Abstract

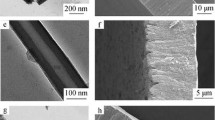

Titanium and its alloys are the most suitable metallic materials available for the fabrication of medical implants. Their biocompatibility can be improved by the growth of TiO2 nanotubes on their surface by a simple anodization process. This work involved an investigation into the anodization behavior of Ti–35Nb–7Zr–5Ta (TNZT) alloy, focusing on the effect of processing conditions (anodization time and type of electrolyte), previous strain hardening, and crystallographic texture of the substrate. Studies about the growth of TiO2 nanotubes on β-type titanium alloys, as the TNZT alloy, are rare in the literature. The TNZT alloy proved to be an excellent substrate for the growth of TiO2 nanotubes, resulting in threefold longer nanotubes than those obtained on a commercially pure (CP) Ti substrate. Moreover, TiO2 nanowires grew after 6 h of anodization in an organic electrolyte, which could not be achieved using the CP-Ti substrate. Samples with different crystallographic textures displayed similar nanotube morphology and only slight differences in grain length, indicating that grain orientation played only a minor role in the growth kinetics. Lastly, the crystallization of nanotubes at 450 °C did not alter their morphology, but caused complete detachment of the TiO2 nanotubes at 700 °C.

Similar content being viewed by others

References

Lutjering G, Willians JC (2007) Titanium (engineering materials and processes). Springer, Berlin

Ridzwan MIZ, Shuib S, Hassan AY, Shokri AA, Mohammad Ibrahim MN (2007) Problem of stress shielding and improvement to the hip implant designs: a review. J Med Sci 7:460–467

Qazi JI, Rack HJ (2005) Metastable beta titanium alloys for orthopedic applications. Adv Eng Mater 7:993–998. https://doi.org/10.1002/adem.200500060

Kopova I, Stráský J, Harcuba P, Landa M, Janeček M, Bačákova L (2016) Newly developed Ti–Nb–Zr–Ta–Si–Fe biomedical beta titanium alloys with increased strength and enhanced biocompatibility. Mater Sci Eng C 60:230–238. https://doi.org/10.1016/j.msec.2015.11.043

Patil PS, Bhongade ML (2016) Dental implant surface modifications: a review. J Dent Med Sci 15:132–141. https://doi.org/10.9790/0853-151003132141

Balla VK, Soderlind J, Bose S, Bandyopadhyay A (2014) Microstructure, mechanical and wear properties of laser surface melted Ti6Al4 V alloy. J Mech Behav Biomed Mater 32:335–344. https://doi.org/10.1016/j.jmbbm.2013.12.001

Macak JM, Tsuchiya H, Ghicov A, Yasuda K, Hahn R, Bauer S, Schmuki P (2007) TiO2 nanotubes: self-organized electrochemical formation, properties and applications. Curr Opin Solid State Mater Sci 11:3–18. https://doi.org/10.1016/j.cossms.2007.08.004

Lee M, Kim T, Bae C, Shin H, Kim J (2010) Fabrication and applications of metal-oxide nanotubes. JOM 62:44–49

Duvvuru MK, Han W, Chowdhury PR, Vahabzadeh S, Sciammarella F, Elsawa SF (2019) Bone marrow stromal cells interaction with titanium; Effects of composition and surface modification. PLoS ONE 14:e0216087. https://doi.org/10.1371/journal.pone.0216087

Barjaktarević DR, Djokić VR, Damnjanović ID, Rakin MP (2018) Nanotubular oxide layers formed on the Ti-based implants surfaces-application and possible damages: a review. Metall Mater Eng. https://doi.org/10.30544/401

Li T, Gulati K, Wang N, Zhang Z, Ivanovski S (2018) Bridging the gap: optimized fabrication of robust titania nanostructures on complex implant geometries towards clinical translation. J Colloid Interface Sci 529:452–463. https://doi.org/10.1016/j.jcis.2018.06.004

