Abstract

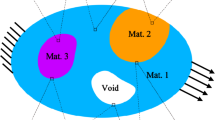

Hybrid lattice structures consisting of multiple microstructures have drawn much attention due to their excellent performance and extraordinary designability. This work puts forward a novel design scheme of lightweight hybrid lattice structures based on independent continuous mapping (ICM) method. First, the effective elastic properties of various microstructure configurations serve as a bridge between the macrostructure and the multiple microstructures by the homogenization theory. Second, a concurrent topology optimization model for seeking optimized macroscale topology and the specified microstructures is established and solved by a generalized multi-material interpolation formulation and sensitivity analysis. Third, several numerical examples show that hybrid lattice structures with different anisotropic configurations accomplish a better lightweight effect than those with various orthogonal configurations, which verifies the feasibility of the presented method. Hence, anisotropic configurations are more conducive to the sufficient utilization of constitutive material. The proposed scheme supplies a reference for the design of hybrid lattice structures and extends the application field of the ICM method.

Similar content being viewed by others

References

Zhu J, Zhou H, Wang C, et al. A review of topology optimization for additive manufacturing: status and challenges. Chin J Aeronaut. 2021;34(1):91–110.

Meng L, Zhang W, Quan D, et al. From topology optimization design to additive manufacturing: today’s success and tomorrow’s roadmap. Arch Comput Method E. 2020;27(3):805–30.

Shi G, Guan C, Quan D, et al. An aerospace bracket designed by thermo-elastic topology optimization and manufactured by additive manufacturing. Chin J Aeronaut. 2020;33(3):1252–9.

Talay E, Özkan C, Gürtaş E. Designing lightweight diesel engine alternator support bracket with topology optimization methodology. Struct Multidiscip Optim. 2021;63(4):2509–29.

Culmone C, Smit G, Breedveld P. Additive manufacturing of medical instruments: a state-of-the-art review. Addit Manuf. 2019;27:461–73.

Jewett JL, Carstensen JV. Topology-optimized design, construction and experimental evaluation of concrete beams. Autom Constr. 2019;102:59–67.

Wu J, Sigmund O, Groen JP. Topology optimization of multi-scale structures: a review. Struct Multidiscip Optim. 2021;63(3):1455–80.

Bendsøe MP, Kikuchi N. Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech. 1988;2:197–224.

Bendsøe MP. Optimal shape design as a material distribution problem. Struct Optim. 1989;1(3):193–202.

Zhou M, Rozvany GIN. The COC algorithm, Part II: topological, geometrical and generalized shape optimization. Comput Methods Appl Mech. 1991;89:309–36.

Wang MY, Wang X, Guo D. A level set method for structural topology optimization. Comput Methods Appl Mech. 2003;192:227–46.

Zheng J, Luo Z, Jiang C, et al. Robust topology optimization for concurrent design of dynamic structures under hybrid uncertainties. Mech Syst Signal Process. 2019;120:540–59.

Takezawa A, Nishiwaki S, Kitamura M. Shape and topology optimization based on the phase field method and sensitivity analysis. J Comput Phys. 2010;229(6):2697–718.

Carraturo M, Rocca E, Bonetti E, et al. Graded-material design based on phase-field and topology optimization. Comput Mech. 2019;64(5):1589–600.

Guo X, Zhang W, Zhong W. Doing topology optimization explicitly and geometrically—a new moving morphable components based framework. J Appl Mech. 2014;81:81009.

Sun Z, Cui R, Cui T, et al. An optimization approach for stiffener layout of composite stiffened panels based on moving morphable components (MMCs). Acta Mech Solida Sin. 2020;33(4):650–62.

Xie YM, Steven GP. A simple evolutionary procedure for structural optimization. Comput Struct. 1993;49:885–96.

Latifi Rostami SA, Kolahdooz A, Zhang J. Robust topology optimization under material and loading uncertainties using an evolutionary structural extended finite element method. Eng Anal Bound Elem. 2021;133:61–70.

Yi GL, Sui YK. An adaptive approach to adjust constraint bounds and its application in structural topology optimization. J Optim Theory Appl. 2016;169(2):656–70.

Peng X, Sui Y. Lightweight topology optimization with consideration of the fail-safe design principle for continuum structures. Eng Optim. 2021;53(1):32–48.

Zhang X, Ye H, Wei N, et al. Design optimization of multifunctional metamaterials with tunable thermal expansion and phononic bandgap. Mater Des. 2021;209:109990.

