Abstract

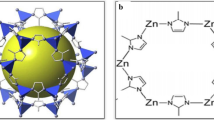

Zeolites are microporous materials with tetrahedral three-dimensional structure; such structure allows the transfer of material through its pores, but small pores prejudice such transfer. One way to overcome these problems is the development of materials combining microporous and mesoporous structures. This study reports the synthesis at room temperature of hierarchical materials, ZSM-5/MCM-48, ZSM-35/MCM-48, ZSM-5/MCM-41 and ZSM-35/MCM-41, from ZSM-5 and ZSM-35 seeds, using ionic liquid (1-hexadecyl-3-methylimidazolium) as supramolecular template. Infrared spectroscopy and attenuated total reflectance analyses confirmed the formation of the materials through the presence of bands at 1220 and 1070 cm−1. SAXS analyses showed that most of the materials have surface fracture dimensions (3 ≤ α < 4), except the sample MCM 41/ZSM 5, having a mass fractal structure. Signals in the high-angle region correlated with XRD analysis, confirming the formation of the materials. TGA analysis shows that ionic liquid decomposition occurs at higher temperatures when the ionic liquid is within the material. Finally, the results obtained by textural analysis via N2 adsorption agreed with data reported in the literature.

Similar content being viewed by others

References

Moliner M, Martínez C, Corma A (2015) Multipore zeolites: synthesis and catalytic applications. Angew Chemie Int Ed 54:3560–3579. https://doi.org/10.1002/anie.201406344

Feliczak-Guzik A (2018) Hierarchical zeolites: synthesis and catalytic properties. Microporous Mesoporous Mater 259:33–45. https://doi.org/10.1016/j.micromeso.2017.09.030

Koshy N, Singh DN (2016) Fly ash zeolites for water treatment applications. J Environ Chem Eng 4:1460–1472. https://doi.org/10.1016/j.jece.2016.02.002

Novak S (2018) Síntese de materiais Micro/Mesoporosos hierárquicos com estrutura MFI, Universidade Estadual de São Paulo (UNESP). http://hdl.handle.net/11449/153109. Accessed 15 July 2019

Xia Y, Mokaya R (2004) On the synthesis and characterization of ZSM-5/MCM-48 aluminosilicate composite materials. J Mater Chem 14:863–870. https://doi.org/10.1039/b313389c

Jia X, Khan W, Wu Z, Choi J, Yip ACK (2018) Modern synthesis strategies for hierarchical zeolites: bottom-up versus top-down strategies. Adv Powder Technol. https://doi.org/10.1016/j.apt.2018.12.014

Jacobsen CJH, Madsen C, Houzvicka J, Schmidt I, Carlsson A (2000) Mesoporous zeolite single crystals. J Am Chem Soc 122:7116–7117. https://doi.org/10.1021/ja000744c

Kloetstra KR, Zandbergen HW, Jansen JC, Van Bekkum H (1996) Overgrowth of mesoporous MCM-41 on faujasite. Microporous Mater 6:287–293. https://doi.org/10.1016/0927-6513(96)00036-3

Liu Y, Zhang W, Pinnavaia TJ (2000) Steam-stable aluminosilicate mesostructures assembled from zeolite type Y seeds. J Am Chem Soc 122:8791–8792. https://doi.org/10.1021/ja001615z

Gonçalves ML, Dimitrov LD, Jordão MH, Wallau M, Urquieta-González EA (2008) Synthesis of mesoporous ZSM-5 by crystallisation of aged gels in the presence of cetyltrimethylammonium cations. Catal Today 133–135:69–79. https://doi.org/10.1016/j.cattod.2007.12.108

Shih PC, Wang JH, Mou CY (2004) Strongly acidic mesoporous aluminosilicates prepared from zeolite seeds: acylation of anisole with octanyl chloride. Catal Today 93–95:365–370. https://doi.org/10.1016/j.cattod.2004.06.025

Prasomsri T, Jiao W, Weng SZ, Garcia Martinez J (2015) Mesostructured zeolites: bridging the gap between zeolites and MCM-41. Chem Commun 51:8900–8911. https://doi.org/10.1039/c4cc10391b

J.C.V.W.J. Roth, J.S.B.S.B. Mccullen, The Synthesis and Properties of M 41S vartuli1998, 1 (1998) 97–119

