Abstract

A theory of viscoelastic crack growth that accounts for global and local (crack-tip) viscoelasticity, as well as continuum nonlinearity, is used to analyze stable and unstable crack growth data on carbon black-filled rubber. First, we briefly review relevant results from a recently published linear theory that compares the effect of various models of the failure zone (fracture process zone) on crack growth. Then, it is shown that an extension of this theory to include nonlinearity is in very good agreement with experimental data on crack opening displacement and crack speed for rubber with three different volume fractions of carbon black.

Similar content being viewed by others

References

Anderson TL (2017) Fracture mechanics: fundamentals and applications, 4th edn. CRC Press, Boca Raton

Dugdale DS (1960) Yielding of sheet steel containing slits. J Mech Phys Solids 8:100–104

Fung YC (1965) Fundamentals of solid mechanics. Prentice-Hall, Englewood Cliffs

Knauss WG (2015) A review of fracture in viscoelastic materials. Int J Fract 196:99–146

Koushik V (2014) Schallamach waves on adhesive surfaces. https://www.youtube.com/watch?v=A2XAi6thL1s

Maugis D, Barquins M (1978) Fracture mechanics and the adherence of viscoelastic bodies. J Phys D 11:1989–2023

Morishita Y, Tsunoda K, Urayama K (2016) Velocity transition in the crack growth dynamics of filled elastomers: contributions of nonlinear viscoelasticity. Phys Rev E 93:043001

Perrin H, Eddi A, Karpitschka S, Snoeijer J, Andreotti B (2019) Peeling an elastic film from a soft viscoelastic adhesive: experiments and scaling laws. Soft Matter 15:770–778

Rice J, Rosengren G (1968) Plane strain deformation near a crack tip in a power-law hardening material. J Mech Phys Solids 16:1–12

Schapery RA (1975a) A theory of crack initiation and growth in viscoelastic media, Part II: approximate methods of analysis. Int J Fract 11:369–388

Schapery RA (1975b) A theory of crack initiation and growth in viscoelastic media, Part III: analysis of continuous growth. Int J Fract 11:549–562

Schapery RA (1984) Correspondence principles and a generalized J integral for large deformation and fracture analysis of viscoelastic media. Int J Fract 25:195–223

Schapery RA (1986) Continuum aspects of crack growth in time-dependent materials. In: Encyclopedia of materials science and engineering. Pergamon Press, Oxford, pp 5043–5053

Schapery RA (1999) Nonlinear viscoelastic and viscoplastic constitutive equations with growing damage. Int J Fract 97:33–66

Schapery RA, Park SW (1999) Methods of interconversion between linear viscoelastic material functions. Part II: approximate analytical method. Int J Solids Struct 36:1677–1699

Schapery RA (2020) The effect of global viscoelasticity on rubber friction with Schallamach waves. Tribol Int 148:106306

Schapery RA (2022) A theory of viscoelastic crack growth-revisited. Int J Fract 233:1–16

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Constitutive equation

The constitutive equation used in large deformation \({J_{v}}\) theory is based on a strain energy density W that is a function of pseudo quantities, in which the Piola stress tensor \({{\varvec{\upsigma}}}\) (whose transpose is called the Lagrangian stress tensor by Fung (1965)), satisfies

where \(\nabla {\mathbf{u}}^{R}\) is the pseudo displacement gradient and \({\mathbf{u}}^{R}\) is the pseudo displacement vector,

in terms of the displacement vector \({\mathbf{u}}\). Although other relaxation moduli could be used, we use here the shear relaxation modulus, G(t), and its equilibrium value, \(G_{e}\). The stresses and displacements are defined in terms of coordinates in the initial, undeformed body.

The inverse of Eq. (35) is

in which Cs(t) is the shear creep compliance.

We should add that Eqs. (34) and (35) have been shown to be a special case of constitutive theory based on nonequilibrium thermodynamics (Schapery 1990, Sect. 3) if the stress therein is interpreted as the Piola stress tensor and strain as the displacement gradient; this is valid because these are conjugate thermodynamic variables. However, rotations in viscoelastic continua may affect the stresses unless the deformation is small (Schapery 1984). Thus, this formulation in not fully frame indifferent.

The mechanical state of an elastic body will be independent of rigid rotation if the strain energy depends on the displacement gradient through Green’s strains (Fung 1965). However, for now, we require only that W depends on the pseudo displacement gradient. Because this means that the stresses and displacements in the viscoelastic body may be affected by rotations when the deformation is large, the excellent agreement found here between theory and experiment for the COD and crack speed is believed to show that this effect is not significant here. This insignificance is apparently at least partly due to the high applied stretching strain, which results in even higher stretching strains, relative to local rotation, in the neighborhood of P and, for points \(\varepsilon_{1} \;{\text{and}}\;\varepsilon_{2}\), in the entire singular-field. Additionally, viscoelasticity reduces the amount of near-tip rotation.

Analysis of viscoelastic crack growth is reduced essentially to elastic analysis when Eq. (34) can be used. One may check this aspect of the constitutive model experimentally by expressing displacement gradients (“nominal strains”) in terms of pseudo variables. The resulting stress-pseudo strain behavior will be (essentially) independent of the strain history if the model is valid. Undoubtedly, it will not be valid for all histories with large strains.

