Abstract

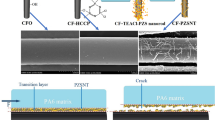

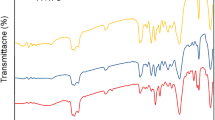

Multiscale thermoplastic laminate composites based on polyamide 6 (PA6) dually reinforced by carbon fiber woven textile structures (CFT) and different micron-sized metal particles are prepared for the first time by microencapsulation strategy. In a first step, activated anionic ring-opening polymerization (AAROP) of ε-caprolactam is carried out in suspension, in the presence of different metal particles, to produce shell-core PA6 microcapsules (PAMC) loaded with 13–19% metal. In a second step, the loaded PAMC are distributed between CFT plies with fiber volume fractions Vf = 0.25 or Vf = 0.50 and then the ply arrays are consolidated by compression molding. Separately, metal-loaded PA6 hybrid composites are prepared by direct compression molding of PAMC and used to compare their properties to the CFT-metal laminates. Light- and scanning electron microscopy are used to study the morphology and the interfaces between the fillers and the polymeric matrix. These structural results are related to the mechanical behavior in tension and the electrical properties. A notable increase of the d.c. electrical conductivity in 7 orders of magnitude is observed for the CFT-metal laminates with respect to the neat PA6. This increase is accompanied by a 2.5–3.0 times growth of the Young’s modulus and of the strength at break. It is concluded that the microencapsulation strategy can be applied to produce multifunctional CFT-metal-PA6 thermoplastic composites with tailored electrical and improved mechanical properties for advanced applications.

Similar content being viewed by others

References

Fogel M, Parlevliet P, Olivier P, Dantras É (2017) Manufacturing of conductive structural composites through spraying of CNTs/epoxy dispersions on dry carbon fiber plies. Compos Part A Appl Sci Manuf 100:40–47

Hine PJ, Bonner M, Ward IM et al (2014) Hybrid carbon fibre/nylon 12 single polymer composites. Compos Part A Appl Sci Manuf 65:19–26

Stavrov D, Bersee HEN (2005) Resistance welding of thermoplastic composites-an overview. Compos Part A Appl Sci Manuf 36:39–54

Steenkamer DA, Sullivan JL (1998) On the recyclability of a cyclic thermoplastic composite material. Compos Part B Eng 29:745–752

Chang IY, Lees JK (1988) Recent development in thermoplastic composites: a review of matrix systems and processing methods. J Thermoplast Compos Mater 1:277–296

Khondker OA, Ishiaku US, Nakai A, Hamada H (2005) Fabrication mechanical properties of unidirectional jute/PP composites using jute yarns by film stacking method. J Polym Environ 13:115–126

Svensson N, Shishoo R, Gilchrist M (1998) Manufacturing of thermoplastic composites from commingled yarns: a review. J Thermoplast Compos Mater 11:22–56

Bernet N, Michaud V, Bourban P-E, Månson J-A (2001) Commingled yarn composites for rapid processing of complex shapes. Compos Part A Appl Sci Manuf 32:1613–1626

Sakaguchi M, Nakai A, Hamada H, Takeda N (2000) The mechanical properties of unidirectional thermoplastic composites manufactured by a micro-braiding technique. Compos Sci Technol 60:717–722

van Rijswijk K, Bersee HEN (2007) Reactive processing of textile fiber-reinforced thermoplastic composites: an overview. Compos Part A Appl Sci Manuf 38:666–681

Sekiguchi H, Coutin B (1973) Polymerizability and related problems in the anionic polymerization of lactams. J Polym Sci Polym Chem Ed 11:1601–1614

Provazník M, Puffr R, Šebenda J (1988) Dielectric properties of lactams and their significance in the polymerization process. Eur Polym J 24:511–514

Luisier A, Bourban P-E, Månson J-AE (2003) Reaction injection pultrusion of PA12 composites: process and modelling. Compos Part A Appl Sci Manuf 34:583–595

Cho B-G, McCarthy SP, Fanucci JP, Nolet SC (1996) Fiber reinforced nylon-6 composites produced by the reaction injection pultrusion process. Polym Compos 17:673–681

van Rijswijk K, Bersee HEN, Jager WF, Picken SJ (2006) Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic composites: choice of activator and initiator. Compos Part A Appl Sci Manuf 37:949–956

van Rijswijk K, Bersee HEN, Beukers A et al (2006) Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic composites: influence of polymerisation temperature on matrix properties. Polym Test 25:392–404

Harkin-Jones E, Crawford R (1996) Rotational molding of liquid plastic systems: an assessment of material moldability. Adv Polym Technol 15:71–100

Harkin-Jones E, Crawford RJ (1996) Mechanical properties of rotationally molded nyrim. Polym Eng Sci 36:615–625

Ying G, Yang G (2009) Manufacturing and physical properties of all-polyamide composites. J Mater Sci 44:4639–4644. https://doi.org/10.1007/s10853-009-3708-0

