Abstract

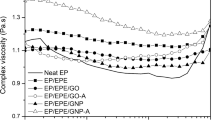

In this report, epoxy resin (EP) composites prepared using polypropylene (PP) and graphene oxide (GO) as additives in varying percentages are reported. Around 21 types of composites were prepared by dispersing polypropylene in 5–35%, or graphene oxide in 5–35%, with 95–65% of epoxy resin. Also, a ternary composite of EP matrix was prepared by adding 1:1 ratio of both PP & GO (5–35%) in 95–5% through a melt condensation technique. The graphene oxide platelets used in the study were obtained through modified Hummers method. The particle size and its structural characteristics were evolved through FESEM & XRD studies. The mechanical aspects of composites were tested by following standard ASTM procedures. The failed portions of the composites were examined through FESEM; it revealed a fiber/thread like structure, which promotes the higher tensile strength, Young’s modulus, etc. In contrast to the plain epoxy resin, the composites display remarkable mechanical properties. Especially, the epoxy resin (80%) blended with 10% PP and 10% GO displays higher tensile strength (22.5 MPa,) tensile modulus (4.56 GPa,) flexural strength (75 MPa), and so on. All these data are very much useful, if these composites are used in the manufacturing of components like space shuttle, engine cover, heaters, brake pad, cryogenic fuel tank, etc. in engineering applications.

Similar content being viewed by others

References

P.S. Bharadiya, S. Mishra, Enriched Mechanical Properties of Epoxy / Coir Fiber Composites with Graphene Oxide, (n.d.) 1–7. https://doi.org/10.31031/RDMS.2019.10.000749

M. Naebe, J. Wang, A. Amini, H. Khayyam, N. Hameed, L.H. Li, Y. Chen, B. Fox, Mechanical Property and Structure of Covalent Functionalised Graphene/Epoxy Nanocomposites, Sci. Rep. 4 (2014). https://doi.org/10.1038/srep04375

B.P. Mishra, D. Mishra, P. Panda, A. Maharana, An experimental investigation of the effects of reinforcement of graphene fillers on mechanical properties of bi-directional glass/epoxy composite, Mater. Today Proc. 33 (2020) 5429–5441. https://doi.org/10.1016/j.matpr.2020.03.154

B. Satheesan, A.S. Mohammed, Tribological characterization of epoxy hybrid nanocomposite coatings reinforced with graphene oxide and titania, Wear. 466–467 (2021) 203560. https://doi.org/10.1016/J.WEAR.2020.203560

U. Kilic, M.M. Sherif, O.E. Ozbulut, Tensile properties of graphene nanoplatelets/epoxy composites fabricated by various dispersion techniques. Polym. Test. 76, 181–191 (2019). https://doi.org/10.1016/J.POLYMERTESTING.2019.03.028

Z.Z. He, Y.B. Zhu, H.A. Wu, Multiscale mechanics of noncovalent interface in graphene oxide layered nanocomposites, Theor. Appl. Mech. Lett. (2021) 100304. https://doi.org/10.1016/j.taml.2021.100304

Y. Wu, B. Tang, K. Liu, X. Zeng, J. Lu, T. Zhang, X. Shen, Enhanced flexural properties of aramid fiber/epoxy composites by graphene oxide, Nanotechnol Rev. 8 (2019). https://doi.org/10.1515/ntrev-2019-0043

J.Z. Liang, Q. Du, G.C.P. Tsui, C.Y. Tang, Tensile properties of graphene nano-platelets reinforced polypropylene composites. Compos. Part. B Eng. 95, 166–171 (2016). https://doi.org/10.1016/j.compositesb.2016.04.011

S.A. Begum, A.V. Rane, K. Kanny, Applications of compatibilized polymer blends in automobile industry, in: Compat. Polym. Blends Micro Nano Scale Phase Morphol. Interphase Charact. Prop. (2019). https://doi.org/10.1016/B978-0-12-816006-0.00020-7

A. Ratnakumar, W.S.M. Rathnayake, L. Karunanayake, A.M.P.B. Samarasekara, D.A.S. Amarasinghe, Microcrystalline Cellulose as Reinforcing Agents for Polypropylene Composites. Trop. Agric. Res. 31, 106 (2020). https://doi.org/10.4038/tar.v31i3.8401

