Abstract

The main policy addressing the packaging waste issue in the countries of the European Union has been to define recycling objectives along with Extended Producer Responsibility (EPR). With EPR, producers finance the recycling and management of waste generated by their products. Within this framework, they are expected to internalise waste management costs and engage in eco-design of their packaging, i.e., use less packaging and increase packaging recyclability (e.g., through substitution of materials). EPR has been extended worldwide over recent decades and applied to various waste streams. In this paper, by exploiting temporal variation of an original panel dataset of EPR compliance costs from 25 European countries (1998–2015) and four packaging materials, I evaluate for the first time whether these costs have led to packaging waste reduction and substitution of packaging materials. I find that the EPR financial incentive has resulted in very little (though statistically significant) packaging reduction and no systematic substitution effects between packaging materials.

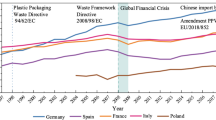

Source: Database created by the author

Source: Database created by the author

Similar content being viewed by others

Notes

Defined in the European Waste Framework Directive (Directive 2008/98/EC).

See Article 5 in Directive 2018/852. Packaging waste was initially regulated under Directive 1994/62/EC and later amended by Directive 2008/98/EC and Directive 2018/852 .

Directive 1994/62/EC , Annex II; Directive 2008/98/EC , Art. 8.

Fleckinger and Glachant (2010) show that individual EPR is akin to a Pigovian tax, whose rate equals the producer’s marginal cost of waste disposal when waste management is provided competitively.

Other aspects of recyclability (e.g., glue, ink) are not usually addressed.

Other incentives to improve product circularity were not considered in collective EPR at the time (with the exception of France for some substances; please refer to Joltreau (2018)). Design for recycling is essential to develop the economy’s circularity (Zotti and Bigano 2019). Circularity aspects are to be considered more comprehensively in EPR in the future. You can refer to the EU Commission guidance on the eco-modulation of EPR fees for a document on the matter (European Commission 2018).

Directive 2008/98/EC , Art. 8.

Austria (AUT), Belgium (BEL), Bulgaria (BGR), Cyrpus (CYP), Czech Republic (CZE), Estonia (EST), Finland (FIN), France (FRA), Germany (DEU), Greece (GRC), Hungary (HUN), Ireland (IRL), Italy (ITA), Latvia (LVA), Lithuania (LTU), Malta (MLT), The Netherlands (NLD), Poland (POL), Portugal (PRT), Romania (ROU), Slovakia (SVK), Slovenia (SVN), Spain (ESP), Sweden (SWE) and the United-Kingdom (GBR).

Prices may be negative when treatment costs are greater than values of recycled content. Therefore perfect recycling markets may not be so “perfect” as they would encourage illegal dumping for some products.

Except when a Pay-As-You-Throw (PAYT) approach is in place. However, PAYT usually accounts for only half of the costs, and the other half is paid through fixed fees to avoid illegal dumping and cover fixed costs. Also, products are binarily differentiated whether or not they are recyclable, but not according to their degree of recyclability. Last but not least, recyclable packaging is usually collected free of charge. For more details, see Tojo et al. (2008). Some municipalities in various EU countries have adopted PAYT (e.g., Besançon in France, Innsbruck in Austria, and Treviso in Italy).

This signal may only be transferred to consumers if producers pass on their compliance costs to product prices. Note that cost pass-through from producers to consumers may be incomplete and averaged across the producer’s various products.

First, while European harmonised recycling and collection targets exist (Directive 2018/852), countries are free to introduce higher national objectives (e.g., in Germany, da Cruz et al. 2014).

In perfect and efficient markets, incentives for final producers through to upstream producers are transmitted along the value chain without friction. Therefore, splitting the responsibility would mean greater compliance costs for actors further up the value chain than for downstream actors.

A firm may nevertheless choose an individual EPR (single recycling loop), but such cases are unusual.

In this context, producers can still benefit from the service of PROs, which handle the purchase of certificates for firms. In Poland, the purchase of recycling certificates to recyclers is made by the PROs (Faolex 2014), and upstream producers pay compliance fees to the PRO. Hence, it can be considered as a PRO-based EPR.

Note that in Hungary less than one-third of the tax revenue is allocated to waste management (OECD 2018), thus corresponding only to a partial interpretation of EPR.

Note that many values are missing before 2004 when a few countries had already implemented such schemes.

This result averages the fee for five materials: paper, glass, PET, aluminium and steel.

