Abstract

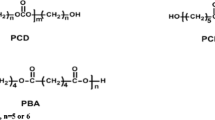

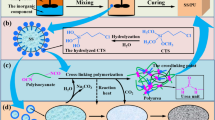

A series of composites of commercial waterborne polyurethane and hybrid silica were prepared by the sol–gel process through in situ synthesis. Mechanical properties, small angle X-ray scattering and differential scanning calorimetry measurements were performed to evaluate the effects that hybrid silica has on the properties of the resulting polyurethane composites. A series of 13 different organosilanes differing in polarity and alkyl chain length was studied. Under the present evaluated conditions, composites bearing hybrid silica were more likely to exhibit a reduction in mechanical resistance when compared to bare polyurethane. Samples also exhibited a negligible variation in glass transition temperature and a reduction in ΔCp. The enthalpy of the crystallization process exhibited an increase. Based on the small angle X-ray scattering measurements, the composites exhibited a small reduction in the interdomain spacing and an increase in the degree of phase separation.

Graphical Abstract

Similar content being viewed by others

References

Szycher M (2012) Szycher’s handbook of polyurethanes. CRC Press, Boca Raton

Van Bogart JWC, Gibson PE, Cooper SL (1983) J Polym Sci Polym Phys Ed 21:65–95

Prisacariu C (2011) Polyurethane elastomers from morphology to mechanical aspects. Springer, Vien

Koberstein JT, Stein RS (1983) J Polym Sci Polym Phys Ed 21:1439–1472

Leung LM, Koberstein JT (1985) Polym Sci Polym Phys Ed 23:1883–1913

Cakic SM, Ristic IS, Marinovic-Cincovic M, Spırkova M (2013) Int J Adhes Adhes 41:132–139

Vega-Baudrit J, Navarrobanon V, Vazquez P, Martin-martinez J (2006) Int J Adhes Adhes 26:378–387

Torró-Palau AM, Fernández-Garcia JC, Orgilés-Barceló AC, Martı́n-Martı́nez JM (2001) Int J Adhes Adhes 21:1–9

Baudrit J, Sibaja-Ballestero M, Vázquez P, Torregrosa-Maciá R, Martín-Martínez Miguel J (2007) Int J Adhes Adhes 27:469–479

Jang ES, Khan SB, Seo J, Akhtar K, Choi J, Kim KI et al. (2011) Macromol Res 19:1006–1013

Lin WC, Yang CH, Wang TL, Shieh YT, Chen WJ (2012) Express Polym Lett 6:2–13

Lai X, Shen Y, Wang L, Li Z (2011) Polym-Plast Technol Eng 50:740–747

Wang L, Shen Y, Lai X, Li Z (2011) Appl Polym Sci 119:3521–3530

Wu D, Qiu F, Xu H, Zhang J, Yang D (2011) J Appl Polym Sci 119:1683–1695

Wu D, Xu H, Qiu F, Yang D (2011) Polym Plast Technol Eng 50:498–508

Jena KK, Sahoo S, Narayan R, Aminabhavi TM, Raju K (2011) Polym Int 60:1504–1513

Jeon HT, Jang MK, Kim BK, Kim KH (2007) Colloids Surf A 302:559–567

Florian P, Jena KK, Allauddin S, Narayan R, Raju KVSN (2010) Ind Eng Chem Res 49:4517–4527

Watanabe L, Shirai H, Fuji T, Takahashi MM (2012) J Appl Polym Sci 126:E522–E529

Jung DH, Jeong MA, Jeong HM, Kim BK (2010) Colloid Polym Sci 288:1465–1470

Jung DH, Jeong HM, Kim BK (2010) Mater Chem 20:3458–4366

Stöber W, Fink A, Bohn E (1968) J Colloid Interface Sci 26:62–69

Lee SK, Yoon SH, Chung I, Hartwig A, Kim BK (2011) J Polym Sci Part A: Polym Chem 49:634–641

Mishra AK, Narayan R, Aminabhavi TM, Pradhan SK, Raju KVSN (2012) J Appl Polym Sci 125:E67–E75

Hosgor Z, Karatas S, Gungor A, Menceloglu Y (2012) Adv Polym Technol 31:390–400

Athawale VD, Kulkarni MA (2011) Pigment Resin Technol 40:49–57

Kang SM, Kim MJ, Kwon SH, Park H, Jeong HM, Kim BK (2012) J Mater Res 27:2837–2843

Heck CA, Giacomolli DA, Livotto PR, dos Santos JHZ, Wolf CR (2014) J Appl Polym Sci 131:41157

Heck CA, dos Santos JHZ, Wolf CR (2015) Int J Adhes Adhes 58:13–20

Saiani A, Daunch WA, Verbeke H, Leenslag J, Higgins JS (2001) Macromolecules 34:9059–9068

Callister Jr WD, Rethwisch DG (2009) Materials science and engineering: an introduction. Wiley, New York

Nunes RCR, Fonseca JLC, Pereira MR (2000) Polym Test 19:93–103

Nunes RCR, Pereira RA, Fonseca JLC, Pereira MR (2001) Polym Test 20:707–712

Bistricic L, Baranovic G, Leskovac M, Bajsic EG (2010) Eur Polym J 46:1975–1987

Samuels SL, Wilkes GL (1973) J Polym Sci B 11:807–811

Saiani A, Novak A, Rodier L, Eeckhaut G, Leenslag J-W, Higgins JS (2007) Macromol 40:7252–7262

Acknowledgments

Heck thanks CNPq for the grant. The authors thank the LNLS (Project SAXS1-11797) for the measurements on the SAXS beamline (Project SAXS1-11797).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Heck, C.A., dos Santos, J.H.Z. & Wolf, C.R. Hybrid silicas/waterborne polyurethane composite properties: In situ formation vs. grafting methods. J Sol-Gel Sci Technol 81, 505–513 (2017). https://doi.org/10.1007/s10971-016-4220-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4220-z