. Koyama, S. Besseghini, Mater. Trans. 47, (2006), 635. https://doi.org/10.2320/matertrans.47.635

T. Fukuda, H. Maeda, M. Yasui, T. Kakeshita, Scripta Mater. 60, 261–263 (2009). https://doi.org/10.1016/j.scriptamat.2008.10.016

E. du Tre´molet de Lacheisserie. CRC, Boca Raton, (1993)

T. Wada, Y. Liang, H. Kato, T. Tagawa, M. Taya, T. Mori, Mater. Sci. Eng. A 361, 75–82 (2003). https://doi.org/10.1016/S0921-5093(03)00444-1

V.Z.C. Paes, J. Varalda, D.H. Mosca, J. Magn. Magn. Mater 475, 539–543 (2019). https://doi.org/10.1016/j.jmmm.2018.11.102

Acknowledgements

This work was supported by a grant of the Romanian Ministry of Research and Innovation, CCCDI – UEFISCDI, Project Numbers PN-III-P2-2.1-PED-2019-3453 Contract No. 493/2020 and PN-III-P2-2.1-PED-2019-1276 Contract No. 324/2020 within PNCDI III.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sofronie, M., Popescu, B. & Enculescu, M. Structural, magnetic and magnetostrictive properties of the ternary iron–palladium–silicon ferromagnetic shape memory ribbons. Appl. Phys. A 127, 168 (2021). https://doi.org/10.1007/s00339-021-04315-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04315-0