Contri Campanelli L, Pereira Sergio Carvalho, da Silva P, Camarinho Oliveira NT, Bolfarini C (2017) Effect of the modification by titanium dioxide nanotubes with different structures on the fatigue response of Ti grade 2. Mater Res 20:120–124. https://doi.org/10.1590/1980-5373-mr-2016-0681

Low IM, Yam FK, Pang WK (2012) In-situ diffraction studies on the crystallization and crystal growth in anodized TiO2 nanofibres. Mater Lett 87:150–152. https://doi.org/10.1016/j.matlet.2012.08.001

Allam NK, Grimes CA (2008) Effect of cathode material on the morphology and photoelectrochemical properties of vertically oriented TiO2 nanotube arrays. Sol Energy Mater Sol Cells 92:1468–1475. https://doi.org/10.1016/j.solmat.2008.06.007

Gong D, Grimes CA, Varghese OK, Hu W, Singh RS, Chen Z, Dickey EC (2001) Titanium oxide nanotube arrays prepared by anodic oxidation. J Mater Res 16:3331–3334. https://doi.org/10.1557/JMR.2001.0457

Raja KS, Misra M, Paramguru K (2005) Formation of self-ordered nano-tubular structure of anodic oxide layer on titanium. Electrochim Acta 51:154–165. https://doi.org/10.1016/J.ELECTACTA.2005.04.011

Regonini D, Bowen CR, Jaroenworaluck A, Stevens R (2013) A review of growth mechanism, structure and crystallinity of anodized TiO2 nanotubes. Mater Sci Eng R Rep 74:377–406. https://doi.org/10.1016/j.mser.2013.10.001

Tan AW, Pingguan-Murphy B, Ahmad R, Akbar SA (2013) Advances in fabrication of TiO2 nanofiber/nanowire arrays toward the cellular response in biomedical implantations: a review. J Mater Sci 48:8337–8353. https://doi.org/10.1007/s10853-013-7659-0

Lim JH, Choi J (2007) Titanium oxide nanowires originating from anodically grown nanotubes: the bamboo-splitting model. Small 3:1504–1507. https://doi.org/10.1002/smll.200700114

Ismail S, Lockman Z, Ahmad ZA (2012) Crystallization of TiO2 nanotubes arrays grown by anodization of Ti in organic electrolyte. Adv Mater Res 620:412–417. https://doi.org/10.4028/www.scientific.net/AMR.620.412

Uchida M, Kim H-M, Kokubo T, Fujibayashi S, Nakamura T (2003) Structural dependence of apatite formation on titania gels in a simulated body fluid. J Biomed Mater Res 64A:164–170. https://doi.org/10.1002/jbm.a.10414

Luttrell T, Halpegamage S, Tao J, Kramer A, Sutter E, Batzill M (2015) Why is anatase a better photocatalyst than rutile? Model studies on epitaxial TiO2 films. Sci Rep 4:4043. https://doi.org/10.1038/srep04043

Regonini D, Satka A, Jaroenworaluck A, Allsopp DWE, Bowen CR, Stevens R (2012) Factors influencing surface morphology of anodized TiO2 nanotubes. Electrochim Acta 74:244–253. https://doi.org/10.1016/j.electacta.2012.04.076

Sopha H, Hromadko L, Nechvilova K, Macak JM (2015) Effect of electrolyte age and potential changes on the morphology of TiO2 nanotubes. J Electroanal Chem 759:122–128. https://doi.org/10.1016/j.jelechem.2015.11.002

Sulka GD, Kapusta-Kołodziej J, Brzózka A, Jaskuła M (2013) Anodic growth of TiO2 nanopore arrays at various temperatures. Electrochim Acta 104:526–535. https://doi.org/10.1016/j.electacta.2012.12.121

Butail G, Ganesan PG, Raddiar M, Teki R, Ravishankar N, Duquette DJ, Ramanath G (2011) Kinetics of titania nanotube formation by anodization of titanium films. Thin Solid Films 519:1821–1824. https://doi.org/10.1016/j.tsf.2010.10.004

