Abstract

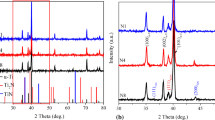

This paper reported a surface modification method to improve corrosion resistance and biocompatibility of a Ti3Zr2Sn3Mo25Nb alloy (named as TLM). A 100-μm-thick layer with an average grain size of 70 nm was created on the alloy surface through sliding friction treatment (SFT), followed by a micro-arc oxidation treatment (MAO) to create a porous coating. Phase composition, morphology, structural characteristics, and elemental characteristics of the MAO coating were inspected by scanning electron microscope (SEM), energy-dispersive spectrometer (EDS) and X-ray photoelectron spectroscopy (XPS). Corrosion resistance of the MAO coating was tested by electrochemical method, and the biocompatibility of the MAO coating was evaluated by cell adhesion and proliferation, and protein adsorption tests. It has found that the surface morphology and chemical composition of the MAO coating produced on the SFT surface (NG-MAO) were not significantly different from those of the MAO coating formed on the original TLM substrate without SFT (CG-MAO). However, the corrosion current density of the NG-MAO coating in 0.9% NaCl solution (PS) and simulated body fluid (SBF) solution decreased 43.4 and 46.7%, respectively, as compared to the CG-MAO coating. The polarization resistance of the NG-MAO coating was also 122% higher than that of the CG-MAO coating in PS. And the protein adsorption capacity and cell proliferation have been significantly increased on the NG-MAO coating compared to its counterpart, the CG-MAO coating.

Graphical abstract

Similar content being viewed by others

References

Geetha M, Singh AK, Asokamani R, Gogia AK (2008) Ti based biomaterials, ultimate choice for orthopedic implants. Prog Mater Sci 54:397–425. https://doi.org/10.1016/j.pmatsci.2008.06.004

Kaur M, Singh K (2019) Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater Sci Eng C 102:844–862. https://doi.org/10.1016/j.msec.2019.04.064

Sidhu SS, Singh H, Gepreel MAH (2020) A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials. Mater Sci Eng C 121:111661. https://doi.org/10.1016/j.msec.2020.111661

Fu YB, Chen HN, Guo RQ, Huang YD, Yabo Fu, Mohammad RT (2021) Extraordinary strength-ductility in gradient amorphous structured Zr-based alloy. J Alloys Compd 888:161507. https://doi.org/10.1016/j.jallcom.2021.161507

Xu XX, Jia ZJ, Zheng YF, Wang YJ (2021) Bioadaptability of biomaterials: Aiming at precision medicine. Matter 4:2648–2650. https://doi.org/10.1016/j.matt.2021.06.033

Tardelli JDC, Bolfarini C, Dos Reis AC (2020) Comparative analysis of corrosion resistance between beta titanium and Ti-6Al-4V alloys: a systematic review. J Trace Elem Med Biol 62:126618. https://doi.org/10.1016/j.jtemb.2020.126618

Ibrahim MZ, Sarhan AAD, Yusuf F, Hamdi M (2017) Biomedical materials and techniques to improve the tribological, mechanical and biomedical properties of orthopedic implants-a review article. J Alloys Comps 714:636–667. https://doi.org/10.1016/j.jallcom.2017.04.231

Pjetursson BE, Thoma D, Jung R, Zwahlen M, Zembic A (2012) A systematic review of the survival and complication rates of implant-supported fixed dental prostheses (FDPs) after a mean observation period of at least 5 years. Clin Oral Implants Res 23:22–38. https://doi.org/10.1111/j.1600-0501.2012.02546.x

Devgan S, Sidhu SS (2019) Evolution of surface modification trends in bone related biomaterials: a review. Mater Chem Phys 233:68–78. https://doi.org/10.1016/j.matchemphys.2019.05.039

Aglietta M, Iorio Siciliano V, Blasi A, Sculean A, Brägger U, Lang NP, Salvi GE (2012) Clinical and radiographic changes at implants supporting single-unit crowns (SCs) and fixed dental prostheses (FDPs) with one cantilever extension. A retrospective study. Clin Oral Implants Res 23:550–555. https://doi.org/10.1111/j.1600-0501.2011.02391.x

Wysotzki P, Sancho A, Gimsa J, Groll J (2020) A comparative analysis of detachment forces and energies in initial and mature cell-material interaction. Colloids Surf B 190:110894. https://doi.org/10.1016/j.colsurfb.2020.110894