Patterns of cost-sharing between producers and public services (e.g., in Germany the PRO bears the full cost of recycling, while there exist a cost-sharing system in other countries; Massarutto 2014), different pricing methodologies (in theory, the producer’s fees are meant to reflect waste management costs, but in general, the pricing methodology is not transparent; also, for example, in the Netherlands, the tax has been designed as a carbon tax (Sevenster et al. 2007)), additional membership fees or unit-based fees, different waste treatment costs (competition between recyclers, costs of labour, available technologies, and infrastructure), different national recycling targets and the remaining efforts needed to achieve them, the number of firms contributing to the PRO... I leave this topic for further research.

For example, a firm exporting products of one ton of equivalent packaging in Germany and one ton in Poland will bear an average compliance cost of €275. This figure is based on the assumption that the importer (who is legally responsible for complying with EPR) passes EPR costs on to the foreign producer.

Note that I use an annual average for the UK, but prices of recycling certificates are marked by strong intra-year variations. However, firms contracting to a PRO can benefit from fixed rates.

For example, in the case where 1 \(m^3\) of glass or plastics are used to produce the same amount of packaging, 250 kg of glass and 130 kg of plastics would be needed.

Equivalent to packaging placed on the market each year, normalised per capita.

The dimension PET is very similar to the dimension Plastics since many PROs do not distinguish between plastic resins during the period 1998-2015. The same argument holds for paper and cardboard and paper and cardboard including composites.

Directive Directive 1994/62/EC , Art. 12.

E.g., Citeo, the French PRO for household packaging, provides a website where members can share their packaging reduction actions (http://reduction.ecoemballages.fr/catalogue/produit/).

This research is limited to the impact of financial incentives provided by EPR and does not analyse in detail other interactions provided by the institutional framework, although its heterogeneity is controlled through country-material fixed effects. I leave institutional economics of EPR as a topic for future research (e.g., see Micheaux 2017 for Waste from Electrical and Electronic Equipment).

Use of importation prices: primary materials for glass and cardboard, secondary materials for plastics, aluminium and steel.

The variable alcoholic_bev\(_{i,t}\) is missing for Malta and the Netherlands.

The log transformation contributes to the smooth the EPR variable distribution. A log-linear model and a linear model were used without significant results for the squared EPR variable (taken in addition to the EPR variable). In addition, column 3 of Table 5 already eliminates high values of EPR, without any significant change in the results. Therefore, the search for a convex effect from the EPR variable does not seem justified.

Taking the log of EPR excludes the few zero values of the variable EPR: in Greece (1998-2000) and Finland in 1998, when no EPR was implemented.

The hypothesis “panels contain unit roots” is rejected with a p-value=0. We consider year>2004 because the test requires a balanced panel.

Except in Greece (1998-2000) and Finland in 1998, when no fees were charged.

Note that if different fees are available for a given year, I have used an annual average.

However, counter-intuitively in the data, Table 3 shows a positive close-to-zero correlation between material prices and the variable EPR.

Fuel prices are linked to material prices. In particular, if fuel costs increase, it is more costly to extract and transport materials.

A 100cL milk brick, as in Eco-Emballages (2015).

Potentially, enterprises aim to reduce input costs and increase competitiveness no matter how expensive materials are. Moreover, country-specific material prices are not relevant if packaging is produced abroad. Prices of substitutes may matter as much as prices of material themselves. Even if fees are small as compared to the packaging cost, they call for strict monitoring. In turn, monitoring leads to internal indicators and indicators to internal strategy, etc. Monitoring and paying for packaging that will become waste may raise awareness among firms of their negative externality on the environment and packaging reduction possibilities (e.g., feeling of guilt about damaging the environment, opportunistically decreasing production costs by reducing packaging use).

The fee of year \(t-2\) is statistically significant when adding the sectoral consumption variables. However, this coefficient may also be the effect of the fee of year \(t-2\) on the fee in t, which in turn affects packaging waste per capita.

The joint null hypothesis of the J test is that instruments are valid, i.e., uncorrelated with the error term.

\(ln(EPR_{t-3})\) may have an effect on \(ln(EPR_{t-2})\).

Belgium, Germany, Estonia, Ireland, Spain, France, Italy, the Netherlands, Austria, Portugal, the United Kingdom.

A rule of thumb is that a VIF under 4 indicates moderate multicollinearity. If VIF(\(\beta\))=4, this means that the standard error of \(\beta\) is twice as large as it would be if the predictor was uncorrelated with other predictors.

Subsidised recycling is not the most environmentally-sound option and can lead to perverse effects on the environment (D’Haultfœuille et al. (2014) for an example in the vehicle sector). The study by Antoni and Marzetti (2019) qualifies this reasoning and shows that curbside collection programmes tend to reduce waste generation in Italy.

