Abstract

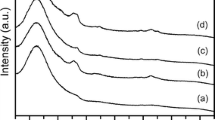

The current work reports the preparation of macroporous carbon/silica foams using sucrose as precursor in the presence of silica gel and water. After a preliminary fast transformation of sucrose into caramel by MW irradiation, the carbon/silica materials are obtained by thermal treatment at 800 °C under nitrogen atmosphere. In contrast to carbon/clay materials prepared by the same synthetic route, the use of microporous silica gel as inorganic support for the chemical transformation of sucrose gives rise to foam-like materials without requiring the addition of blowing agents. The resulting materials are low-density monoliths (0.17 g cm−3) that show several populations of macropores centered at 150 and in the range of 30–5 µm, as well as mesopores around 5–6 nm. The porosity is close to 97%, as determined from helium pycnometry, which gave a skeletal density value of 6.08 g cm−3. The resulting foams show electrical conductivity values around 3 mS cm−1 due to the generated graphene-like materials, as corroborated by Raman spectroscopy. A preliminary evaluation of these macroporous materials as adsorbents of aromatic pollutants was carried out using methylene blue (MB) as a model dye. The regeneration of the MB-loaded foams to make possible their application in successive adsorption cycles was assessed by solid–liquid extraction and electrochemical regeneration. In both cases, the treatment produced an increase in the uptake capacity, which could be due to an increment in porosity and specific surface area, from 360 to 440 m2 g−1, as determined from mercury porosimetry and N2 adsorption measurements. In addition, the electrochemical method allowed a partial degradation of the pollutant, as determined by UV–Vis and HPLC–MS. Thus, the carbon/silica materials here developed are promising adsorbents for treatment of polluted effluents.

Similar content being viewed by others

References

Inagaki M, Kang F, Toyoda M, Konno H (2014) Carbon materials for adsorption of molecules and ions. In: Advanced materials science and engineering of carbon. Butterworth-Heinemann, Boston, pp 335–361

Niu Z, Liu L, Zhang L, Chen X (2014) Porous graphene materials for water remediation. Small 10:3434–3441

Li Y, Du Q, Liu T et al (2013) Comparative study of methylene blue dye adsorption onto activated carbon, graphene oxide, and carbon nanotubes. Chem Eng Res Des 91:361–368

Kemp KC, Seema H, Saleh M et al (2013) Environmental applications using graphene composites: water remediation and gas adsorption. Nanoscale 5:3149–3171

Ruiz-Garcia C, Darder M, Aranda P, Ruiz-Hitzky E (2014) Toward a green way for the chemical production of supported graphenes using porous solids. J Mater Chem A 2:2009–2017

Ruiz-Hitzky E, Darder M, Fernandes FM, Zatile E, Palomares FJ, Aranda P (2011) Supported graphene from natural resources: easy preparation and applications. Adv Mater 23:5250–5255

Bakandritsos A, Kouvelos E, Steriotis T, Petridis D (2005) Aqueous and gaseous adsorption from montmorillonite-carbon composites and from derived carbons. Langmuir 21:2349–2355

Darder M, Ruiz-Hitzky E (2005) Caramel-clay nanocomposites. J Mater Chem 15:3913–3918. doi:10.1039/B505958E

Gupta SS, Sreeprasad TS, Maliyekkal SM, Das SK, Pradeep T (2012) Graphene from sugar and its application in water purification. ACS Appl Mater Interfaces 4:4156–4163

BeMiller JN, Whistler RL (1996) In: Fennema OR (ed) Food chemistry, 3rd edn. Marcel Dekker, New York

Gómez-Avilés A, Darder M, Aranda P, Ruiz-Hitzky E (2007) Functionalized carbon-silicates from caramel-sepiolite nanocomposites. Angew Chem Int Ed 46:923–925

Gómez-Avilés A, Darder M, Aranda P, Ruiz-Hitzky E (2010) Multifunctional materials based on graphene-like/sepiolite nanocomposites. Appl Clay Sci 47:203–211

Inagaki M, Qiu J, Guo Q (2015) Carbon foam: preparation and application. Carbon 87:128–152

Inagaki M, Kang F, Toyoda M, Konno H (2014) Carbon foams. In: Advanced materials science and engineering of carbon. Butterworth-Heinemann, Boston, pp 189–214

Prabhakaran K, Singh PK, Gokhale NM, Sharma SC (2007) Processing of sucrose to low density carbon foams. J Mater Sci 42:3894–3900. doi:10.1007/s10853-006-0481-1

Vijayan S, Narasimman R, Prudvi C, Prabhakaran K (2014) Preparation of alumina foams by the thermo-foaming of powder dispersions in molten sucrose. J Eur Ceram Soc 34:425–433