Yu S, Yu ZT, Wang G, Han JY, Ma X, Dargusch MS (2011) Biocompatibility and osteoconduction of active porous calcium-phosphate films on a novel Ti-3Zr-2Sn-3Mo-25Nb biomedical alloy. Colloids Surf B 85:83–115. https://doi.org/10.1016/j.colsurfb.2011.02.025

Deng CH, Shen XK, Yang WH, Luo Z, Ma PP, Shen TT, Liu J, Cai KY (2018) Construction of zinc-incorporated nano-network structures on a biomedical titanium surface to enhance bioactivity. Appl Surf Sci 453:263–270. https://doi.org/10.1016/j.apsusc.2018.05.097

Kurup A, Dhatrak P, Khasnis N (2021) Surface modification techniques of titanium and titanium alloys for biomedical dental applications: a review. Mater Today Proc 39:84–90. https://doi.org/10.1016/j.matpr.2020.06.163

Zhang LC, Chen LY, Wang LQ (2020) Surface modification of titanium and titanium alloys: technologies, developments, and future interests. Adv Eng Mater 22:2070017. https://doi.org/10.1002/adem.201901258

Wang YJ (2016) Bioadaptability: an innovative concept for biomaterials. J Mater Sci Technol 32:801–809. https://doi.org/10.1016/j.jmst.2016.08.002

Yu S, Yu Z, Guo DG, Zhu H, Zhang MH, Han JY, Zhe Yu, Yu ZT et al (2022) Enhanced bioactivity and interfacial bonding strength of Ti3Zr2Sn3Mo25Nb alloy through graded porosity and surface bioactivation. J Mater Sci Technol 100:137–149. https://doi.org/10.1016/j.jmst.2021.06.008

Wang L, Zhou WH, Yu ZT, Yu S, Zhou L, Cao YM, Dargusch M, Wang G (2021) An in vitro evaluation of the hierarchical micro/nanoporous structure of a Ti3Zr2Sn3Mo25Nb Alloy after surface dealloying. ACS Appl Mater Interfaces 13:15017–15030. https://doi.org/10.1021/acsami.1c02140

Liu XY, Chu PK, Ding CX (2004) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R Rep 47:49–121. https://doi.org/10.1016/j.mser.2004.11.001

Song C, Liu M, Deng ZQ, Niu SP, Deng CM, Liao HL (2018) A novel method for in-situ synthesized TiN coatings by plasma spray-physical vapor deposition. Mater Lett 217:127–130. https://doi.org/10.1016/j.matlet.2018.01.068

Yu S, Guo DG, Han JY, Sun LJ, Zhu H, Yu ZT, Dargusch M, Wang G (2020) Enhancing antibacterial performance and bioactivity of pure titanium by a two-step electrochemical surface coating. ACS Appl Mater Interfaces 12:44433–44446. https://doi.org/10.1021/acsami.0c10032

Doe Y, Ida H, Seiryu M et al (2020) Titanium surface treatment by calcium modification with acid-etching promotes osteogenic activity and stability of dental implants. Materialia 12:100801. https://doi.org/10.1016/j.mtla.2020.100801

Cao Y, Dhahad HA, El-Shorbagy MA, Alijani HQ, Zakeri M, Heydari A, Bahonar E, Slouf M et al (2021) Green synthesis of bimetallic ZnO–CuO nanoparticles and their cytotoxicity properties. Sci Rep 11:23479. https://doi.org/10.1038/s41598-021-02937-1

Hu MR, Wang YF, Yan ZF, Zhao YX, Xia L, Bowen C, Di YB, Zhuang XP (2021) Hierarchical dual-nanonet of polymer nanofibers and supramolecular nanofibrils for air filtration with high filtration efficiency, low air resistance and high moisture permeation. J Mater 24. https://doi.org/10.1039/D1TA01505B

Gu YH, Chen LL, Yue W, Chen P, Chen F, Ning CY (2016) Corrosion behavior and mechanism of MAO coated Ti6Al4V with a grain-fined surface layer. J Alloys Compd 664:770–776. https://doi.org/10.1016/j.jallcom.2015.12.108

Huo WT, Lin X, Cao HH, Yu S, Yu ZT, Zhang YS (2018) Manipulating the degradation behavior and biocompatibility of Mg alloy through a two-step treatment combining sliding friction treatment and micro-arc oxidation. J Mater Chem B 6:6431–6443. https://doi.org/10.1039/C8TB01072B