Hoffmann F, Cornelius M, Morell J, Fröba M (2006) Silica-based mesoporous organic-inorganic hybrid materials. Angew Chemie Int Ed 45:3216–3251. https://doi.org/10.1002/anie.200503075

Meynen V, Cool P, Vansant EF (2009) Verified syntheses of mesoporous materials. Microporous Mesoporous Mater 125:170–223. https://doi.org/10.1016/j.micromeso.2009.03.046

Rogers RD, Seddon KR (2003) Seddon ionic liquids solvents of the future? Science 302:792–793

Antonietti M, Kuang D, Smarsly B, Zhou Y (2004) Ionische Flüssigkeiten für die Synthese funktioneller Nanopartikel und anderer anorganischer Nanostrukturen. Angew Chemie 116:5096–5100. https://doi.org/10.1002/ange.200460091

Avellaneda RS, Ivanova S, Sanz O, Romero-Sarria F, Centeno MA, Odriozola JA (2009) Ionic liquid templated TiO2 nanoparticles as a support in gold environmental catalysis. Appl Catal B Environ 93:140–148. https://doi.org/10.1016/j.apcatb.2009.09.023

Ismail AA, Mohamed RM, Fouad OA, Ibrahim IA (2006) Synthesis of nanosized ZSM-5 using different alumina sources. Cryst Res Technol 41:145–149. https://doi.org/10.1002/crat.200510546

Byggningsbacka R, Kumar N, Lindfors LE (1998) Comparative study of the catalytic properties of ZSM-22 and ZSM-35/ferrierite zeolites in the skeletal isomerization of 1-butene. J Catal 178:611–620. https://doi.org/10.1006/jcat.1998.2174

Yuan Z, Zhu X, Li M, Lu W, Li X, Zhang H (2016) A highly ion-selective zeolite flake layer on porous membranes for flow battery applications. Angew Chemie Int Ed 55:3058–3062. https://doi.org/10.1002/anie.201510849

Chen L-H, Li X-Y, Rooke JC, Zhang Y-H, Yang X-Y, Tang Y, Xiao F, Su B-L (2012) Hierarchically structured zeolites: synthesis, mass transport properties and applications. J Mater Chem Dyn 22:17381–17403. https://doi.org/10.1039/c2jm31957h

Dutta S, Bhaumik A, Wu KC (2014) Hierarchically porous carbon derived from polymers and biomass: effect of interconnected pores on energy applications. Energy Environ Sci 7:3445–3816. https://doi.org/10.1039/c4ee01075b

Du X, He J (2011) Spherical silica micro/nanomaterials with hierarchical structures: synthesis and applications. Nanoscale 3:3984–4002. https://doi.org/10.1039/c1nr10660k

Parlett CMA, Wilson K, Lee AF, Lee AF, Wilson K (2013) Hierarchical porous materials: catalytic applications. Chem Soc Rev 42:3876–3893. https://doi.org/10.1039/c2cs35378d

Pan T, Wu Z, Yip ACK (2019) Advances in the green synthesis of microporous. Catalysts 9:1–18. https://doi.org/10.3390/catal9030274

Mignoni ML (2012) Zeólitas obtidas com líquidos iônicos como direcionadores de estrutura: síntese e reatividade. Tese de doutorado, Universidade Federal do Rio Grande do Sul (UFRGS). http://hdl.handle.net/10183/55505. Accessed 28 Sept 2018

Kumar D, Schumacher K, Du Fresne C, von Hohenesche M, Grün KK Unger (2001) MCM-41, MCM-48 and related mesoporous adsorbents: their synthesis and characterisation. Colloids Surf A Physicochem Eng Asp 187–188:109–116. https://doi.org/10.1016/S0927-7757(01)00638-0

Zhou Y, Antonietti M (2004) A series of highly ordered, super-microporous, lamellar silicas prepared by nanocasting with ionic liquids. Chem Mater 16:544–550. https://doi.org/10.1021/cm034442w

Ilavsky J, Jemian PR (2009) Irena: tool suite for modeling and analysis of small-angle scattering. J Appl Crystallogr 42:347–353. https://doi.org/10.1107/s0021889809002222

Kline SR (2006) Reduction and analysis of SANS and USANS data using IGOR Pro. J Appl Crystallogr 39:895–900. https://doi.org/10.1107/s0021889806035059

