Abstract

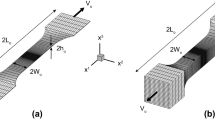

The modified Gurson–Tvergaard–Needleman model, that considers shear decohesion as an increment in the total void volume fraction, is used to investigate the effect of superimposed hydrostatic pressure on the ductility of a round bar specimen. Experiments indicate that the fracture mode is not uniform across the cross section of a round bar specimen–no shear damage exists at the center while it is pronounced at the edge. The damage mechanisms of shear decohesion and void growth are delayed by applying superimposed hydrostatic pressure, which leads to an increase in the fracture strain and ductility. However, the effect of pressure on ductility depends on the location within the cross section. Void growth at both the center and the edge becomes increasingly delayed with increasing pressure, but this effect is more significant at the edge because of the existence of shear stress. Shear decohesion at the edge becomes the dominant damage mechanism, rather than void growth, when pressure is increased. The numerical results presented herein are used to explain and discuss this phenomenon in depth.

Similar content being viewed by others

References

Abaqus/CAE User’s Manual (2014) ABAQUS Inc., Waltham

Ashby MF, Embury JD, Cooksley SH, Teirlinck D (1985) Fracture maps with pressure as a variable. Scr Metall 19(4):385–390

Barsoum I, Faleskog J (2007) Rupture mechanisms in combined tension and shear-Micromechanics. Int J Solids Struct 44:5481–5498

Besson J, Steglich D, Brocks W (2001) Modeling of crack growth in round bars and plane strain specimens. Int J Solids Struct 38:8259–8284

Bridgman PW (1952) Studies in large plastic flow and fracture. Harvard University Press, Cambridge

Brownrigg A, Spitzig WA, Richmond O, Teirlinck D, Embury JD (1983) The influence of hydrostatic pressure on the flow stress and ductility of a spherodized 1045 steel. Acta Metall 31(8):1141–1150

Brünig M, Gerke S, Hagenbrock V (2013) Micro-mechanical studies on the effect of the stress triaxiality and the Lode parameter on ductile damage. Int J Plasticity 50:49–65

Chen S, Osovski S (2020a) Damage evolution around an embedded pore in quasi-static shear dominant compression and tension specimens. Mech Mater 148:103513

Chen S, Osovski S (2020b) Damage evolution around shear loaded intervoid ligaments in plane strain and plane stress. Eur J Mech A Solids 80:103909

Chen XX, Wu PD, Embury JD, Huang Y (2010) Enhanced ductility in round tensile bars produced by cladding a ductile ring. Model Simul Mater Sci Eng 18(2):025005

Chen D, Li Y, Yang X, Jiang W, Guan L (2021) Efficient parameters identification of a modified GTN model of ductile fracture using machine learning. Eng Fract Mech 245:107535

Chu C, Needleman A (1980) Void nucleation effects in biaxially stretched sheets. J Eng Mater Technol 102(3):249–256

French IE, Weinrich PF (1975) The influence of hydrostatic pressure on the tensile deformation and fracture of copper. Metall Trans A 6(4):785–790

French IP, Weinrich PF, Weaver C (1973) Tensile fracture of free machining brass as a function of hydrostatic pressure. Acta Metall 21(8):1045–1049

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I—Yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99(1):2-15.S

Kao AS, Kuhn HA, Richmond O, Spitzig WA (1989) Workability of 1045 spheroidized steel under superimposed hydrostatic pressure. Metall Trans A 20(9):1735–1741

Kao AS, Kuhn HA, Richmond O, Spitzig WA (1990) Tensile fracture and fractographic analysis of 1045 spheroidized steel under hydrostatic pressure. J Mater Res 5(1):83–91

Korbel A, Raghunathan VS, Teirlinck D, Spitzig WA, Richmond O, Embury JD (1984) A structural study of the influence of pressure on shear band formation. Acta Metall 32(4):511–519

Li X, Chen Z, Dong C (2021) Size effect on the damage evolution of a modified GTN model under high/low stress triaxiality in meso-scaled plastic deformation. Mater Today Commun 26:101782

Nahshon K, Hutchinson J (2008) Modification of the Gurson model for shear failure. Eur J Mech A Solids 27(1):1–17

Peng J, Wu PD, Huang Y, Chen XX, Lloyd DJ, Embury JD, Neale KW (2009) Effects of superimposed hydrostatic pressure on fracture in round bars under tension. Int J Solids Struct 46(20):3741–3749

Shahzamanian MM, Wu PD (2021) Study of forming limit diagram (FLD) prediction of anisotropic sheet metals using Gurson model in M-K method. IntJ Mater Form 14:1031–1041

Shahzamanian MM, Lloyd DJ, Wu PD, Xu Z (2021a) Study of influence of superimposed hydrostatic pressure on bendability of sheet metals. Eur J Mech A Solids 85:104132

Shahzamanian MM, Lloyd DJ, Partovi A, Wu PD (2021b) Study of influence of width to thickness ratio in sheet metals on bendability under ambient and superimposed hydrostatic pressure. Appl Mech 2:542–558

Shahzamanian M, Thomsen C, Partovi A, Xu Z, Wu P (2021c) Numerical study about the influence of superimposed hydrostatic pressure on shear damage mechanism in sheet metals. Metals 11:1193

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17(4):389–407

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32(1):157–169

Wu PD, Chen XX, Lloyd DJ, Embury JD (2010) Effects of superimposed hydrostatic pressure on fracture in sheet metals under tension. Int J Mech Sci 52(2):236–244

Yang X, Li Y, Jiang W, Duan M, Chen D, Li B (2021) Ductile fracture prediction of additive manufactured Ti6Al4V alloy based on an extended GTN damage model. Eng Fract Mech 256:107989

Acknowledgements

The very useful comments and suggestions by two anonymous reviewers were greatly appreciated. This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC, Project No: RGPIN-2016-06464).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shahzamanian, M.M., Thomsen, C., Partovi, A. et al. The effect of superimposed hydrostatic pressure on shear decohesion in round bar tensile specimens. Int J Fract 233, 179–194 (2022). https://doi.org/10.1007/s10704-021-00614-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00614-y