Abstract

A common way to improve the scratch resistance of a sensitive surface is to coat it with a thin film. However, the substrate/thin film adhesion must be well controlled and measurable. The contribution of the present work is to propose a global energy balance model of the blistering process for the scratching of a substrate/thin film system, which permits one to determine the adhesion of the system. The adhesion can be measured by following the delaminated area as a function of the scratching distance during blistering. The particular case of an experimental stable blistering process was studied and the corresponding substrate/thin film adhesion was derived using the global energy balance model.

Similar content being viewed by others

Abbreviations

- V tip :

-

Scratching velocity

- F n , F t :

-

Normal and tangential loads respectively

- T :

-

Temperature

- ΔW :

-

Work provided by the loading indenter

- ΔEF :

-

Fracture energy

- ΔED :

-

Energy released in dissipative phenomena other than fracture

- ΔEE :

-

Elastic energy

- d :

-

Scratching distance

- µ app :

-

Apparent friction coefficient

- µ local :

-

Local friction coefficient

- ΔAinterf. :

-

Surface created at the interface

- ΔAcoh. :

-

Surface created within the material

- γ s−interf. :

-

Surface energy required to create 1 unit of interfacial new surface

- γ s−coh. :

-

Surface energy required to create 1 unit of cohesive new surface

- δW D :

-

Dissipative work (fracture excluded) per unit of scratching distance

- δW E :

-

Elastic work per unit of scratching distance

- δW DP :

-

Plastic deformation work of the system per unit of scratching distance

- δW DF :

-

Work due to the true local friction

- σ y :

-

Yield stress of the substrate

- S t :

-

Cross section of the plastic zone in the scratching track left on the surface

- ΔAB :

-

Area of the blister

- p atm :

-

Atmospheric pressure

- \( \overline {h_{{\text{a}}} } \) :

-

Average height of the blister

- ΔA :

-

Delaminated area variation

- Δd :

-

Scratching distance variation

- W idth :

-

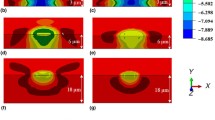

Width of the blister as defined in Fig. 1

- R :

-

Radius of curvature of the indenter tip

- a :

-

Contact radius

- e :

-

Thickness of the film

- L g :

-

Width of the groove

- \( \dot \varepsilon \) :

-

Strain rate

References

Bull SJ, Berasetegui EG (2006) Tribol Int 39:99. doi:https://doi.org/10.1016/j.triboint.2005.04.013

Hutchinson JW, Suo Z (1992) Adv Appl Mech 29:63

Mittal KL (1978) Adhesion measurement of thin films, thick films and bulk coatings. STP 640, ASTM, Philadelphia, PA

Thouless MD (1998) Eng Fract Mech 61:75. doi:https://doi.org/10.1016/S0013-7944(98)00049-6

Volinsky AA, Moody NR, Gerberich WW (2002) Acta Mater 50:441. doi:https://doi.org/10.1016/S1359-6454(01)00354-8

Ritter JE, Lardner TJ, Rosenfeld L, Lin MR (1989) J Appl Phys 66:3626. doi:https://doi.org/10.1063/1.344071

Bull SJ, Rickerby DS (1990) Surf Coat Tech 42:149. doi:https://doi.org/10.1016/0257-8972(90)90121-R

Perry AJ (1983) Thin Solid Films 107:167. doi:https://doi.org/10.1016/0040-6090(83)90019-6

Kriese MD, Boismier DA, Moody NR, Gerberich WW (1998) Eng Fract Mech 61:1. doi:https://doi.org/10.1016/S0013-7944(98)00050-2

Holmberg K, Laukkanen A, Ronkainen H, Wallin K, Varjus S, Koskinen J (2006) Surf Coat Tech 200:3793. doi:https://doi.org/10.1016/j.surfcoat.2005.03.040

Blees MH, Winkelman GB, Balkenende AR, den Toonder JMJ (2000) Thin Solid Films 359:1. doi:https://doi.org/10.1016/S0040-6090(99)00729-4

Bull SJ (1997) Tribol Int 30:491. doi:https://doi.org/10.1016/S0301-679X(97)00012-1

Li J, Beres W (2007) Can Metall Q 46:155

Le Houérou V, Robert C, Gauthier C, Schirrer R (2008) Wear 265:507. doi:https://doi.org/10.1016/j.wear.2007.11.019

Gauthier C, Schirrer R (2000) J Mater Sci 35:2121. doi:https://doi.org/10.1023/A:1004798019914

Dupeux M (2004) Mecanique Indust 5:441. doi:https://doi.org/10.1051/meca:2004044

Bucaille JL, Gauthier C, Felder E, Schirrer R (2006) Wear 260:803. doi:https://doi.org/10.1016/j.wear.2005.04.007

Lafaye S, Gauthier C, Schirrer R (2005) Tribol Int 38:113. doi:https://doi.org/10.1016/j.triboint.2004.06.006

Acknowledgement

The authors would like to thank C. Robert for his preliminary experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Le Houérou, V., Gauthier, C. & Schirrer, R. Energy based model to assess interfacial adhesion using a scratch test. J Mater Sci 43, 5747–5754 (2008). https://doi.org/10.1007/s10853-008-2869-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2869-6