Abstract

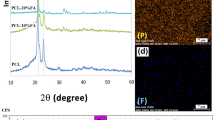

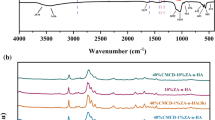

The present study evaluates the effect of adding different contents of hydroxyapatite (HA) nanoparticles on the mechanical properties of poly(lactic acid)/thermoplastic polyurethane (PLA/TPU) (90/10, 75/25, and 50/50 w/w) blends. Various theoretical models were utilized to describe the observed mechanical behavior of the prepared blend nanocomposites. Scanning electron microscopy revealed that 75/25 blend has the smoothest surface. Also, transmission electron microscopy confirmed a matrix–droplet morphology for all the 90/10 and 75/25 blends and a co-continuous morphology for the 50/50 blends. In addition, the HA nanoparticles in all blend nanocomposites were mainly present in the PLA phase, although others were localized at the interface. The results of tensile test demonstrated that the tensile strength and modulus of PLA/TPU blends decreased with increasing TPU amount. Also, the tensile strength and modulus of 75/25 blend improved with the addition of HA content. Among the blend nanocomposites, the 75/25 blend containing 5 phr HA nanoparticles revealed the highest tensile strength and modulus, i.e., an enhancement of about 14 and 36% compared to those of the 75/25 blend. The results of theoretical models and experimental data obtained from the tensile test were in good agreement for the blends and blend nanocomposites.

Similar content being viewed by others

References

Mousavi SR, Zamani MH, Estaji S et al (2022) Mechanical properties of bamboo fiber-reinforced polymer composites: a review of recent case studies. J Mater Sci. https://doi.org/10.1007/s10853-021-06854-6

Shojaei S, Nikuei M, Goodarzi V et al (2019) Disclosing the role of surface and bulk erosion on the viscoelastic behavior of biodegradable poly ($\varepsilon$-caprolactone)/poly(lactic acid)/hydroxyapatite nanocomposites. J Appl Polym Sci 136:47151

Aghajan MH, Panahi-Sarmad M, Alikarami N et al (2020) Using solvent-free approach for preparing innovative biopolymer nanocomposites based on PGS/gelatin. Eur Polym J 131:109720

Hu C, Hahn L, Yang M et al (2021) Improving printability of a thermoresponsive hydrogel biomaterial ink by nanoclay addition. J Mater Sci 56:691–705. https://doi.org/10.1007/s10853-020-05190-5

Sun Y, Xue J, Dong S et al (2020) Biomass-derived porous carbon electrodes for high-performance supercapacitors. J Mater Sci 55:5166–5176. https://doi.org/10.1007/s10853-019-04343-5

Khasraghi SS, Shojaei A, Sundararaj U (2020) Highly biocompatible multifunctional hybrid nanoparticles based on Fe3O4 decorated nanodiamond with superior superparamagnetic behaviors and photoluminescent properties. Mater Sci Eng C 114:110993

Khasraghi SS, Shojaei A, Sundararaj U (2019) Bio-based UV curable polyurethane acrylate: morphology and shape memory behaviors. Eur Polym J 118:514–527

Abrisham M, Noroozi M, Panahi-Sarmad M et al (2020) The role of polycaprolactone-triol (PCL-T) in biomedical applications: a state-of-the-art review. Eur Polym J 131:109701

Ahmadipour M, Mohammadi H, Pang AL et al (2022) A review: silicate ceramic-polymer composite scaffold for bone tissue engineering. Int J Polym Mater Polym Biomater 71:180–195

Karimpour-Motlagh N, Khonakdar HA, Jafari SMA et al (2020) Influence of polypropylene and nanoclay on thermal and thermo-oxidative degradation of poly (lactide acid): TG-FTIR, TG-DSC studies and kinetic analysis. Thermochim Acta 691:178709

Bahrani S, Hashemi SA, Mousavi SM, et al (2022) Conductive polymers in green analytical chemistry. In: Amiri A, Hussain CM (eds) Conductive polymers in analytical chemistry. ACS Publications, pp 1–37

