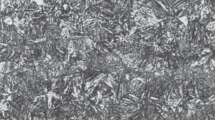

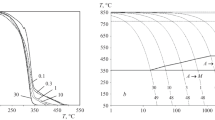

The influence of cooling rate in the process of thermal treatment on the formation of the microstructure of 13KhMF heat-resistant steel is investigated. The relationships between the microstructure, strength characteristics, crack-resistance characteristics, and creep resistance of the material are determined. The transformations of the structure are modeled by the changes in the duration of tempering. The bainitemartensite structure is characterized by the best combination of properties and the largest period of transformation of the structure. The comparison of the results of laboratory and long-term in-service degradation and their influence on the structure, strength, and crack-resistance characteristics shows that they are similar.

Similar content being viewed by others

References

E. I. Krutasova, Reliability of the Metal of Power-Generating Plants [in Russian], Énergoizdat, Moscow (1981).

V. A. Nakhalov, Reliability of Pipe Bends in Thermal Power Plants [in Russian], Énergoatomizdat, Moscow (1983).

T. G. Berezina, N. V. Bugai, and I. N. Trunin, Diagnostics and Prediction of the Durability of the Metal of Thermal Power Plants [in Russian], Tekhnika, Kiev (1991).

A. Hernas and J. Dobrzański, Trwałość i Niszczenie Elementów Kotłów i Turbin Parowych, WPŚ, Gliwice (2003).

A. Hernas, Żarowytrzymałość stali i stopów, WPŚ, Gliwice (2000).

Yu. Zabara, “It is always possible to find the way out,” Obrii PIB, No. 24 (82), (2002), http://www.obriy.pib.com.ua/

O. Z. Student, “Features of the influence of hydrogen on the threshold crack resistance characteristics of structural steels,” Mashynoznavstvo, No. 2, 17–23 (1999).

H. V. Krechkovs’ka, O. Z. Student, and A. D. Markov, “Structural changes in the metal of a steam pipeline of thermal power plant, made of 15Kh1M1F steel,” Nauk. Notatky, Issue 20, 213–217 (2007),

T. Stakhiv, I. Dzioba, B. Lonyuk, and O. Student, “Structural degradation of heat-resistant steels and their influence on crackresistance indices,” Fiz.-Khim. Mekh. Mater., Special Issue No. 3, 67–72 (2002).

L. O. Babii, O. Z. Student, A. D. Zahurs’kyi, and A. D. Markov, “Creep of degraded 2.25Cr–Mo steel in hydrogen,” Fiz.-Khim. Mekh. Mater., 43, No. 5, 91–96 (2007).

K.-H. Schwalbe, U. Zerbst, Y.-J. Kim et al, EFAM ETM 97: the ETM Method for Assessing Crack-Like Defects in Engineering Structures. Report GKSS 98/E/6/, GKSS Research Centre Geesthacht GmbH, Geesthacht (1998).

British Standard BS7910. Guide on Methods for Assessing the Acceptability of Flaws in Metallic Structures, British Standards Institutions, London (2005).

API 579. Recommended Practice for Fitness-for-Service, American Petroleum Institute, Washington DC (2000).

R6. Assessment of the Integrity of Structures Containing Defects, British Energy Generation Ltd, Gloucester (2001).

SINTAP: Structural Integrity Assessment Procedure for European Industry, Project No BE95-1426, British Steel, Rotterdam (1999).

M. Koçak, S. Webster, J. J. Janosh, et al. (editors), FITNET. Fitness for Service Procedure, GKSS Research Centre Geesthacht GmbH, Stuttgart (2008).

A. Neimitz, I. Dzioba, M. Graba, and J. Okrajni, Ocena wytrzymałości, trwałości i bezpieczeństwa pracy elementów konstrukcyjnych zawierających defekty, WPŚk, Kielce (2008).

.I. R. Dzioba, O. Z. Student, and A. D. Markov, “On the contemporary SINTAP approach and its application to the evaluation of the serviceability of welded joints of steam pipelines of thermal power plants,” Fiz.-Khim. Mekh. Mater., 41, No. 6, 70–79 (2005).

I. Dzioba, “Failure assessment analysis of pipelines for heat and power generating plants according to the SINTAP procedures,” Int. J. Press. Ves. Pip., 82, No. 10, 787–796 (2005).

I. Dzioba, “Wpływ długotrwałej eksploatacji na własności złączy spawanych rurociągów energetycznych,” Energetyka, XVIII, 39–42 (2008).

O. M. Romaniv, A. N. Tkach, I. R. Dzioba, et al., “Effect of long-term thermomechanical influence on the crack resistance of 1Kh1MF steel,” Fiz.-Khim. Mekh. Mater., 25, No. 2, 87–92 (1989).

O. M. Romaniv, H. M. Nykyforchyn, I. R. Dzioba, et al., “Influence of the in-service damage to 12Kh1MF steel for steam pipe-lines on the characteristics of its crack resistance,” Fiz.-Khim. Mekh. Mater., 34, No. 1, 101–104 (1998).

H. K. D. H. Bhadeshia, Bainite in Steels, Institute of Materials, London (2001).

H. K. D. H. Bhadeshia and R. C. Thomson, “Changes in chemical composition of carbides in 2.25Cr–1.0Mo power plant steel. Part 1. Bainitic microstructure,” Mater. Sci. Technol., 10, No. 3, 193–203 (1994).

PN-EN 10222-2:2002. Stal 13HMF, PKN, Warszawa (2002).

PN-EN 100002-1+AC1. Metallic Materials. Tensile Testing. Part 1: Method of Test at Ambient Temperature, PKN, Warszawa (1998).

ASTM E 1820-05. Standard Test Method for Measurement of Fracture Toughness, ASTM International, West Conshohocken (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 46, No. 3, pp. 65–72, May–June, 2010.

Rights and permissions

About this article

Cite this article

Dzioba, I.R. Properties of 13KhMF steel after operation and degradation under the laboratory conditions. Mater Sci 46, 357–364 (2010). https://doi.org/10.1007/s11003-010-9297-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-010-9297-x