Abstract

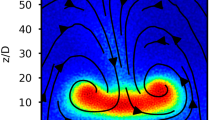

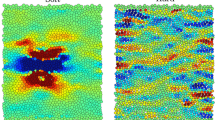

What is the effect of interstitial fluid viscosity on granular density segregation in a horizontal rotating cylinder? We conducted experiments in the rolling regime with equal amounts of equal sized high and low density, nearly spherical granular particles saturated with air, water, and water-glycerin mixtures. We held particle density, rotation rate and characteristic length scale constant to highlight differences due purely to the interstitial fluid. Images of the granular flow at an end wall were used to determine radial and axial density segregation rates and patterns. Over a four decade change in viscosity, segregation rates varied by only a factor of two. However, for ratios of lubrication to frictional stresses above one, segregation rates decreased by about 30%, and we observed several notable phenomena in the segregation pattern formation. These were a creeping mode of radial density segregation, a change in shape of the granular bed to kidney shaped from flat, and for cylinders more than half full the typically reported unsheared central portion of the granular bed (often referred to in the literature as a core region) was disrupted by a wavy instability where the rate of disappearance of the core region decreased as the fill level increased.

Similar content being viewed by others

References

Alonso M., Satoha M., Miyanamia K.: Optimum combination of size ratio, density ratio and concentration to minimize free surface segregation. Powder Technol. 68(2), 145–152 (1991)

Metcalfe G., Shattuck M.: Pattern formation during mixing and segregation of flowing granular materials. Physica A 233, 709–717 (1996)

Cleary P.W., Metcalfe G., Liffman K.: How well do discrete element granular flow models capture the essentials of mixing processes?. Appl. Math. Model. 22, 995–1008 (1998)

Fiedor S.J., Ottino J.M.: Dynamics of axial segregation and coarsening of dry granular materials and slurries in circular and square tubes. Phys. Rev. Lett. 91(24), 244301 (2003). doi:10.11103/PhysRevLett.91.244301

Khakhar D.V., Orpe A.V., Hajra S.J.: Segregation of granular material in rotating cylinders. Physica 318, 129–136 (2003)

Jain N., Ottino J.M., Lueptow R.M.: Regimes of segregation and mixing in combined size and density granular systems: an experimental study. Granul. Matter 7, 69–81 (2005). doi:10.1007/s10035-005-0198-x

Jain N., Khakhar D.V., Lueptow R.M., Ottino J.M.: Self-organization in granular slurries. Phys. Rev. Lett. 86(17), 3371–3774 (2001)

Mikamia T., Kamiyaa H., Horio M.: Numerical simulation of cohesive powder behavior in a fluidized bed. Chem. Eng. Sci. 53(10), 1927–1940 (1998). doi:10.1016/S0009-2509(97)00325-4

Tegzes P., Vicsek T., Schiffer P.: Development of correlations in the dynamics of wet granular avalanches. Phys. Rev. E 67, 051303 (2003). doi:10.1103/PhysRevE.67.051303

Schiffer P.: Granular physics: a bridge to sandpile stability. Nat. Phys. 1, 21–22 (2005). doi:10.1038/nphys129

Scheel M., Seemann R., Brinkmann M., di Michiel M., Sheppard A., Breidenbach B., Herminghaus S.: Morphological clues to wet granular pile stability. Nat. Mater. 7, 189–193 (2008). doi:10.1038/nmat2117

Liffman K., Nguyen M., Metcalfe G., Cleary P.: Forces in piles of granular material: an analytic and 3D DEM study. Granul. Matter 3, 165–176 (2001)

Kudrolli A.: Size separation in vibrated granular matter. Rep. Prog. Phys. 67, 209–247 (2004). doi:10.1088/0034-4885/67/3/R01

Xu, Q., Orpe, A.V., Kudrolli, A.: Lubrication effects on the flow of wet granular materials. Phys. Rev. E 76(3) (2007) doi:10.1103/PhysRevE.76.031302

Li H., McCarthy J.J.: Controlling cohesive particle mixing and segregation. Phys. Rev. Lett. 90(18), 184301 (2003). doi:10.1103/PhysRevLett.90.184301

Jain N., Ottino J.M., Lueptow R.M.: Effect of interstitial fluid on a granular flowing layer. J. Fluid Mech. 508, 23–44 (2004). doi:10.1017/S0022112004008869

Huang N., Ovarlez G., Bertrand F., Rodts S., Coussot P., Bonn D.: Flow of wet granular materials. Phys. Rev. Lett. 94, 028301 (2005)

Liao C.-C., Hsiau S-S.: Influence of interstitial fluid viscosity on transport phenomenon in sheared granular materials. Chem. Eng. Sci. 64, 2562–2569 (2009). doi:10.1016/j.ces.2009.02.030

