Abstract

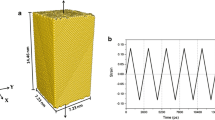

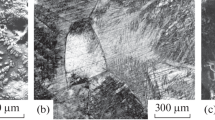

Temperature, strain rate, and defects are important considerations in determining the mechanical properties of materials. The mechanical properties of nanocrystalline copper-tantalum (Cu-Ta) alloy are investigated using classical molecular dynamics simulation approach in which embedded atom method of potential with periodic boundary conditions in all directions has been adopted. Numerical simulation has been performed to predict the mechanical properties of nanocrystalline copper-tantalum alloy. The virtual tensile test has been conducted at a fixed strain rate and increasing temperature where the discreet change in temperature from 50 to 1600 K has been used as a controlling parameter. The strain rate is fixed in the direction of the principal crystallographic planes and has not been affected by the change in temperature. The mechanical properties of the Cu-Ta nanocrystalline alloy such as yield strength, ultimate strength, and Young’s modulus are observed. Further, simulations are carried out to analyze the vacancy formation energy with vacancy concentration and potential energy response at discrete temperatures. Nanocrystalline Cu-Ta alloy is observed to be more susceptible to failure at high temperatures. Particularly at 300 K, the strength of nanocrystalline Cu-Ta is 6 GPa which decreases to 4 GPa at 1200 K.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The custom code generated for the current study is available from the corresponding author on reasonable request.

References

Suryanarayana C, Koch C (2000) Nanocrystalline materials – current research and future directions. Hyperfine Interact 130:5

Birringer R (1989) Nanocrystalline materials. Mater Sci Eng A 117(33–43):09215093

Tian L (2017) A short review on mechanical behavior of nanocrystalline materials. Int J Metall Met Phys 2:008

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51(4):427–556

Pandey AK, Siddiqui SA, Dwivedi A, Raj K, Misra N (2011) Density functional theory study on the molecular structure of loganin. J Appl Spectrosc 25:361849

Metropolis N, Ulam S (1949) The Monte Carlo method. J Am Stat Assoc 44(247):335–341

Iftimie R, Minary P, Mark E, Tuckerman. (2005) Ab initio molecular dynamics: concepts, recent developments, and future trends. Proc Natl Acad Sci USA 102(19):6654–6659

Foulkes WMC, Mitas L, Needs RJ, Rajagopal G (2001) Quantum Monte Carlo simulations of solids. Rev Mod Phys 73(1):33–83

McQuarrie DA (1976) Statistical mechanics. Harper & Row, New York

Rice BM, and Sewell TD. (2008) Equilibrium molecular dynamics simulations. In: Peiris, S.M., Piermarini, G.J. (eds) Static compression of energetic materials. Shock wave and high pressure phenomena. Springer, Berlin, Heidelberg.

Lu L, Li SX, Lu K (2001) An abnormal strain rate effect on tensile behavior in nanocrystalline copper. Scr Mater 45(10):1163–1169

Yang X, Zhai P, Li L, Zhang Q (2012) Molecular dynamics simulation on mechanical properties of crystalline CoSb3 with vacancy defect. Physica B Condens Matter 407(12):2234–2238

Dewapriya MAN, Rajapakse RKND (2014) Molecular dynamics simulations and continuum modeling of temperature and strain rate dependent fracture strength of graphene with vacancy defects. J Appl Mech 81(8):081010

Hahn EN, Germann TC, Ravelo R, Hammerberg JE, Meyers MA (2017) On the ultimate tensile strength of tantalum. Acta Mater 126:313–328

Ruan Z, Wu W, Li N (2018) Effects of strain rate, temperature and grain size on the mechanical properties and microstructure evolutions of polycrystalline nickel nanowires: a molecular dynamics simulation. Wuhan Univ J Nat Sci 23:251–258

Ruicheng F, Hui C, Haiyan L, Zhiyuan R, Changfeng Y (2018) Effects of vacancy concentration and temperature on mechanical properties of single-crystal γ-TiAl based on molecular dynamics simulation. High Temp Mater Process 37(2):113–120

Srinivasan S, Sharma S, Turnage S, Hornbuckle BC, Kale C, Darling KA, Solanki K (2021) Role of tantalum concentration, processing temperature, and strain-rate on the mechanical behavior of copper-tantalum alloys. Acta Mater 208:116706

Cotterill RMJ. and Pedersen LB. (1972) Temperature dependence of the vacancy formation energy in krypton by molecular dynamic simulation. Department of Structural Properties of Materials, Plenum Press, 2800 Lyngby - Denmark.

