Abstract

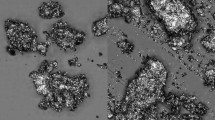

Combinations of NiCoCrAlY APS and high-velocity oxygen fuel (HVOF) bond coatings were deposited on alloy 247 disk substrates with APS yttria-stabilized zirconia (YSZ) top coatings to assess the benefit of air plasma sprayed (APS) ‘flash’ bond coatings. Using 1-h cycles at 1100 ℃ in air with 10% H2O and HVOF-only and APS-only bond coatings as a baseline, it was found that APS flash coatings extended the average coating lifetime by 16% to 35% with the thicker flash coating performing best. Principal component analysis and energy dispersive spectroscopy (EDS) compositional mapping on coatings characterized after 0, 100, 300 and 500 cycles and after failure showed that the Al in the bond coatings was depleted due to both oxidation and back diffusion into the substrate. The APS-only bond coating had significant oxidation throughout the bond coating and was so depleted in Al, that Al diffused from the substrate to the coating. Residual stress maps of the thermally-grown alumina scale were obtained every 100 cycles using photo-stimulated luminescence piezospectroscopy (PLPS) revealing that the Thick Flash coating had the slowest rate of damage accumulation in the oxide scale.

Similar content being viewed by others

References

B. A. Pint, JOM 65, 2013 (1024). https://doi.org/10.1007/s11837-013-0642-z.

Bobby, N.: Hydrogen-Capable Gas Turbines for Deep Decarbonization. In: EPRI (ed.) EPRI Report No. 3002017544. EPRI, Charlotte, NC, (2019); Michalski, J.et al. : Hydrogen generation by electrolysis and storage in salt caverns: Potentials, economics and systems aspects with regard to the German energy transition. Int. J. Hydro. Energy 42, 13427 (2017). https://doi.org/10.1016/j.ijhydene.2017.02.102

G. W. Goward, Surface and Coatings Technology 108, 1998 (73). https://doi.org/10.1016/S0257-8972(98)00667-7.

J. T. Demasi-Marcin and D. K. Gupta, Surface and Coatings Technology 68, 1994 (1). https://doi.org/10.1016/0257-8972(94)90129-5.

J. R. Nicholls, MRS Bull 28, 2003 (659). https://doi.org/10.1557/mrs2003.194.

Gildersleeve V, EJ Viswanathan, V Lance, MJ Haynes, JA Pint, BA, Sampath S Surface and Coatings Technology 375 782 (2019)

M.J Lance, B.P. Thiesing, J.A. Haynes, E.J. Gildersleeve, S. Sampath, B.A. Pint Surface and Coatings Technology (2019). https://doi.org/10.1016/j.surfcoat.2019.124940.

M. J. Lance, B. P. Thiesing, J. A. Haynes, C. M. Parish, and B. A. Pint, Oxidation of Metals 91, 2019 (691). https://doi.org/10.1007/s11085-019-09903-3.

W. Nowak, et al., Surface and Coatings Technology 260, 2014 (82). https://doi.org/10.1016/j.surfcoat.2014.06.075.

Z. Zou, et al., Surface and Coatings Technology 319, 2017 (370). https://doi.org/10.1016/j.surfcoat.2017.04.026.

C. Mercer, D. Hovis, A. H. Heuer, T. Tomimatsu, Y. Kagawa, and A. G. Evans, Surface and Coatings Technology 202, 2008 (4915). https://doi.org/10.1016/j.surfcoat.2008.04.070.

M. J. Lance, K. A. Unocic, J. A. Haynes, and B. A. Pint, Surface and Coatings Technology 260, 2014 (107). https://doi.org/10.1016/j.surfcoat.2014.08.082.

J. A. Nychka and D. R. Clarke, Surface and Coatings Technology 146, 2001 (110). https://doi.org/10.1016/s0257-8972(01)01455-4.

J. A. Haynes, M. K. Ferber, and W. D. Porter, Journal of Thermal Spray Technology 9, 2000 (38). https://doi.org/10.1361/105996300770350041.

M. J. Lance, J. A. Haynes, and B. A. Pint, Surface and Coatings Technology 308, 2016 (19). https://doi.org/10.1016/j.surfcoat.2016.09.087.

M. J. Lance, J. A. Haynes, and B. A. Pint, Surface and Coatings Technology 337, 2018 (136). https://doi.org/10.1016/j.surfcoat.2017.12.062.

M. J. Lance, K. A. Unocic, J. A. Haynes, and B. A. Pint, Surface and Coatings Technology 284, 2015 (9). https://doi.org/10.1016/j.surfcoat.2015.08.067.

D. Renusch, M. Schorr, and M. Schutze, Materials and corrosion 59, 2008 (547). https://doi.org/10.1002/maco.200804137.

W. G. Sloof and T. J. Nijdam, International Journal of Materials Research 100, 2009 (1318). https://doi.org/10.3139/146.110201.

H. E. Evans and M. P. Taylor, Oxidation of Metals 55, 2001 (17). https://doi.org/10.1023/a:1010369024142.

Acknowledgements

The authors would like to thank Prof. S. Sampath and E. Gildersleeve at Stony Brook University's Center for Thermal Spray Research for the coating fabrication. At ORNL, G. Garner, and T. Geer assisted with the experimental work and J. A Haynes, Y.-F. Su and E. Lara-Curzio provided helpful comments on the manuscript. This research was sponsored by the U.S. Department of Energy, Office of Fossil Energy and Carbon Management, Turbine Program (R. Dennis program manager and P. Burke project manager).

Author information

Authors and Affiliations

Contributions

Michael Lance and Bruce Pint wrote the main manuscript text. Michael Lance conducted the research. Ken Kane conducted the furnace cycle testing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lance, M.J., Kane, K.A. & Pint, B.A. The Effect of APS-HVOF Bond Coating Thickness Ratio on TBC Furnace Cycle Lifetime. Oxid Met 98, 385–397 (2022). https://doi.org/10.1007/s11085-022-10127-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-022-10127-1