J. Patil, H. Patil, R. Sankpal, D. Rathod, K. Patil, P.R. Kubade, H.B. Kulkarni, Studies on mechanical and thermal performance of carbon nanotubes/polypropylene nanocomposites, Mater. Today Proc. 46 (2021) 7182–7186. https://doi.org/10.1016/J.MATPR.2020.11.452

M. Ajorloo, M. Fasihi, H. Khoramishad, The role of nanofiller size and polymer chain configuration on the properties of polypropylene/graphite nanoplates composites. J. Taiwan. Inst. Chem. Eng. 108, 82–91 (2020). https://doi.org/10.1016/j.jtice.2019.12.010

F. Khosravi Maleki, M.K.M. Nasution, M.S. Gok, V. Arab, Maleki, An experimental investigation on mechanical properties of Fe2O3 microparticles reinforced polypropylene. J. Mater. Res. Technol. 16, 229–237 (2022). https://doi.org/10.1016/J.JMRT.2021.11.104

Y. Hernández, T. Lozano, A.B. Morales-Cepeda, F. Navarro-Pardo, M.E. Ángeles, L. Morales-Zamudio, J.A. Melo-Banda, S. Sánchez-Valdes, G. Martínez-Colunga, F. Rodríguez, Stearic acid as interface modifier and lubricant agent of the system: Polypropylene/calcium carbonate nanoparticles. Polym. Eng. Sci. 59, E279–E285 (2019). https://doi.org/10.1002/PEN.25053

M.S. Kabbani, H.A. El Kadi, Predicting the effect of cooling rate on the mechanical properties of glass fiber–polypropylene composites using artificial neural networks. J. Thermoplast Compos. Mater. 32, 1268–1281 (2019). https://doi.org/10.1177/0892705718792351

V. Selvakumar, K. Palanikumar, K. Palanivelu, Studies on Mechanical Characterization of Polypropylene/Na +-MMT Nanocomposites. J Min. Mater Charact Eng 9, 671–681 (2010)

H. Sun, J. Zhang, Modified epoxy resin with SEBS-g-MAH to fabricate crack-free and robust hydrophobic coatings on the surface of PP/SEBS matrix. Surf. Interfaces 28, 101662 (2022). https://doi.org/10.1016/J.SURFIN.2021.101662

R.S. Negi, L. Prasad, A. Yadav, J. Winczek, Physical and Mechanical Properties of Pinecone Scale Fiber/Vigna Mungo Powder Reinforced Polypropylene Based Hybrid Composites, https://doi.org/10.1080/15440478.2022.2025983. (2022) 1–11.

Z. Ren, S. Hao, Y. Xing, C. Yang, S. Dai, Properties of graphene oxide modified epoxy resin and its composites. Hangkong Cailiao Xuebao/Journal Aeronaut. Mater. 39, 25–32 (2019). https://doi.org/10.11868/j.issn.1005-5053.2018.000142

E. Kusrini, A. Suhrowati, A. Usman, M. Khalil, V. Degirmenci, Synthesis and characterization of graphite oxide, graphene oxide, and reduced graphene oxide from graphite waste using modified hummers’ method and zinc as reducing agent, Int. J. Technol. 10 (2019). https://doi.org/10.14716/ijtech.v10i6.3639

H.A. Hessain, J.J. Hassan, Green synthesis of reduced graphene oxide using ascorbic acid, Iraqi J. Sci. 61 (2020). https://doi.org/10.24996/ijs.2020.61.6.9

A. Huntsman ® Casting System Araldite ® DBF Resin 100 pbw Aradur ® HY 951 Hardener 10 pbw, (2005). http://www.electrical-insulation-materials.com (accessed February 21, 2022)

S.M. Sapuan, M. Harimi, M.A. Maleque, Mechanical properties of epoxy/coconut shell filler particle composites, Arab. J. Sci. Eng. 28 (2003)