Entezam M, Ehghaghiyan A, Sedeh NN et al (2019) Physicomechanical and antimicrobial characteristics of hydrogel based on poly (vinyl alcohol): performance improvement via inclusion of chitosan-modified nanoclay. J Appl Polym Sci 136:47444

Tang Y, Liu S, Deng Y et al (2021) An improved method for soft tissue modeling. Biomed Signal Process Control 65:102367

Zhao R, Zhang L, Guo B et al (2021) Unveiling substitution preference of chromium ions in sulphoaluminate cement clinker phases. Compos Part B Eng 222:109092

Guo J, Xiao C, Gao J et al (2021) Interplay between counter-surface chemistry and mechanical activation in mechanochemical removal of N-faced GaN surface in humid ambient. Tribol Int 159:107004

Jagadeesh D, Kanny K, Prashantha K (2017) A review on research and development of green composites from plant protein-based polymers. Polym Compos 38:1504–1518

Sanusi OM, Benelfellah A, Bikiaris DN, Ait Hocine N (2021) Effect of rigid nanoparticles and preparation techniques on the performances of poly (lactic acid) nanocomposites: a review. Polym Adv Technol 32:444–460

Jafari SMA, Khajavi R, Goodarzi V et al (2019) Nonisothermal crystallization kinetic studies on melt processed poly (ethylene terephthalate)/polylactic acid blends containing graphene oxide and exfoliated graphite nanoplatelets. J Appl Polym Sci 136:47569

Jiang J, Yang S, Li L, Bai S (2020) High thermal conductivity polylactic acid composite for 3D printing: synergistic effect of graphene and alumina. Polym Adv Technol 31:1291–1299

Sanusi OM, Benelfellah A, Papadopoulos L et al (2021) Properties of poly (lactic acid)/montmorillonite/carbon nanotubes nanocomposites: determination of percolation threshold. J Mater Sci 56:16887–16901. https://doi.org/10.1007/s10853-021-06378-z

Paydayesh A, Mousavi SR, Estaji S et al (2022) Functionalized graphene nanoplatelets/poly (lactic acid)/chitosan nanocomposites: mechanical, biodegradability, and electrical conductivity properties. Polym Compos 43:411–421

Sharma S, Singh AA, Majumdar A, Butola BS (2019) Tailoring the mechanical and thermal properties of polylactic acid-based bionanocomposite films using halloysite nanotubes and polyethylene glycol by solvent casting process. J Mater Sci 54:8971–8983. https://doi.org/10.1007/s10853-019-03521-9

Alam F, Verma P, Mohammad W et al (2021) Architected poly (lactic acid)/poly ($\varepsilon$-caprolactone)/halloysite nanotube composite scaffolds enabled by 3D printing for biomedical applications. J Mater Sci 56:14070–14083. https://doi.org/10.1007/s10853-021-06145-0

Aghjeh MR, Nazari M, Khonakdar HA et al (2015) In depth analysis of micro-mechanism of mechanical property alternations in PLA/EVA/clay nanocomposites: a combined theoretical and experimental approach. Mater Des 88:1277–1289

Nofar M, Tabatabaei A, Sojoudiasli H et al (2017) Mechanical and bead foaming behavior of PLA-PBAT and PLA-PBSA blends with different morphologies. Eur Polym J 90:231–244

Fortelny I, Ujcic A, Fambri L, Slouf M (2019) Phase structure, compatibility, and toughness of PLA/PCL blends: A review. Front Mater 206

Si W-J, Yuan W-Q, Li Y-D et al (2018) Tailoring toughness of fully biobased poly (lactic acid)/natural rubber blends through dynamic vulcanization. Polym Test 65:249–255

Wei Q, Sun D, Zhang K et al (2021) Research on the miscibility, mechanical properties and printability of polylactic acid/poly ($\varepsilon$-caprolactone) blends: insights from molecular dynamics simulation and experiments. J Mater Sci 56:9754–9768. https://doi.org/10.1007/s10853-021-05918-x