Narasimman R, Vijayan S, Prabhakaran K (2014) Carbon particle induced foaming of molten sucrose for the preparation of carbon foams. Mater Sci Eng B-Adv Funct Solid-State Mater 189:82–89

Jana P, Fierro V, Celzard A (2016) Sucrose-based carbon foams with enhanced thermal conductivity. Ind Crop Prod 89:498–506

Nagel B, Pusz S, Trzebicka B (2014) Review: tailoring the properties of macroporous carbon foams. J Mater Sci 49:1–17. doi:10.1007/s10853-013-7678-x

Martínez-Huitle CA, Brillas E (2009) Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods: a general review. Appl Catal B-Environ 87:105–145

Omorogie MO, Babalola JO, Unuabonah EI (2016) Regeneration strategies for spent solid matrices used in adsorption of organic pollutants from surface water: a critical review. Desalin Water Treat 57:518–544

Weng C-H, Hsu M-C (2008) Regeneration of granular activated carbon by an electrochemical process. Sep Purif Technol 64:227–236

García-Otón M, Montilla F, Lillo-Ródenas MA, Morallón E, Vázquez JL (2005) Electrochemical regeneration of activated carbon saturated with toluene. J Appl Electrochem 35:319–325

Hussain SN, Asghar HMA, Campen AK, Brown NW, Roberts EPL (2013) Breakdown products formed due to oxidation of adsorbed phenol by electrochemical regeneration of a graphite adsorbent. Electrochim Acta 110:550–559

Liu D, Roberts EPL, Martin AD et al (2016) Electrochemical regeneration of a graphite adsorbent loaded with Acid Violet 17 in a spouted bed reactor. Chem Eng J 304:1–9

Caja Muñoz B (2015) Master Degree dissertation, Universidad Autónoma de Madrid-Universidad Rey Juan Carlos, Madrid

Valle Torrijos S (2010) Master Degree dissertation, Universidad Carlos III de Madrid, Leganés

Lee H, Rajagopalan R, Robinson J, Pantano CG (2009) Processing and characterization of ultrathin carbon coatings on glass. ACS Appl Mater Interfaces 1:927–933

Gómez-Avilés A, Darder M, Aranda P, Ruiz-Hitzky E (unpublished results)

Quantachrome-Corporation (2016) Mercury porosimetry. http://www.quantachrome.com/pdf_brochures/07128.pdf. Accessed Apr 11 2017

Villanueva A, Morales-Varela MC, Ruiz-Hitzky E (2004) Microwave-assisted synthesis of MPS3 materials (M = Mn, Cd) using a Dewar-ampoule device. Eur J Inorg Chem 2004:949–952

Vanderkaaden A, Haverkamp J, Boon JJ, Deleeuw JW (1983) Analytical pyrolysis of carbohydrates.1. Chemical interpretation of matrix influences on pyrolysis-mass spectra of amylose using pyrolysis-gas chromatography-mass spectrometry. J Anal Appl Pyrol 5:199–220

Walter RH, Fagerson IS (1968) Volatile compounds from heated glucose. J Food Sci 33:294–297

Ni Z, Wang Y, Yu T, Shen Z (2008) Raman spectroscopy and imaging of graphene. Nano Res 1:273–291

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Adamčíková L, Pavlíková K, Ševčík P (2000) The decay of methylene blue in alkaline solution. React Kinet Catal L 69:91–94

Berenguer R, Marco-Lozar JP, Quijada C, Cazorla-Amorós D, Morallón E (2010) Electrochemical regeneration and porosity recovery of phenol-saturated granular activated carbon in an alkaline medium. Carbon 48:2734–2745

Riyanto MM (2015) Electrochemical degradation of methylen blue using carbon composite electrode (C-PVC) in sodium chloride. IOSR J Appl Chem 8:31–40

Iler RK (1979) The chemistry of silica. Wiley, New York

Rouquerol F, Rouquerol J, Sing K (1999) Adsorption by powders and porous solids. Principles methodology and applications. Academic Press, London

Acknowledgements

Authors thank the CICYT (Spain, projects MAT2012-31759 and MAT2015-71117-R), the EU COST Action MP1202. LNNano/CNPEM is acknowledged for X-ray microtomography images. The authors also thank Mr. A. Valera for technical assistance in the FESEM study, as well as Dr. D. Gamarra and Dr. A. L. Duque from Universidad de Extremadura for the textural characterization of the foams.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Canencia, F., Darder, M., Aranda, P. et al. Conducting macroporous carbon foams derived from microwave-generated caramel/silica gel intermediates. J Mater Sci 52, 11269–11281 (2017). https://doi.org/10.1007/s10853-017-1227-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1227-y