Dencheva N, Sampaio AS, Oliveira FM et al (2014) Preparation and properties of polyamide-6-based thermoplastic laminate composites by a novel in-mold polymerization technique. J Appl Polym Sci 131:40083

Guo Z, Sang L, Wang Z et al (2016) Deposition of copper thin films by plasma enhanced pulsed chemical vapor deposition for metallization of carbon fiber reinforced plastics. Surf Coatings Technol 307:1059–1064

Lupoi R, O’Neill W (2010) Deposition of metallic coatings on polymer surfaces using cold spray. Surf Coatings Technol 205:2167–2173

Zhou XL, Chen AF, Liu JC et al (2011) Preparation of metallic coatings on polymer matrix composites by cold spray. Surf Coatings Technol 206:132–136

Che H, Vo P, Yue S (2017) Metallization of carbon fibre reinforced polymers by cold spray. Surf Coatings Technol 313:236–247

Archambault G, Jodoin B, Gaydos S, Yandouzi M (2016) Metallization of carbon fiber reinforced polymer composite by cold spray and lay-up molding processes. Surf Coatings Technol 300:78–86

Kong K, Cheedarala RK, Kim M et al (2016) Electrical thermal heating and piezoresistive characteristics of hybrid CuO–woven carbon fiber/vinyl ester composite laminates. Compos Part A 85:103–112

Oliveira F, Dencheva N, Martins P (2016) Reactive microencapsulation of carbon allotropes in polyamide shell-core structures and their transformation in hybrid composites with tailored electrical properties. EXPRESS Polym Lett 10:160–175

Brêda C, Dencheva N, Lanceros-Mendez S, Denchev Z (2016) Preparation and properties of metal-containing polyamide hybrid composites via reactive microencapsulation. J Mater Sci 51:10534–10554. https://doi.org/10.1007/s10853-016-0274-0

Dencheva N, Denchev Z, Lanceros-Méndez S, Ezquerra Sanz T (2016) One-step in situ synthesis of polyamide microcapsules with inorganic payload and their transformation into responsive thermoplastic composite materials. Macromol Mater Eng 301:119–124

Dencheva NV, Vale DM, Denchev ZZ (2016) Dually reinforced all-polyamide laminate composites via microencapsulation strategy. Polym Eng Sci 57:806–820

Gürdal Z, Haftka RT, Hajela P (1999) Design and optimization of laminated composite materials. Wiley, New York

Dan F, Vasiliu-Oprea C (1998) Anionic polimerization of caprolactama in organic media. Morphological aspects. Colloid Polym Sci 276:483–495

Vasiliu-Oprea C, Dan F (1996) On the relation between synthesis parameters and morphology of anionic polycaproamide obtained in organic media. I. Influence of the Na[O(CH2)2OCH3]2AlH2/isophorone diisocyanate catalytic system. J Appl Polym Sci 62:1517–1527

Ricco L, Monticelli O, Russo S et al (2002) Fast-activated anionic polymerization of ε-caprolactam in suspension, 1. Role of the continuous phase on characteristics and properties of powdered PA6. Macromol Chem Phys 203:1436–1444

Mendes SF, Costa CM, Serra RS et al (2012) Influence of filler size and concentration on the low and high temperature dielectric response of poly(vinylidene fluoride)/Pb(Zr0.53Ti0.47)O3 composites. J Polym Res 19:9967

Lopes AC, Costa CM, Serra RS et al (2013) Dielectric relaxation, ac conductivity and electric modulus in poly(vinylidene fluoride)/NaY zeolite composites. Solid State Ionics 235:42–50

Costa P, Silva J, Lanceros-Méndez S (2016) Strong increase of the dielectric response of carbon nanotube/poly(vinilidene fluoride) composites induced by carbon nanotube type and pre-treatment. Compos Part B Eng 93:310–316

Acknowledgements

The authors gratefully acknowledge the financial support of the project TSSiPRO NORTE-01-0145-FEDER-000015, supported by the regional operation program NORTE2020, under the Portugal 2020 Partnership Agreement, through the European Regional Development Fund, as well as funding from FCT—Portuguese Foundation for Science and Technology within the strategic projects UID/CTM/50025/2013, LA25/2013-2014 and UID/FIS/04650/2013. FMO acknowledges also the PhD grant PD/BD/114372/2016 of FCT-Portugal (AdvaMTech—PhD Program in Advanced Materials and Processing) and PM the FCT SFRH/BPD/96227/2013 grant. Finally, ZZD is thankful to FCT for the SFRH/BSAB/130271/2017 personal research grant. Finally, SLM acknowledges funding from the Basque Government Industry Department under the ELKARTEK program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Oliveira, F., Dencheva, N., Martins, P. et al. A new approach for preparation of metal-containing polyamide/carbon textile laminate composites with tunable electrical conductivity. J Mater Sci 53, 11444–11459 (2018). https://doi.org/10.1007/s10853-018-2435-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2435-9