Abstract

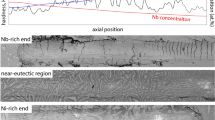

The temperature-dependent hardness of additively-manufactured near-eutectic Ni–Nb was investigated. This alloy was found to have solidified into a two-phase nanoscale microstructure with peak hardness of H ≅ 14–17 GPa at temperatures up to 400 °C, above which irreversible softening was observed despite retention of significant strength compared to traditionally-synthesized Ni-based superalloys. Experiments and molecular-dynamics simulations show that deformation for single-phase nanocrystalline volumes was confined to intragranular slip-band formation in δ-Ni3Nb and to intergranular grain-boundary sliding in μ-Ni6Nb7. However, microscopy in the nanostructured two-phase regions after severe plastic deformation indicated that phase boundaries acted as nucleation sites for dislocations, promoting twinning-induced plasticity (TWIP) in the μ-Ni6Nb7 grains. This work highlights (1) that additive manufacturing techniques enable formation of unique microstructures that exhibit superior mechanical properties, and (2) that multi-phase intermetallic compounds provide a route to mitigate brittle fracture though the promotion of twinning-induced plasticity. High strength and the absence of interface decohesion (cracking) suggests that multi-phase intermetallic systems may be a viable route for design of new printable superalloys. These results suggest that additive manufacturing methods and rapid solidification via non-equilibrium pathways may enable a pathway for achieving high combined strength and ductility.

Similar content being viewed by others

References

Perepezko JH (2009) The Hotter the engine, the better. Science (1979) 326:1068–1069. https://doi.org/10.1126/science.1179327

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23:1917–1928. https://doi.org/10.1007/s11665-014-0958-z

Lewandowski JJ, Seifi M (2016) Metal Additive manufacturing: a review of mechanical properties. Annu Rev Mater Res 46:151–186. https://doi.org/10.1146/annurev-matsci-070115-032024

Chen S, Tong Y, Liaw PK (2018) Additive manufacturing of high-entropy alloys: a review. Entropy. https://doi.org/10.3390/e20120937

Agrawal P, Thapliyal S, Nene SS et al (2020) Excellent strength-ductility synergy in metastable high entropy alloy by laser powder bed additive manufacturing. Addit Manuf 32:101098. https://doi.org/10.1016/j.addma.2020.101098

Babuska TF, Wilson MA, Johnson KL et al (2019) Achieving high strength and ductility in traditionally brittle soft magnetic intermetallics via additive manufacturing. Acta Mater. https://doi.org/10.1016/j.actamat.2019.08.044

Gorsse S, Hutchinson C, Gouné M, Banerjee R (2017) Additive manufacturing of metals: a brief review of the characteristic microstructures and properties of steels, Ti–6Al–4V and high-entropy alloys. Sci Technol Adv Mater 18:584–610. https://doi.org/10.1080/14686996.2017.1361305

de Cooman BC, Kwon O, Chin K-G (2012) State-of-the-knowledge on TWIP steel. Mater Sci Technol 28:513–527

de Cooman BC, Estrin Y, Kim SK (2018) Twinning-induced plasticity (TWIP) steels. Acta Mater 142:283–362

Deng Y, Tasan CC, Pradeep KG et al (2015) Design of a twinning-induced plasticity high entropy alloy. Acta Mater 94:124–133. https://doi.org/10.1016/j.actamat.2015.04.014

Asaro RJ, Suresh S (2005) Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater 53:3369–3382

Ding Q, Bei H, Wei X et al (2021) Nano-twin-induced exceptionally superior cryogenic mechanical properties of a Ni-based GH3536 (Hastelloy X) superalloy. Mater Today Nano 14:100110. https://doi.org/10.1016/j.mtnano.2021.100110

Ren L, Xiao W, Ma C et al (2018) Development of a high strength and high ductility near β-Ti alloy with twinning induced plasticity effect. Scr Mater 156:47–50. https://doi.org/10.1016/j.scriptamat.2018.07.012

Ding ZY, He QF, Chung D, Yang Y (2020) Evading brittle fracture in submicron-sized high entropy intermetallics in dual-phase eutectic microstructure. Scr Mater 187:280–284. https://doi.org/10.1016/j.scriptamat.2020.06.032

Gschneidner K, Russell A, Pecharsky A et al (2003) A family of ductile intermetallic compounds. Nat Mater 2:587–591

Yang T, Zhao YL, Tong Y et al (1979) (2018) Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 362:933–937

Liu CT, Maziasz PJ, Wright JL (1996) Key microstructures controlling the mechanical properties of two-phase TiAl alloys with lamellar structures. MRS Online Proc Lib (OPL) 460