In its Directive on single-use plastics, the EU considers ten items to be banned from 3 July 2021 if sustainable alternatives are available/affordable. This ban will apply to cotton bud sticks, cutlery, plates, straws, stirrers, and sticks for balloons. It will also apply to cups, food, and beverage containers of expanded polystyrene. However, this is a waste prevention measure for plastics/expanded polystyrene, but regardless of the materials, waste generation may not be affected (e.g., material substitution).

At the exception of Germany, Duales System Deutschland since 2010; Malta, GreenPak since 2013; Slovakia, ENVI-PAK since 2011.

Prior to 2012, glass packaging in Ecoembes (Spain) was only subject to unit-based fees.

References

Acemoglu D, Aghion P, Bursztyn L, Hemous D (2012) The environment and directed technical change. Am Econ Rev 102(1):131–166

Acemoglu D, Naidu S, Restrepo P, Robinson JA (2019) Democracy does cause growth. J Polit Econ 127(1):47–100

ADEME (2016) Le gisement des emballages ménagers en France. Focus sur 10 marchés de grande consommation (1997–2012). Rapport du Conseil National de l’Emballage (CNE), l’ADEME et Eco-Emballages

Allwood JM, Ashby MF, Gutowski TG, Worrell E (2011) Material efficiency: a white paper. Resour Conserv Recycl 55(3):362–381

Amorce (2015) Panorama des filières REP Européennes. Série Technique. Amorce (Association des collectivités territoriales et des professionnels) DT 68. ADEME 8482

Anderson T, Hsiao C (1982) Formulation and estimation of dynamic models using panel data. J Econ 18(1):47–82

Antoni GD, Marzetti GV (2019) Recycling and waste generation: an estimate of the source reduction effect of recycling programs. Ecol Econ 161:321–329

Arellano M (1989) A note on the Anderson–Hsiao estimator for panel data. Econ Lett 31(4):337–341

Arellano M, Bond S (1991) Some tests of specification for panel data: Monte Carlo evidence and an application to employment equations. Rev Econ Stud 58(2):277–297

Arnaud B (2017) Extended producer responsibility and green marketing: an application to packaging. Environ Resour Econ 67(2):285–296

Baltagi B (2015) The Oxford handbook of panel data. Oxford University Press, Oxford

Belastingdienst (2019) Packaging tax abolished. www.belastingdienst.nl. Retrieved 01 Oct 2019

Bezin E (2019) The economics of green consumption, cultural transmission and sustainable technological change. J Econ Theory 181:497–546

Breusch TS, Pagan AR (1980) The Lagrange multiplier test and its applications to model specification in econometrics. Rev Econ Stud 47(1):239–253

Brouillat E, Oltra V (2012) Extended producer responsibility instruments and innovation in eco-design: an exploration through a simulation model. Ecol Econ 83(Supplement C):236–245

Brunnermeier SB, Cohen M (2003) Determinants of environmental innovation in US manufacturing industries. J Environ Econ Manag 45(2):278–293

Cainelli G, D’Amato A, Mazzanti M (2020) Resource efficient eco-innovations for a circular economy: evidence from EU firms. Res Policy 49(1):103827

Calcott P, Walls M (2000) Can downstream waste disposal policies encourage upstream design for environment? Am Econ Rev 90(2):233–237

Calcott P, Walls M (2005) Waste, recycling, and design for environment: roles for markets and policy instruments. Resour Energy Econ 27(4):287–305

Calel R, Dechezleprêtre A (2016) Environmental policy and directed technological change: evidence from the European carbon market. Rev Econ Stat 98(1):173–191

Chamberlain G (1992) Comment: sequential moment restrictions in panel data. J Bus Econ Stat 10(1):20–26

Charlot S, Crescenzi R, Musolesi A (2015) Econometric modelling of the regional knowledge production function in Europe. J Econ Geogr 15(6):1227–1259

da Cruz N, Ferreira S, Cabral M, Simões P, Marques R (2014) Packaging waste recycling in Europe: is the industry paying for it? Waste Manag 34(2):298–308

Defra (2016) The producer responsibility obligations (packaging waste) (Amendment) regulations 2016, 1(871). Defra, London. https://www.legislation.gov.uk/uksi/2016/1146/memorandum/contents. Retrieved 01 Oct 2019

Defra (2019) Packaging waste: producer responsibilities. Defra, London. https://www.gov.uk/guidance/packaging-producer-responsibilities. Retrieved 01 Nov 2019

D’Haultfœuille X, Givord P, Boutin X (2014) The environmental effect of green taxation: the case of the French bonus/malus. Econ J 124(578):F444–F480

