Abstract

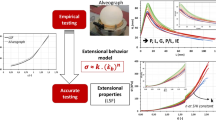

In this work, we investigate the large amplitude oscillatory shear (LAOS) behavior of white-wheat, wholegrain-wheat and chickpea flour doughs experimentally and theoretically. In order to accurately model the LAOS behavior of those doughs, it was important to study their linear viscoelastic as well as stress relaxation behaviors. We analyzed the linear viscoelastic behavior theoretically through the single spring-pot model, the fractional Maxwell model (FMM) and the fractional Kelvin-Voigt model. We found that the FMM is best suited to describe the LVE of the doughs we investigated. The damping function form was chosen based on stress relaxation and strain sweep experiments. We found that the Soskey-Winter (SW) equation is suitable for accurately describing the damping behavior of doughs. The LAOS experimental results were obtained at a set of strain amplitude and frequency values to build the Lissajous-Bowditch curves in Pipkin space. We modeled the LAOS stress response using the Kay-Bernstein Kearsley and Zapas (K-BKZ) model coupled with the FMM and SW models. The SW parameters were optimized for each dough by fitting the LAOS Lissajous-Bowditch curves in Pipkin space. The obtained fits to LAOS stress response were very good and illustrate that the FMM-SW-K-BKZ model provides an excellent description of the LAOS behavior of the different variety of doughs examined in this work. Moreover, the study shows that LAOS Lissajous-Bowditch curves provide characteristically different shapes for wheat and chickpea flour doughs.

Similar content being viewed by others

References

AACC (2000) Approved methods of the AACC, 10th edition. American Association of Cereal Chemists, St. Paul

Almusallam AS, Ahmed J, Nahar S, Chacko S (2016) Oscillatory shearing behavior of rocket leaves powder incorporated dough. Korea-Australia Rheol J 28:149–158

Almusallam AS, Zafar TA, Sidhu JS (2022) Oscillatory and thermo rheological studies of wheat and chickpea flour blended doughs for producing Arabic flat bread. J Eng Res. https://doi.org/10.36909/jer.15023

Amirkaveei S, Dai SMN, Qi F, Shahedi M, Tanner RI (2009) A comparison of the rheology of four wheat flour doughs via a damage function model. Appl Rheol 19:34305

Bernstein B, Kearsley E, Zapas L (1963) A study of stress relaxation with finite strain. Transac Soc Rheol 7:391–410

Bonfanti A, Kaplan JL, Charras G, Kabla A (2020) Fractional viscoelastic models for power-law materials. Soft Matter 16:6002–6020

Burnham KP, Anderson DR (2004) Multimodel inference: understanding AIC and BIC in model selection. Sociol Methods Res 33:261–304

Caputo M (1967) Linear models of dissipation whose Q is almost frequency independent—II. Geophys J Int 13:529–539

Chakrabarti-Bell S, Bergström J, Lindskog E, Sridhar T (2010) Computational modeling of dough sheeting and physical interpretation of the non-linear rheological behavior of wheat flour dough. J Food Eng 100(2):278–288

Ewoldt RH, Hosoi AE, Mckinley GH (2008) New measures for characterizing nonlinear viscoelasticity in large amplitude oscillatory shear. J Rheol 52:1427–1458

Faber T, Jaishankar A, Mckinley G (2017a) Describing the firmness, springiness and rubberiness of food gels using fractional calculus. Part II: measurements on semi-hard cheese. Food Hydrocoll 62:325–339

Faber T, Jaishankar A, mckinley g H (2017b) Describing the firmness, springiness and rubberiness of food gels using fractional calculus. Part I: theoretical framework. Food Hydrocoll 62:311–324

Faridy J-CM, Stephanie C-GM, Gabriela M-MO, Cristian J-M (2020) Biological activities of chickpea in human health (Cicer arietinum L.). A review. Plant Foods Hum Nutr 75:142–153

Gabriele D, DE Cindio B, D'antona P (2001) A weak gel model for foods. Rheol Acta 40:120–127

Hicks CI, See H, Ekwebelam C (2011) The shear rheology of bread dough: modeling. Rheol Acta 50:701–710

Hyun K, Wilhelm M, Klein CO, Cho KS, Nam JG, Ahn KH, Lee SJ, Ewoldt RH, Mckinley GH (2011) A review of nonlinear oscillatory shear tests: analysis and application of large amplitude oscillatory shear (LAOS). Prog Polym Sci 36:1697–1753

Jaishankar A, Mckinley GH (2013) Power-law rheology in the bulk and at the interface: quasi-properties and fractional constitutive equations. Proc Royal Soc A: Math, Phys Eng Sci 469:20120284

Jaishankar A, Mckinley GH (2014) A fractional K-BKZ constitutive formulation for describing the nonlinear rheology of multiscale complex fluids. J Rheol 58:1751–1788

Jóźwiak B, Orczykowska M, Dziubiński M (2015) Fractional generalizations of maxwell and Kelvin-Voigt models for biopolymer characterization. PLoS One 10:e0143090

Kaye A (1962) Non-Newtonian flow in incompressible fluids. College of Aeronautics Note, p 134 & 149

Larson RG (1998) The structure and rheology of complex fluids. Oxford University Press

Lefebvre J (2006) An outline of the non-linear viscoelastic behaviour of wheat flour dough in shear. Rheol Acta 45:525–538

Macosko CW (1994) Rheology: principles, measurements, and applications. Wiley-VCH

Mariotti M, Lucisano M, Pagani MA, Ng PKW (2009) The role of corn starch, amaranth flour, pea isolate, and Psyllium flour on the rheological properties and the ultrastructure of gluten-free doughs. Food Res Int 42:963–975

Martinetti L, Ewoldt RH (2019) Time-strain separability in medium-amplitude oscillatory shear. Phys Fluids 31:021213