Ye H, Yuan B, Li J, et al. Geometrically nonlinear topology optimization of continuum structures based on an independent continuous mapping method. Acta Mech Solida Sin. 2021;34(4):658–72.

Ye H, Li J, Yuan B, et al. Acceleration design for continuum topology optimization by using Pix2pix neural network. Int J Appl Mech. 2021;13(04):2150042.

Liu L, Yan J, Cheng G. Optimum structure with homogeneous optimum truss-like material. Comput Struct. 2008;86(13–14):1417–25.

Wang Y, Wang MY, Chen F. Structure-material integrated design by level sets. Struct Multidiscip Optim. 2016;54(4):1145–56.

Rodrigues H, Guedes JM, Bendsoe MP. Hierarchical optimization of material and structure. Struct Multidiscip Optim. 2002;24(1):1–10.

Xia L, Breitkopf P. Multiscale structural topology optimization with an approximate constitutive model for local material microstructure. Comput Methods Appl Mech. 2015;286:147–67.

Wang C, Gu X, Zhu J, et al. Concurrent design of hierarchical structures with three-dimensional parameterized lattice microstructures for additive manufacturing. Struct Multidiscip Optim. 2020;61(3):869–94.

Wang Y, Zhang L, Daynes S, et al. Design of graded lattice structure with optimized mesostructures for additive manufacturing. Mater Des. 2018;142:114–23.

Liu P, Kang Z, Luo Y. Two-scale concurrent topology optimization of lattice structures with connectable microstructures. Addit Manuf. 2020;36:101427.

Wang L, Chan Y, Ahmed F, et al. Deep generative modeling for mechanistic-based learning and design of metamaterial systems. Comput Methods Appl Mech. 2020;372:113377.

Chan Y, Shintani K, Chen W. Robust topology optimization of multi-material lattice structures under material and load uncertainties. Front Mech Eng. 2019;14(2):141–52.

Liu Z, Xia L, Xia Q, et al. Data-driven design approach to hierarchical hybrid structures with multiple lattice configurations. Struct Multidiscip Optim. 2020;61(5):2227–35.

Wu Z, Fan F, Xiao R, et al. The substructuring-based topology optimization for maximizing the first eigenvalue of hierarchical lattice structure. Int J Numer Methods Eng. 2020;121(12):2964–78.

Long K, Wang X, Gu X. Concurrent topology optimization for minimization of total mass considering load-carrying capabilities and thermal insulation simultaneously. Acta Mech Sinica. 2018;34(2):315–26.

Bai S, Kang Z. Robust topology optimization for structures under bounded random loads and material uncertainties. Comput Struct. 2021;252:106569.

Zhao Z, Zhou S, Feng X, et al. On the internal architecture of emergent plants. J Mech Phys Solids. 2018;119:224–39.

Zhao Z, Zhou S, Feng X, et al. Morphological optimization of scorpion telson. J Mech Phys Solids. 2020;135:103773.

Zhang H, Wu W, Kang Z, et al. Topology optimization method for the design of bioinspired self-similar hierarchical microstructures. Comput Method Appl Mech. 2020;372:113399.

Zhang H, Luo Y, Kang Z. Bi-material microstructural design of chiral auxetic metamaterials using topology optimization. Compos Struct. 2018;195:232–48.

Wang W, Ye H, Sui Y. Lightweight topology optimization with buckling and frequency constraints using the independent continuous mapping method. Acta Mech Solida Sin. 2019;32(3):310–25.

Ye H, Dai Z, Wang W, et al. ICM method for topology optimization of multimaterial continuum structure with displacement constraint. Acta Mech Sinica. 2019;35(3):552–62.

Deng H, Vulimiri PS, To AC. An efficient 146-line 3D sensitivity analysis code of stress-based topology optimization written in MATLAB. Optim Eng. 2021. https://doi.org/10.1007/s11081-021-09675-3.

Acknowledgements

This work was supported by the Beijing Natural Science Foundation (No. 3192005), National Natural Science Foundation of China (No. 11872080) and Taishan University Youth Teacher Science Foundation (No. QN-01-201901).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, N., Ye, H., Zhang, X. et al. Topology Optimization for Design of Hybrid Lattice Structures with Multiple Microstructure Configurations. Acta Mech. Solida Sin. 35, 367–383 (2022). https://doi.org/10.1007/s10338-021-00302-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-021-00302-3