Didier E, Sittler E (2014) Mieux concevoir les produits pour mieux valoriser les déchets. Rapport d’information fait au nom de la Commission du développement durable, des infrastructures, de l’équipement et de l’aménagement du territoire. French Senate

Directive 1994/62/EC (1994) European Parliament and Council Directive 94/62/EC of 20 December 1994 on packaging and packaging waste. http://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX:31994L0062

Directive 2008/98/EC (2008) Directive of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098

Directive 2018/852 (2018) Directive (eu) 2018/852 of the European Parliament and of the Council of 30 May 2018 amending Directive 94/62/EC on packaging and packaging waste. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32018L0852

Dugoua E, Dumas M (2021) Green product innovation in industrial networks: a theoretical model. J Environ Econ Manag 107:102420

Dussaux D, Glachant M (2014) Recycler les déchets ou importer les matières premières? ADEME (French Environment & Energy Management Agency)

Eco-Emballages (2015) Guide de la déclaration. Eco-Emballages, French PRO for household packaging

EEA (2013) Municipal waste management in Croatia. European Environment Agency, Prepared by Birgitte Kjaer, ETC/SCP

EEA (2017) Waste prevention in Europe—policies, status and trends in reuse in 2017. European Environment Agency. EEA Report No 4/2018

EEA (2019a) An overview of the policies, approaches and targets of 32 European countries. European Environment Agency. EEA report no. 26/2019

EEA (2019b) Paving the way for a circular economy: Insights on status and potentials. European Environment Agency. EEA Report No. 11/2019

EEA (2020) The sustainability transition in Europe in an age of demographic and technological change. European Environment Agency. EEA Report No 23/2019

Egger P, Pfaffermayr M (2003) The proper panel econometric specification of the gravity equation: a three-way model with bilateral interaction effects. Empir Econ 28(3):571–580

Eichner T, Pethig R (2001) Product design and efficient management of recycling and waste treatment. J Environ Econ Manag 41(1):109–134

European Commission (2009) Waste prevention best practice factsheets. Carbon tax on packaging (Netherlands). http://ec.europa.eu/environment/waste/prevention/pdf/Netherlands_Factsheet.pdf

European Commission (2012) Use of economic instruments and waste management performances. https://ec.europa.eu/environment/waste/pdf/final_report_10042012.pdf

European Commission (2014) Development of Guidance on Extended Producer Responsibility (EPR). DG Environment

European Commission (2018) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee to the Regions. A European Strategy for Plastics in a Circular Economy. SWD(2018) 16 final

Europen (2013) Packaging and packaging waste statistics, 1998–2010. The European Organization for Packaging and the Environment

Eurostat (2018) Packaging waste statistics. Data extracted in April 2018

Faolex (2011) Governmental decree no. 343 of 2011 (xii. 29.) korm. implementing act no. lxxxv of 2011 regarding the environmental protection fee

Faolex (2014) Regulation from the ministry of the environment on model documents dpo and dpr. “rozporzadzenie ministra Środowiska z dnia 15 grudnia 2014 r. w sprawie wzorów dokumentów dpo i dpr”. http://extwprlegs1.fao.org/docs/pdf/pol151944.pdf

Flash Eurobarometer 315 (2011) Attitudes of European entrepreneurs towards eco-innovation. http://ec.europa.eu/commfrontoffice/publicopinion/flash/fl_315_en.pdf

Fleckinger P, Glachant M (2010) The organization of extended producer responsibility in waste policy with product differentiation. J Environ Econ Manag 59(1):57–66

Fleckinger P, Joltreau E (2020) Implementing a Circular Economy with Producer Responsibility Organizations. Presented paper at the European Association of Environmental and Resource Economists 2020 conference

Fost Plus (2004) Annual Report. Faits et chiffres 2004. Fost Plus, Belgian PRO for household packaging

Fullerton D, Wu W (1998) Policies for green design. J Environ Econ Manag 36(2):131–148

Glachant, M, Touboul S (2019) La Responsabilité Elargie du Producteur incite-t-elle suffisamment à la prévention des déchets d’emballages? Working Paper 19-CER-01

Glachant M (2004) Changing product characteristics to reduce waste generation, Chapter 9. OECD Publishing, Paris, pp 181–203

Heckman JJ, Hotz VJ (1989) Choosing among alternative nonexperimental methods for estimating the impact of social programs: the case of manpower training. J Am Stat Assoc 84(408):862–874

Hendry DF, Doornik JA (2015) Empirical model discovery and theory evaluation: automatic selection methods in econometrics. MIT Press, Cambridge

Hoover KD (2003) Causality in macroeconomics. Cambridge University Press, Cambridge