Jiao ZB, Luan JH, Liu CT (2016) Strategies for improving ductility of ordered intermetallics. Prog Nat Sci: Mater Int 26:1–12. https://doi.org/10.1016/j.pnsc.2016.01.014

Potnis G, Goswami D, Das J (2023) Twinning mediated plasticity in high entropy CoCr1.3FeNi0.7MnNbx (x= 0.3, 0.367, 0.4) ultrafine lamellar eutectic by tuning stacking fault energy. Scr Mater 227:115271

Zhang Y, Li J, Wang X et al (2019) The interaction and migration of deformation twin in an eutectic high-entropy alloy AlCoCrFeNi2.1. J Mater Sci Technol 35:902–906

Sundararaman M, Mukhopadhyay P, Banerjee S (1988) Precipitation of the δ-Ni3Nb phase in two nickel base superalloys. Metall Trans A 19:453–465

Wu Y, Li S, Kang M et al (2019) Slip and fracture behavior of δ-Ni3Nb plates in a polycrystalline nickel-based superalloy during fatigue. Scr Mater 171:36–41. https://doi.org/10.1016/j.scriptamat.2019.06.013

Karthik GM, Asghari-Rad P, Sathiyamoorthi P et al (2021) Architectured multi-metal CoCrFeMnNi-Inconel 718 lamellar composite by high-pressure torsion. Scr Mater 195:113722

Schröders S, Sandlöbes S, Berkels B, Korte-Kerzel S (2019) On the structure of defects in the Fe 7 Mo 6 μ-Phase. Acta Mater 167:257–266. https://doi.org/10.1016/j.actamat.2019.01.045

Cheng Y, Wang G, Liu J, He L (2021) Atomic configurations of planar defects in μ phase in Ni-based superalloys. Scr Mater 193:27–32. https://doi.org/10.1016/j.scriptamat.2020.09.045

Jones MR, DelRio FW, Pegues JW et al (2021) Additive manufacturing of high-strength multiphase nanostructures in the binary Ni–Nb system for the discovery of new types of superalloys. J Mater Res 36:3167–3181. https://doi.org/10.1557/s43578-021-00290-7

Shaw LL, Ortiz AL, Villegas JC (2008) Hall–Petch relationship in a nanotwinned nickel alloy. Scr Mater 58:951–954. https://doi.org/10.1016/j.scriptamat.2008.01.025

Cordero ZC, Knight BE, Schuh CA (2016) Six decades of the Hall-Petch effect: a survey of grain-size strengthening studies on pure metals. Int Mater Rev 61:495–512. https://doi.org/10.1080/09506608.2016.1191808

Kozar RW, Suzuki A, Milligan WW et al (2009) Strengthening mechanisms in polycrystalline multimodal nickel-base superalloys. Metall and Mater Trans A 40:1588–1603

Chandross M, Argibay N (2020) Ultimate strength of metals. Phys Rev Lett 124:125501. https://doi.org/10.1103/PhysRevLett.124.125501

George EP, Raabe D, Ritchie RO (2019) High-entropy alloys. Nat Rev Mater 4:515–534. https://doi.org/10.1038/s41578-019-0121-4

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448–511. https://doi.org/10.1016/j.actamat.2016.08.081

Kustas AB, Susan DF, Johnson KL et al (2018) Characterization of the Fe–Co–1.5V soft ferromagnetic alloy processed by laser engineered net shaping (LENS). Addit Manuf 21:41–52

Tukey J (1953) Multiple comparisons. J Am Stat Assoc 48:624–625

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19

Thompson AP, Aktulga HM, Berger R et al (2022) LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput Phys Commun 271:108171

Zhang Y, Ashcraft R, Mendelev MI et al (2016) Experimental and molecular dynamics simulation study of structure of liquid and amorphous Ni62Nb38 alloy. J Chem Phys 145:204505

Anderson MP, Srolovitz DJ, Grest GS, Sahni PS (1984) Computer simulation of grain growth—I. Kinet Acta Metall 32:783–791

Holm EA, Glazier JA, Srolovitz DJ, Grest GS (1991) Effects of lattice anisotropy and temperature on domain growth in the two-dimensional Potts model. Phys Rev A (Coll Park) 43:2662–2668

Plimpton S, Corbett Battaile MC, Holm L, et al (2009) Crossing the mesoscale no-man’s land via parallel kinetic Monte Carlo, Sandia Report SAND2009-6226

Espinosa HD, Prorok BC, Peng B (2004) Plasticity size effects in free-standing submicron polycrystalline FCC films subjected to pure tension. J Mech Phys Solids 52:667–689. https://doi.org/10.1016/j.jmps.2003.07.001