Mi H-Y, Jing X, Napiwocki BN et al (2017) Biocompatible, degradable thermoplastic polyurethane based on polycaprolactone-block-polytetrahydrofuran-block-polycaprolactone copolymers for soft tissue engineering. J Mater Chem B 5:4137–4151

Cai W, Mu X, Pan Y et al (2018) Facile fabrication of organically modified boron nitride nanosheets and its effect on the thermal stability, flame retardant, and mechanical properties of thermoplastic polyurethane. Polym Adv Technol 29:2545–2552

Shakouri Z, Nazockdast H (2018) Microstructural development and mechanical performance of PLA/TPU blends containing geometrically different cellulose nanocrystals. Cellulose 25:7167–7188

Lin W, Qu J-P (2019) Enhancing impact toughness of renewable poly (lactic acid)/thermoplastic polyurethane blends via constructing cocontinuous-like phase morphology assisted by ethylene–methyl acrylate–glycidyl methacrylate copolymer. Ind Eng Chem Res 58:10894–10907

Kahraman Y, Özdemir B, Kiliç V et al (2021) Super toughened and highly ductile PLA/TPU blend systems by in situ reactive interfacial compatibilization using multifunctional epoxy-based chain extender. J Appl Polym Sci 138:50457

Mousavi SR, Amraei IA (2016) Influence of nanosilica and methyl methacrylate-butadiene-styrene core-shell rubber particles on the physical-mechanical properties and cure kinetics of diglycidyl ether of bisphenol-A-based epoxy resin. High Perform Polym 28:809–819. https://doi.org/10.1177/0954008315600228

Mousavi SR, Amraei IA (2015) Toughening of dicyandiamide-cured DGEBA-based epoxy resin using MBS core-shell rubber particles. J Compos Mater 49:2357–2363. https://doi.org/10.1177/0021998314545338

Mousavi SR, Estaji S, Paydayesh A et al (2022) A review of recent progress in improving the fracture toughness of epoxy-based composites using carbonaceous nanofillers. Polym Compos. https://doi.org/10.1002/pc.26518

Tayouri MI, Mousavi SR, Estaji S, Nemati Mahand S, Jahanmard R, Arjmand M, Arnhold K, Khonakdar HA (2022) Polystyrene/polyolefin elastomer/halloysite nanotubes blend nanocomposites: morphology-thermal degradation kinetics relationship. Polym Adv Technol. https://doi.org/10.1002/pat.5664

Nowruzi Varzeghani H, Amiri Amraei I, Mousavi SR (2020) Dynamic cure kinetics and physical-mechanical properties of PEG/Nanosilica/Epoxy composites. Int J Polym Sci 2020:1–10. https://doi.org/10.1155/2020/7908343

Rashidifard S, Amraei IA, Heidar H, Mousavi SR (2021) Investigating the electrical properties of epoxy resin containing MWCNT–PANI with a core-shell morphology: synthesis and characterization. Polym Sci Ser B 63:418–431

Mousavi SR, Estaji S, Raouf Javidi M et al (2021) Toughening of epoxy resin systems using core–shell rubber particles: a literature review. J Mater Sci 56:18345–18367. https://doi.org/10.1007/s10853-021-06329-8

Mousavi SR, Estaji S, Rostami E et al (2022) Effect of a novel green modification of alumina nanoparticles on the curing kinetics and electrical insulation properties of epoxy composites. Polym Adv Technol 33:49–65

Kuliaei A, Amraei IA, Mousavi SR (2021) Investigating the relationship between tack and degree of conversion in DGEBA-based epoxy resin cured with dicyandiamide and diuron. J Polym Eng 41:537–545

Khatami M, Alijani HQ, Mousazadeh F et al (2020) Calcium carbonate nanowires: greener biosynthesis and their leishmanicidal activity. Rsc Adv 10:38063–38068

Khasraghi SS, Shojaei A, Janmaleki M, Sundararaj U (2021) Efficient inductively heated shape memory polyurethane acrylate network with silane modified nanodiamond@ Fe3O4 superparamagnetic nanohybrid. Eur Polym J 159:110735

Khasraghi SS, Rezaei M (2015) Preparation and characterization of UHMWPE/HDPE/MWCNT melt-blended nanocomposites. J Thermoplast Compos Mater 28:305–326