Jaffe AB, Palmer K (1997) Environmental regulation and innovation: a panel data study. Rev Econ Stat 79(4):610–619

Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, Ramani N, Law KL (2015) Plastic waste inputs from land into the ocean. Science 347(6223):768–771

Joltreau E (2018) Pricing products’ negative externalities at end-of-life using eco-modulation. Discussion from case studies. Econ Policy Energy Environ 1:149–172

Joltreau E, Sommerfeld K (2018) Why does emissions trading under the EU Emissions Trading System (ETS) not affect firms’ competitiveness? Empirical findings from the literature. Clim Policy 0(0):1–19

Kato K, Galvao AF, Montes-Rojas G (2012) Asymptotics for panel quantile regression models with individual effects. J Econ 170(1):76–91

Kleibergen F, Paap R (2006) Generalized reduced rank tests using the singular value decomposition. J Econ 133(1):97–126

Laing T, Sato M, Grubb M, Comberti C (2013) Assessing the effectiveness of the EU Emissions Trading System. Working Paper 126, Centre for Climate Change Economics and Policy

Legifrance (2018) Code de l’environnement. https://www.legifrance.gouv.fr/affichCode.do?cidTexte=LEGITEXT000006074220 (retrieved 01.10.2019). Version consolidée au 5 juillet 2018

Levin A, Lin C-F, James Chu C-S (2002) Unit root tests in panel data: asymptotic and finite-sample properties. J Econ 108(1):1–24

Lindhqvist T (2000) Extended producer responsibility in cleaner production. IIIEE dissertation

Machado JA, Santos Silva J (2019) Quantiles via moments. J Econ 213(1):145–173 (Annals: In Honor of Roger Koenker)

Massarutto A (2014) The long and winding road to resource efficiency—an interdisciplinary perspective on extended producer responsibility. Resour Conserv Recycl 85:11–21

Matsueda N, Nagase Y (2012) An economic analysis of the Packaging waste Recovery Note System in the UK. Resour Energy Econ 34(4):669–679

Mazzanti M, Zoboli R (2008) Waste generation, waste disposal and policy effectiveness: evidence on decoupling from the European Union. Resour Conserv Recycl 52(10):1221–1234

Mazzanti M, Zoboli R (2009) Municipal waste Kuznets curves: evidence on socio-economic drivers and policy effectiveness from the EU. Environ Resour Econ 44(2):203

Mazzanti M, Musolesi A (2020) A semiparametric analysis of green inventions and environmental policies

Micheaux H (2017) Le retour du commun au cœur de l’action collective: le cas de la Responsabilité Elargie du Producteur comme processus de responsabilisation et de co-régulation. Ph.D. thesis, PSL Research University

Musolesi A, Mazzanti M (2014) Nonlinearity, heterogeneity and unobserved effects in the carbon dioxide emissions-economic development relation for advanced countries. Stud Nonlinear Dyn Econom 18(5):521–541

OECD (2018) OECD environmental performance reviews. Hungary

OECD (2001) Extended producer responsibility: a guidance manual for governments. OECD Publishing, Paris

OECD (2004) Economic aspects of extended producer responsibility. OECD Publishing, Paris

OECD (2016) Extended producer responsibility: updated guidance for efficient waste management. OECD Publishing, Paris

Parente PM, Silva JS (2012) A cautionary note on tests of overidentifying restrictions. Econ Lett 115(2):314–317

Patulny R, Norris K (2005) Sustaining interest: are green values converting to votes? Int J Environ Workplace Employ IJEWE 1(3–4):296–309

Popp D, Hafner T, Johnstone N (2011) Environmental policy vs. public pressure: innovation and diffusion of alternative bleaching technologies in the pulp industry. Res Policy 40(9):1253–1268

Porter ME, van der Linde C (1995) Toward a new conception of the environment-competitiveness relationship. J Econ Perspect 9(4):97–118

Røine K, Lee C-Y (2006) With a little help from EPR? Technological change and innovation in the Norwegian plastic packaging and electronics sectors. J Ind Ecol 10(1–2):217–237

Rouw M, Worrell E (2011) Evaluating the impacts of packaging policy in The Netherlands. Resour Conserv Recycl 55(4):483–492

Runkel M (2003) Product durability and extended producer responsibility in solid waste management. Environ Resour Econ 24(2):161–182

Sachs N (2006) Planning the funeral at the birth: extended producer responsibility in the European union and the United States. Harvard Environ Law Rev 30:156

Schumacher I (2014) An empirical study of the determinants of green party voting. Ecol Econ 105:306–318

Sevenster MWL, Bergsma G, Vroonhof J (2007) Environmental indices for the Dutch packaging tax. CE Delft, Report (revised version)