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Daw MS, Foiles SM, Baskes MI (1993) The embedded-atom method: a review of theory and applications. Mater Sci Eng R Rep 9(7):251–310

Diwan BD (2013) Size effect on the cohesive energy of palladium nanoparticle. J Comput Theor Nanosci 10(11):2779–2781

Bringa EM, Caro A, Wang Y, Victoria M, Mcnaney JM, Remington BA, Smith RF, Torralva BR, Swygenhoven HV (2005) Ultrahigh strength in nano-crystalline materials under shock loading. Science 309(5742):1838–1841

Rudd RE, Germann TC, Remington BA, Wark JS (2010) Metal deformation and phase transitions at extremely high strain rates. MRS Bull 35:999–1006

Holian BL, Lomdahl PS (1998) Plasticity induced by shock waves in nonequilibrium molecular-dynamics simulations. Science 280:2085–2088

Subramanian PR, Laughlin DE (1989) The Cu-Ta (copper-tantalum) system. Bull alloy phase diagr 10(6):652–655

Zhao Y, Lu G (2009) First-principles simulations of copper diffusion in tantalum and tantalum nitride. Phys Rev B Condens Matter Mater Phys 79(21):1–9

Monticelli L, Tieleman DP (2013) Force fields for classical molecular dynamics. Methods Mol Biol 924:197–213

Gonzalez MA (2011) Force fields and molecular dynamics simulations. Neutrons et Simulations 12:169–200

Zhou XW, Johnson RA, Wadley HNG (2004) Misfit-energy-increasing dislocations in vapor-deposited CoFe/NiFe multilayers. Phys Rev B 69:144113

Hirel P (2015) Atomsk: a tool for manipulating and converting atomic data files. Comput Phys Commun 197:212–219

Kalibaeva G, Ferrario M, Ciccotti G (2003) Constant pressure-constant temperature molecular dynamics: a correct constrained NPT ensemble using the molecular virial. Mol Phys 101(6):765–778

Nazareth J (2009) Conjugate gradient method. Wiley Interdisciplinary Reviews: Comput Stat 1(3):348–353

Belak J (1998) On the nucleation and growth of voids at high strain-rates. J Comp-Aid Mater Des 5(2–3):193–206

Tang Y, Bringa EM, Meyers MA (2012) Ductile tensile failure in metals through initiation and growth of nanosized voids. Acta Mate 60:4856–4865

Sadeghzadeh S (2018) Effects of vacancies and divacancies on the failure of C3N nanosheets. Diam Relat Mater 89:257–265

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model Simul Mat Sci Eng 18:015012

Chen P, Zhang Z, Liu C, An T, Yu H, Qin F (2019) Temperature and grain size dependences of mechanical properties of nanocrystalline copper by molecular dynamics simulation. Model Simul Mat Sci Eng 27:065012

Antoun T, Seaman L, Kanel D, Razorenov G (2003) Spall fracture. Springer, New York

Lubarda V, Schneider M, Kalantar D, Remington B, Meyers M (2004) Void growth by dislocation emission. Acta Mater 52:1397–1408

Meyers M, Aimone C (1983) Dynamic fracture (spalling) of metals. (1983) Prog Mater Sci 28:1–96

Li Z, Gao Y, Zhan S, Fang H, Zhang Z (2020) Molecular dynamics study on temperature and strain rate dependences of mechanical properties of single crystal Al under uniaxial loading. AIP Adv 10:075321

Turnage SA, Rajagopalan M, Darling KA, Garg P, Kale C, Bazehhour B (2018) Anomalous mechanical behavior of nanocrystalline binary alloys under extreme conditions. Nat Commun 9:2699

Wang W, Ma Y, Yang M, Jiang P, Yuan F, Wu X (2018) Strain rate effect on tensile behavior for a high specific strength steel: from quasi-static to intermediate strain rates. Metals 8(1):11

Wang W, Yi C, Fan K (2013) Molecular dynamics study on temperature and strain rate dependences of mechanical tensile properties of ultrathin nickel nanowires. Trans Nonferrous Met Soc 23:3353–3361

Yu R, Zhai P, Li G, Liu L (2012) Molecular dynamics simulation of the mechanical properties of single-crystal bulk Mg2Si. J Electron Mater 41:1465–1469

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design of the study. Mahesh Kumar Gupta: methodology, software, investigation, writing—original draft. Vinay Panwar: conceptualization, writing—review and editing, supervision, project administration. Rajendra Prasad Mahapatra: validation, formal analysis, supervision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, M.K., Panwar, V. & Mahapatra, R.P. Computational analysis of mechanical behavior and potential energy of thermoresponsive copper-tantalum nanoalloy. J Mol Model 28, 187 (2022). https://doi.org/10.1007/s00894-022-05183-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-022-05183-y