Beaucage G (2002) Approximations leading to a unified exponential/power-law approach to small-angle scattering. J Appl Crystallogr 28:717–728. https://doi.org/10.1107/s0021889895005292

Beaucage G (1996) Small-angle scattering from polymeric mass fractals of arbitrary mass-fractal dimension. J Appl Crystallogr 29:134–146. https://doi.org/10.1107/S0021889895011605

Treacy MM, Higgins JB (2001) Collection of simulated XRD powder patterns for zeolites, 4th edn. Elsevier, Amsterdam. https://doi.org/10.1016/s0166-9834(00)81382-2

Duran A, Serna C, Fornes V, Fernandez Navarro JM (1986) Structural considerations about SiO2 glasses prepared by sol–gel. J Non Cryst Solids 82:69–77. https://doi.org/10.1016/0022-3093(86)90112-2

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC technical report). Pure Appl Chem 87:1051–1069. https://doi.org/10.1515/pac-2014-1117

Bernardes AA, Radtke C, Alves MDCM, Baibich IM, Lucchese M, Dos Santos JHZ (2014) Synthesis and characterization of SiO2–CrO3, SiO2–MoO3, and SiO2–WO3 mixed oxides produced using the non-hydrolytic sol-gel process. J Sol Gel Sci Technol 69:72–84. https://doi.org/10.1007/s10971-013-3188-1

Corrêa GG, Morais EC, Brambilla R, Bernardes AA, Radtke C, Dezen D, Júnior AV, Fronza N, Santos JHZD (2014) Effects of the sol–gel route on the structural characteristics and antibacterial activity of silica-encapsulated gentamicin. Colloids Surf B Biointerf 116:510–517. https://doi.org/10.1016/j.colsurfb.2014.01.043

Hench LL, West JK (1990) The sol–gel process. Chem Rev 90:33–72. https://doi.org/10.1021/cr00099a003

Pauwels B, Van Tendeloo G, Thoelen C, Van Rhijn W, Jacobs PA (2001) Structure determination of spherical MCM-41 particles. Adv Mater 13:1317–1320. https://doi.org/10.1002/1521-4095(200109)13:17%3c1317:AID-ADMA1317%3e3.0.CO;2-5

Schumacher K, Grün M, Unger KK (1999) Novel synthesis of spherical MCM-48. Microporous Mesoporous Mater 27:201–206. https://doi.org/10.1016/S1387-1811(98)00254-6

Schmidt R, Stöcker M, Akporiaye D, Heggelund Tørstad E, Olsen A (1995) High-resolution electron microscopy and X-ray diffraction studies of MCM-48. Microporous Mater. 5:1–7. https://doi.org/10.1016/0927-6513(95)00030-d

Tao Y, Kanoh H, Kaneko K (2003) ZSM-5 monolith of uniform mesoporous channels. J Am Chem Soc 125:6044–6045. https://doi.org/10.1021/ja0299405

Li X, Liu X, Liu S, Xie S, Zhu X, Chen F, Xu L (2013) Activity enhancement of ZSM-35 in dimethyl ether carbonylation reaction through alkaline modifications. RSC Adv 3:16549–16557. https://doi.org/10.1039/c3ra42197j

Chen Y, Han D, Cui H, Zhang Q (2019) Synthesis of ZSM-5 via organotemplate-free and dry gel conversion method: investigating the effects of experimental parameters. Elsevier, Amsterdam. https://doi.org/10.1016/j.jssc.2019.120969

Na J, Liu G, Zhou T (2013) Synthesis and catalytic performance of ZSM-5/MCM-41 zeolites with varying mesopore size by surfactant-directed recrystallization. Catal Lett 143(3):267–275. https://doi.org/10.1007/s10562-013-0963-0

Li R, Chong S, Altaf N, Gao Y, Louis B, Wang Q (2019) Synthesis of ZSM-5/siliceous zeolite composites for improvement of hydrophobic adsorption of volatile organic compounds. Front Chem 7:1–10. https://doi.org/10.3389/fchem.2019.00505

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Aguiar Pedott, V., Bordin, I., dos Santos da Silva, A. et al. Hierarchical pore structure of zeolite/MCM obtained by supramolecular templating using ionic liquid (C16MI·Cl) as the structure-directing agent. J Mater Sci 55, 2343–2352 (2020). https://doi.org/10.1007/s10853-019-04117-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04117-z