Staiger D, Stock JH (1997) Instrumental variables regression with weak instruments. Econometrica 65(3):557–586

Stock J, Yogo M (2005) Identification and inference for econometric models: essays in honor of Thomas J. Rothenberg, Chapter 5. In: Testing for weak instruments in linear IV regression. Cambridge University Press, pp 80–108

Tencati A, Pogutz S, Moda B, Brambilla M, Cacia C (2016) Prevention policies addressing packaging and packaging waste: some emerging trends. Waste Manag 56:35–45

Tojo N, Neubauer A, Bräuer I (2008) Waste management policies and policy instruments in Europe. an overview. IIIEE Rep 2. https://www.ecologic.eu/sites/files/publication/2015/holiwastd1-1_iiiee_report_2__0.pdf

Tripathi A, Singh M (2016) Determinants of sustainable/green consumption: a review. Int J Environ Technol Manag 19:316

van Sluisveld MA, Worrell E (2013) The paradox of packaging optimization—a characterization of packaging source reduction in the Netherlands. Resour Conserv Recycl 73(Supplement C):133–142

van Rossem C, Tojo N, Lindhqvist T (2006) Extended producer responsibility: an examination of its impact on innovation and greening products. Greenpeace International

Vernier J (2018) Les filières rep. responsabilité élargie des producteurs en matière de prévention et de gestion des déchets générés par leurs produits. French Ministry of the Environment, J. Vernier, President of the Commission of EPR programmes

Watkins E, Gionfra S, Schweitzer J-P, Pantzar M, JC, ten Brink P, (2017) EPR in the EU Plastics Strategy and the Circular Economy: a focus on plastic packaging. IEEP, Institute for European Environmental Policy

Weber RL, Manning KV, White MW (1965) College physics, 4th edn. McGraw-Hill, New York. First ed. published in 1947 under title: College technical physics

Wernick IK, Themelis NJ (1998) Recycling metals for the environment. Annu Rev Energy Env 23(1):465–497

Wooldridge JM (2005) Fixed-effects and related estimators for correlated random-coefficient and treatment-effect panel data models. Rev Econ Stat 87(2):385–390

Worrell E, Faaij A, Phylipsen G, Blok K (1995) An approach for analysing the potential for material efficiency improvement. Resour Conserv Recycl 13(3):215–232

Xu Y, Li J, Liu L (2016) Current status and future perspective of recycling copper by hydrometallurgy from waste printed circuit boards. Procedia Environmental Sciences 31:162–170 (Selected proceedings of the tenth international conference on waste management and technology)

Zaliasis T (2016) Zaliasis Taskas 2016 fees. http://www.zaliasistaskas.lt/multimedia/inner-files/fees-16.pdf

Zellner A (1962) An efficient method of estimating seemingly unrelated regressions and tests for aggregation bias. J Am Stat Assoc 57(298):348–368

Zoboli R, Barbieri N, Ghisetti C, Marin G, Paleari S (2019) Towards an Innovation-intensive Circular Economy. Integrating Research, Industry and Policies. FEEM, SEEDS and Catholic University Report

Zotti J, Bigano A (2019) Write circular economy, read economy’s circularity. How to avoid going in circles. Econ Polit 36:629–652

Acknowledgements

I thank Stéphanie Monjon, Daniel Herrera, Matthieu Glachant, Damien Dussaux, Sophie Bernard, Philippe Delacote and the anonymous referees for helpful comments as well as the seminar participants at the 33rd annual congress of the European Economic Association and the 71st European Meeting of the Econometric Society (EEA-ESEM, University of Cologne, 2018), the seminar participants of the German Institute for Economic Research, Climate Policy (2018), the economics lab. of University of Paris-Dauphine (2019) and Ecole des Mines Paristech (2019). The usual disclaimer applies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Implementation of EPR in the Europe of 28

This annex tries to provide an overview of EPR compliance schemes for packaging and packaging waste legislation in the EU-28.

Column (1) lists the ISO code of the 28 countries members of the European Union. In the empirical analysis, 25 countries are considered: Austria (AUT), Belgium (BEL), Bulgaria (BGR), Cyprus (CYP), Czech Republic (CZE), Estonia (EST), Finland (FIN), France (FRA), Germany (DEU), Greece (GRC), Hungary (HUN), Ireland (IRL), Italy (ITA), Latvia (LVA), Lithuania (LTU), Malta (MLT), The Netherlands (NLD), Poland (POL), Portugal (PRT), Romania (ROU), Slovakia (SVK), Slovenia (SVN), Spain (ESP), Sweden (SWE) and the United-Kingdom (GBR).