1.2 Effective compliance

Convolution integrals such as Eqs. (35) and (36) do not converge when evaluated numerically by standard methods if there are many decades over which the compliance and modulus vary. However, by changing the variable of integration to its logarithm, an excellent approximation becomes apparent, as originally shown by Schapery (1975a). Specifically, using Eq. (36) to illustrate this, let

showing that, for most functions \({\mathbf{u}}^{R}\), the lower limit of the integral, \(- \infty ,\) can be replaced by a finite value because of the cutoff function \(10^{z}\). When the pseudo COD, \(v^{R}\), obeys a power law in time, as it does for the present class of problems,

where c does not depend on time; then, the integral can be found analytically if the curvature of C is small in logarithmic coordinates. Equation (36) becomes, with \(c = 1\) for simplicity,

where w is the weight function,

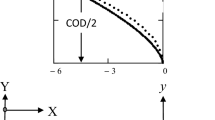

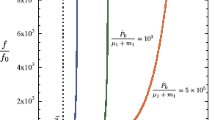

which is plotted in Fig.

9 for the smallest and largest p-values needed here. Figure

10 shows that it is sufficient to use − 3 as the lower limit in Eq. (39). The compliance for CB = 0.05 is used in Fig. 10 because it exhibits the largest curvature of the three CB-filled elastomers.

Now, we define an effective compliance when Eq. (38) applies,

Inasmuch as the creep master curve can be approximated by a power law over any one-decade time range (the effective width of the weight function), one may use

to evaluate the effective modulus, where

is the local slope. This approximation used in Eq. (41) yields,

where \(s_{f}\) given by Eq. (18). Thus,

Figure

11 shows the variation of \(s_{f}\) with Lt; the “bumpiness” is due to cubic spline interpolation of the compliance.

Figure 12 shows how well Eq. (44) agrees with the “exact” (using numerical integration) Eq. (41) for p = 0.4 and 2, respectively. Furthermore, one would not be able to see easily in Fig. 12 the effect of using constant vs. varying shift factors.

1.3 Power law nonlinearity

When the elastic strain energy density is a homogeneous function of degree N + 1 in the pseudo displacement gradient, then

where c is a scalar and N is a constant. Let us define

Equation (46) becomes,

and we find,

which yields the simple result,

which, in turn, implies that the pure shear stress–strain behavior has the form \(\sigma = {\text{sgn}} (\varepsilon )\sigma_{0} \varepsilon^{N}\), where \(\sigma_{0}\) is a constant with stress dimensions.

The homogeneity assumption excludes dependence on displacement gradients through Green’s strains unless the nonlinear component in the latter is negligible or dominant.

Stresses and displacements in a plane-strain or plane-stress singular-field, defined in polar coordinates \((r,\;\theta )\), are (Rice and Rosengren 1968)

in which \({\mathbf{g(}}\theta ,\;N{\mathbf{)}}\) and \({\mathbf{h}}(\theta ,\;N)\) are a dimensionless tensor and vector that depend on only \(\theta\) and N; \(\theta\) = 0 is the line of crack prolongation and \(r = 0\) at P; they may be found by solving the equilibrium equations in terms of \({\mathbf{u}}\). The stresses and displacements are uniquely defined by J, N and \(\sigma_{0}\), apart from rigid body displacements. Extension to viscoelasticity is easily performed using substitutions \(J \to J_{v} \;{\text{and}}\;{\mathbf{u}} \to {\mathbf{u}}^{R}\).

Equation (51) was derived using small strain theory. However, with large deformations, Piola stresses and pseudo displacements obey the same r-behavior because the equilibrium equations and boundary traction conditions are identical to those of small strain theory, apart from a possibly nonsymmetrical stress tensor (Schapery 1984).

Inasmuch as the FZ serves to remove the singularity, the stresses deviate from Eq. (51)within some radius that is proportional to \(\alpha\). Along the line of crack growth \(X\)(see Fig. 1) the normal stress \(\sigma_{y}\) is assumed to be continuous at P; and therefore equal to \(\sigma_{m}\), regardless of the value of \(J_{v}\). This continuity at P is a reasonable assumption because it is true for linear theory (Schapery 1975a). Inasmuch as \(\alpha\) and r are the only local dimensions, this stress must have the form

where \(X \ge a\), and \(f(0) = 1\). It must also blend into the singular solution when \({\text{X}} - a \gg \alpha\). Suppose, for example, it is essentially equal to the singular solution at \(X - a = 10\alpha\). Thus, from Eq. (51),

which obviously means that \(\alpha\) must be proportional to \(J_{v}\) since the left side does not depend on \(\alpha\). This proportionality was proven in Schapery (1986), but not as directly as it is here.

1.4 Singular-field COD

Using notation for a viscoelastic material, the pseudo COD at a fixed spatial point x within the singular-field follows from Eq. (51). It is useful to write it using normalized variables,

where \(k_{d}\) is a dimensionless constant. For a crack propagating at constant speed \(\dot{a}\), the COD at \(x = \dot{a}t\) follows from Eq. (45), assuming \(x \gg \alpha\),

This result may be compared to the linear viscoelastic displacement in Eq. (9) after using Eq. (17),

It is helpful to replace \(k_{d}\) with the constant \(k_{D}\), which is unity for a linear material,

1.5 Definition of \(J_{v}\)

A line integral version of the two-dimensional \(J_{v}\) is

where \({\mathbf{T}}\) is the traction vector and S is the path of counterclockwise integration surrounding the crack tip, which starts on one crack face and ends on the opposite face, for a crack along the \(x_{1}\) axis. Additionally, \(n_{1}\) is the \(x_{1}\) component of the outer unit normal to the path.

Rights and permissions

About this article

Cite this article

Schapery, R.A. Stable and unstable viscoelastic crack growth: experimental validation of nonlinear theory for rubber. Int J Fract 238, 1–15 (2022). https://doi.org/10.1007/s10704-022-00639-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-022-00639-x