Drahun J.A., Bridgwater J.: The mechanisms of free surface segregation. Powder Technol. 36(1), 39–53 (1983)

Fuerstenau, M.C., Han, K.N. (eds.): Principles of Mineral Processing. Society for Mining Metallurgy & Exploration (2003)

Galvin K.P., Walton K., Zhou J.: How to elutriate particles according to their density. Chem. Eng. Sci. 64, 2003–2010 (2009). doi:10.1016/j.ces.2009.01.031

Liffman, K., Metcalfe, G.: Add segregation to kill segregation. Aust. Bulk Handl. Rev., Feb/March, 46–47 (1999)

Metcalfe, G., Liffman, K.: A method and device for separating particulate material. Patent number WO2003011483 (2003)

Hayter, D., Pereira, G., Liffman, K., Aldham, B., Johns, S., Šutalo, I.D., Brooks, G., Cleary, P., Metcalfe, G.: Density segregation of granular material in a rotating cylindrical tumbler. In: Nicolau, D.V., Metcalfe, G. (eds.) Biomedical Applications of Micro- and Nanoengineering IV and Complex Systems. SPIE Conference Proceedings, vol. 7270, p. 727010 (2008). doi:10.1117/12.814431

Coussot P., Ancey C.: Rheophysical classification of concentrated suspensions and granular pastes. Phys. Rev. E 59(4), 4445–4457 (1999)

Bagnold R.A.: Experiments on a gravity-free dispersion of large solid spheres in a Newtonian fluid under shear. Proc. R. Soc. Lond. A 225, 49–63 (1954)

Metcalfe G.: Tracking particles in tumbling containers. In: Fleck, N.A., Cocks , A.C.F. (eds) Mechanics of Granular and Porous Materials, pp. 287–298. Kluwer, Dordrecht (1996)

Metcalfe G., Graham L., Zhou J., Liffman K.: Measurement of particle motions within tumbling granular flows. Chaos 9, 581–593 (1999)

Maneval J.E., Hill K.M., Smith B.E., Caprihan A., Fukushima E.: Effects of end wall friction in rotating cylinder granular flow experiments. Granul. Matter 7, 199–202 (2005). doi:10.1007/s10035-005-0211-4

McCarthy J.J., Shinbrot T., Metcalfe G., Wolf J.E., Ottino J.M.: Mixing of granular materials in slowly rotated containers. AIChE J. 42(12), 3351–3363 (1996)

Pereira G.G., Sinnott M.D., Cleary P.W., Liffman K., Metcalfe G., Šutalo I.D.: Insights from simulations into mechanisms for density segregation of granular mixtures in rotating cylinders. Granul. Matter 13, 53–74 (2011)

Boateng A.A., Barr P.V.: Granular flow behaviour in the transverse plane of a partially filled rotating cylinder. J. Fluid Mech. 330, 233–249 (1997)

Santomaso A., Olivi M., Canu P.: Mechanisms of mixing of granular materials in drum mixers under rolling regime. Chem. Eng. Sci. 59, 3269–3280 (2004). doi:10.1016/j.ces.2004.04.026

Pohlman N.A., Ottino J.M., Lueptow R.M.: End-wall effects in granular tumblers: from quasi-two-dimensional flow to three-dimensional flow. Phys. Rev. E 74, 031305 (2006). doi:10.1103/PhysRevE.74.031305

Metcalfe G., Tennakoon S.G.K., Kondic L., Schaeffer D.G., Behringer R.P.: Granular friction, Coulomb failure, and the fluid-solid transition for horizontally shaken granular materials. Phys. Rev. E 65, 031302 (2002)

Socie B.A., Unbanhowar P., Lueptow R.M., Jain N., Ottino J.M.: Creeping motion in granular flow. Phys. Rev. E 71, 031304 (2005). doi:10.1103/PhysrevE.71.031304

Komatsu T.S., Inagaki S., Nakagawa N., Nasuno S.: Creep motion in a granular pile exhibiting steady surface flow. Phys. Rev. Lett. 86(9), 1757–1760 (2001). doi:10.1103/PhysRevLett.86.1757

Jaeger H.M., Nagel S.R., Behringer R.P.: Granular solids, liquids, and gases. Rev. Mod. Phys. 68, 1259–1273 (1996). doi:10.1103/RevModPhys.68.1259

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

The Below is the Electronic Supplementary Material.

Rights and permissions

About this article

Cite this article

Ahmed, S., John, S.E., Šutalo, I.D. et al. Experimental study of density segregation at end walls in a horizontal rotating cylinder saturated with fluid: friction to lubrication transition. Granular Matter 14, 319–332 (2012). https://doi.org/10.1007/s10035-012-0335-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-012-0335-2