Abstract

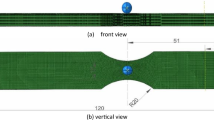

For aeronautical composite materials, the appearance of internal delamination has a fatal impact on their mechanical properties and may even seriously threaten aircraft flight safety. In this study, the effect of internal delamination damage with different sizes and depths on the tensile strength of aeronautical composites was investigated. Firstly, based on carbon-fiber-reinforced composites commonly used in aircraft, laminate specimens with internal delamination damages of different depths and diameters were fabricated, and tensile tests of composite materials were carried out. Then, the finite element model for the carbon-fiber-reinforced laminate specimens was established, and the validity of the model was verified by comparing its simulation results with the experimental data. Furthermore, by changing the geometric parameters of the internal delamination damage model, the influence of delamination damage on the tensile strength of carbon-fiber-reinforced composites was analyzed and summarized. The results show that, on the one hand, for the internal delamination damages of the same area, the closer is the delamination damage to the surface layer, the lower is the tensile strength. In particular, the closer is the delamination damage to the surface layer, the greater is the decrease in tensile strength, which exhibits an obvious nonlinear relationship. On the other hand, for the internal delamination defects of the same depth, the difference in delamination area has little effect on the tensile strength. This law provides a reference for the damage detection and maintenance focus of aeronautical composite structures, which is of great significance to ensure the safe use of aeronautical composites.

Similar content being viewed by others

References

Cai J, Dai DQ. Inspection interval optimization for aircraft composite structures with dent and delamination damage. J Syst Eng Electron. 2021;32(01):252–60.

Towsyfyan H, Biguri A, Boardman R, Blumensath T. Successes and challenges in non-destructive testing of aircraft composite structures. Chin J Aeronaut. 2020;33(3):771–91.

Bolotin VV. Mechanics of delaminations in laminate composite structures. Mech Compos Mater. 2001;37(5–6):367–80.

Imran M, Khan R, Badshah S. Investigating the effect of delamination size, stacking sequences and boundary conditions on the vibration properties of carbon fiber reinforced polymer composite. Mater Res. 2019;22(2): e20190478.

Luo YS, Yang SX, Lv XF, He J, Liu Y, Cheng QC. An algorithm based on logarithm of wavenumber amplitude for detection of delamination in carbon fiber composite. Meas Sci Technol. 2021;32(10): 105024.

Wang XM, Xie FY. Tensile strength and failure behavior of T-stiffened panels with embedded delamination: experimental investigation. Iran Polym J. 2021;30(9):897–905.

Wang Q, Xia RC, Liu QH, Zhou HB, Qiu JX, Zhao BY. Pixel-based thermal sequence processing algorithm based on R2 fractile threshold of non-linear fitting in active infrared thermography. Infrared Phys Technol. 2020;109: 103422.

Wang RB, Pei CX, Xia RC, Wang Q, Chen ZM. A portable fiber laser thermography system with beam homogenizing for CFRP inspection. NDT E Int. 2021;124: 102550.

Wang Q, Zhou HB, Liu M, Li XY, Hu QP. Study of the skin depth and defect detection in carbon fiber composites with Terahertz waves. Optik. 2018;178:1035–44.

Wang Q, Hu QP, Qiu JX, Pei CX, Liu M, Li XY, Zhou HB. Detection of internal defects in aviation composites with differential laser infrared thermal imaging. Infrared Laser Eng. 2019;48(05):127–33.

de Castro DSV, Matvieieva N, Grosso M, Camerini CG, Kotik HG, Heuer H. Evaluation of mode II delamination area by non-destructive techniques: accuracy and influence on fracture toughness calculation. J Nondestruct Eval. 2021;40(3):58.

Yi Q, Tian GY, Malekmohammadi H, Zhu J, Laureti S, Ricci M. New features for delamination depth evaluation in carbon fiber reinforced plastic materials using eddy current pulse-compression thermography. NDT E Int. 2019;102:264–73.

Ranjit S, Choi M, Kim W. Quantification of defects depth in glass fiber reinforced plastic plate by infrared lock-in thermography. J Mech Sci Technol. 2016;30(3):1111–8.

Liu Z, Li PF, Srikanth N. Effect of delamination on the flexural response of [+45/–45/0]2s carbon fibre reinforced polymer laminates. Compos Struct. 2018;209:93–102.

Qin R, Zhou W, Han KN, Liu J, Ma LH. Near-surface delamination induced local bending failure of laminated composites monitored by acoustic emission and micro-CT. J Mater Sci. 2021;56(36):19936–54.

Cheng P, Peng Y, Wang K, Wang YQ. Mechanical performance and damage behavior of delaminated composite laminates subject to different modes of loading. J Braz Soc Mech Sci Eng. 2021;43(10):455.

Durdu O, Ozdemir O, Kemiklioglu U. Low-velocity impact behaviours of thermoplastic composites reinforced polypropylene glass fabric with different embedded delaminations. Plast Rubber Compos. 2021;51(1):35–46.

Chen JF, Morozov EV, Shankar K. Simulating progressive failure of composite laminates including in-ply and delamination damage effects. Composites A. 2014;61:185–200.

Zhao LB, Liu YL, Hong HM, Wang KK, Zhao J. Compressive failure analysis for low length-width ratio composite laminates with embedded delamination. Compos Commun. 2018;9:17–21.

Wang KK, Zhao LB, Hong HM, Zhang JY, Gong Y. Parameter studies and evaluation principles of delamination damage in laminated composites. Chin J Aeronaut. 2021;34(07):62–72.

Wu WL, Wang QT, Li W. Comparison of tensile and compressive properties of Carbon/Glass interlayer and intralayer hybrid composites. Materials. 2018;11(7):1105.

Reis PNB. Effect of interlayer delamination on mechanical behavior of Carbon/Epoxy laminates. J Compos Mater. 2009;43(22):2609–21.

Standardization Administration of the People's Republic of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials, GB/T 3354-2014.

Yin DJ, Zheng J, Xiong C, Yin JH. Experimental and numerical studies of perforated CFRP laminates under quasi-static tensile load. IOP Conf Ser Mater Sci Eng. 2021;1040(1): 012011.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and the manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Q., Chen, Q., Chen, Y. et al. The Effect of Internal Delamination Damage on the Tensile Strength of Aeronautical Composites. Acta Mech. Solida Sin. 35, 979–986 (2022). https://doi.org/10.1007/s10338-022-00335-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-022-00335-2