Abstract

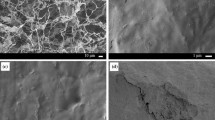

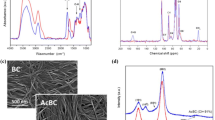

New nanocomposites based on bacterial cellulose nanofibers (BCN) and polyurethane (PU) prepolymer were prepared and characterized by SEM, FT-IR, XRD, and TG/DTG analyses. An improvement of the interface reaction between the BCN and the PU prepolymer was obtained by a solvent exchange process. FT-IR results showed the main urethane band at 2,270 cm−1 to PU prepolymer; however, in nanocomposites new bands appear as disubstituted urea at 1,650 and 1,550 cm−1. In addition, the observed decrease in the intensity of the hydroxyl band (3,500 cm−1) suggests an interaction between BCN hydroxyls and NCO-free groups. The nanocomposites presented a non-crystalline character, significant thermal stability (up to 230 °C) and low water absorption when compared to pristine BCN.

Similar content being viewed by others

References

Czaja WK, Young DJ, Kawecki M, Brown RM. The future prospects of microbial cellulose in biomedical applications. Biomacromolecules. 2007;8:1–12.

Matthews FL, Rawlings RD. Composite materials: engineering and science. London: Chapman & Hall; 1994.

Yano H, Sugiyama J, Nakagaito AN, Nogi M, et al. Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater. 2005;17:153–5.

Gatenholm P, Klemm D. Bacterial nanocellulose as a renewable material for biomedical applications. MRS Bull. 2010;35:208–13.

Klemm D, Schumann D, Udhardt U, Marsch S. Bacterial synthesized cellulose-artificial blood vessels for microsurgery. Prog Polym Sci. 2001;26:1561–603.

Klemm D, Heublein B, Fink HP, Bohn A. Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Edit. 2005;44:3358–93.

Pinto ERP. Estudo do sistema Celulose Bacteriana-Poliuretano para a produção de novos compósitos. Master Science Dissertation. Universidade Estadual Paulista, Instituto de Química, Brazil. 2007;1–170.

Nogi M, Yano H. Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry. Adv Mater. 2008;20:1849–52.

Hu L, Wan YZ, He F, Luo HL, et al. Effect of coupling treatment on mechanical properties of bacterial cellulose nanofibre-reinforced UPR ecocomposites. Mater Lett. 2009;63:1952–4.

Maria LCS, Santos ALC, Oliveira PC, Valle ASS, et al. Preparation and antibacterial activity of silver nanoparticles impregnated in bacterial cellulose. Polimeros. 2010;20:72–7.

Vilar W. Química e Tecnologia dos poliuretanos. Rio de Janeiro: Vilar Consultoria; 2004.

Ionescu M, Sinharoy S, Petrovic ZS. Polyacetal polyols for polyurethanes. J Polym Environ. 2009;17:123–30.

Palaskar DV, Boyer A, Cloutet E, Alfos C, Cramail H. Synthesis of biobased polyurethane from oleic and ricinoleic acids as the renewable resources via the AB-type self-condensation approach. Biomacromolecules. 2010;11:1202–11.

Petrovic ZS, Cvetkovic I, Hong D, Wan XM, et al. Vegetable oil-based triols from hydroformylated fatty acids and polyurethane elastomers. Eur J Lipid Sci Technol. 2010;112:97–102.

Bledzki AK, Gassan J. Composites reinforced with cellulose based fibres. Prog Polym Sci. 1999;24:221–74.

Qiu WL, Zhang FR, Endo T, Hirotsu T. Isocyanate as a compatibilizing agent on the properties of highly crystalline cellulose/polypropylene composites. J Mater Sci. 2005;40:3607–14.

Botaro VR, Gandini A, Belgacem MN. Heterogeneous chemical modification of cellulose for composite materials. J Thermoplast Compos Mater. 2005;18:107–17.

Qiu WL, Endo T, Hirotsu T. Interfacial interactions of a novel mechanochemical composite of cellulose with maleated polypropylene. J Appl Polym Sci. 2004;94:1326–35.