Horstemeyer MF, Baskes MI, Plimpton SJ (2001) Length scale and time scale effects on the plastic flow of fcc metals. Acta Mater 49:4363–4374

Elmustafa AA, Stone DS (2003) Nanoindentation and the indentation size effect: kinetics of deformation and strain gradient plasticity. J Mech Phys Solids 51:357–381. https://doi.org/10.1016/S0022-5096(02)00033-9

Nix WD, Gao H (1998) Indentation size effects in crystalline materials: a law for strain gradient plasticity. J Mech Phys Solids 46:411–425. https://doi.org/10.1016/S0022-5096(97)00086-0

Pharr GM, Herbert EG, Gao Y (2010) The indentation size effect: a critical examination of experimental observations and mechanistic interpretations. Annu Rev Mater Res 40:271–292

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2004) Sample dimensions influence strength and crystal plasticity. Science (1979) 305:986–989

Li TL, Bei H, Morris JR et al (2012) Scale effects in convoluted thermal/spatial statistics of plasticity initiation in small stressed volumes during nanoindentation. Mater Sci Technol 28:1055–1059. https://doi.org/10.1179/1743284712Y.0000000007

Silva CC, De Albuquerque VHC, Miná EM et al (2018) Mechanical properties and microstructural characterization of aged nickel-based alloy 625 weld metal. Metall Mater Trans A 49:1653–1673

Belan J, Vaško A, Kuchariková L et al (2018) The high-temperature loading influence on orthorhombic Ni3Nb DOa δ-phase formation and its effect on fatigue lifetime in alloy 718. Manuf Technol 18:875–882

Fukuchi M, Watanabe K (1986) On the plastic deformation of a Ni3Nb single crystal. Trans Jpn Inst Metals 27:434–440

Hagihara K, Nakano T, Umakoshi Y (2000) Plastic deformation behaviour and operative slip systems in Ni3Nb single crystals. Acta Mater 48:1469–1480. https://doi.org/10.1016/S1359-6454(99)00447-4

Afonso CRM, Martinez-Orozco K, Amigó V et al (2020) Characterization, corrosion resistance and hardness of rapidly solidified Ni–Nb alloys. J Alloys Compd 829:154529. https://doi.org/10.1016/j.jallcom.2020.154529

Ezugwu EO, Bonney J, Yamane Y (2003) An overview of the machinability of aeroengine alloys. J Mater Process Technol 134:233–253

Bolcavage A, Kattner UR (1996) A reassessment of the calculated Ni–Nb phase diagram. J Phase Equilib 17:92–100. https://doi.org/10.1007/BF02665782

Wang H, Dhiman A, Ostergaard HE et al (2019) Nanoindentation based properties of Inconel 718 at elevated temperatures: a comparison of conventional versus additively manufactured samples. Int J Plast 120:380–394

Feng K, Chen Y, Deng P et al (2017) Improved high-temperature hardness and wear resistance of Inconel 625 coatings fabricated by laser cladding. J Mater Process Technol 243:82–91

Korznikov AV, Tram G, Dimitrov O et al (2001) The mechanism of nanocrystalline structure formation in Ni3Al during severe plastic deformation. Acta Mater 49:663–671

Fecht H-J (1995) Nanostructure formation by mechanical attrition. Nanostruct Mater 6:33–42

Lu JZ, Zhong JW, Luo KY et al (2011) Micro-structural strengthening mechanism of multiple laser shock processing impacts on AISI 8620 steel. Mater Sci Eng: A 528:6128–6133. https://doi.org/10.1016/j.msea.2011.04.018

Ren XD, Zhou WF, Liu FF et al (2016) Microstructure evolution and grain refinement of Ti—Al–4V alloy by laser shock processing. Appl Surf Sci 363:44–49. https://doi.org/10.1016/j.apsusc.2015.11.192

Hong CS, Tao NR, Huang X, Lu K (2010) Nucleation and thickening of shear bands in nano-scale twin/matrix lamellae of a Cu–Al alloy processed by dynamic plastic deformation. Acta Mater 58:3103–3116

Huang CX, Hu WP, Wang QY et al (2015) An ideal ultrafine-grained structure for high strength and high ductility. Mater Res Lett 3:88–94. https://doi.org/10.1080/21663831.2014.968680

Wu H, Fan G (2020) An overview of tailoring strain delocalization for strength-ductility synergy. Prog Mater Sci 113:100675. https://doi.org/10.1016/j.pmatsci.2020.100675

Beyerlein IJ, Zhang X, Misra A (2014) Growth twins and deformation twins in metals. Annu Rev Mater Res 44:329–363