Column (2) provides the name of the legislation in force concerning packaging waste management.

Column (3) describes the form of EPR implementation.

Column (4) gives the start date of EPR.

Column (5) gives the number of collective schemes, implying the presence of competition if this number is greater than one (col. (7)). Note that this number may evolve quickly.

Column (6) reports the name of the PRO that I have considered when constructing the dataset. The methodology is thereafter explained in “Appendix 2”.

Appendix 2: Construction of the EPR Variable

Table 12 lists the PRO considered for each country. In some countries several PROs compete in the same waste stream. I assume that fees charged by the different PROs are similar. In fact, I have mostly considered PROs belonging to PRO-Europe, the umbrella organisation for European packaging recycling schemes using the trademark “The Green Dot”. PRO Europe diffuses reports on their members’ commercial policy, which have been used for constructing the dataset.

Commercial policies of PROs go to very simple (one fee per material: cardboard, glass, plastics, metals) to very detailed: e.g. differentiation between plastic resins, differentiation between aluminium and steel, additional fees for composite packaging and non-recyclable materials, industrial vs. household packaging, function of the packaging (primary, secondary, tertiary), etc.

For plastics, I decide to create a dimension PET either equal to the PET fee when existing, or to the plastic fee. Often, PROs distinguish between “PET” and “other plastics”. Some PROs only have a category “plastics”. In addition, I create a dimension Plastics, which is a weighted average of the different plastic resin fees when existing, or equal to the plastic fee. The weighting given to each criterion relies on numbers found in Fost Plus (2004): 40% PET, 5% HDPE, 55% other plastics.

For metals, I create two dimensions Aluminium and Steel. Following the same reasoning, the Aluminium fee is either equal to the aluminium fee when existing, or the metal fee. Therefore it happens that both dimensions, Aluminium and Steel, are redundant.

For paper and cardboard, it happens that PROs distinguish between paper and cardboard and composite paper and cardboard (e.g. juice carton with an aluminium component). I therefore create a dimension Paper and Cardboard equals to the paper and carboard fee, and a Paper and Cardboard including Composites which is a weighted average, calculated as follows: 90% Paper and cardboard, 10% drink beverages. The weighting given to each criterion relies on numbers found in Fost Plus (2004). When no distinction exists between paper and cardboard, and composite paper and cardboard, both dimensions are redundant.

For glass packaging, I simply use the glass fee.

To further ensure comparison between countries, the construction of the variable EPR only encompasses:

-

Household packaging

-

Packaging being the closest to the product to be packaged (e.g. sales packaging, primary packaging) if fees are differentiated according to the packaging type.

-

Weight-based component of the contribution (i.e., I exclude unit-based fees and participation/membership fees)

Annual membership fees do not provide incentives to eco-design of packaging. Hence, excluding them from the database is not a problem. Nevertheless, unit fees provide incentives to remove group packaging. It is very complicated to control for unit-based pricing since the pricing methodology is not constant overtime. For example in France, the unit-based pricing was first differentiated according to the packaging volume, then to the weight-based contribution (lighter packaging have lower unit-based fee). As unit fees are solely used in three countries (Greece, France, Spain), removing these countries from the econometric sample as robustness check is sufficient.

The EPR variable does not include national VAT.

The main data source is PRO-Europe reports, where PROs usually report their commercial policyFootnote 47 and personal communication with PROs.

Data stem from the following sources: Austria: ARA Recycling; Belgium: Fost Plus, PRO-Europe; Bulgaria: PRO-Europe; Cyprus: PRO-Europe; Czech Republic: PRO-Europe; Estonia: PRO-Europe; Finland: Finnish Packaging Recycling RINKI; France: Citeo (former Eco-Emballages); Germany: PRO-Europe; Great Britain: The Environment Exchange; Greece: PRO-Europe; Hungary: PRO-Europe and RSM Hungary Tax and Financial Advisory Services; Ireland: Repak Limited; Italy: CONAI Consorzio Nazionale Imballaggi; Latvia: PRO-Europe; Lithuania: PRO-Europe and Žaliasis taškas; Malta: PRO-Europe; Netherlands: Afvalfonds Verpakkingen and PRO-Europe; Poland: Rekopol and PRO-Europe; Portugal: PRO-Europe; Romania: PRO-Europe; Slovakia: PRO-Europe; Slovenia: PRO-Europe; Spain: PRO-Europe; Sweden: PRO-Europe.

All data are converted in euro when needed using yearly averages of exchange rate from the European Central Bank.

Appendix 3: Construction of the greenvote Variable

Green votes are a valuable indicator for citizens’ environmental concerns (Schumacher 2014). I collect data from the Norsk Senter for Forskningsdata (NSD), which provides data on results for several elections (presidential, parliamentarian, European) for 34 countries (mostly EU members) between 1990 and 2013.