Apolinário A, Sousa CT, Ventura J, Costa JD, Leitão DC, Moreira JM, Sousa JB, Andrade L, Mendes AM, Araújo JP (2014) The role of the Ti surface roughness in the self-ordering of TiO2 nanotubes: a detailed study of the growth mechanism. J Mater Chem A 2:9067–9078. https://doi.org/10.1039/C4TA00871E

Shin Y, Lee S (2008) Self-organized regular arrays of anodic TiO2 nanotubes. Nano Lett 8:3171–3173. https://doi.org/10.1021/nl801422w

Leonardi S, Russo V, Li Bassi A, Di Fonzo F, Murray TM, Efstathiadis H, Agnoli A, Kunze-Liebhäuser J (2015) TiO2 nanotubes: interdependence of substrate grain orientation and growth rate. ACS Appl Mater Interfaces 7:1662–1668. https://doi.org/10.1021/am507181p

Crawford GA, Chawla N (2009) Tailoring TiO2 nanotube growth during anodic oxidation by crystallographic orientation of Ti. Scr Mater 60:874–877. https://doi.org/10.1016/j.scriptamat.2009.01.043

Hielscher R, Schaeben H (2008) A novel pole figure inversion method: specification of the MTEX algorithm. J Appl Crystallogr 41:1024–1037. https://doi.org/10.1107/S0021889808030112

Ozkan S, Mazare A, Schmuki P (2018) Critical parameters and factors in the formation of spaced TiO2 nanotubes by self-organizing anodization. Electrochim Acta 268:435–447. https://doi.org/10.1016/j.electacta.2018.02.120

Ozkan S, Nguyen NT, Mazare A, Hahn R, Cerri I, Schmuki P (2017) Fast growth of TiO2 nanotube arrays with controlled tube spacing based on a self-ordering process at two different scales. Electrochem Commun 77:98–102. https://doi.org/10.1016/j.elecom.2017.03.007

Berger S, Hahn R, Roy P, Schmuki P (2010) Self-organized TiO2 nanotubes: factors affecting their morphology and properties. Phys status solidi 247:2424–2435. https://doi.org/10.1002/pssb.201046373

Conradie F, Treurnicht N, Sacks N (2014) Alpha case characterization of hot rolled titanium. Adv Mater Res 1019:311–317. https://doi.org/10.4028/www.scientific.net/AMR.1019.311

Peng W, Zeng W, Zhang Y, Shi C, Quan B, Wu J (2013) The effect of colored titanium oxides on the color change on the surface of Ti–5Al–5Mo–5V–1Cr–1Fe alloy. J Mater Eng Perform 22:2588–2593. https://doi.org/10.1007/s11665-013-0573-4

Losertová M, Štefek O, Galajda M, Konečná K, Martynková GS, Barabaszová KČ (2019) Microstructure and electrochemical behavior of TiO2 nanotubes coated on titanium-based substrate before and after thermal treatment. J Nanosci Nanotechnol 19:2989–2996. https://doi.org/10.1166/jnn.2019.15859

Acknowledgements

The authors gratefully acknowledge LNNano/CNPEM (National Nanotechnology Laboratory of the National Center for Research on Energy and Materials) for providing access to its SEM facilities. This work was supported by the Brazilian research funding agency FAPESP (São Paulo Research Foundation) [Grant #2017/16715-0].

Author information

Authors and Affiliations

Contributions

LF is the main author, performed the experiments, and took the lead in writing the paper. MGM and AC contributed to the implementation of the research and to the interpretation of the results. RC designed and supervised the study and revised the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fanton, L., Cremasco, A., Mello, M.G. et al. Anodization growth of TiO2 nanotubes on Ti–35Nb–7Zr–5Ta alloy: effects of anodization time, strain hardening, and crystallographic texture. J Mater Sci 54, 13724–13739 (2019). https://doi.org/10.1007/s10853-019-03870-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03870-5