N. Norhakim, S.H. Ahmad, C.H. Chia, N.M. Huang, Mechanical and thermal properties of graphene oxide filled epoxy nanocomposites, Sains Malaysiana. 43 (2014)

G.S. Hikku, K. Jeyasubramanian, A. Venugopal, R. Ghosh, Corrosion resistance behaviour of graphene/polyvinyl alcohol nanocomposite coating for aluminium-2219 alloy. J. Alloys Compd. 716, 259–269 (2017). https://doi.org/10.1016/J.JALLCOM.2017.04.324

K. Jeyasubramanian, M. Muthuselvi, G.S. Hikku, M. Muthuselvan, E. Muthusankar, Influence of aggregation and dispersion of minium nanoparticles decorated reduced graphene oxide platelets and their super-capacitive performances. Mater. Sci. Semicond. Process. 136, 106143 (2021). https://doi.org/10.1016/J.MSSP.2021.106143

S.Y. Fu, X.Q. Feng, B. Lauke, Y.W. Mai, Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part. B Eng. 39, 933–961 (2008). https://doi.org/10.1016/J.COMPOSITESB.2008.01.002

H. Ebadi-Dehaghani, H.A. Khonakdar, M. Barikani, S.H. Jafari, Experimental and theoretical analyses of mechanical properties of PP/PLA/clay nanocomposites, Compos. Part B Eng. 69 (2015) 133–144. https://doi.org/10.1016/J.COMPOSITESB.2014.09.006

Y. Zare, H. Garmabi, A developed model to assume the interphase properties in a ternary polymer nanocomposite reinforced with two nanofillers. Compos. Part. B Eng. 75, 29–35 (2015). https://doi.org/10.1016/J.COMPOSITESB.2015.01.031

P. Hung, K. tak Lau, B. Fox, N. Hameed, B. Jia, J.H. Lee, Effect of graphene oxide concentration on the flexural properties of CFRP at low temperature. Carbon N. Y. 152, 556–564 (2019). https://doi.org/10.1016/J.CARBON.2019.06.032

J. Phiri, L.S. Johansson, P. Gane, T. Maloney, A comparative study of mechanical, thermal and electrical properties of graphene-, graphene oxide- and reduced graphene oxide-doped microfibrillated cellulose nanocomposites. Compos. Part. B Eng. 147, 104–113 (2018). https://doi.org/10.1016/j.compositesb.2018.04.018

S.H. Kim, Y. Zhang, J.H. Lee, S.Y. Lee, Y.H. Kim, K.Y. Rhee, S.J. Park, A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers. Nanotechnol Rev. 10, 1827–1837 (2021). https://doi.org/10.1515/ntrev-2021-0111

T. Jiang, T. Kuila, N.H. Kim, B.C. Ku, J.H. Lee, Enhanced mechanical properties of silanized silica nanoparticle attached graphene oxide/epoxy composites. Compos. Sci. Technol. 79, 115–125 (2013). https://doi.org/10.1016/J.COMPSCITECH.2013.02.018

B.J. Wang, W.Bin Young, The Natural Fiber Reinforced Thermoplastic Composite Made of Woven Bamboo Fiber and Polypropylene, Fibers Polym. 2021 231. 23 (2021) 155–163. https://doi.org/10.1007/S12221-021-0982-1

P. Song, Z. Cao, Y. Cai, L. Zhao, Z. Fang, S. Fu, Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polym. (Guildf) 52, 4001–4010 (2011). https://doi.org/10.1016/j.polymer.2011.06.045

D.G. Papageorgiou, I.A. Kinloch, R.J. Young, Mechanical properties of graphene and graphene-based nanocomposites. Prog Mater. Sci. 90, 75–127 (2017). https://doi.org/10.1016/j.pmatsci.2017.07.004

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Disclosure statement

The authors report there are no competing interests to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raja, G.M., Vasanthanathan, A. & Jeyasubramanian, K. Novel Ternary Epoxy Resin Composites Obtained by Blending Graphene Oxide and Polypropylene Fillers: An Avenue for the Enhancement of Mechanical Characteristics. J Inorg Organomet Polym 33, 383–397 (2023). https://doi.org/10.1007/s10904-022-02494-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-022-02494-8