For many years an important task for metallurgical scientists is the search for alternative technologies of iron production from mineral raw materials without using expensive coke, natural gas and with the least pressure on ecology. Technologies are required with maximum extraction of iron from ore, and with the least pollution of the atmosphere using cheap and least scarce reducing agents, for example power generating coal. Recently in OAO VNIIMT a new method has been developed and proven under laboratory conditions for direct preparation of iron by reduction of fine-grained material with solid reducing agent in a direct current electric arc furnace, including ground ore, iron-bearing sludge, etc. This technology makes it possible to prepare cast iron containing 3–4% carbon in a molten condition that may be granulated, cast into pigs, and treated in a ladle-furnace unit with minimum specific yield of gas and slag.

Similar content being viewed by others

References

L. Ya. Shparber, Iron and Cast Iron Metallurgy, Books 1 and 2 [in Russian], ASSOD, Tula (1996).

N. P. Lyakishev and A. V. Nikolaev, “Some questions of metallurgical technology of the future,” in: Proc. Internat. Congr. “300 Years of Ural Metallurgy”, Nizhnii Tagil (2001), pp. 166–178.

N. P. Lyakishev, “Some problems of the contemporary steel smelting process,” Stal’, No. 9, 1–6 (1886).

Yu. S. Yusfin, A. A. Gimmel’farb, and N. F. Pashkov, New Metal Production Processes [in Russian], Metallurgiya, Moscow (1994).

Yu. G. Yaroshenko, Ya. M. Gordon, and I. Yu. Khodorovskaya, Energy-Effective and Resource Saving Ferrous Metallurgy Technology [in Russian], Yu. G. Yaroshenko (editor), OOO UIPTs, Ekaterinburg (2012).

V. A. Romenets, R. S. Valavin, A. B. Usachev, et al., Romelt Process [in Russian], V. A. Romanets (editor), ID Ruda Metally, Moscow (2005)

L. A. Zainullin, A. Yu. Epishin, D. A. Artov, et al., “High-temperature carbothermal reduction of siderite ores in an electric arc,” Metallurg, No. 11, 31–34 (2016).

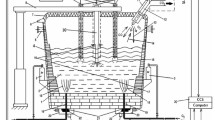

L. A. Zainullin, A. Yu. Epishin, et al., RF Patent 2612330, MPK5 C21B13/10, Method of Material Direct Reduction Containing Metal Oxides with Preparation of Molten Metal and a Device for Accomplishing the Method, No. 2014154385; Claim 12.30.2014, Publ. 03.07.2017, Bull. No. 7.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 62, No. 7, pp. 33–37, July 2018.

Rights and permissions

About this article

Cite this article

Zainullin, L.A., Epishin, A.Y., Karelin, V.G. et al. Analysis of Economic and Energy Efficiency of Using Electric-Arc Reduction for Iron-Containing Materials. Metallurgist 62, 642–647 (2018). https://doi.org/10.1007/s11015-018-0703-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0703-1