Uvarov V, Popov I (2007) Metrological characterization of X-ray diffraction methods for determination of crystallite size in nano-scale materials. Mater Charact 58:883–891. https://doi.org/10.1016/j.matchar.2006.09.002

Li XY, Lu L, Li JG, Zhang X, Gao HJ (2020) Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat Rev Mater 5:706–723. https://doi.org/10.1038/s41578-020-0212-2

Zhang YS, Zhang LC, Niu HZ, Bai XF, Yu S, Ma XQ, Yu ZT (2014) Deformation twinning and localized amorphization in nanocrystalline tantalum induced by sliding friction. Mater Lett 127:4–7. https://doi.org/10.1016/j.matlet.2014.04.079

Liu CQ, Chen XH, Zhang W, Zhang YS, Pan FS (2020) Microstructural evolution in the ultrafine-grained surface layer of Mg-Zn-Y-Ce-Zr alloy processed by sliding friction treatment. Mater Charact 166:110423. https://doi.org/10.1016/j.matchar.2020.110423

Yu ZT, Yu S, Ma XQ, Cheng J (2017) Development and application of novel biomedical titanium alloy materials. Acta Metall Sin-Engl 53: 1238–64. https://doi.org/10.11900/0412.1961.2017.00288.

Li RY, Wei YJ, Gu L, Qin YG, Li DD (2020) Sol–gel-assisted micro-arc oxidation synthesis and characterization of a hierarchically rough structured Ta–Sr coating for biomaterials. RSC Adv 10:20020–20027. https://doi.org/10.1039/D0RA01079K

Pesode P, Barve S (2021) Surface modification of titanium and titanium alloy by plasma electrolytic oxidation process for biomedical applications: a review. Mater Today Proc 46:594–602. https://doi.org/10.1016/j.matpr.2020.11.294

Huang R, Han Y (2013) The effect of SMAT-induced grain refinement and dislocations on the corrosion behavior of Ti-25Nb-3Mo-3Zr-2Sn alloy. Mater Sci Eng C 33:2353–2359. https://doi.org/10.1016/j.msec.2013.01.068

Gheytani M, Bagheri HR, Masiha HR, Aliofkhazraei M (2014) Effect of SMAT preprocessing on MAO fabricated nanocomposite coating. Surf Eng 30:244–255. https://doi.org/10.1179/1743294414Y.0000000251

Jin L, Cui WF, Song X, Liu G, Zhou L (2014) Surface nanocrystalline characteristics and corrosion resistance of β-type titanium alloy. Rare Metal Mat Eng 43:80–84

Huang R, Zhuang HY, Han Y (2013) Second-phase-dependent grain refinement in Ti–25Nb–3Mo–3Zr–2Sn alloy and its enhanced osteoblast response. Mater Sci Eng C 35:144–152. https://doi.org/10.1016/j.msec.2013.10.037

Xu L, Wu C, Lei XC, Zhang K, Liu CC, Ding JN, Shi XL (2018) Effect of oxidation time on cytocompatibility of ultrafine-grained pure Ti in micro-arc oxidation treatment. Surf Coat Technol 342:12–22. https://doi.org/10.1016/j.surfcoat.2018.02.044

Cao HH, Huo WT, Ma SF, Zhang YS, Zhou L (2018) Microstructure and corrosion behavior of composite, coating on pure Mg acquired by sliding friction, treatment and micro-arc oxidation. Materials 11:1232. https://doi.org/10.3390/ma11071232

Li GL, Cao HL, Zhang WJ, Ding X, Yang GZ, Qiao YQ, Liu XY, Jiang XQ (2016) Enhanced osseointegration of hierarchical micro/nanotopographic titanium fabricated by microarc oxidation and electrochemical treatment. ACS Appl Mater Interfaces 8:3840–3852. https://doi.org/10.1021/acsami.5b10633

Zhao QM, Yi L, Jiang LB, Ma YQ, Lin H, Dong J (2019) Surface functionalization of titanium with zinc/strontium-doped titanium dioxide microporous coating via microarc oxidation. Nanomedicine 16:149–161. https://doi.org/10.1016/j.nano.2018.12.006