I choose to consider parliamentarian elections, because not every country held presidential elections. In parallel, in presidential regimes, these elections may be concentrated around charismatic figures rather than parties or ideas. I exclude European elections because of the low turnout.

Table 13 lists parties that I identified as “green” in parliamentary elections. Share of votes allocated to green parties are then compiled under a same share “green votes”.

Green parties sometimes form coalition with other parties. For example, in Portugal, the Green party is associated with the Communists so that it is impossible in the data to distinguish green voters from communists. While some green voters may have been dissuaded from voting for this coalition if they do not share communist ideas, I decide to still include coalitions’ election results as green votes.

In addition, there exists farmer and peasant movements, which have some ecological claims. However the movements seem to specifically call for more consideration for farmers and peasants. I therefore decide to exclude peasant movements when they are not in coalition with more general green parties, because they seem specific to one category of the population. If there are several rounds, I use results from the first round (except for Germany where the second round corresponds to the round where citizens choose a party, while in the first round people vote for a personality).

The imputation strategy for missing values between two election dates that is used, is to replace missing values with the latest available value (most recent election). This strategy corresponds to the assumption that people do not change their mind between two election dates, and only think about whether they want a greener society during the election time. While this can be considered a strong assumption, I believe that it is less strong that assuming that citizens linearly increase or decrease their green preferences between two elections. Also, this would introduce more within variations, which could affect the coefficients.

Figure 8 displays election performances of green parties in European countries in 2013 and 1998. Top countries, whose green parties collect more than 8% of the votes are Austria, Latvia, Belgium and Germany. For Austria and Latvia, this score represents quite a substantial evolution as compared to 1998. Some other countries, (i.e., Spain, Slovakia, Poland, Malta, Hungary and Bulgaria) experience 0% of votes for green parties. Note that I did not include the peasant party for Poland (that accounts for around 8% of the votes).

Appendix 4: Construction of the Material price Variable

Material prices are proxied by import unit value (€/t) from the BACI database, provided by the CEPII. To get unit values, import flows in US dollars (USD) are divided over the same flows in tonnes. USD are then converted to euros, using exchange rates annual data from Eurostat (year average). I use the product classification established by Dussaux and Glachant (2014) to target flows of materials.

I use imports because I believe that it represents a better proxy of material prices than export prices, which rely on domestic production capacity. I assume that if countries want to produce packaging, they will either use materials produced nationally (for which price information is not available) or import materials, whose prices are competitive with national prices.

For aluminium and steel, I use prices of secondary materials because primary materials exhibit too extreme variations. This should not be a major issue since recycling of metals do not alter the metals’ properties (Wernick and Themelis 1998). Accordingly, recycled and primary metals should be close substitutes and present similar price evolution.

For plastics, I also use prices of secondary materials because primary materials are not available in the database. This may be more of a problem, since unlike metals, the properties of plastic resins cannot be fully restored through recycling (Wernick and Themelis 1998). Prices of secondary plastics may sometimes decorrelate from primary materials. However, price of primary plastics should be linked to fuel prices, that are included in the econometric regression.

As shown in Fig. 9, there exist important differences between material prices that are likely to affect decisions on product design. Malta is excluded from the graphic, because it has extreme values.

Intra-country variations are very large, in particular for plastics and glass, which may question the accuracy of import unit value.

Appendix 5: Simulations

Simulations of EPR compliance costs are run for several commonly consumed products, in order to grasp how expensive are EPR compliance costs to firms. I rely on items given as examples in Eco-Emballages (2015) and 2015 EPR compliance costs, when available.

-

370g jam in glass jar with steel lid (Table 14)

-

1.5 l mineral water in PET bottle with HDPE stopper (Table 15)

-

33 cl aluminium can (Table 16)

These simulations rely on the assumptions that sale prices are identical across European countries. Unit fees are used in the simulations. Unit fees are charged per item of packaging and are used in Greece (HE.R.R.C.o; 0.04 €cent), France (Citeo, from 0.01-0.07 €cent) and Spain (Ecoembes, 0.28 €cent for glass only). along with a weight-based fee.Footnote 48 Eco-Emballages (2015) reported in 2015 that unit fees would reach 25% of firms’ total financial contribution at most.

Rights and permissions

About this article

Cite this article

Joltreau, E. Extended Producer Responsibility, Packaging Waste Reduction and Eco-design. Environ Resource Econ 83, 527–578 (2022). https://doi.org/10.1007/s10640-022-00696-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10640-022-00696-9