Wu QJ, Henriksson M, Liu X, Berglund LA. A high strength nanocomposite based on microcrystalline cellulose and polyurethane. Biomacromolecules. 2007;8:3687–92.

Seydibeyoglu MO, Oksman K. Novel nanocomposites based on polyurethane and micro fibrillated cellulose. Compos Sci Technol. 2008;68:908–14.

Fischer F, Rigacci A, Pirard R, Berthon-Fabry S, Achard P. Cellulose-based aerogels. Polymer. 2006;47:7636–45.

Nakagaito AN, Nogi M, Yano H. Displays from transparent film of natural nanofibers. MRS Bull. 2010;35:214–8.

Barud HS, Souza JL, Santos DB, Crespi MS, Ribeiro CA, Messaddeq Y, Ribeiro SJL. Bacterial cellulose/poly(3-hydroxybutyrate) composite membranes. Carbohydr Polym. 2011;83:1279–84.

ASTM. D2572–03: standard test method for isocyanate groups in urethane materials or prepolymers. West Conshohocken: Pennsylvania; 2003.

Mantanis GI, Young RA, Rowell RM. Swelling of compressed cellulose fiber webs in organic liquids. Cellulose. 1995;2:1–22.

Kunzek H, Muller S, Vetter S, Godeck R. The significance of physico chemical properties of plant cell wall materials for the development of innovative food products. Eur Food Res Technol. 2002;214:361–76.

Lee KY, Bismarck A. Susceptibility of never-dried and freeze-dried bacterial cellulose towards esterification with organic acid. Cellulose. 2012;19:891–900.

Jonoobi M, Harun J, Mathew AP, Hussein MZB, Oksman K. Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose. 2010;17:299–307.

Matsuda T, Kurohane K, Imai Y. Di-(2-ethylhexyl) phthalate enhances skin sensitization to isocyanate haptens in mice. Toxicol Lett. 2010;192:97–100.

Barud HS, de Araujo AM, Santos DB, de Assuncao RMN, et al. Thermal behavior of cellulose acetate produced from homogeneous acetylation of bacterial cellulose. Thermochim Acta. 2008;471:61–9.

Silverstein RM, Bassler GC, Morrill TC. Identificação espectrométrica de compostos orgânicos. Rio de Janeiro: LTC; 1994.

Coleman MM, Lee KH, Skrovanek DJ, Painter PC. Hydrogen-bonding in polymers. 4. Infrared temperature studies of a simple polyurethane. Macromolecules. 1986;19:2149–57.

Rivera-Armenta JL, Heinze T, Mendoza-Martinez AM. New polyurethane foams modified with cellulose derivatives. Eur Polym J. 2004;40:2803–12.

Osullivan AC. Cellulose: the structure slowly unravels. Cellulose. 1997;4:173–207.

Wada M, Okano T. Localization of I-alpha and I-beta phases in algal cellulose revealed by acid treatments. Cellulose. 2001;8:183–8.

Cao Q, Liu PS. Structure and mechanical properties of shape memory polyurethane based on hyperbranched polyesters. Polym Bull. 2006;57:889–99.

Barud HS, Ribeiro CA, Crespi MS, Martines MAU, et al. Thermal characterization of bacterial cellulose-phosphate composite membranes. J Therm Anal Calorim. 2007;87:815–8.

Husic S, Javni I, Petrovic ZS. Thermal and mechanical properties of glass reinforced soy-based polyurethane composites. Compos Sci Technol. 2005;65:19–25.

Javni I, Petrovic ZS, Guo A, Fuller R. Thermal stability of polyurethanes based on vegetable oils. J Appl Polym Sci. 2000;77:1723–34.

Acknowledgements

Financial support from Brazilian agencies “Fundação de amparo a pesquisa do estado de São Paulo (FAPESP), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)” and “Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq)” and technical support from Electron Microscopy Laboratory/National Synchrotron Light Laboratory (LME/LNLS) are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pinto, E.R.P., Barud, H.S., Polito, W.L. et al. Preparation and characterization of the bacterial cellulose/polyurethane nanocomposites. J Therm Anal Calorim 114, 549–555 (2013). https://doi.org/10.1007/s10973-013-3001-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3001-y