Meng Y, Guan X, Liu X, Zhang H (2019) The rheology and microstructure of composite wheat dough enriched with extruded mung bean flour. LWT 109:378–386

Mohammed I, Ahmed AR, Senge B (2012) Dough rheology and bread quality of wheat–chickpea flour blends. Ind Crop Prod 36:196–202

Mohammed MAP, Tarleton E, Charalambides MN, Williams JG (2013) Mechanical characterization and micromechanical modeling of bread dough. J Rheol 57:249–272

Ng TSK, Mckinley GH (2008) Power law gels at finite strains: the nonlinear rheology of gluten gels. J Rheol 52:417–449

Ng TSK, Mckinley GH, Ewoldt RH (2011) Large amplitude oscillatory shear flow of gluten dough: a model power-law gel. J Rheol 55:627–654

Phan-Thien N, Newberry M, Tanner RI (2000) Non-linear oscillatory flow of a soft solid-like viscoelastic material. J Non-Newtonian Fluid Mech 92:67–80

Phan-Thien N, Safari-Ardi M, Morales-Patino A (1997) Oscillatory and simple shear flows of a flour-water dough: a constitutive model. Rheol Acta 36:38–48

Qi F, Dai S-C, Newberry MP, Love RJ, Tanner RI (2008) A simple approach to predicting dough sheeting thickness. J Cereal Sci 47:489–495

Rathinaraj JDJ, Keshavarz B, Mckinley GH (2022) Why the Cox–Merz rule and Gleissle mirror relation work: a quantitative analysis using the Wagner integral framework with a fractional Maxwell kernel. Phys Fluids 34:033106

Rathinaraj JDJ, Mckinley GH, Keshavarz B (2021) Incorporating rheological nonlinearity into fractional calculus descriptions of fractal matter and multi-scale complex fluids. Fractal Fractional 5:174

Rolon-Garrido VH, Wagner MH (2009) The damping function in rheology. Rheol Acta 48:245–284

Šćepanović P, Goudoulas TB, Germann N (2018) Numerical investigation of microstructural damage during kneading of wheat dough. Food Struct 16:8–16

Sidhu JS, Kabir Y, Huffman FG (2007) Functional foods from cereal grains. Int J Food Prop 10:231–244

Sofou S, Muliawan EB, Hatzikiriakos SG, Mitsoulis E (2008) Rheological characterization and constitutive modeling of bread dough. Rheol Acta 47:369–381

Soskey PR, Winter HH (1984) Large step shear strain experiments with parallel-disk rotational rheometers. J Rheol 28:625–645

Struck S, Straube D, Zahn S, Rohm H (2018) Interaction of wheat macromolecules and berry pomace in model dough: rheology and microstructure. J Food Eng 223:109–115

Summo C, De Angelis D, Ricciardi L, Caponio F, Lotti C, Pavan S, Pasqualone A (2019) Nutritional, physico-chemical and functional characterization of a global chickpea collection. J Food Compos Anal 84:103306

Sun X, Koksel F, Nickerson MT, Scanlon MG (2020) Modeling the viscoelastic behavior of wheat flour dough prepared from a wide range of formulations. Food Hydrocoll 98:105129

Takeh A, Shanbhag S (2013) A computer program to extract the continuous and discrete relaxation spectra from dynamic viscoelastic measurements. Appl Rheol 23:24628

Tanner RI, Qi F, Dai S (2008) Bread dough rheology and recoil I. Rheolo J Non-Newtonian Fluid Mech 148:33–40

Tanner RI, Qi F, Dai S (2011) Bread dough rheology: an improved damage function model. Rheol Acta 50:75–86

Turksoy S, Erturk MY, Bonilla J, Turasan H, Kokini JL (2020) Effect of aging at different temperatures on LAOS properties and secondary protein structure of hard wheat flour dough. J Cereal Sci 92:102926

Wagner CE, Barbati AC, Engmann J, Burbidge AS, Mckinley GH (2017) Quantifying the consistency and rheology of liquid foods using fractional calculus. Food Hydrocoll 69:242–254

Wagner M (1976) Analysis of time-dependent non-linear stress-growth data for shear and elongational flow of a low-density branched polyethylene melt. Rheol Acta 15:136–142

Xu F, Hu HQL, Dai X, Zhang H (2017) Rheological and microstructural properties of wheat flour dough systems added with potato granules. Int J Food Prop 20:S1145–S1157

Yazar G, Duvarci O, Tavman S, Kokini JL (2017) Non-linear rheological behavior of gluten-free flour doughs and correlations of LAOS parameters with gluten-free bread properties. J Cereal Sci 74:28–36

Yazar G, Duvarci OC, Tavman S, Kokini JL (2016) Effect of mixing on LAOS properties of hard wheat flour dough. J Food Eng 190:195–204

Zafar TA, Aldughpassi A, Al-Mussallam A, Al-Othman A (2020) Microstructure of whole wheat versus white flour and wheat-chickpea flour blends and dough: impact on the glycemic response of pan bread. Inter J Food Sci 2020:1–9

Zafar TA, Allafi AR, Alkandari D, Al-Othman A (2021) Rheological characteristics of wheat–chickpea composite flour doughs and effect of Amla powder (Phyllanthus emblica L.) addition on the functional properties of bread. Food Sci Technol Int 27:264–275

Acknowledgement

The authors would like to acknowledge the support of Kuwait University Research sector through grant GE 01/07.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Almusallam, A.S., Daffallah, I.E. & Sidhu, J.S. Large amplitude oscillatory shear of doughs, based on different flours, modeled using the fractional K-BKZ framework. Rheol Acta 62, 303–316 (2023). https://doi.org/10.1007/s00397-023-01395-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-023-01395-y