Abstract

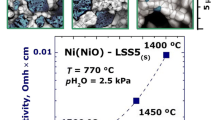

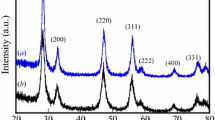

Lamellar NiO–GDC (Gadolinium-doped Ceria) and CoO–GDC directionally solidified eutectic ceramics (DSECs) were produced by the laser floating-zone technique and subjected to reduction in order to obtain porous cermets of Ni–GDC and Co–GDC, which have potential applications as anodes in solid oxide fuel cells (SOFC). The reduction of these DSECs into porous cermets was studied at 650 °C in NiO–GDC and at 500 and 700 °C in CoO–GDC, all of them processed with similar reduction kinetics. In comparison to similar Ni–YSZ and Co–YSZ lamellar cermets previously studied, no sharp reduction front was observed. The interface between the reduced and nonreduced zones is broader, with pores homogenously distributed in wide areas. Afterwards, the microstructure, texture, and crystallography of the samples were studied by electron microscopy as well as by electron and X-ray diffraction when completely reduced. The single crystal NiO and CoO lamellae transformed into porous polycrystalline metallic lamellae. Moreover, microscopy observations revealed a porous nanostructure of Co particles obtained by reduction at low temperatures (500 °C). Many of the Co and Ni particles seemed to have roughly maintained the previous crystallographic orientation with respect to the GDC phase, although the disorder of the crystallographic orientation increased significantly. In addition, a significant amount of the Ni particles reoriented to form an epitaxial interface with the (100)–GDC surface.

Similar content being viewed by others

References

Singhal SC, Kendall K (eds) (2003) High-temperature solid oxide fuel cells: fundamentals, design and applications: fundamentals, design and applications. Elsevier, Amsterdam

Steele BC, Heinzel A (2001) Materials for fuel-cell technologies. Nature 414(6861):345–352

Minh NQ (1993) Ceramic fuel cells. J Am Ceram Soc 76:563–588

Markin TC, Bows RJ, Dell RM (1976) High temperature solid electrolyte fuel cells. In: Proceedings of a conference of superionic conductors, Plenum Press, New York

Steele BCH (2000) Appraisal of Ce1−yGdyO2−y/2 electrolytes for IT-SOFC operation at 500 C. Sol State Ion 129(1):95–110

Tsoga A, Naoumidis A, Nikolopoulos P (1996) Wettability and interfacial reactions in the systems Ni/YSZ and Ni/Ti-TiO2/YS. Acta Mater 44:3679–3692

Laguna-Bercero MA, Larrea Á (2007) YSZ-induced crystallographic reorientation of Ni particles in Ni-YSZ cermets. J Am Ceram Soc 90(9):2954–2960

Laguna-Bercero MA, Larrea Á, Merino RI, Peña JI, Orera VM (2005) Stability of channeled Ni-YSZ cermets produced from self-assembled NiO-YSZ directionally solidified eutectics. J Am Ceram Soc 88(11):3215–3217

Laguna-Bercero MA, Larrea A, Merino RI, Peña JI, Orera VM (2008) Crystallography and thermal stability of textured Co-YSZ cermets from eutectic precursors. J Eur Ceram Soc 28:2325–2329

Ortega-San-Martín L, Gil V, Peña JI, Larrea Á, Orera VM (2012) Redox behaviour and ageing of GDC-Co cermets: a comparison between lamellar and conventional cermets. Solid State Ionics 226:30–36

Marlin S, Orera VM, Peña JI, Ortega-San-Martín L (2010) Molten cermet material. Patent application publication WO 2010/103498 A1

LLorca J, Orera VM (2006) Directionally solidified eutectic ceramic oxides. Prog Mater Sci 51:711–809

Serrano-Zabaleta S, Laguna-Bercero MA, Ortega-San-Martín L, Larrea A (2014) Orientation relationships and interfaces in directionally solidified eutectics for solid oxide fuel cell anodes. J Eur Ceram Soc 34(9):2123–2132

Jackson KA, Hunt JD (1966) Lamellar and rod eutectic growth. Trans Metal Soc AIME 236:1129–1142

Serrano-Zabaleta S, Larrea A (2015) Calculation of orientation relationships in directionally solidified eutectics ceramics (DSEC) by a modified coincidence of reciprocal lattice points (CLRP) model. J Am Ceram Soc 99(3):1015–1022

Pauling L (1929) The principles determining the structure of complex ionic crystals. J Am Chem Soc 51:1010–1026

Ortega-San-Martin L, Peña JI, Larrea Á, Gil V, Orera VM (2010) Textured cermets of CeO2 (or GDC) with Co for solid oxide fuel cells anodes. Int J Hydrog Energy 35(20):11499–11504

