Abstract

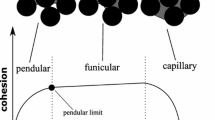

In solid mixing the raw materials typically differ at least in one material property, such as particle size, solid density and wetting properties, which in turn influence particle mobility. For example, smaller particles can percolate through the voids of larger ones under the influence of strain and gravity. This may produce fine particle accumulation at the bottom of the mixing vessel which results in undesired, inhomogeneous final products. When wet particles with different wetting properties need to be mixed, heteroagglomeration may occur as another segregation mechanism. We present a new capillary bridge force model to study segregation in moist cohesive mixing processes using DEM. New analytical equations of best fit are derived by solving the Young–Laplace equation and performing a regression analysis, in order to investigate discontinuous mixing processes of dry and moist materials with different particle sizes and different contact angles. Compared to a dry mixing process, mixing efficiency is improved by the addition of a small amount of liquid. While percolating segregation is reduced, heteroagglomerates occur in the wet mixing process.

Similar content being viewed by others

References

Johanson, J.R.: Particle segregation... and what to do about it. Chem. Eng. 85(11), 183–188 (1978)

Williams, J.C.: The segregation of particulate materials. A review. Powder Technol. 15(2), 245–251 (1976). https://doi.org/10.1016/0032-5910(76)80053-8

Bridgwater, J.: Fundamental powder mixing mechanisms. Powder Technol. 15(2), 215–236 (1976)

Marinelli, J., Carson, J.W.: Solve solids flow problems in bins, hoppers, and feeders. Chem. Eng. Prog. 88(5), 22–28 (1992)

Gögelein, C., Brinkmann, M., Schröter, M., Herminghaus, S.: Controlling the formation of capillary bridges in binary liquid mixtures. Langmuir 26(22), 17184–17189 (2010)

Lian, G., Seville, J.: The capillary bridge between two spheres: New closed-form equations in a two century old problem. Adv. Colloid Interface Sci. 227, 53–62 (2016). https://doi.org/10.1016/j.cis.2015.11.003

Johanson, J.R.: Smooth out solids blending problems. Chem. Eng. Prog. 96(4), 21–37 (2000)

Hoffmann, T.: Mischen und Befeuchten von Schuttgutern. Universität-Gesamthochschule-Paderborn (1995)

Cundall, P.A., Strack, O.D.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Tsuji, Y., Tanaka, T., Ishida, T.: Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71(3), 239–250 (1992). https://doi.org/10.1016/0032-5910(92)88030-L

Mikami, T., Kamiya, H., Horio, M.: Numerical simulation of cohesive powder behavior in a fluidized bed. Chem. Eng. Sci. 53(10), 1927–1940 (1998). https://doi.org/10.1016/S0009-2509(97)00325-4

Remy, B., Khinast, J.G., Glasser, B.J.: Wet granular flows in a bladed mixer: experiments and simulations of monodisperse spheres. AIChE J. 58(11), 3354–3369 (2012)

Soulie, F., Cherblanc, F., El Youssoufi, M.S., Saix, C.: Influence of liquid bridges on the mechanical behaviour of polydisperse granular materials. Int. J. Numer. Anal. Methods Geomech. 30(3), 213–228 (2006)

Anand, A., Curtis, J.S., Wassgren, C.R., Hancock, B.C., Ketterhagen, W.R.: Segregation of cohesive granular materials during discharge from a rectangular hopper. Granul. Matter 12(2), 193–200 (2010)

Butt, H.-J., Kappl, M.: Normal capillary forces. Adv. Colloid Interface Sci. 146(1), 48–60 (2009)

Derjaguin, B.: Untersuchungen über die Reibung und Adhäsion, IV. Kolloid-Zeitschrift 69(2), 155–164 (1934). https://doi.org/10.1007/bf01433225

Alchikh-Sulaiman, B., Ein-Mozaffari, F., Lohi, A.: Evaluation of poly-disperse solid particles mixing in a slant cone mixer using discrete element method. Chem. Eng. Res. Des. 96, 196–213 (2015). https://doi.org/10.1016/j.cherd.2015.02.020

Stieß, M., Ripperger, S.: Mechanische Verfahrenstechnik-Partikeltechnologie 1, vol. 1. Springer, Berlin (2009)

Fisher, R.A.: On the capillary forces in an ideal soil; correction of formulae given by W. B. Haines. J. Agric. Sci. 16(03), 492–505 (1926). https://doi.org/10.1017/S0021859600007838

Hotta, K., Takeda, K., Iinoya, K.: The capillary binding force of a liquid bridge. Powder Technol. 10(4–5), 231–242 (1974). https://doi.org/10.1016/0032-5910(74)85047-3

Schubert, H.: Kapillarität in porösen Feststoffsystemen. Springer, Berlin (1982)

Lian, G., Thornton, C., Adams, M.J.: A theoretical study of the liquid bridge forces between two rigid spherical bodies. J. Colloid Interface Sci. 161(1), 138–147 (1993). https://doi.org/10.1006/jcis.1993.1452

Willett, C.D., Adams, M.J., Johnson, S.A., Seville, J.P.: Capillary bridges between two spherical bodies. Langmuir 16(24), 9396–9405 (2000)

Shi, D., McCarthy, J.J.: Numerical simulation of liquid transfer between particles. Powder Technol. 184(1), 64–75 (2008). https://doi.org/10.1016/j.powtec.2007.08.011

Pitois, O., Moucheront, P., Chateau, X.: Liquid bridge between two moving spheres: an experimental study of viscosity effects. J. Colloid Interface Sci. 231(1), 26–31 (2000)

McCarthy, J.J.: Micro-modeling of cohesive mixing processes. Powder Technol. 138(1), 63–67 (2003). https://doi.org/10.1016/j.powtec.2003.08.042

Chaudhuri, B., Mehrotra, A., Muzzio, F.J., Tomassone, M.S.: Cohesive effects in powder mixing in a tumbling blender. Powder Technol. 165(2), 105–114 (2006). https://doi.org/10.1016/j.powtec.2006.04.001

Nakamura, H., Fujii, H., Watano, S.: Scale-up of high shear mixer-granulator based on discrete element analysis. Powder Technol. 236, 149–156 (2013). https://doi.org/10.1016/j.powtec.2012.03.009

Mani, R., Kadau, D., Or, D., Herrmann, H.J.: Fluid depletion in shear bands. Phys. Rev. Lett. 109(24), 248001 (2012)

Mani, R., Kadau, D., Herrmann, H.J.: Liquid migration in sheared unsaturated granular media. Granul. Matter 15(4), 447–454 (2013). https://doi.org/10.1007/s10035-012-0387-3

Acknowledgements

The authors gratefully acknowledge the financial support by the Deutsche Forschungsgemeinschaft (DFG NI 414/25-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schmelzle, S., Nirschl, H. DEM simulations: mixing of dry and wet granular material with different contact angles. Granular Matter 20, 19 (2018). https://doi.org/10.1007/s10035-018-0792-3

Received:

Published:

DOI: https://doi.org/10.1007/s10035-018-0792-3