Estaji S, Paydayesh A, Mousavi SR et al (2021) Polycarbonate/poly (methyl methacrylate)/silica aerogel blend composites for advanced transparent thermal insulations: mechanical, thermal, and optical studies. Polym Compos 42:5323–5334

Mousavi SR, Faraj Nejad S, Jafari M, Paydayesh A (2021) Polypropylene/ethylene propylene diene monomer/cellulose nanocrystal ternary blend nanocomposites: effects of different parameters on mechanical, rheological, and thermal properties. Polym Compos 42:4187–4198

Zheng Y, Wang X, Wu G (2020) Chemical modification of carbon fiber with diethylenetriaminepentaacetic acid/halloysite nanotube as a multifunctional interfacial reinforcement for silicone resin composites. Polym Adv Technol 31:527–535

Akindoyo JO, Beg MDH, Ghazali S et al (2017) Effects of surface modification on dispersion, mechanical, thermal and dynamic mechanical properties of injection molded PLA-hydroxyapatite composites. Compos Part A Appl Sci Manuf 103:96–105

Al-Ahmed ZA, Al-Radadi NS, Ahmed MK et al (2020) Dye removal, antibacterial properties, and morphological behavior of hydroxyapatite doped with Pd ions. Arab J Chem 13:8626–8637

Ma J, He Y, Zeng G et al (2018) High-flux PVDF membrane incorporated with $β$-cyclodextrin modified halloysite nanotubes for dye rejection and Cu (II) removal from water. Polym Adv Technol 29:2704–2714

Padmanabhan VP, TSN SN, Sagadevan S et al (2019) Advanced lithium substituted hydroxyapatite nanoparticles for antimicrobial and hemolytic studies. New J Chem 43:18484–18494

Zeng J-H, Qiu P, Xiong L et al (2019) Bone repair scaffold coated with bone morphogenetic protein-2 for bone regeneration in murine calvarial defect model: systematic review and quality evaluation. Int J Artif Organs 42:325–337

Taherian S, Rahmani S, Sharif A et al (2019) In-situ polymerization of aliphatic-aromatic polyamide nanocomposites in the presence of halloysite nanotubes. Polym Adv Technol 30:538–544

Ahmed S, Jones FR (1990) A review of particulate reinforcement theories for polymer composites. J Mater Sci 25:4933–4942. https://doi.org/10.1007/BF00580110

Chow TS (1980) The effect of particle shape on the mechanical properties of filled polymers. J Mater Sci 15:1873–1888. https://doi.org/10.1007/BF00550613

Gopi JA, Nando GB (2014) Modeling of youngs modulus of thermoplastic polyurethane and polydimethylsiloxane rubber blends based on phase morphology. Adv Polym Sci Technol An Int J 4:43–51

Veenstra H, Verkooijen PCJ, van Lent BJJ et al (2000) On the mechanical properties of co-continuous polymer blends: experimental and modelling. Polymer (Guildf) 41:1817–1826

Einstein A (1905) On the movement of small particles suspended in a stationary liquid demanded by the molecular-kinetic theory of heat. Ann Phys 17:549–560

Einstein A (1956) Investigations on the Theory of the Brownian Movement. Courier Corporation

Paul B (1959) Prediction of elastic constants of multi-phase materials

Ohama Y (1987) Principle of latex modification and some typical properties of latex-modified mortars and concretes adhesion; binders (materials); bond (paste to aggregate); carbonation; chlorides; curing; diffusion. Mater J 84:511–518

Ishai O, Cohen LJ (1967) Elastic properties of filled and porous epoxy composites. Int J Mech Sci 9:539–546

Turcsanyi B, Pukanszky B, Tüdõs F (1988) Composition dependence of tensile yield stress in filled polymers. J Mater Sci Lett 7:160–162

Dayma N, Satapathy BK (2010) Morphological interpretations and micromechanical properties of polyamide-6/polypropylene-grafted-maleic anhydride/nanoclay ternary nanocomposites. Mater Des 31:4693–4703