Laguna-Bercero MA, Larrea A, Pena JI, Merino RI, Orera VM (2005) Structured porous Ni-and Co-YSZ cermets fabricated from directionally solidified eutectic composites. J Eur Ceram Soc 25(8):1455–1462

Gil V, Moure C, Tartaj J (2007) J Eur Ceram Soc 27:4205–4209

Bonvalot-Dubois B, Dhalenne G, Berthon J, Revcolevschi A, Rapp RA (1988) Reduction of NiO platelets in a NiO/ZrO2 (CaO) directional composite. J Am Ceram Soc 71(4):296–301

Cales B, Baumard JF (1984) Mixed conduction and defect structure of ZrO2-CeO2-Y2O3 solid solutions. J Electrochem Soc 131:2407–2413

Perez-Arantegui J, Larrea A (2015) Electron backscattering diffraction as a complementary analytical approach to the microstructural characterization of ancient materials by electron microscopy. Trends Anal Chem 72:193–201

Waldbilig D, Word A, Ivey DG (2005) Electrochemical and microstructural characterization of the redox tolerance of solid oxide fuel cell anodes. J Power Sour 145:206–215

Dickey EC, Dravid VP, Nellist PD, Wallis DJ, Pennycook SJ, Revcolevschi A (1997) Structure and Bonding at Ni–ZrO2 (Cubic) Interfaces Formed by the Reduction of a NiO-ZrO2 (Cubic) Composite. Microsc Microanal 3:443–450

Larrea A, Laguna-Bercero MA, Merino RI, Orera VM (2009) Orientation relationship and interfaces in Ni and Co-YSZ cermets prepared from directionally solidified eutectics. Cent Eur J Phys 7(2):242–250

Dickey EC, Maa Bagiyono Y, Lian GD, Sinnott SB, Wagner T (2000) Preferred crystallographic orientation relationships of nickel films deposited in (100) cubic-zirconia substrates. Thin Sol Films 372:37–44

Swanson HE, Tatge E (1954) Standard x-ray diffraction powder patterns. Acta Crystallogr 7:464–464

Brauer G, Gradinger H (1954) Über heterotype mischphasen bei seltenerdoxyden. I. Z Anorg Allg Chem 276:209–226

Muñoz MC, Gallego S, Beltrán JI, Cerdá J (2006) Adhesion at metal-ZrO2 interfaces. Surf Sci Rep 61:303–344

Schulze H, Li J, Dickey EC, Trolier-McKinstry S (2009) Synthesis, phase characterization, and properties of chemical solution- deposited nickel manganite thermistor thin films. J Am Ceram Soc 92(3):738–744

Zhao Y, Feltes TE, Regalbuto JR, Meyer RJ, Klie RF (2010) In situ electron energy loss spectroscopy study of metallic Co and Co oxides. J Appl Phys 108(6):063704

Liu JF, Yin S, Wu HP, Zeng YW, Hu XR, Wang YW et al (2006) Wurtzite-to-rocksalt structural transformation in nanocrystalline CoO. J Phys Chem B 110(43):21588–21592

Nam KM, Shim JH, Han DW, Kwon HS, Kang YM, Li Y et al (2010) Syntheses and characterization of wurtzite CoO, rocksalt CoO, and spinel Co3O4 nanocrystals: their interconversion and tuning of phase and morphology. Chem Mater 22(15):4446–4454

Liu X, Prewitt CT (1990) High-temperature X-ray diffraction study of Co3O4: transition from normal to disordered spinel. Phys Chem Miner 17:168–172

O’Neill HSC (1985) Thermodynamics of Co3O4: a possible electron spin unpairing transition in Co3+. Phys Chem Miner 12(3):149–154

Acknowledgements

This study was funded by MAT2012-30763 and MAT2015-68078-R projects, which are financed by the Spanish Government (Ministerio de Economía y Competitividad) and the Feder Program of the European Union. E.C. Dickey acknowledges support from the National Science Foundation under grant #1139792. S. Serrano-Zabaleta would like to thank Dr. J. Liu, Dr. E. Mily, Dr. A. Moballegh, Dr. W. Cheng, Dr. M. Burch, D. Oni, E. Grimley, D. Monroe, and H. Dycus from the NCSU for all the support and help provided. The use of Servicio General de Apoyo a la Investigación (SAI, University of Zaragoza) is additionally acknowledged. The authors acknowledge the use of the Analytical Instrumentation Facility (AIF) at North Carolina State University, which is supported by the State of North Carolina and the U.S. National Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there is no conflict of interest that could potentially influence or bias the submitted work.

Rights and permissions

About this article

Cite this article

Serrano-Zabaleta, S., Larrea, A., Larrañaga, A. et al. Microstructure, texture, and crystallography in Ni–GDC and Co–GDC porous cermets obtained from directionally solidified eutectic ceramics. J Mater Sci 52, 5477–5488 (2017). https://doi.org/10.1007/s10853-016-0225-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0225-9