Jiang L, Kumar MA, Beyerlein IJ et al (2019) Twin formation from a twin boundary in Mg during in-situ nanomechanical testing. Mater Sci Eng, A 759:142–153

Arul Kumar M, Beyerlein IJ, Tome CN (2016) Grain size constraints on twin expansion in hexagonal close packed crystals. J Appl Phys 120:155105

Jiang L, Gong M, Wang J et al (2022) Visualization and validation of twin nucleation and early-stage growth in magnesium. Nat Commun 13:1–11

Yoo MH (1969) Interaction of slip dislocations with twins in HCP metals. Oak Ridge National Lab, Tenn

Ahmadikia B, Wang L, Kumar MA, Beyerlein IJ (2023) Grain boundary slip–twin transmission in titanium. Acta Mater 244:118556

Wang J, Beyerlein IJ, Tomé CN (2014) Reactions of lattice dislocations with grain boundaries in Mg: implications on the micro scale from atomic-scale calculations. Int J Plast 56:156–172

Knezevic M, Beyerlein IJ, Nizolek T et al (2013) Anomalous basal slip activity in zirconium under high-strain deformation. Mater Res Lett 1:133–140

Kim Y-W (1994) Ordered intermetallic alloys, part III: gamma titanium aluminides. Jom 46:30–39

Hanamura T, Uemori R, Tanino M (1988) Mechanism of plastic deformation of Mn-added TiAl L 10-type intermetallic compound. J Mater Res 3:656–664

Kovarik L, Unocic RR, Li J et al (2009) Microtwinning and other shearing mechanisms at intermediate temperatures in Ni-based superalloys. Prog Mater Sci 54:839–873. https://doi.org/10.1016/j.pmatsci.2009.03.010

Kumar MA, Beyerlein IJ (2020) Influence of plastic properties on the grain size effect on twinning in Ti and Mg. Mater Sci Eng A 771:138644

Hugo RC, Kung HW, Knapp JA, Follstaedt DM (2003) Acta Mater 51:1937–1943

Jakob S, JK W (2003) A maximum in the strength of nanocrystalline copper. Science (1979) 301:1357–1359. https://doi.org/10.1126/science.1086636

Yip S (2004) Mapping plasticity. Nat Mater 3:11–12

Zhang T, Zhou K, Chen ZQ (2015) Strain rate effect on plastic deformation of nanocrystalline copper investigated by molecular dynamics. Mater Sci Eng A 648:23–30

Schiøtz J, di Tolla FD, Jacobsen KW (1998) Softening of nanocrystalline metals at very small grain sizes. Nature 391:561–563

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2002) Nat Mater 1:45–49

Gertsman VY, Hoffmann M, Gleiter H, Birringer R (1994) The study of grain size dependence of yield stress of copper for a wide grain size range. Acta Metall Mater 42:3539–3544

Liu J, Fan X, Zheng W et al (2020) Nanocrystalline gold with small size: inverse Hall–Petch between mixed regime and super-soft regime. Phil Mag 100:2335–2351

McCabe RJ, Beyerlein IJ, Carpenter JS, Mara NA (2014) The critical role of grain orientation and applied stress in nanoscale twinning. Nat Commun 5:1–7

Beyerlein IJ, Wang J, Kang K et al (2013) Twinnability of bimetal interfaces in nanostructured composites. Mater Res Lett 1:89–95

Kumar MA, Beyerlein IJ (2020) Local microstructure and micromechanical stress evolution during deformation twinning in hexagonal polycrystals. J Mater Res 35:217–241

Wu X, Yang M, Jiang P et al (2020) Deformation nanotwins suppress shear banding during impact test of CrCoNi medium-entropy alloy. Scr Mater 178:452–456. https://doi.org/10.1016/j.scriptamat.2019.12.017

Acknowledgements

This work was funded by the Laboratory Directed Research and Development program at Sandia National Laboratories, a multi-mission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC., a wholly owned subsidiary of Honeywell International, Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA0003525. F.W.D. was supported by the Center for Integrated Nanotechnologies, a Department of Energy office of Basic Energy Sciences user facility. I.J.B. gratefully acknowledges support from the Office of Naval Research under contract N00014-21-1-2536. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of the U.S. Department of Energy or the United States Government. The authors acknowledge Raymond Puckett at Sandia for conducting the AM processing experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None of the authors have conflict(s) of interest to report.

Ethical approval

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jones, M.R., Bobbitt, N.S., DelRio, F.W. et al. Evidence of twinning-induced plasticity (TWIP) and ultrahigh hardness in additively-manufactured near-eutectic Ni–Nb. J Mater Sci 58, 9723–9736 (2023). https://doi.org/10.1007/s10853-023-08636-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08636-8