Souza JCM, Sordi MB, Kanazawa M, Ravindran S, Henriques B, Silva FS, Aparicio C, Cooper LF (2019) Nano-scale modification of titanium implant surfaces to enhance osseointegration. Acta Biomater 94:112–131. https://doi.org/10.1016/j.actbio.2019.05.045

Bigerelle M, Anselme K, Noël B, Ruderman I, Hardouin P, Lost A (2002) Improvement in the morphology of Ti-based surfaces: a new process to increase in vitro human osteoblast response. Biomaterials 23:1563–1577. https://doi.org/10.1016/S0142-9612(01)00271-X

Guo Y, Duan TG, Chen Y, Wen Q (2015) Solvothermal fabrication of three-dimensionally sphere-stacking Sb–SnO2 electrode based on TiO2 nanotube arrays. Ceram 41:8723–8729. https://doi.org/10.1016/j.ceramint.2015.03.092

Zhu WQ, Shao SY, Xu LN, Chen WQ, Yu XY, Tang KM, Tang ZH, Zhang FM et al (2019) Enhanced corrosion resistance of zinc-containing nanowires-modified titanium surface under exposure to oxidizing microenvironment. J Nanobiotechnol 17:55. https://doi.org/10.1186/s12951-019-0488-9

Balusamy T, Jamesh M, Kumar S, Sankara Narayanan TSN (2012) Corrosion resistant Ti alloy for sulphuric acid medium: suitability of Ti–Mo alloys. Werkst Korros 63:9. https://doi.org/10.1002/maco.201106275

Gheytani M, Aliofkhazraei M, Bagheri HR, Masiha HR, Rouhaghdam AS (2015) Wettability and corrosion of alumina embedded nanocomposite MAO coating on nanocrystalline AZ31B magnesium alloy. J Alloys Compd 649:666–673. https://doi.org/10.1016/j.jallcom.2015.07.139

Wei GB, Ma PX (2004) Structure and properties of nano-hydroxyapatite/polymer composite scaffolds for bone tissue engineering. Biomaterials 25:4749–4757. https://doi.org/10.1016/j.biomaterials.2003.12.005

Mendonça G, Mendonça DBS, Aragão FJL, Cooper LF (2008) Advancing dental implant surface technology: From micro- to nanotopography. Biomaterials 29:3822–3835. https://doi.org/10.1016/j.biomaterials.2008.05.012

Richert L, Vetrone F, Yi J-H, Zalzal SF, Wuest JD, Rosei F, Nanci A (2008) Surface Nanopatterning to Control Cell Growth. Adv Mater 20:1488–1492. https://doi.org/10.1002/adma.200701428

Variola F, Vetrone F, Richert L et al (2009) Improving biocompatibility of implantable metals by nanoscale modification of surfaces: an overview of strategies, fabrication methods, and challenges. Small 5:996–1006. https://doi.org/10.1002/smll.200801186

Andrukhov O, Huber R, Shi B, Berner S, Fan XHR, Moritz A, Spencer ND, Schedle A (2016) Proliferation, behavior, and differentiation of osteoblasts on surfaces of different microroughness. Dent Mater 32:1374–1384. https://doi.org/10.1016/j.dental.2016.08.217

Acknowledgements

The authors acknowledge the financial support of the National Natural Science Foundation of China (32071327), National Key Research and Development Program of China (2016YFC1102003), International Science and Technology Cooperation Base of Shaanxi Province (2017GHJD-014) and Science and Technology Program of Shaanxi Province (2019GY-200). And G.W. was grateful for the support from the Queensland Centre for Advanced Materials Processing and Manufacturing (AMPAM) and the ARC Research Hub for Advanced Manufacturing of Medical Devices.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Prime Novelty Statement: This paper reported that a micro-arc oxidation coating was created on a nanograined layer induced by sliding friction treatment on a β-titanium Ti3Zr2Sn3Mo25Nb alloy. The nanocrystalline layer reduced the porosity and increased the thickness of the MAO coating, leading to an enhanced corrosion resistance. The specific porous structure and roughness are favorable for cells to adhere and grow in and enhanced the hydrophilicity to absorb proteins.

Rights and permissions

About this article

Cite this article

Yu, S., Zeng, D., Zhu, H. et al. Improvement on biocompatibility and corrosion resistance of a Ti3Zr2Sn3Mo25Nb alloy through surface nanocrystallization and micro-arc oxidation. J Mater Sci 57, 5298–5314 (2022). https://doi.org/10.1007/s10853-022-06977-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-06977-4