Narkis M, Nicolais L (1971) Stress–strain behavior of SAN/glass bead composites above the glass transition temperature. J Appl Polym Sci 15:469–476

Omonov TS, Harrats C, Groeninckx G, Moldenaers P (2007) Anisotropy and instability of the co-continuous phase morphology in uncompatibilized and reactively compatibilized polypropylene/polystyrene blends. Polymer (Guildf) 48:5289–5302

Michler GH (2008) High-impact rubber-modified polymers. 351–371

Yu F, Huang H-X (2015) Simultaneously toughening and reinforcing poly (lactic acid)/thermoplastic polyurethane blend via enhancing interfacial adhesion by hydrophobic silica nanoparticles. Polym Test 45:107–113

Shen W, Wu W, Liu C et al (2020) Thermal conductivity enhancement of PLA/TPU/BN composites by controlling BN distribution and annealing treatment. Plast Rubber Compos 49:204–213

Gopi JA, Nando GB (2017) Preparation and characterization of nanohydroxyapatite-based nanocomposites derived from immiscible blends of thermoplastic polyurethane and polydimethylsiloxane rubber. J Thermoplast Compos Mater 30:465–489

Zimina A, Senatov F, Choudhary R et al (2020) Biocompatibility and physico-chemical properties of highly porous PLA/HA scaffolds for bone reconstruction. Polymers (Basel) 12:2938

Chow WS, Bakar AA, Ishak ZAM et al (2005) Effect of maleic anhydride-grafted ethylene–propylene rubber on the mechanical, rheological and morphological properties of organoclay reinforced polyamide 6/polypropylene nanocomposites. Eur Polym J 41:687–696

Kiani F, Entezam M, Khonakdar HA et al (2020) Assessment of compatibilization role of nanoclay in immiscible polystyrene/ethylene–octene copolymer blends via wide-angle X-ray scattering, microstructure, rheological analyses, and mechanical properties. J Appl Polym Sci 137:48748

Dike AS, Yilmazer U (2020) Improvement of organoclay dispersion into polystyrene-based nanocomposites by incorporation of SBS and maleic anhydride-grafted SBS. J Thermoplast Compos Mater 33:554–574

Fenouillot F, Cassagnau P, Majesté J-C (2009) Uneven distribution of nanoparticles in immiscible fluids: morphology development in polymer blends. Polymer (Guildf) 50:1333–1350

As’ habi L, Jafari SH, Baghaei B et al (2008) Structural analysis of multicomponent nanoclay-containing polymer blends through simple model systems. Polymer (Guildf) 49:2119–2126

Yousefzade O, Jeddi J, Vazirinasab E, Garmabi H (2019) Poly (lactic acid) phase transitions in the presence of nano calcium carbonate: opposing effect of nanofiller on static and dynamic measurements. J Thermoplast Compos Mater 32:312–327

Dos Santos EA, Farina M, Soares GA, Anselme K (2008) Surface energy of hydroxyapatite and $β$-tricalcium phosphate ceramics driving serum protein adsorption and osteoblast adhesion. J Mater Sci Mater Med 19:2307–2316

Entezam M, Khonakdar HA, Yousefi AA et al (2013) On nanoclay localization in polypropylene/poly (ethylene terephthalate) blends: correlation with thermal and mechanical properties. Mater Des 45:110–117

Pukánszky B (2005) Interfaces and interphases in multicomponent materials: past, present, future. Eur Polym J 41:645–662

Zuiderduin WCJ, Westzaan C, Huetink J, Gaymans RJ (2003) Toughening of polypropylene with calcium carbonate particles. Polymer (Guildf) 44:261–275

Panda BP, Mohanty S, Nayak SK (2015) Mechanism of toughening in rubber toughened polyolefin—a review. Polym Plast Technol Eng 54:462–473

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghassemi, B., Estaji, S., Mousavi, S.R. et al. In-depth study of mechanical properties of poly(lactic acid)/thermoplastic polyurethane/hydroxyapatite blend nanocomposites. J Mater Sci 57, 7250–7264 (2022). https://doi.org/10.1007/s10853-022-07129-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07129-4